Page 3

Utica®

Click-Type Torque (Sensing) Wrenches

PL12-UT02

July 27, 2007

2. While holding the barrel of the wrench securely

in one hand rotate the handle of the wrench

until the major five foot pound increment below

the torque desired is even with the edge of the

sleeve and the 0 increment on the sleeve is in

line with the zero line of the barrel.

3. Rotate the handle clockwise until the fine

torque increment desired lines up with the zero

line on the barrel. Release the lock collar and

the wrench is automatically locked at the

torque setting selected.

NOTE: The lock collar will not lock until an increment line

on the sleeve lines up with the zero line on the barrel.

4. For Newton meter torque settings, use the

same procedure as above using the Newton

meter major scale on the barrel and the lower

set of graduations on the sleeve. The picture at

the right shows a setting of 59.0 Nm. This can

be accomplished by setting 57.6 on the major scale plus 1.4

on the fine scale to equal 59.0 NM. Note that the fine scale

has been rounded to the nearest whole decimal.

SETTING THE TCI-150FRN & TCI-250FRN TORQUE

WRENCHES

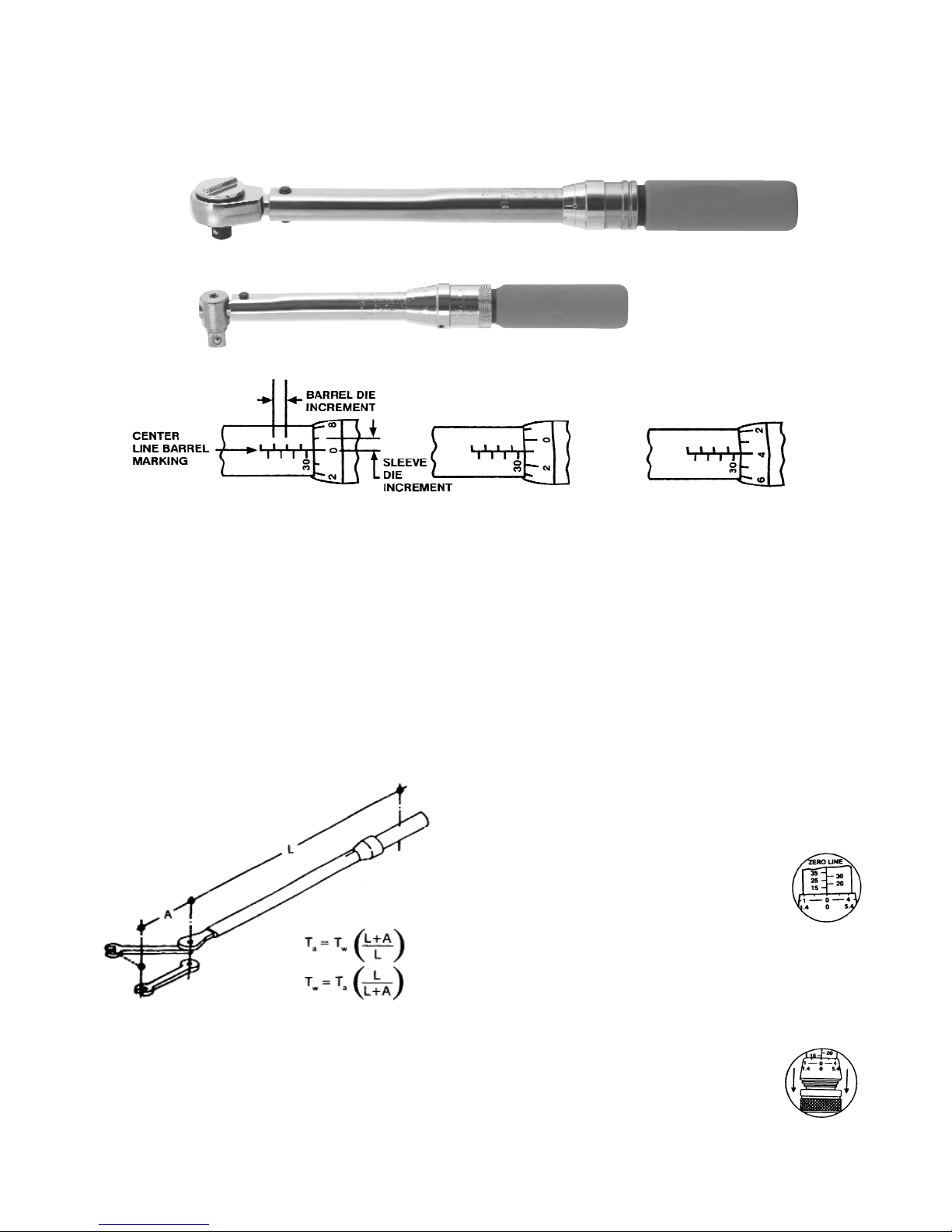

The torque settings of the wrench are from two micrometer

scales: the Major scale and the Fine scale. This wrench has

the dual capacity of working in English units (foot-pounds) and

International units (Newton meters): therefore, there are two

major and fine scales. The major English scale is located on

one side of the barrel and is divided into increments of 10 Ft.-

Lbs. The major International scale is located on the opposite

side of the barrel and is divided into increments of

13.6 Nm. The fine micrometer adjustments are

made with the sleeve which has increments of

one Ft.-Lb. on the upper scale and increments of

1.36 Nm (rounded) on the lower scale.

Setting the wrench is accomplished by considering all torque

settings as being made up of two parts, 10 Ft.-Lbs.(13.6 Nm)

increments and 1 Ft.-Lb. (13.6 Nm) increments. Thus a torque

setting of 65 Ft.-Lbs. would be considered as 60Ft.-Lbs. on the

major scale plus 5 Ft.-Lbs. on the fine scale. The wrench is set

to desired torque as follows:

1. Grasp the Locking Collar between the thumb

and forefinger and pull it toward the handle

of the wrench as far as it will go. Hold it in

this position.

2. While holding the barrel of the wrench

securely in one hand rotate the handle of the

wrench until the major 10 Ft.Lbs. increment

