Smitec COSMOS 301 Series User manual

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

Smitec S.p. ., viale Vittorio Veneto 4, 24016 San Pellegrino Terme (BG), Italy, www.smitec.it

Installation, use and maintenance manual

BEFORE STARTING UP THE COSMOS 3 1X SERVO-DRIVES, CAREFULLY

READ THIS MANUAL AND FOLLOW ALL INSTRUCTIONS, IN ORDER TO

ENSURE MAXIMUM SAFETY

SERVO DRIVES

COSMOS 3 1X SERIES

The technical data and the drawings in this manual might have been modified later;

always refer to the latest version.

Ver. 1.09 SMIT Cdd 1/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

CONTENTS

1 PR FAC .............................................................................................................................................................4

2 G N RAL INSTRUCTIONS .................................................................................................................................5

3 Safety instructions .................................................................................................................................................7

3.1 General information .......................................................................................................................................7

3.2 Precautions against risk of lectric Shock .....................................................................................................8

3.3 Precautions against hot components ............................................................................................................9

4 T CHNICAL F ATUR S ....................................................................................................................................10

4.1 Description ...................................................................................................................................................10

4.2 Technical specifications ...............................................................................................................................12

4.2.1 nvironmental features ........................................................................................................................12

4.2.2 Ratings .................................................................................................................................................13

4.2.3 Motor output .........................................................................................................................................13

4.2.4 Dynamic brake output ..........................................................................................................................14

4.2.5 ncoder input .......................................................................................................................................14

4.2.6 Resolver input ......................................................................................................................................14

4.2.7 Digital inputs ........................................................................................................................................14

4.2.8 Digital outputs ......................................................................................................................................14

4.2.9 Static brake output ...............................................................................................................................14

4.2.10 Counter input .....................................................................................................................................14

4.2.11 0 ÷ 10 V input .....................................................................................................................................14

4.2.12 4 ÷ 20 mA input ..................................................................................................................................15

4.2.13 Motor temperature sensor input .........................................................................................................15

4.2.14 0 ÷ 10 V output ...................................................................................................................................15

4.2.15 Reference voltage output ...................................................................................................................15

4.2.16 Thermocouple input ...........................................................................................................................15

4.3 Configurations / order codes .......................................................................................................................16

4.4 Model code ..................................................................................................................................................18

4.5 Accessories .................................................................................................................................................19

4.6 Heat dissipation ...........................................................................................................................................20

4.7 lectromagnetic compatibility ( MC) ...........................................................................................................22

4.8 Mechanical specifications ............................................................................................................................23

4.8.1 Weight .................................................................................................................................................. 23

4.8.2 xternal dimensions without operator interface ...................................................................................23

4.8.3 xternal dimensions with operator interface VISIO 3000 ....................................................................24

5 INSTALLATION AND START-UP .......................................................................................................................25

5.1 Preliminary operations .................................................................................................................................25

5.2 Positioning and installation ..........................................................................................................................25

5.3 lectrical connections ..................................................................................................................................27

5.3.1 Connections (KZ010374) .....................................................................................................................27

5.3.2 Connections (KZ010375 and KZ010376) ............................................................................................28

5.3.3 Connections (KZ010377 and KZ010389) ............................................................................................29

5.3.4 Connections (KZ010385) .....................................................................................................................30

5.3.5 Connections (KZ010387 and KZ010388) ............................................................................................31

5.4 Mains power and MI filters ........................................................................................................................32

5.4.1 Power supply with IT distribution networks ..........................................................................................33

5.4.2 Cables and protection devices .............................................................................................................34

5.5 Installation criteria for UL certification ..........................................................................................................36

5.6 Motor, brake resistor and DC bus wiring .....................................................................................................37

5.7 24V auxiliary and I/O power ........................................................................................................................41

5.7.1 Connections (KZ010374) .....................................................................................................................41

5.7.2 Connections (KZ010375 and KZ010376) ............................................................................................42

5.7.3 Connections (KZ010377 and KZ010389) ............................................................................................43

5.7.4 Connections (KZ010385) .....................................................................................................................44

5.7.5 Connections (KZ010387 and KZ010388) ............................................................................................45

