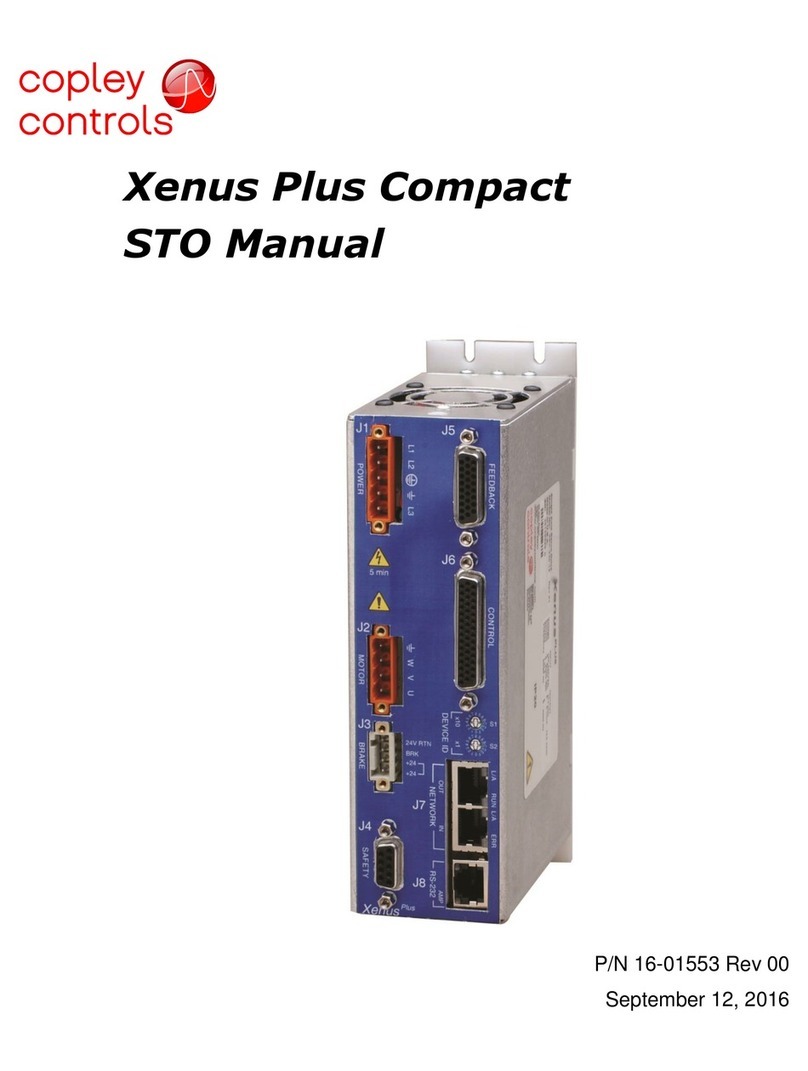

Xenus XTL

™DIGITAL SERVO DRIVE

for BRUSHLESS/BRUSH MOTORS

Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547

T

ech

Support:

E-mail:

[email protected],

Internet:

http://www

.copleycontrols.com

Page

2

of

30

GENERAL SPECIFICATIONS

Test conditions: Wye connected load: 2 mH line-line. Ambient temperature = 25 °C. Power input = 230 Vac, 60 Hz, 1 Ø

MODEL XTL-230-18 XTL-230-36 XTL-230-40 Same specs for -S and -R models

OUTPUT CURRENT

Peak Current 18 (12.7) 36 (25.5) 40 (28.3) Adc (Arms, sinusoidal)

Peak time 1 1 1 s

Continuous current (Note 1) 6 (4.24) 12 (8.5) 20 (14.1) Adc (Arms, sinusoidal)

INPUT POWER

Mains voltage, phase, frequency 100~240 Vac, ±10%, 1 Ø or 3 Ø, 47~63 Hz

Mains current 20 Arms

+24 Vdc Control power +20 to +32 Vdc, 500 mA max Required for operation

DIGITAL CONTROL

Digital Control Loops Current, velocity, position. 100% digital loop control

Sampling rate (time) Current loop: 15 kHz (67 µs), Velocity & position loops: 3 kHz (333 µs)

Bus voltage compensation Changes in bus or mains voltage do not affect bandwidth

Minimum load inductance 200 µH line-line

COMMAND INPUTS (NOTE: DIGITAL INPUT FUNCTIONS ARE PROGRAMMABLE)

