WARNING

PLEASE READ THESE INSTRUCTIONS CAREFULLY AND KEEP FOR FUTURE REFERENCE

1

INTENDED USE.

Only use the Paint Roller as described in

this instruction manual.

This Paint Roller it is not suitable for

industrial or commercial use.

The use of any accessory or attachment

or performance of any operation with this

product other than those recommended

in this instruction manual may present a

risk of personal injury and/or damage to

property.

This Paint Roller is not intended for

use by persons with reduced physical,

sensory or mental capabilities, or lack

of experience and knowledge, unless

they have been given supervision or

instructions concerning use of the

product by a person responsible for their

safety.

Children should be supervised to ensure

they do not play with the product.

WORK AREA SAFETY.

Keep your work area clean and well lit.

Cluttered or dark areas invite accidents.

Always ensure there is adequate

ventilation when painting.

We also recommend wearing goggles

and overalls.

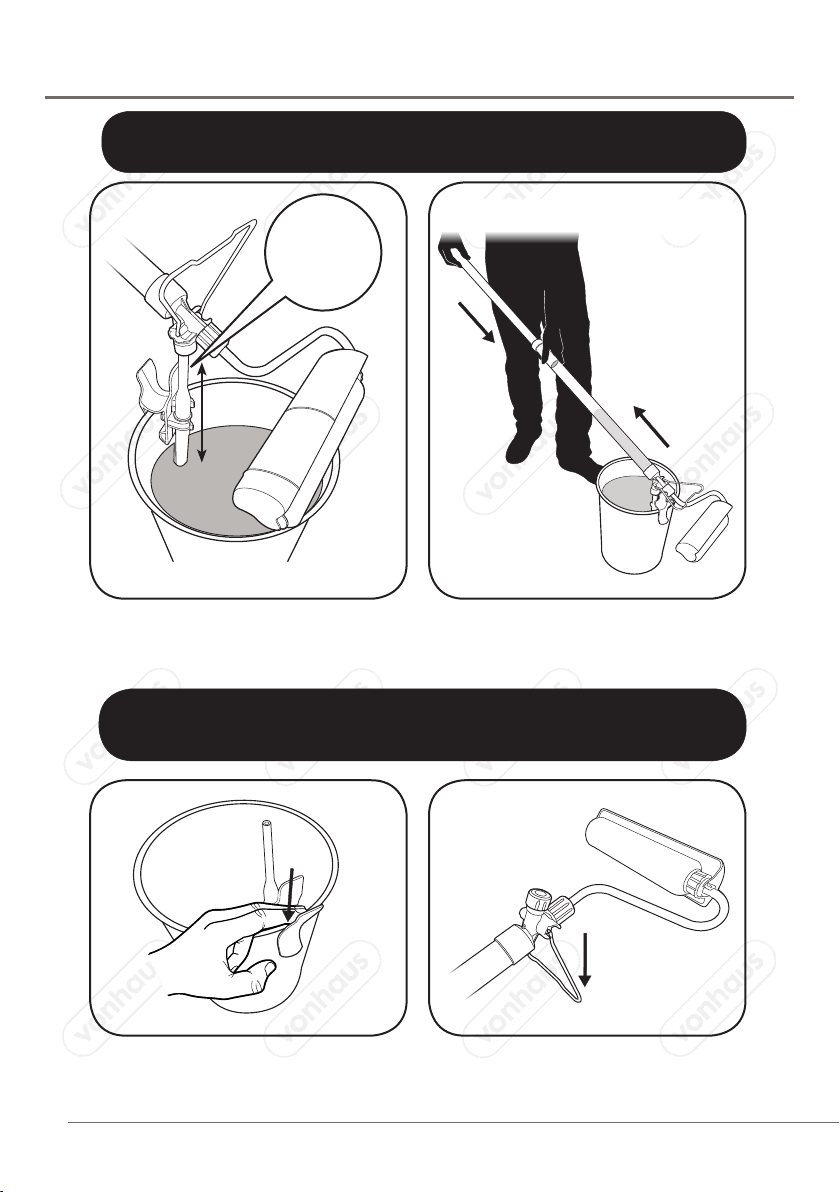

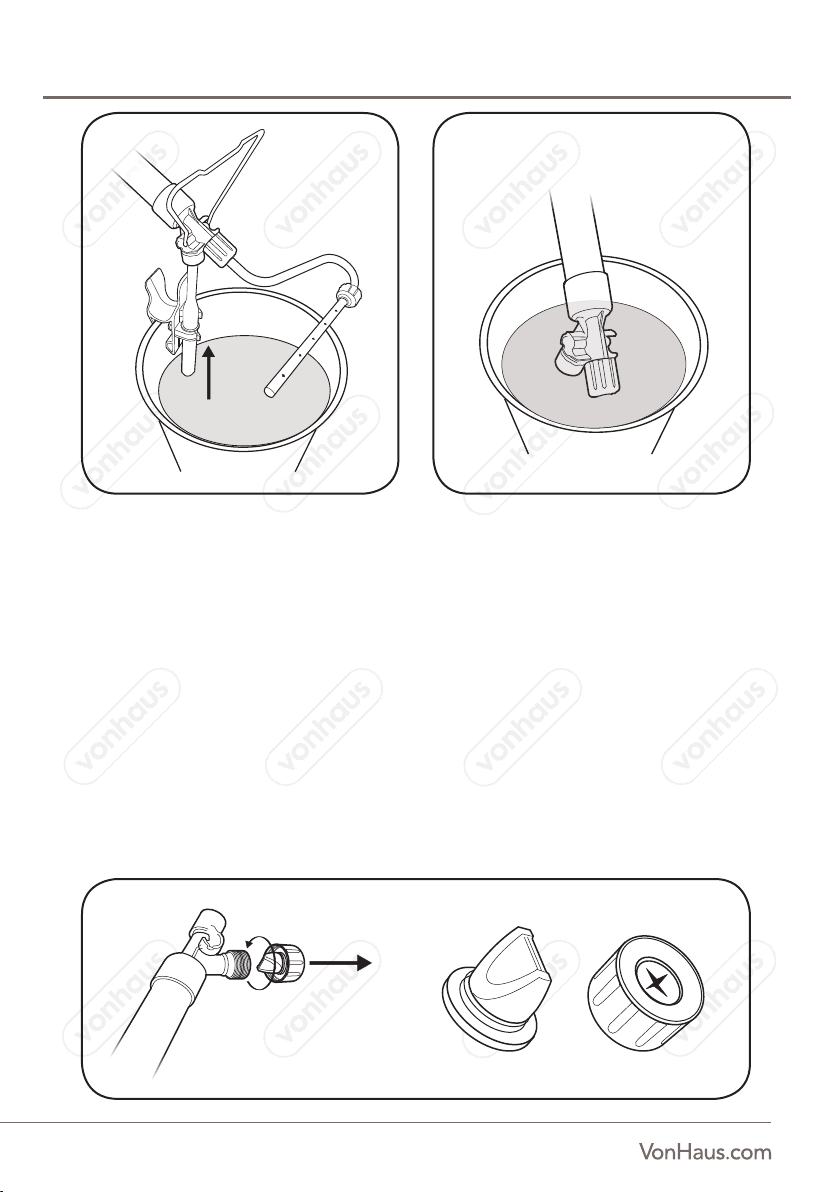

You must clean the Paint Roller Barrel

thoroughly after each use.

STORAGE & MAINTENANCE.

Store the product out of reach of children

and do not allow persons unfamiliar

with the product or these instructions to

operate the product.

The following safety symbols may

appear on this product. Please ensure

you understand their meanings before

operating the Paint Roller in order

to prevent personal injury and avoid

damage to the tool.

SAFETY SYMBOLS

WARNING! Pay

attention to all

safety and

guidance

Read manual

before use

Wear eye

protection