5.7.6 24V auxiliary power ..............................................................................................................................46

5.7.7 24V digital inputs ..................................................................................................................................47

5.7.8 Counter input .......................................................................................................................................48

5.7.9 24V digital outputs ...............................................................................................................................49

5.7.10 Motor brake output .............................................................................................................................49

5.7.11 Incremental encoder ..........................................................................................................................50

5.7.12 Resolver .............................................................................................................................................52

5.7.13 Motor temperature sensor ..................................................................................................................54

5.7.14 0 to 10V analogue input and 10V reference generator ......................................................................55

5.7.15 4 to 20mA analogue input ..................................................................................................................56

Ver. 1.09 SMIT Cdd 2/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

5.7.16 0 to 10V analogue output ...................................................................................................................57

5.7.17 Thermocouple J input ........................................................................................................................58

5.8 Field bus ......................................................................................................................................................59

5.8.1 FL XTRON versions ...........................................................................................................................59

5.8.2 FLxIO versions .....................................................................................................................................60

5.9 RS485 interface ...........................................................................................................................................62

5.10 Removable operator interface (HMI) .........................................................................................................63

5.10.1 Function of the keys ...........................................................................................................................64

6 UPDATING TH FIRMWAR .............................................................................................................................65

7 STORAG ........................................................................................................................................................... 72

8 MAINT NANC .................................................................................................................................................. 73

9 DISPOSAL AND D MOLITION ..........................................................................................................................74

Ver. 1.09 SMIT Cdd 3/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

1 PREFACE

This manual provides the information required for installation, use and maintenance of servo-drives/inverters

of COSMOS 301X series.

The instructions included in this manual are addressed to the following professionals:

User User is a person, a company or an institution that buys the equipment and uses it for the

purposes it was designed for.

User / operator User or operator is a person authorized by the user to work on the equipment.

Qualified personnel It refers to all persons with specific competence, able to recognize and avoid the dangers

deriving from the use of the equipment.

The present instructions must be made available to all above persons.

Ver. 1.09 SMIT Cdd 4/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

2 GENERAL INSTRUCTIONS

The assembly instructions are an integral part of the equipment and must be kept for future reference, until it

is dismantled. The present instructions reflect the state of the art at the moment when the equipment was

sold; they will remain fully acceptable despite subsequent upgrades based on new experience.

DO NOT USE THE EQUIPMENT, NOR MAKE ANY INTERVENTION BEFORE INTEGRALLY

READING AND UNDERSTANDING THIS MANUAL.

IN PARTICULAR, ADOPT ALL SAFETY PRECAUTIONS AND PRESCRIPTIONS INDICATED IN THIS MANUAL.

THE EQUIPMENT CAN NOT BE USED FOR DIFFERENT PURPOSES THAN THE ONES DESCRIBED IN THIS

MANUAL; SMITEC S.p.A. SHALL NOT BE HELD RESPONSIBLE FOR ANY DAMAGES, INCONVENIENCES OR

ACCIDENTS DUE TO THE NON-COMPLIANCE WITH THE PRESCRIPTIONS.

In order to make the manual consultation easier, the following symbols have been adopted:

The indication of "FORBIDD N B HAVIOR".

The symbol "DANG R" is used when the non-compliance with the prescriptions or misuse

may cause serious injuries.

The symbol "DANG R OF HOT SURFAC S" is used when the non-compliance with the

prescriptions may cause serious injuries.

The symbol "DANG R OF L CTRICAL SHOCK" is used when the non-compliance with

the prescriptions may cause serious injuries.

The symbol "US OF INDIVIDUAL PROT CTIONS" means that protective gloves must be

worn.

The symbol "US OF INDIVIDUAL PROT CTIONS" means that protective glasses must

be worn.

The indication of "PARTICULAR R L VANT INFORMATION".

Ver. 1.09 SMIT Cdd 5/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

The safety prescriptions aim at establishing a series of behaviours and obligations to be complied with, while

performing the activities described later on in this manual.

These prescriptions constitute the prescribed method of operating the machine, in a way that is safe for

personnel, tools/equipment and environment.

