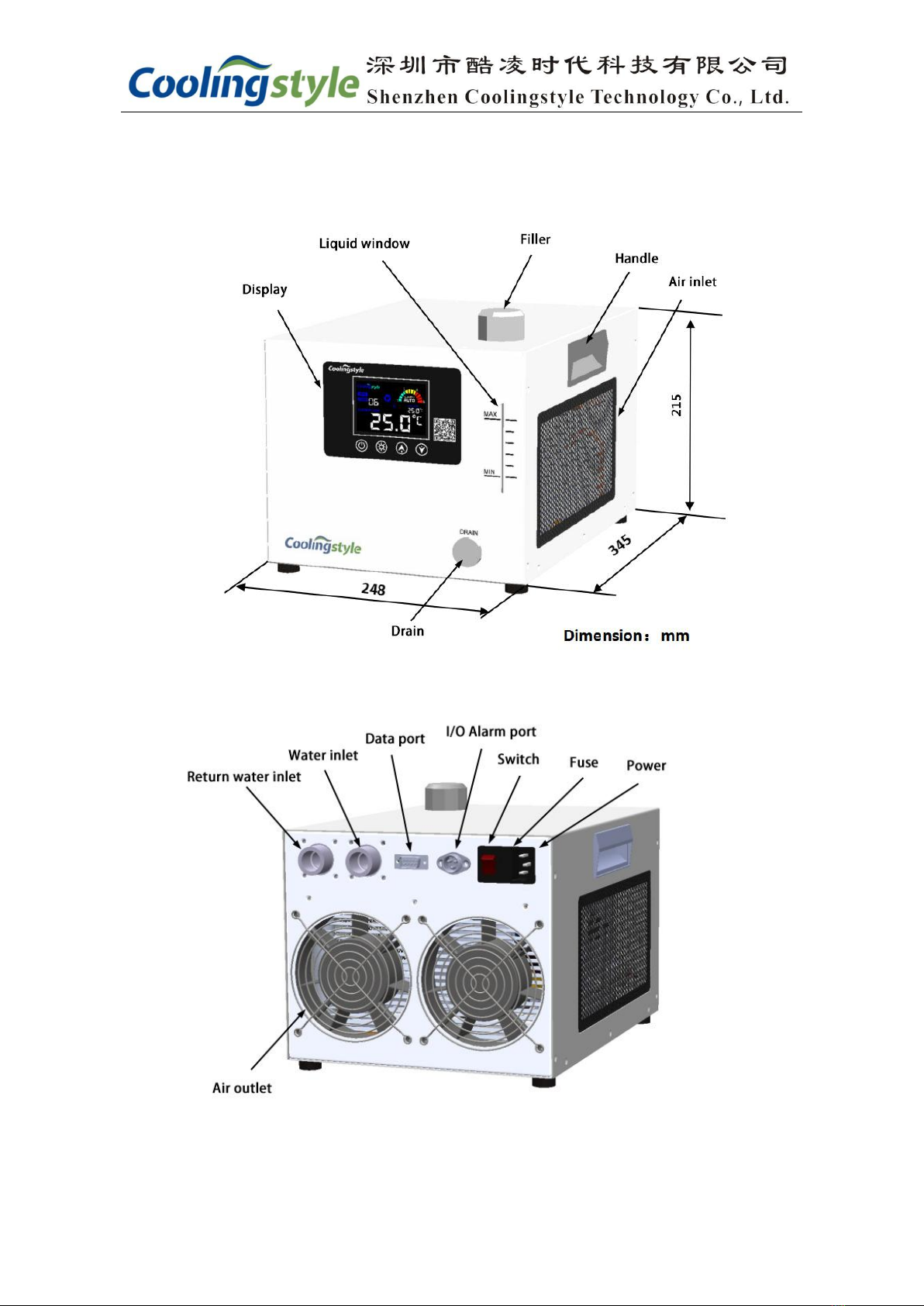

(For products without flow monitoring function, this mark will not light up).

This area displays 2 types of contents:

a) During normal operation, the real-time flow will be displayed; for example: "06" means the

flow is 6.0~6.9L/min, press the "up" key to display one decimal place.

b) In the fault state, the fault code is displayed.

Fault indication: when lit, it indicates that the chiller is in a fault state;

Dynamic flow indication: when the flow rate is not zero, the 3 arc-shaped icons will

cyclically light up; when the flow rate is zero, all 3 arc-shaped icons will flash;

Compressor speed indication: When the chiller uses a DC compressor, this icon

indicates the compressor speed; when an AC compressor is used, the fixed speed is displayed here.

Cooling indication: when lit, the compressor is working and the chiller is in the cooling

state;

Heating indication: when lit, it indicates that the internal heating device is in working

condition;

High temperature alarm indication: when lit, it means that the water temperature

exceeds the high temperature alarm threshold;

Setting value: Under normal circumstances, display the set target temperature;

when setting the flow alarm threshold, display the flow threshold;

Real-time water temperature: indicates the current water temperature.

Operation area: There are 4 buttons. The buzzer will emit a short "beep" sound when pressed

effectively, and there will be no response when pressed invalid. The specific instructions are as