6

3

2

1

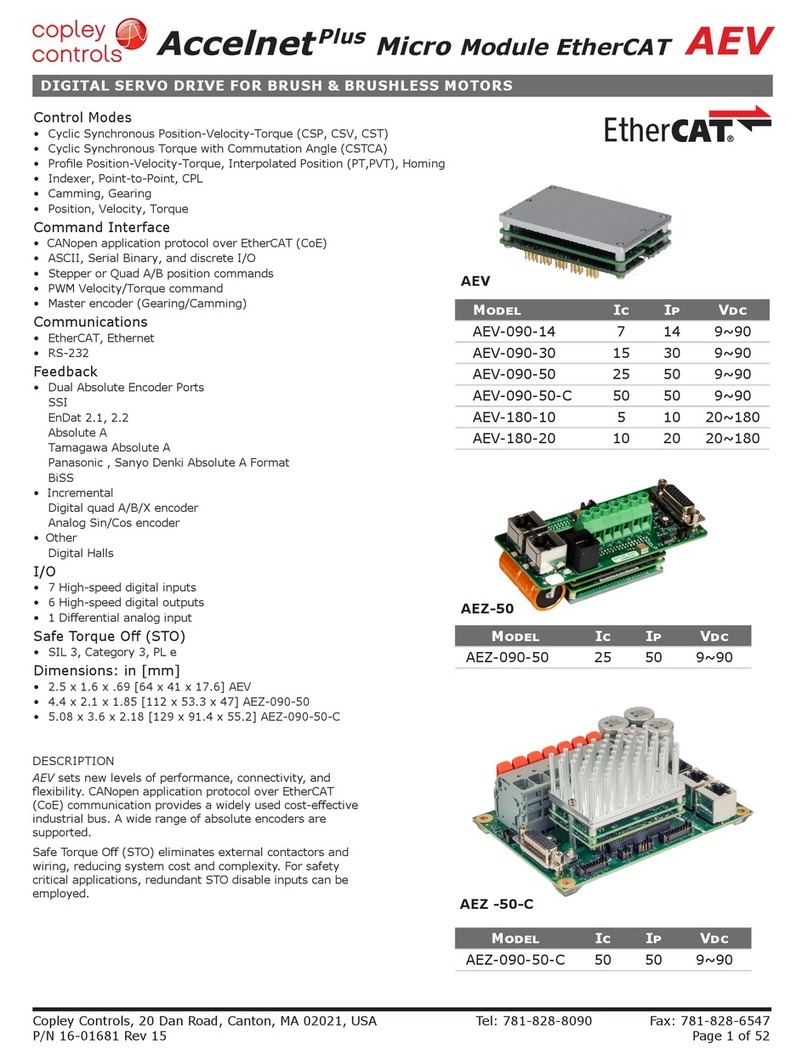

Set x10 x1 Set x10 x1

Dec Dec

0 0 0 8 128 8

1 16 1 9 144 9

2 32 2 A 160 10

3 48 3 B 176 11

4 64 4 C 192 12

5 80 5 D 208 13

6 96 6 E 224 14

7 112 7 F 240 15

RoHS

1 8 1 8

RunErr

OUT

AMP

X1X10

S2S1

DEV ID

J1

SIGNAL

SAFETY

BRAKE

I/O

NETWORK

RUNERR L/A L/A

AccelnetPlus

Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547

Web: www.copleycontrols.com Page 5 of 33

BE2

AccelnetPlus 2-Axis Panel EtherCAT

therCAT PORTS

8 position, 4 signals

EtherCAT is the open, real-time Ethernet network developed by

EtherCAT enables high-speed control of multiple axes while

Data protocol is CANopen application protocol

based on DSP-402 for motion control devices.

More information on EtherCAT can be found on this web-site:

port connects to a master, or to the OUT port of a device that is

‘upstream’, between the Accelnet and the master.

The OUT port connects to ‘downstream’ nodes.