Ver. 1.09 SMIT Cdd 6/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

3 Safety instructions

3.1 General information

Do not install or use the equipment before integrally reading and understanding this

manual. In case of difficulties of interpretation, contact SMIT C technical service.

It is absolutely forbidden to use the equipment for different purposes than the ones

described in this manual. The technical data and the drawings in this manual might have

been modified later; always refer to the latest version. All upgrades can be requested to

SMIT C S.p.A. directly.

Make sure that the personnel is qualified and adequately informed about the risks he may

run and how to avoid them.

The COSMOS 301X series servo drives is authorized can be used only after the

classification of the machine operating area and after checking the safety levels, which

must correspond to the assembly safety levels.

Precautions during handling and assembly

Use adequate tools during the assembly, in order to avoid crushing or abrasions.

Metal components and sharp surfaces may cause cuts and tears. In case of contact, be

very careful and wear the personal protection equipment.

Ver. 1.09 SMIT Cdd 7/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

3.2 Precautions against risk of Electric Shock

The high voltage of some accessories and components in the servo-driver/inverter might

cause electrocution, if the user came into contact with them. Be careful to the terminal

boards and to the motor/dynamic brake connection.

There are some condensers inside the driver which maintain a dangerous voltage for at

least 6 minutes after switching them off. Before starting any operation, make sure that the

driver has been switched off at least 6 minutes earlier and that the motor is still.

Avoid any metal components (screws, electrical cables…) fall into the driver during the

installation, because they might cause short-circuits.

The driver is an electric generator. The running speed becomes electric potential. High

voltage is already generated at 300 rpm.

During installation and maintenance, disconnect the device from the mains power supply.

Risk of lectric Shock.

Some components (such as the aluminium heat sink) are made of conductive materials.

They must be safely connected to the protective conductor (P /Ground) by using the

specific terminal strips, in order to avoid lectric Shock.

Never use the device if it is partially or totally disassembled. Risk of lectric Shock and/or

damages to people and properties.

Ver. 1.09 SMIT Cdd 8/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

3.3 Precautions against hot components

W RNING

The parts of the apparatus can reach an extremely high temperature in operating mode or

post-operation; take particular care not to touch the parts of the equipment in these cases,

or use special protections and precautions during handling: HOT SURFAC , RISK OF

BURN.

VERTISSEMENT

Les pièces de l'appareil peuvent atteindre une température extrêmement élevée en mode

de fonctionnement ou post-opération; veillez particulièrement à ne pas toucher les pièces

de l'équipement dans ces cas, ou utilisez des protections et des précautions spéciales

lors de la manipulation: SURFAC CHAUD , RISQU D BRÛLUR .

Ver. 1.09 SMIT Cdd 9/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4 TECHNICAL FEATURES

4.1 Description

The servo-drives/inverters of the COSMOS 301X series have been designed for three-phase asynchronous

electrical motors and for brushless AC motors (BLAC). The core of the power section is an intelligent IGBT

module (IPM), featuring the necessary protections that guarantee an extreme reliability and efficiency,

besides reducing the need for external components. The servo-drives/inverters of the COSMOS 301X series

for asynchronous and brushless motors is constituted by an aluminium dissipater and by electronic boards

included in a special “plastic case”.

In particular, the servo-drives/inverters of the COSMOS 301X series for asynchronous and/or brushless AC

motors can control start/stop functions, motor speed and position and motor torque and can perform

diagnostic activity, etc. They are also used to manage abnormal conditions, by providing real-time diagnostic

information (diagnostics are included in the machine into which the drive is incorporated) that can be viewed

by connecting the system to other instruments (such as an HMI) or by using a “master” device (on versions

equipped with a field bus).

Servo-drives/inverters for asynchronous and brushless motors are mainly intended for the so-called “second

environment”, i.e. heavy industry. Some versions only require 230V AC single-phase power supply; others

require 24V DC auxiliary power.

The control logic is implemented by 32-bit micro-controllers, equipped with a set of instructions optimized for

speed and specialized in controlling precision motors. Thanks to their design features, the drives/inverters

can be considered as of digital type, because they are completely controlled by the micro-controller. As a

consequence, the servo-drive/inverter is a very flexible appliance which can be reset through a software and

is open to all improvements offered by the new technologies in the future.

