American Coolair Corp. Form No. 610-40-13 (August 2021) 1

Operation and Maintenance Instructions for Type S

Manual & Motor Operated Wall Shutters

Single-Panel Motor Operated

Shutter Models S24 - S36

Manually Operated Shutter

Models S24 - S60

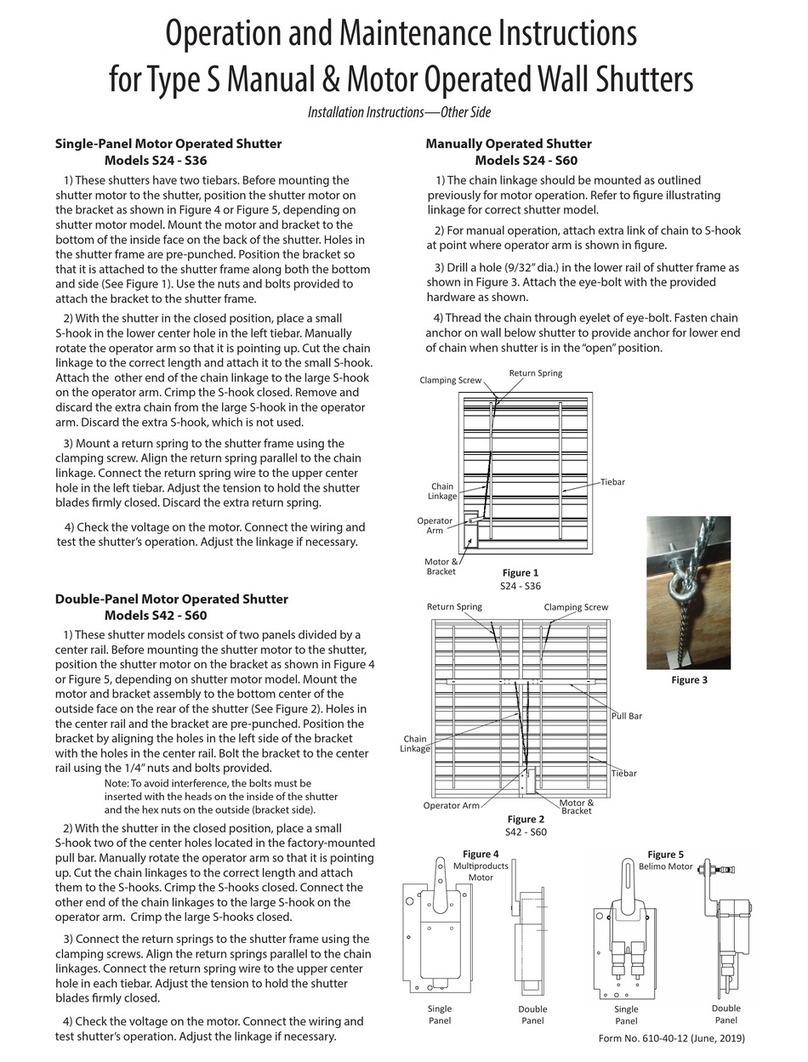

1) These shutters have two tiebars. Before mounting the

shutter motor to the shutter, position the shutter motor on

the bracket as shown in Figure 4 or Figure 5, depending on

shutter motor model. Mount the motor and bracket to the

bottom of the inside face on the back of the shutter. Holes in

the shutter frame are pre-punched. Position the bracket so

that it is attached to the shutter frame along both the

bottom and side (Figure 1). Use the nuts and bolts provided

to attach the bracket to the shutter frame.

2) With the shutter in the closed position, place a small

S-hook in the lower center hole in the left tiebar. Manually

rotate the operator arm so that it is pointing up. Cut the

chain linkage to the correct length and attach it to the small

S-hook. Attach the other end of the chain linkage to the

large S-hook on the operator arm. Crimp the S-hook closed.

Remove and discard the extra chain from the large S-hook in

the operator arm. Discard the extra S-hook, which is not

used.

3) Mount a return spring to the shutter frame using the

clamping screw. Align the return spring parallel to the chain

linkage. Connect the return spring wire to the upper center

hole in the left tiebar. Adjust the tension to hold the shutter

blades firmly closed. Discard the extra return spring.

4) Check the voltage on the motor. Connect the wiring and

test the shutter’s operation. Adjust the linkage if necessary.

Double-Panel Motor Operated

Shutter Models S24 - S36

1) These shutter models consist of two panels divided by a

center rail. Before mounting the shutter motor to the

shutter, position the shutter motor on the bracket as shown

in Figure 4 or Figure 5, depending on shutter motor model.

Mount the motor and bracket assembly to the bottom center

of the outside face on the rear of the shutter (See Figure 2).

Holes in the center rail and the bracket are pre-punched.

Position the bracket by aligning the holes in the left side of

the bracket with the holes in the center rail. Bolt the bracket

to the center rail using the 1/4” nuts and bolts provided.

Note: To avoid interference, the bolts must be

inserted with the heads on the inside of the shutter

and the hex nuts on the outside (bracket side).

2) With the shutter in the closed position, place a small S-

hook in two of the center holes located in the factory-

mounted pull bar. Manually rotate the operator arm so that it

is pointing up. Cut the chain linkages to the correct length

and attach them to the S-hooks. Crimp the S-hooks closed.

Connect the other end of the chain linkages to the large S-

hook on the operator arm. Crimp the large S-hooks closed.

3) Connect the return springs to the shutter frame using the

clamping screws. Align the return springs parallel to the

chain linkages. Connect the return spring wire to the upper

center hole in each tiebar. Adjust the tension to hold the

shutter blades firmly closed.

4) Check the voltage on the motor. Connect the wiring

and test shutter’s operation. Adjust the linkage if necessary.

1) The chain linkage should be mounted as outlined

previously for motor operation. Refer to figure

illustrating linkage for correct shutter model.

2) For manual operation, attach extra link of chain to S-

hook at point where operator arm is shown in figure.

3) Drill a hole (9/32” dia.) in the lower rail of shutter

frame as shown in Figure 3. Attach the eye-bolt with the

provided hardware as shown.

4) Thread the chain through eyelet of eye-bolt. Fasten

chain anchor on wall below shutter to provide anchor for

lower end of chain when shutter is in the “open”

position.

Return Spring

Clamping Screw

Chain Linkage

Operator Arm

Motor &

Bracket

Tiebar

Figure 1

S24 - S36

Figure 2

S42 - S60

Figure 3

Manual Chain Eyebolt

Return Spring

Clamping Screw

Pull Bar

Tiebar

Chain Linkage

Operator Arm

Motor &

Bracket

Figure 4

Multiproducts Motor

Figure 5

Belimo Motor

Clockwise Motor

Rotation

Orange Side

Facing Out

Single Panel

Mount Holes

Double Panel

Mount Holes