Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547

T

ech

Support:

E-mail:

[email protected],

W

eb:

http://www

.copleycontrols.com

Page

2

of

34

RoHS

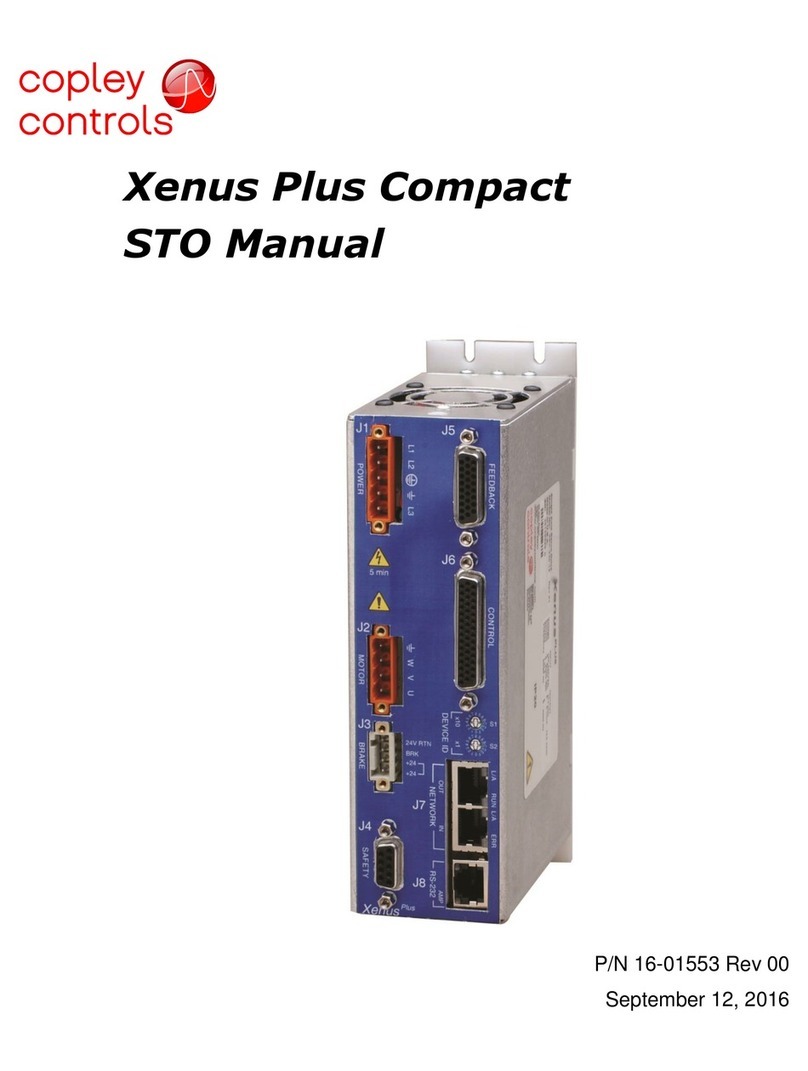

Xenus

PLUS 2-Axis CANopen

XP2

Rev 01

MODEL XP2-230-20

INPUT POWER

Mains current 20 Arms

Sampling r

Bus voltage compensation Changes in bus or mains voltage do not affect bandwidth

Minimum load inductance

Distributed Control Modes

Stand-alone mode

PWM minimum pulse width 220 ns

ASCII RS-232, 9600~115,200 Baud, 3-wire, RJ-12 connector

Number 22

Ω

Number 4

Ωinput impedance, 14-bit resolution

Ω

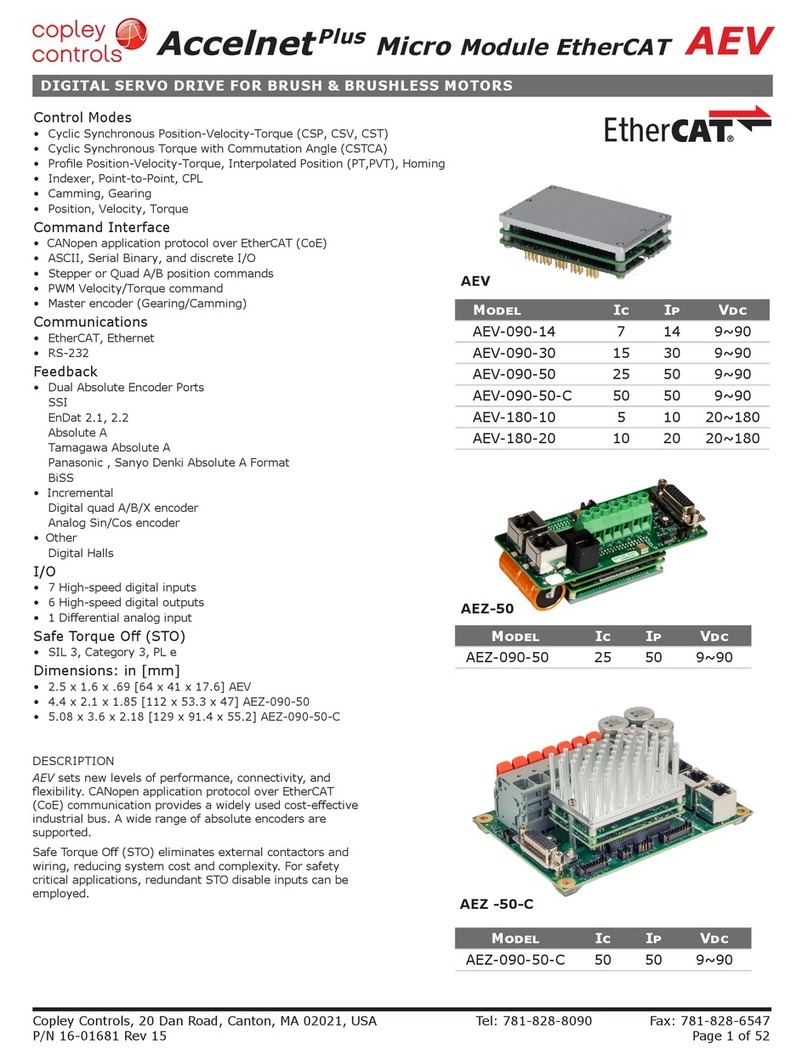

Function PWM outputs are inactive and current to the motor will not be possible when the STO function is asserted

Standard Designed to IEC-61508-1, IEC-61508-2, IEC-61800-5-2, ISO-13849-1

Safety Integrity Level SIL 3, Category 3, Performance level d

Inputs 2 two-terminal: STO-IN1+,STO-IN1-, STO-IN2+, STO-IN2-

Number 7

RS-232 PORT

Mode Full-duplex, DTE serial communication port for drive setup and control, 9,600 to 115,200 baud

Protocol Binary and ASCII formats

CAN PORT

Address selection 16 position rotary switch on front panel with 3 additional address bits available as

STATUS INDICATOR LEDS

GENERAL SPECIFICATIONS