The equipment is designed for asynchronous motors and brushless AC motors. It operates on 230VAC

single-phase power and on 24VDC auxiliary power (on certain versions only). Auxiliary power, when

applicable, is used to feed the control section of the device.

Versions equipped with field bus interface feature a “master” device sending commands to the equipment

(such as start, stop, motor speed/position, parameters for the motor and/or servo-drive/inverter, etc.),

besides having a diagnostic function.

Some versions of servo-drive/inverter can be connected to an external HMI display (model “VISIO 3000”),

which performs diagnostic functions, parametrization, parameters readout, analogue/digital values readout,

besides sending some commands to the equipment.

The equipment operation is controlled by micro-controllers, which can be updated by uploading new firmware

versions. They communicate through field bus, they can control analogue/digital I/O and the motor.

Ver. 1.09 SMIT Cdd 10/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

The servo-drives/inverters of the COSMOS 301X series comply with N 61800-3 (2004) + A1 (2012)

standards ( MC Requirements); they can be installed in the second environment (“Second Environment”,

category C3), provided they comply with the conditions indicated in this Installation, Use and Maintenance

Manual.

No ordinary/extraordinary maintenance is allowed for COSMOS 301X servo-drives/inverters; in case of bad

operation and/or break, it is necessary to replace the equipment integrally. Any repairs must be performed

exclusively by SMIT C S.p.A.

Ver. 1.09 SMIT Cdd 11/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.2 Technical specifications

4.2.1 Environmental features

Operational temperature 0 ÷ +40°C when operating at full load

0 ÷ +55°C with current derating

Pollution degree (UL) Use in Pollution degree 2 nvironment

Maximum surrounding air temperature

(UL) 0 ÷ +40 °C

Output current derating depending on

the ambient temperature

Output current derating depending on

the distance from obstructions

Air humidity during operation 5 ÷ 85% non condensing

Storage temperature -25 ÷ +55°C

Air humidity during storage 5 ÷ 95%

Transportation temperature -25 ÷ +70°C

Air humidity during transportation 5 ÷ 95%

Maximum altitude 1000 m above sea level at rated output current

2000 m above sea level with current derating

Output current derating depending on

the altitude

Ver. 1.09 SMIT Cdd 12/74

1000 4000

2000 3000 h [m]

Iout [%]

100

90

80

70

40 55

45 50 Tamb [°C]

Iout [%]

100

90

80

70

80 60 40 c [mm]

Iout [%]

100

90

80

70

100 20

c

c

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.2.2 Ratings

Mains voltage single-phase 230 VAC ± 15% 50/60 Hz

Distribution systems allowed TT, TN (operation with IT systems is possible only by disconnecting the

integrated mains filter)

Maximum short-circuit current 5 kA at the installation point

Maximum mains input current 10 A RMS

Auxiliary mains voltage 24 VDC -15 ÷ +20%; max ripple 5% of the rated value

Maximum auxiliary current

Depending on the various models:

KZ010374, KZ010375, KZ010376: 0.2 A

KZ010377, KZ010389: 2.0 A

KZ010387, KZ010388: 0.5 A

KZ010385: 0.4 A

4.2.3 Motor output

Output voltage Three-phase 0 ÷ 230 V

Output frequency

Depending on the various models:

KZ010374, KZ010375, KZ010377, KZ010387, KZ010388, KZ010389:

0÷500 Hz

KZ010376, KZ010385: 0÷128 Hz

Switching frequency

Depending on the various models:

KZ010374, KZ010375, KZ010376: 4/8/10/12/16 kHz

KZ010377, KZ010385, KZ010387, KZ010388, KZ010389: 5/10/15 kHz

Maximum output current

4.2 A DC

4.2 A RMS with fsw = 4 kHz

Output current derating depending on the switching frequency,

according to the following diagram:

Asynchronous motor maximum size 0.75 kW (shaft rating)

Available active power 1 kW max. (1.34 HP)

Peak output current 15 A

Protections Against phase-to-phase short-circuit, overload, servo-drive overheating,

motor overheating

Ver. 1.09 SMIT Cdd 13/74

4 5 6 7 8 9 10 11 12 13 14 15 16

0

1

2

3

4

5

fPWM [kHz]

Iout [ARMS]

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.2.4 Dynamic brake output

Type Control circuit of the brake resistor with IGBT

Protections Against brake resistor short-circuit

Brake resistor resistance 30 ÷ 150 Ω

Average available power 150 W max.

