Xenus Plus User Guide 16-01344 Rev 06

Copley Controls 3

TABLE OF CONTENTS

About This Manual..................................................................................................................................................................................... 5

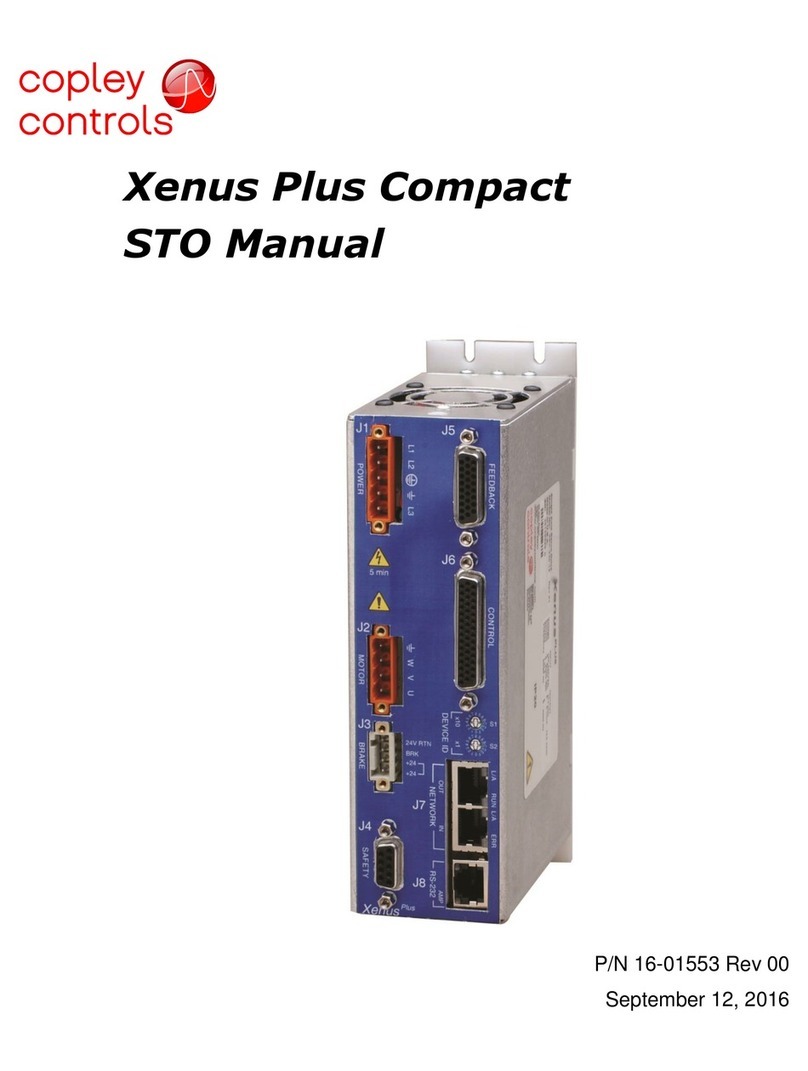

1: Introduction.................................................................................................................................................................................... 10

