RoHS

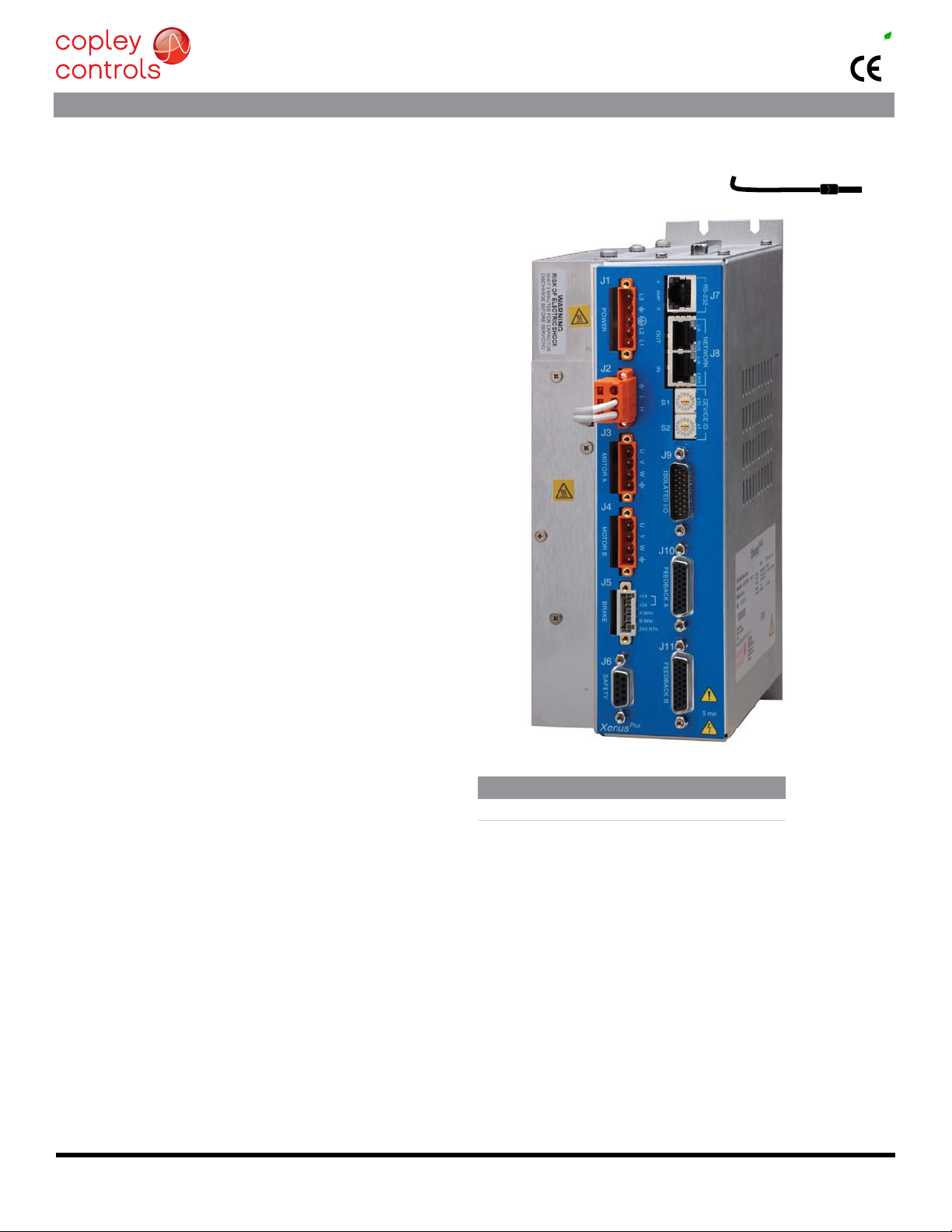

Xenus

PLUS 2-Axis

MACRO

XM2

Rev 01

Copley Controls, 20 Dan Road, Canton, MA 02021, USA

16-01419 Rev A Page 2 of 34

GENERAL SPECIFICATIONS

MODEL XM2-230-20

OUTPUT CURRENT () 0~40 C Ambient

Control power +24 Vdc, ±10% Required for operation

Digital Control Loops Current, velocity, position. 100% digital loop control