4.2.5 Encoder input

Type Input for readout of incremental encoder with 5 V differential signals

Maximum input frequency 200 kHz

Power supply 5 V, max 200 mA

4.2.6 Resolver input

Type Input for resolver readout

Excitation signal frequency 5 kHz

4.2.7 Digital inputs

Type (KZ 1 375 and KZ 1 376) 24 V digital inputs, compatible with type 1 and type 3, according to

I C 61131-2

Type (other versions) 24 V digital inputs

Max. frequency of input signal 1 kHz

4.2.8 Digital outputs

Type 24 V pnp (current-sourcing) digital outputs

Maximum available current 30 mA

Protections Against short-circuit, overload and overheating

4.2.9 Static brake output

Type (KZ 1 377 and KZ 1 389) 24 V pnp (current-sourcing) digital output

Type (KZ 1 387 and KZ 1 388) 24 V npn (current-sinking) digital output

Max. available current 500 mA

4.2.1 Counter input

Type 24 V digital input

Maximum input current 4.5 mA @ Vin=24 V

Input signal frequency range 0 ÷ 100 kHz

4.2.11 ÷ 1 V input

Input voltage range 0 ÷ 10 V DC

Input resistance 147 kΩ typ.

Resolution 12 bit

Ver. 1.09 SMIT Cdd 14/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.2.12 4 ÷ 2 mA input

Input current range 4 ÷ 20 mA DC

Resolution 12 bit

4.2.13 Motor temperature sensor input

Sensor type NTC, PTC and thermal trip device

Resolution 12 bit

4.2.14 ÷ 1 V output

Output voltage range 0 ÷ 10 V DC

Resolution 10 bit

Max. available current 10 mA

4.2.15 Reference voltage output

Output voltage 10 V DC - fixed value

Max. available current 10 mA

4.2.16 Thermocouple input

Sensor type Insulated thermocouples – J type

Input voltage range -6.3 ÷ +27.5 mV

Input temperature range

The diagram shows the temperature range depending on the cold joint

temperature:

Resolution 12 bit

Cold junction compensation internal

Sensor interruption detection yes (by internal pull-up and full-scale voltage readout)

Ver. 1.09 SMIT Cdd 15/74

-147

Tcold joint [°C]

T [°C]

-62

+502

+587

80

0

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.3 Configurations / order codes

Up to date, we defined some standard configurations of servo-drives/inverters, with their order code and type

number (4 figures, indicating the series, the maximum current and the release). These data are indicated on

the driver label.