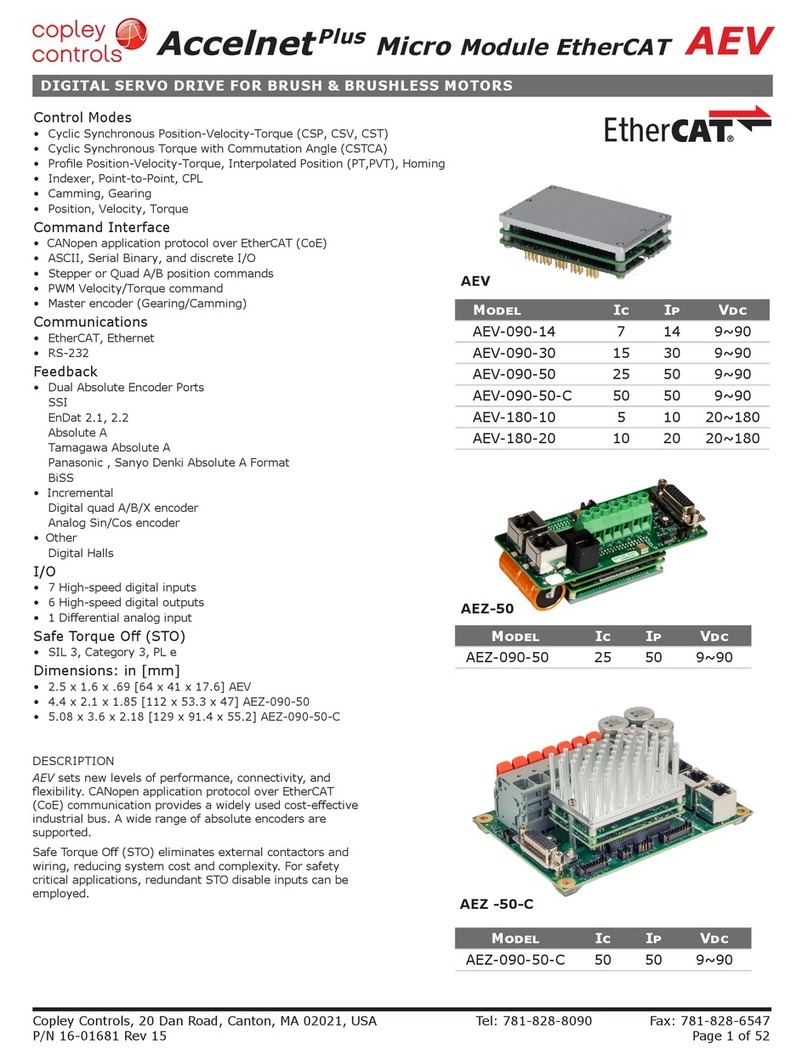

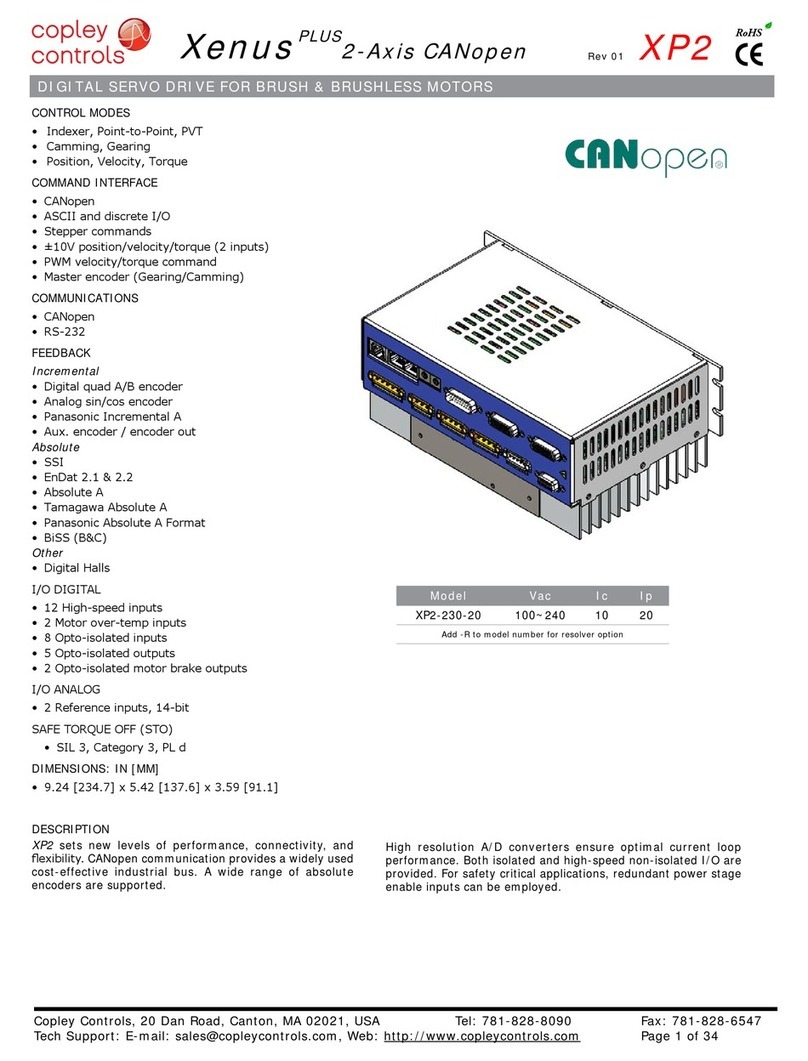

1.1: Xenus Plus Family Overview.................................................................................................................................................... 11

1.2: CME.......................................................................................................................................................................................... 12

1.3: CML/CMO................................................................................................................................................................................. 13

1.4: Copley Virtual Machine (CVM) ................................................................................................................................................. 13