EtherCAT D

based on their position on the network. But when the device must have a positive

is provided by two 16-position rotary switches with hexadecimal encoding. These

shows the decimal values of the hex settings of each switch.

set x10 to the hex value in the same row:

Decimal values

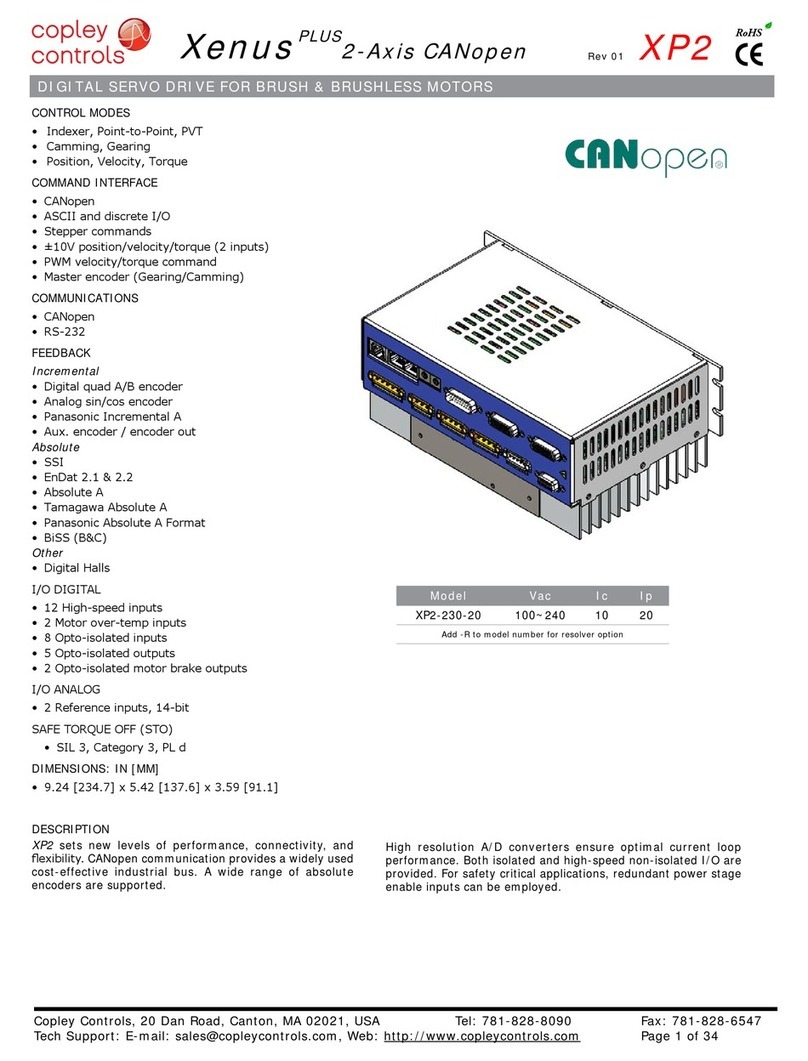

AMP LEDS &

ETHERCAT COMMUNICATIONS

INDICATORS: DRIVE STATE

Two bi-color LEDs give the state of the BE2 drive. Colors do not alternate, and can be solid ON or

blinking. When multiple conditions occur, only the top-most condition will be displayed.

When that condition is cleared the next one below will shown.

the condition causing the fault is removed.

Drive will only move in direction not inhibited by limit switch.

reference inputs or EtherCAT commands.

Latching Faults

RUN

Blinking = Pre-operational

On = Operational

ERR Red: Shows errors such as watchdog timeouts and unsolicited state changes in the BEL due to local errors.

Off = EtherCAT communications are working correctly

Single Flash = Local error, slave has changed EtherCAT state autonomously

Double Flash = PDO or EtherCAT watchdog timeout,or an application watchdog timeout has occurred

A green LED indicates the state of the EtherCAT network:

LED Link Activity Condition