Distributed Control Modes

CANopen Position, Velocity, Torque, Homing, Prole, and Interpolated prole modes

DeviceNet®Compatible with Allen-Bradley PLC’s

ASCII Multiple drives accessible from a single RS-232 port

Stand-alone mode

Analog torque, velocity, position reference ±10 Vdc, 12 bit resolution Dedicated differential analog input

Input impedance 74.8 kΩBetween Ref(+), Ref(-)

Digital position reference Pulse/Direction, CW/CCW Stepper commands (2 MHz maximum rate)

Quad A/B Encoder 2 M line/sec, 8 Mcount/sec (after quadrature)

Digital torque & velocity reference PWM , Polarity PWM = 0% - 100%, Polarity = 1/0

PWM 50% PWM = 50% ±50%, no polarity signal required

PWM frequency range 1 kHz minimum, 100 kHz maximum

PWM minimum pulse width 220 ns

Indexing Up to 32 programs can be launched from inputs or ASCII commands. Each program can

consist of moves, I/O commands, time delays, and other programmable operations.

Camming Master quadrature encoder provides position as index to cam table.

Digital inputs initiate cam functions.

DIGITAL INPUTS

Number 12

Inputs [IN1~5,11,12] 74HC14 Schmitt trigger, 330 µs RC lter, Vin-LO < 1.35 Vdc, Vin-HI >3.65 Vdc, +24 Vdc max

[IN1] dedicated to drive enable function, other inputs are programmable

Input [IN6] 74HC14 Schmitt trigger, 100 ns RC lter, Vin-LO < 1.35 Vdc, Vin-HI >3.65 Vdc, +12 Vdc max

Inputs [IN7~10] Single-ended: Comparator with 2.5 Vdc reference, 100 ns RC lter, Vin-LO <2.3 Vdc, Vin-HI > 2.45 Vdc

Differential: RS-485 line receiver on input pairs [IN9-7], and [IN10-8], 100 ns RC lters, +12 Vdc max

All inputs 10 kΩpull-up to +5 Vdc or pull-down to ground, selectable in groups, active level programmable

DIGITAL OUTPUTS (NOTE 2)

Number 4

[OUT1], [OUT2], [OUT3] Current-sinking MOSFET with 1 kΩpullup to +5 Vdc through diode

Current rating 1 Adc max, +40 Vdc max. Functions programmable

External yback diode required if driving inductive loads

Brake [OUT4] Opto-isolated, current-sinking with yback diode to +24 Vdc, 1 Adc max

MULTI-MODE ENCODER PORT

As Input Secondary digital quadrature encoder (A, /A, B, /B, X, /X), 121 Ωterminating resistors

18 M-counts/sec, post-quadrature (4.5 M-lines/sec)

As Output Quadrature encoder emulation with programmable resolution to 4096 lines (65,536 counts) per rev

from analog sin/cos encoders or resolvers. Buffered signals from digital quad A/B/X primary encoder

A, /A, B, /B, X, /X, from 26LS31 differential line driver

RS-232 PORT

Signals RxD, TxD, Gnd in 6-position, 4-contact RJ-11 style modular connector

Mode Full-duplex, DTE serial communication port for drive setup and control, 9,600 to 115,200 baud

Protocol Binary and ASCII formats

CAN PORTS

Signals CANH, CANL, Gnd in 8-position RJ-45 style modular connector, wired as per CAN Cia DR-303-1, V1.1

Format CAN V2.0b physical layer for high-speed connections compliant

Data CANopen Device Prole DSP-402

Address selection 16 position rotary switch on front panel with 3 additional address bits available as

digital inputs or programmable to ash memory (7-bit addressing, 127 nodes per CAN network)

STATUS INDICATORS

Drive Status Bicolor LED, drive status indicated by color, and blinking or non-blinking condition

CAN Status Bicolor LED, status of CAN bus indicated by color and blink codes to CAN Indicator Specication 303-3

REGENERATION

Operation Internal solid-state switch drives external regen resistor (see Ordering Guide for types)

Cut-In Voltage +HV > 390 Vdc Regen output is on, (optional external) regen resistor is dissipating energy

Drop-Out Voltage +HV < 380 Vdc Regen output is off, (optional external) regen resistor not dissipating energy

Tolerance ±2 Vdc For either Cut-In or Drop-Out voltage

NOTES:

1. Heatsinking and/or forced-air cooling is required for continuous output power rating

2. Brake[OUT4] is programmable as motor brake, or as general purpose digital output