below the torque desired is even with the

edge of the sleeve and the 0 increment on

the sleeve is in line with the zero line of the barrel.

3. Rotate the handle clockwise until the fine torque increment

desired lines up with the zero line on the barrel. Release the

lock collar and the wrench is automatically locked at the torque

setting selected. NOTE: The lock collar will not

lock until an increment line on the sleeve lines

up with the zero line on the barrel.

4. For Newton meter torque settings, repeat the

above procedure using the Newton Meter major

scale on the barrel and the lower set of

graduations on the sleeve. The picture at the

right shows a setting of 79.9 Nm. This is done

by setting 74.5 on the major scale plus 5.4 on

the fine scale to equal 79.9 Nm. Note: fine scale is rounded to

the nearest whole decimal.

“PRE-SET” SENSING TYPE TORQUE WRENCHES

This type torque wrench is designed so when torque is applied to

a fastener, it will momentarily release and signal by feel impulse

and audible click (or snap) that the preset torque value has been

reached.

This preset torque wrench is calibrated and sealed at the factory to

the torque value specified on the customer’s purchase order.

Wrenches are also available not preset or sealed when requested

by the customer. Wrenches preset at the factory are set to an

accuracy tolerance of ±4%of the specified torque value.

TO USE:

1. Attach the proper socket or adapter to the arm or square

drive (A).

2. Attach the wrench to the fastener and apply force to the

torque wrench by grasping the padded handle portion (H) at

the end of the wrench.

CAUTION: Do not apply force by holding any part of the wrench,

other than the padded handle. Do not use an extension or other

lever aid on the wrench. Apply force with a steady, smooth

action. When the set torque is reached, the wrench will

momentarily release with a feel impulse and audible click, or

snap. The wrench will move through a small arc about the pivot

pin (B). At this point the set torque has been achieved and force

on the handle (H) must be released. The wrench will snap back

automatically to it’s original position and be ready for the next

torque application.

3. Caution: Don’t apply force after the wrench releases, (clicks,

or snaps) at the set torque. If the fastener is over torqued,

loosen it and repeat the operation.

4. Always actuate the the wrench a few times before use and

after a period when the wrench has not been in use.