Ver. 1.09 SMIT Cdd 16/74

TYPE * ** * - * *

Series

3 = 3000

Peak current

01 = 14Apk – 0,75kW

02 = 2 x 12Apk – 0,37kW

15 = 15Apk – 2.2kW

25 = 25Apk – 5.5kW

50 = 50Apk – 7.5kW

HW Version

Se uential number, depending on the other figures

Communication

C = EtherCAT

D = Sercos II

E = Ethernet

F = FlxIO

N = None

R = RS485

S = Sercos III

T = Flextron

Type of motor controlled

A = Asyncronous

B = Brushless

U = Brushless + Asyncronous

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

Order

code Type Field

bus Motor type Encoder type I/O Static

brake

Dynamic

brake

KZ010374 3010TA Flextron

Three-phase,

asynchronous

motor

- - - -

KZ010375 3010FU FLxIO

Brushless motors

+ Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. ABUVW

2 x InD - X

KZ010376 3010FA FLxIO

Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. AB

2 x InD - -

KZ010377 3010RU RS485

Brushless motors

+ Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. ABUVW

+ resolver

17 x InD

5 x OutD

2 x InA

1 x OutA

X X

KZ010385 3012RA RS485

Three-phase,

asynchronous

motors

-

4 x InD

6 x OutD

1 x InTC

- -

KZ010387 3011RU RS485

Brushless motors

+ Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. ABUVW

+ resolver

4 x InD

1 x OutD

2 x InA

1 x OutA

X X

KZ010388 3011RA RS485

Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. AB

4 x InD

1 x OutD

2 x InA

1 x OutA

X -

KZ010389 3010RA RS485

Three-phase,

asynchronous

motors

Incremental encoder with

differential line-driver

outputs – 5V ch. AB

17 x InD

5 x OutD

2 x InA

1 x OutA

X -

Ver. 1.09 SMIT Cdd 17/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.4 Model code

The specific features of a servo-driver/inverter of the COSMOS 301X series are defined by an alpha-numeric

code printed on the device label, near the MOD L code. Here is the code table:

Ver. 1.09 SMIT Cdd 18/74

MODEL * * * * * . * * * * * . * * * * *

Reserved

Reserved

Auxiliary power

1 = 24Vdc

Main power

1 = 230Vac 1PH

Maximum output current - Asynchronous motor power

1 = 15Apk – 0,75kW

2 = 2 x 12Apk – 0,370kW

Dynamic brake

0 = Absent

1 = Present

Encoder inputs and thermocouple

0 = Absent

1 = Incremental 5V diff. AB

2 = Incremental 5V diff. AB+UVW

3 = Resolver

4 = Resolver + Incremental 5V diff. AB

5 = Resolver + Incremental 5V diff. AB+UVW

6 = TC + Incremental 5V diff. AB

7 = TC + Incremental 5V diff. AB+UVW

8 = TC

Motor brake

0 = Absent

1 = Present

Physical layer communication/fieldbus

0 = Absent

1 = EIA-RS485, 2 ports, max 2.5Mbps, automatic termination

2 = EIA-RS485, 1 porta, max 2.5Mbps, no termination

3 = EIA-RS485, 1 porta, max 250kbps, no termination

4 = EIA-RS485, 1 porta, max 2.5Mbps, termination inserted

Support VISION 3000

0 = Absent

1 = Present

Pulse counter digital input

0 = Absent

1 = Present

Common digital inputs

0÷9 = 0÷9

inputs

i

A÷G = 10÷16

inputs

Common digital outputs

0÷6 = 0÷6 outputs

Analog input

0 = Absent

1 = 0÷10V

2 = 4÷20mA

3 = 0÷10V/POT

4 = 0÷10V/POT + 4÷20mA

Analog output

0 = Absent

1 = 0÷10V

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.5 Accessories

The servo-drives/inverters of the COSMOS 301X series are supplied with a series of removable connectors

for power connection and I/O (where relevant). These connectors can be ordered separately, as well as

other accessories not included in the drive.

Here is a list of the order codes.

Item Order code

Operator interface VISIO 3000 KZ010262

Connector 24VDC for code KZ010374 KF101066

Connector 24VDC for code KZ010375/76 KF101067

Connector 24VDC and I/O (8x2) for code KZ010377/89 KF101064

Connector I/O (9x2) for code KZ010377/89 KF101065

Connector 24VDC and I/O (8x1) for code KZ010385/87/88 KF101068

Connector I/O (9x1) for code KZ010385/87/88 KF101069

Adapter cable RS485 for programming KF131284

Converter USB-RS485 KZ020087

Software WinMicro for programming KW050111

Ver. 1.09 SMIT Cdd 19/74

Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

4.6 Heat dissipation

During operation, a servo-drive/inverter dissipates a certain quantity of electric power, due to the imperfect

nature of electronic components. As a consequence, the components temperature increases, especially for

the power section components. This increase must be taken into consideration in order to correctly

determine the capacity of the electrical panel cooling system.

The amount of dissipated power depends on the supplied output current and on the switching frequency of

the PWM signals. The below diagram, valid for all releases, shows the total thermal dissipation, depending

on the rated output current; the four curves represent different switching frequencies. Please consider that:

•In case of variable output current, the average dissipated power must not be calculated from the

average current only, but also by including instantaneous power dissipation.

