Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547

T

ech

Support:

E-mail:

[email protected],

W

eb:

http://www.copleycontrols.com P

age

2

of

32

RoHS

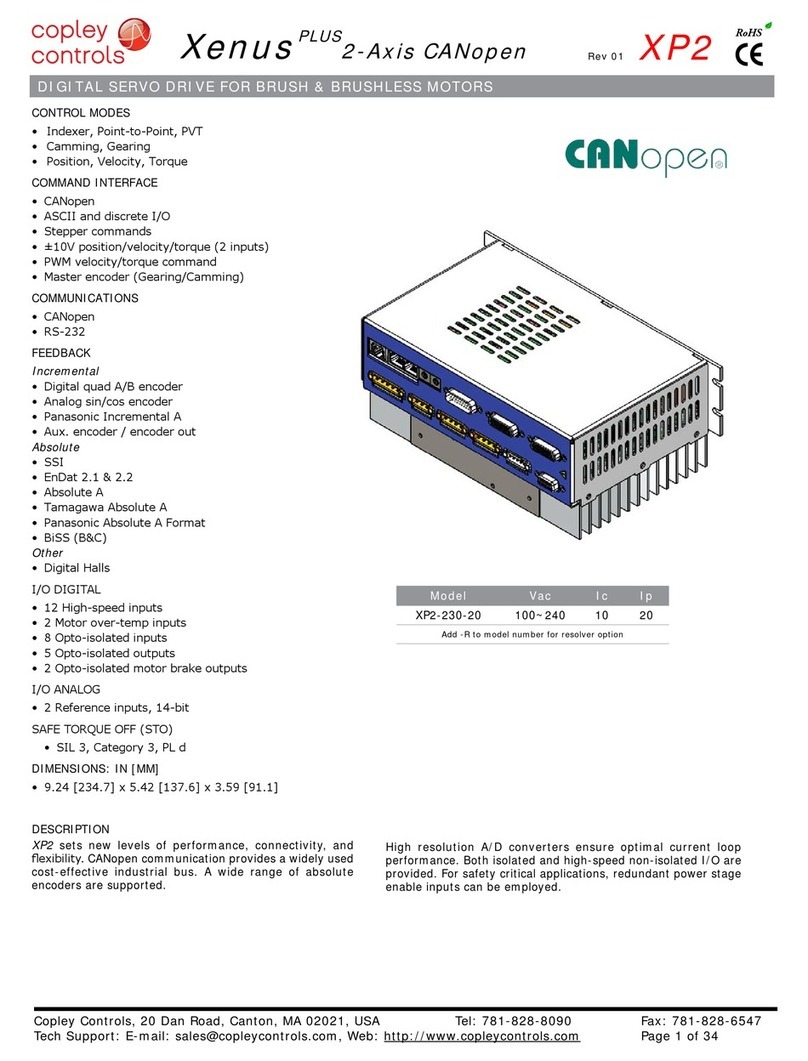

Xenus PLUS 2-Axis EtherCAT

800-1782

GENERALSPECIFICATIONS

Testconditions:Wyeconnectedload:2mHline-line.Ambienttemperature=25°C.Powerinput=230Vac,60Hz,1Ø

MODEL 800-1782

OUTPUTCURRENT(EACHAXIS)

PeakCurrent 20(14) Adc(Arms,sinusoidal)

Peak time 1s

Continuouscurrent(Heatsinkrequired) 10(7) Adc(Arms,sinusoidal)

INPUTPOWER

Mainsvoltage,phase,frequency 100~240 Vac,±10%,1Øor3Ø,47~63Hz

MaximumMainsCurrent,1Ø(Note2,page3) 20 Arms

MaximumMainscurrent,3Ø(Note2,page3) 15.4 Arms

+24VdcControlpower +20to+32Vdc,0.5~1.1Adc(Note3,page3) Requiredforoperation

DIGITALCONTROL

DigitalControlLoops Current,velocity,position.100%digitalloopcontrol

Sampling rate(time) Currentloop:16kHz(62.5µs),Velocity&positionloops:4kHz(250µs)

Busvoltagecompensation Changesinbusormainsvoltagedonotaffectbandwidth

Minimum load inductance 200µHline-line

COMMANDINPUTS(NOTE:DIGITALINPUTFUNCTIONSAREPROGRAMMABLE)

Distributed Control Modes

CAN application layer overEtherCAT(CoE) CyclicSynchronousPosition-Velocity-Torque,ProlePosition-Velocity-Torque,

InterpolatedPosition,Homing

Stand-alone mode

Analogtorque,velocity,positionreference ±10Vdc,14bitresolution Dedicateddifferentialanaloginput

Digitalpositionreference Pulse/Direction,CW/CCW Steppercommands(2MHzmaximumrate)

QuadA/BEncoder 2Mline/sec,8Mcount/sec(afterquadrature)

Digitaltorque&velocityreference PWM,Polarity PWM=0%-100%,Polarity=1/0

PWM50% PWM=50%±50%,nopolaritysignalrequired

PWMfrequencyrange 1kHzminimum,100kHzmaximum

PWM minimum pulse width 220 ns

Indexing Upto32sequencescanbelaunchedfrominputsorASCIIcommands.