1.5: Indexer 2................................................................................................................................................................................... 13

1.6: CPL........................................................................................................................................................................................... 13

2: Operational Theory........................................................................................................................................................................ 14

2.1: Drive Power Architecture.......................................................................................................................................................... 15

2.2: Operating Modes ...................................................................................................................................................................... 17

2.3: Input Command Types ............................................................................................................................................................. 28

2.4: Communication......................................................................................................................................................................... 33

2.5: Status Indicators....................................................................................................................................................................... 38

2.6: Protection.................................................................................................................................................................................. 50

2.7: Position and Velocity Errors...................................................................................................................................................... 52

2.8: Inputs XEL/XPL/XML................................................................................................................................................................ 55

2.9: Inputs XE2/XP2/XM2/800-1818/800-1819/800-1887 ............................................................................................................... 56

2.10: Outputs, XEL/XPL/XML .......................................................................................................................................................... 58

2.11: Outputs, XE2/XP2/XM2/800-1818/800-1819/800-1887 ......................................................................................................... 58

2.12: Brake Operation...................................................................................................................................................................... 58

2.13: Regen Resistor Theory........................................................................................................................................................... 61

3: Specifications ................................................................................................................................................................................ 64

3.1: Agency Approvals..................................................................................................................................................................... 65

3.2: Power Input............................................................................................................................................................................... 65

3.3: Power Output............................................................................................................................................................................ 66

3.4: Control Loops ........................................................................................................................................................................... 67

3.5: Regen Circuit Output (External Regen Resistor)...................................................................................................................... 67

3.6: Regen Circuit Output (Internal Regen Resistor)....................................................................................................................... 67

3.7: Digital Command Inputs ........................................................................................................................................................... 68

3.8: Analog Inputs............................................................................................................................................................................ 68

3.9: Digital Inputs............................................................................................................................................................................. 69

3.10: Analog Output......................................................................................................................................................................... 70

3.11: Digital Outputs ........................................................................................................................................................................ 70

3.12: Encoder Power Outputs.......................................................................................................................................................... 71

3.13: Primary Encoder Inputs .......................................................................................................................................................... 71

3.14: Analog Encoder Inputs ........................................................................................................................................................... 72

3.15: Hall Switch Inputs ................................................................................................................................................................... 73

3.16: Resolver Interface................................................................................................................................................................... 74

3.17: Multi-Mode Port ...................................................................................................................................................................... 75

3.18: Serial Interface........................................................................................................................................................................ 76

3.19: Network Interfaces.................................................................................................................................................................. 77

3.20: Status Indicators..................................................................................................................................................................... 78

3.21: Fault Levels ............................................................................................................................................................................ 78

3.22: Power Dissipation................................................................................................................................................................... 79

3.23: Thermal Impedance................................................................................................................................................................ 79

3.24: Mechanical and Environmental............................................................................................................................................... 80

3.25: Dimensions............................................................................................................................................................................. 81

4: Wiring.............................................................................................................................................................................................. 84

4.1: General Wiring Instructions ...................................................................................................................................................... 85

4.2: AC Mains (J1)........................................................................................................................................................................... 88

4.3: Motor(s) .................................................................................................................................................................................... 91

4.4: Regen Resistor (Optional) ........................................................................................................................................................ 93

4.5: Logic Supply / Brake................................................................................................................................................................. 96

4.6: Ferrules –XE2/XP2/XM2/800-1818/800-1819/800-1887......................................................................................................... 98

Motor Torque Off ............................................................................................................................................................................ 99

4.7: (MTO) ....................................................................................................................................................................................... 99

4.8: Safe Torque Off (STO) ........................................................................................................................................................... 104

4.9: RS-232 Serial Communications.............................................................................................................................................. 106

4.10: Network Ports ....................................................................................................................................................................... 107

4.11: Control I/O ............................................................................................................................................................................ 110

4.12: Motor Feedback.................................................................................................................................................................... 126

A: Regen Resistor Sizing and Configuration................................................................................................................................. 134

A.1: Sizing a Regen Resistor......................................................................................................................................................... 135

B: I2T Time Limit Algorithm................................................................................................................................................................... 139

B.1: I2T Algorithm........................................................................................................................................................................... 140

C: Thermal Considerations.............................................................................................................................................................. 143

C.1: Operating Temperature and Cooling Configurations ............................................................................................................. 144

C.2: Heatsink Mounting Instructions (XEL/XPL/XML).................................................................................................................... 148