Sampling r

Bus voltage compensation Changes in bus or mains voltage do not affect bandwidth

Minimum load inductance

Distributed Control Modes

MACRO Velocity, Torque

Stand-alone mode

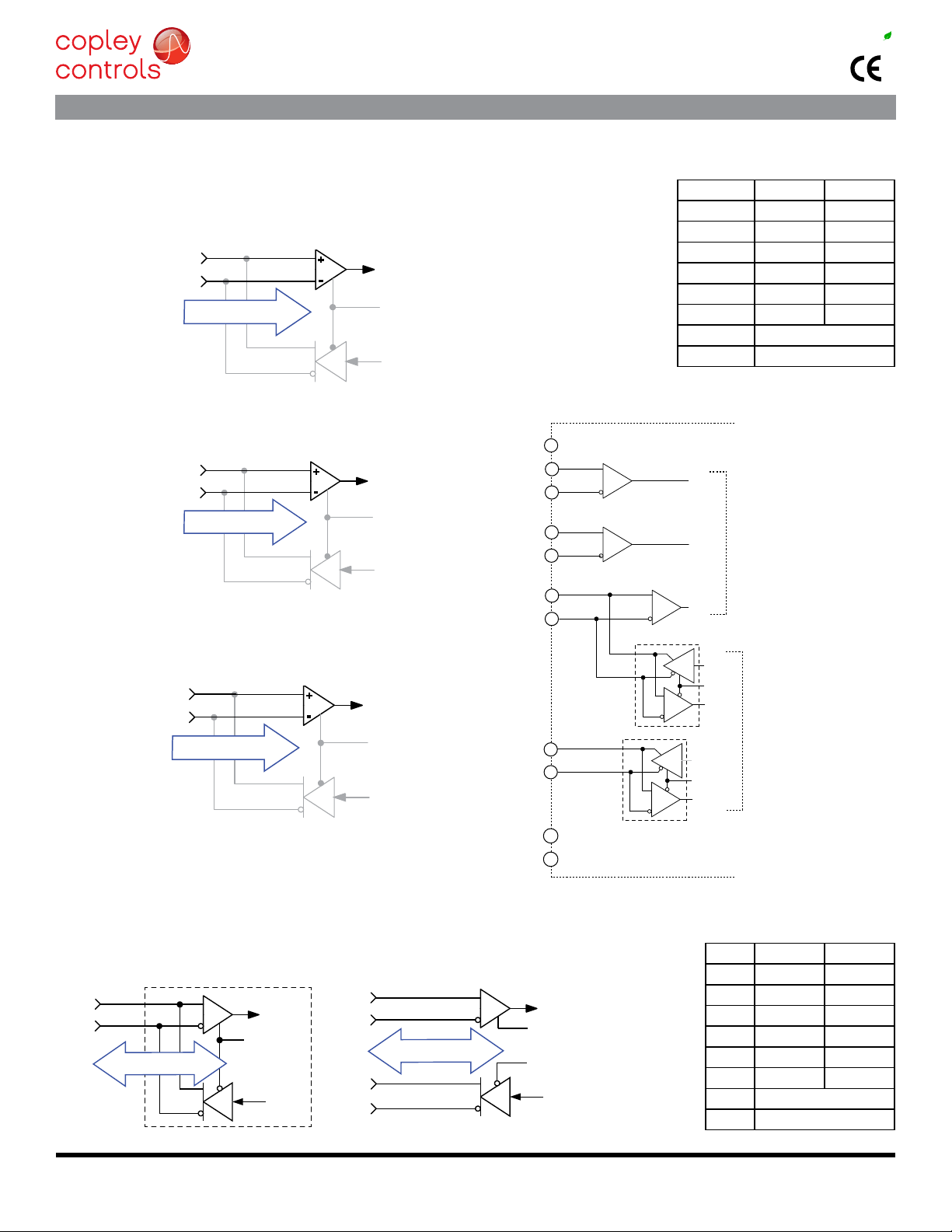

Analog torque, velocity, position reference ±10 Vdc, 14 bit resolution Dedicated differential analog input