Camming Upto10CAMtablescanbestoredinashmemory

ASCII RS-232,DTE,9600~115,200Baud,3-wire,RJ-12connector

DIGITALINPUTS

Number 20

[IN1,11] Digital,Schmitttrigger,1µsRClter,24Vdccompatible,programmablepull-up/downto+5Vdc/ground,

Vt+=2.5~3.5Vdc,VT-=1.3~2.2Vdc,VH=0.7~1.5Vdc

[IN2~5,12~15] Programmableassingle-endedordifferentialpairs,100nsRClter,5Vdcmax,

10 kΩprogrammablepull-up/downperinputto+5Vdc/ground,

SE:Vin-LO≤2.3Vdc,Vin-HI≥2.7Vdc,VH=45mVtyp,DIFF:Vin-LO≤200mVdc,Vin-HI≥200mVdc,VH=45mVtyp,

[IN6~9] Opto-isolated,single-ended,±15~30Vdccompatible,bi-polar,groupof4withcommonreturn

Ratedimpulse≥800V, Vin-LO≤6.0Vdc,Vin-HI≥10.0Vdc,Inputcurrent±3.6mA@±24Vdc,typical

[IN16~19] DedicatedfunctionforNSKmotorlimitswitches.Internal6Vpowerwithcurrent-limitingresistors.

[IN10,20] Motorovertempsignalsonfeedbackconnectors,Schmitttrigger,24Vdccompatible,

330µsRClter,4.99kpullupto+5Vdc,Vt+=2.5~3.5Vdc,VT-=1.3~2.2Vdc,VH=0.7~1.5Vdc

SAFETORQUEOFF(STO)INPUTS

Function PWMoutputsinactiveandcurrenttothemotorwillnotbepossiblewhentheSTOfunctionisactivated

Standard ConformancetoIEC61508-1,IEC61508-2,IEC61800-5-2,ISO13849-1

SafetyIntegrityLevel SIL3,Category3,PerformanceLeveld

Inputs 2two-terminal:STO_IN1+,STO_IN1-,STO_IN2+,STO_IN2-

Type Opto-isolators,24Vcompatible,Vin-LO≤6.0Vdcoropen,Vin-HI≥15.0Vdc,

Inputcurrent(typical) STO_IN1:11.2mA,STO_IN2:11.2mA

Responsetime 2ms(IN1,IN2)fromVin≤6.0Vdctointerruptionofenergysuppliedtomotor

Reference CompleteinformationandspecicationsareintheXenusPlusDual-AxisSTOManual

ANALOGINPUTS

Number 2

[AIN1~2] Differential,±10Vdc,5kΩinput impedance, 14-bit resolution

DIGITALOUTPUTS

Number 5

[OUT1~3] Opto-isolatedsolid-staterelays,60mAdcmax,24Vdctolerant,Ratedimpulse≥800V, series20ohmresistor

MOSFETchannelconnectsthe(±)outputs,Rds-On=10Ωmax@60mAdc,maxVout=32Vdc

Td-ON=5000µsmax@60mA,Td-OFF=5000µsmax@60mA,timesincluderise/falltimes

[OUT6~7] Motorbrakecontrol:opto-isolated,current-sinkingwithybackdiodeto+24Vdc(J5-4~5),1Adcmax,Ratedimpulse≥800V

Td-ON=250µsmax@20mA,Td-OFF=250µsmax@200mA,timesincluderise/falltimes,

Programmable for other functions if not used for brake

RS-232PORT

Signals RxD,TxD,Gndin6-position,4-contactRJ-12stylemodularconnector,non-isolated,commontoSignalGround

Mode Full-duplex, DTE serial communication port for drive setup and control, 9,600 to 115,200 baud

Protocol BinaryandASCIIformats

ETHERCATPORTS

Format DualRJ-45receptacles,100BASE-TX

Protocol EtherCAT,CANapplicationlayeroverEtherCAT(CoE)

STATUSINDICATORS

AMP BicolorLED,drivestateindicatedbycolor,andblinkingornon-blinkingcondition

RUN GreenLED,statusofEtherCATstate-machine(ESM)

ERR RedLED,showserrorsduetotime-outs,unsolicitedstatechanges,orlocalerrors

L/A GreenLED,Link/Act,showsthestateofthephysicallinkandactivityonthelink(EtherCATconnection)

RUN,ERR,andL/ALEDcolorsandblinkcodesconformtoETG.1300S(R)V1.1.0