•Power dissipation mostly depends on the drive switching frequency.

•The dissipated power from the braking resistors must be calculated separately.

•Power dissipation scarcely depends on the power factor of the load, but mostly on the absolute value of

the output current; this is to say that the dissipated power is not strictly linked to the active power

supplied to the load.

Ver. 1.09 SMIT Cdd 20/74

This manual suits for next models

16

Table of contents

Other Smitec Servo Drive manuals

Popular Servo Drive manuals by other brands

Allen-Bradley

Allen-Bradley MP-Series installation instructions

SYNAPTICON

SYNAPTICON SOMANET Node 400 Documentation

YASKAWA

YASKAWA SGD7W Series Selection Manual

SSD Drives

SSD Drives 637 product manual

YASKAWA

YASKAWA Sigma-7-S Series product manual

AXOR Industries

AXOR Industries MiniMagnum Series Service manual

Mitsubishi Electric

Mitsubishi Electric MR-J4W2-0303B6 instruction manual

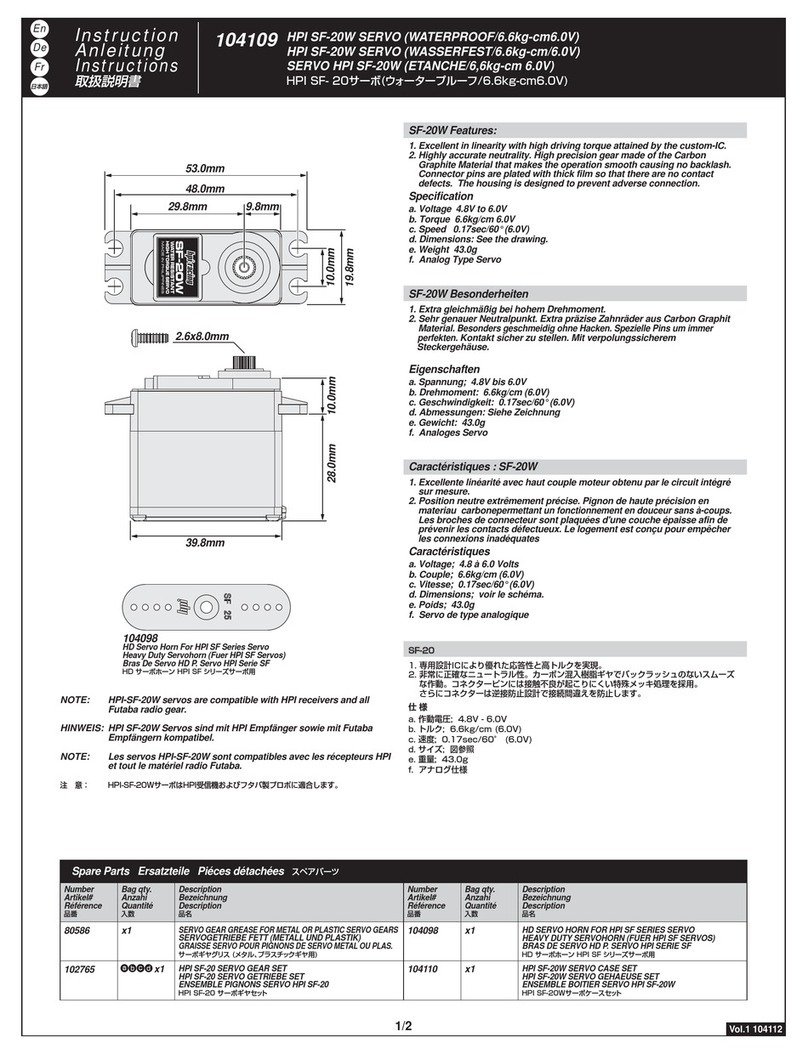

HPI Racing

HPI Racing SF-20W instruction manual

Moons'

Moons' Applied Motion Products SSDC-ECX-H Hardware manual

Mitsubishi Electric

Mitsubishi Electric Melservo-J3 Series MR-J3-B manual

Omron

Omron 1S Series instruction manual

Panasonic

Panasonic MINAS A6N Series manual