Number 22

Ω

Ω

Ω

Number 2

Ωinput impedance, 14-bit resolution

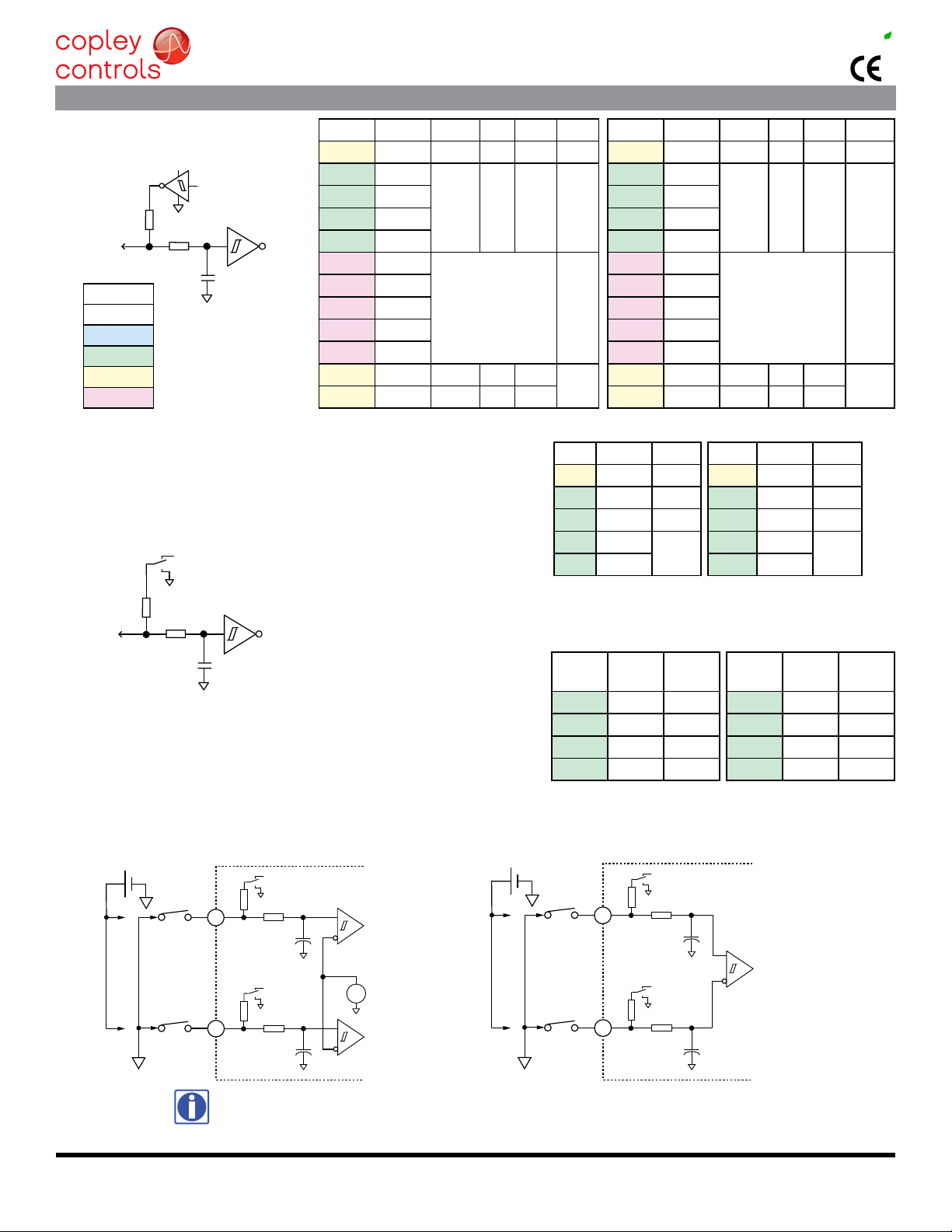

SAFE TORQUE OFF (STO)

Safety Integrity Level SIL 3, Category 3, Performance level d

Inputs 2 two-terminal: STO-IN1+,STO-IN1-, STO-IN2+, STO-IN2-

RS-232 PORT

Protocol Binary and ASCII formats

ETHERCAT PORTS

Protocol EtherCAT, CAN application layer over EtherCAT (CoE)

STATUS INDICATOR LEDS