Handbook for Use and Maitenance

TABLE OF CONTENTS

IDENTIFICATION DATA .............................................................................................. 2

LIMITS IN USE............................................................................................................ 2

(CHAPTER 1) - TECHNICAL FEATURES ........................................................................ 4

1.1 - GENERAL ...................................................................................................... 4

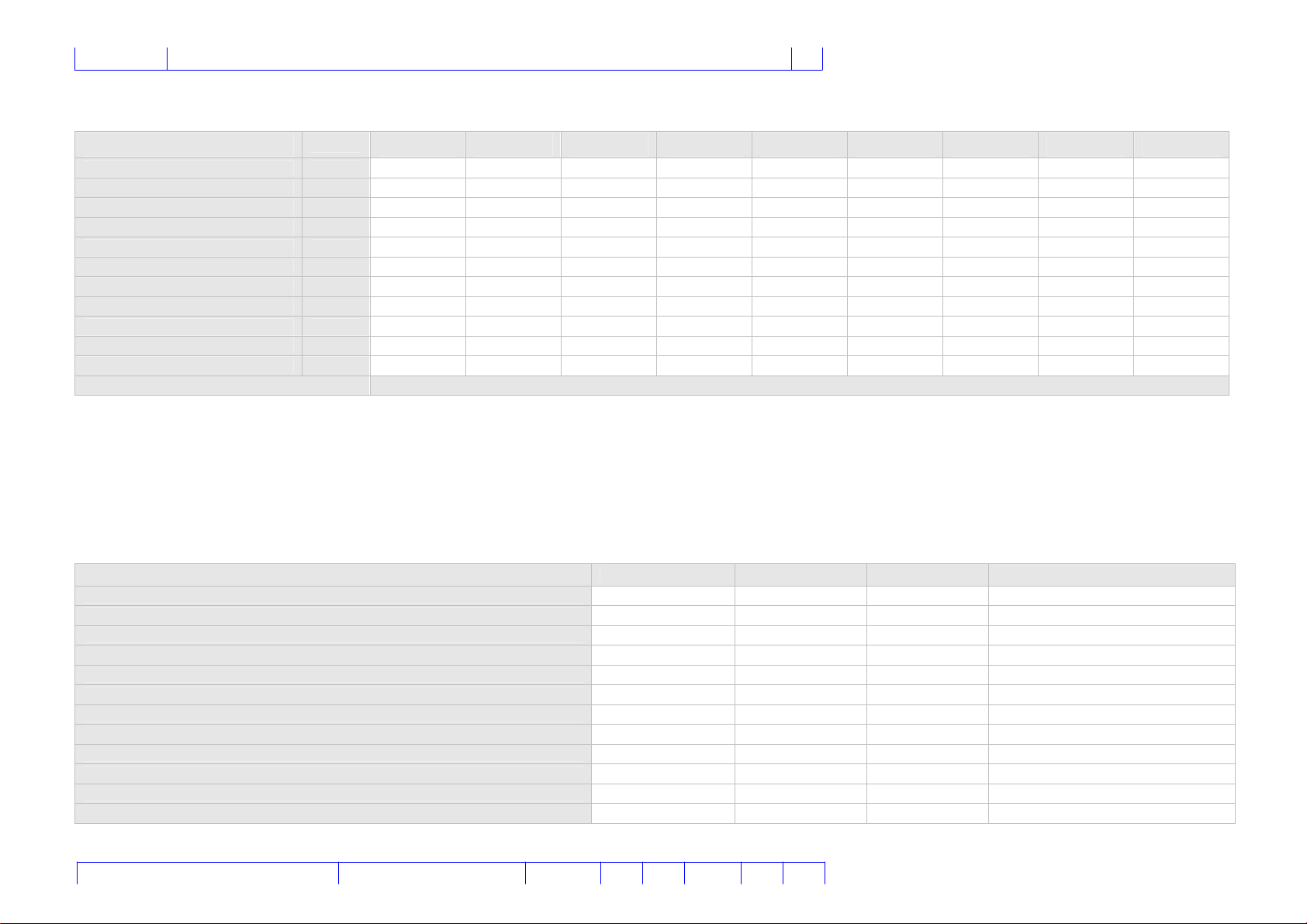

1.2.1 Table 1 : TECHNICAL INFORMATION ................................................................ 5

1.2.2 Table 2 : THEORETICAL TIME AND PEED FOR VARIOU MOVEMENT ............... 5

1.3 - NOTION FOR THE FIR T IN TALLATION ......................................................... 9

1.3.1 - ELECTRIC UPPLY OF THE MACHINE ................................................................ 9

1.3.2 - HYDRAULIC UPPLY OF THE MACHINE ........................................................... 10

1.3.3 - PRE URE-READING OUTLET ON 50000 WB ................................................. 11

1.3.4 - ETTING OF THE VARIABLE DI PLACEMENT PUMP .......................................... 11

1.3.5 - READING OF THE WORKING PRE URE ....................................................... 11

(CHAPTER 2) - INSTRUCTIONS FOR USE .................................................................. 14

2.1 - AFETY RULE .............................................................................................14

2.2 - TART-UP ....................................................................................................17

2.3 - TABILIZATION ............................................................................................18

2.4 - RETRACTING AND HOMING THE TABILIZER .................................................21

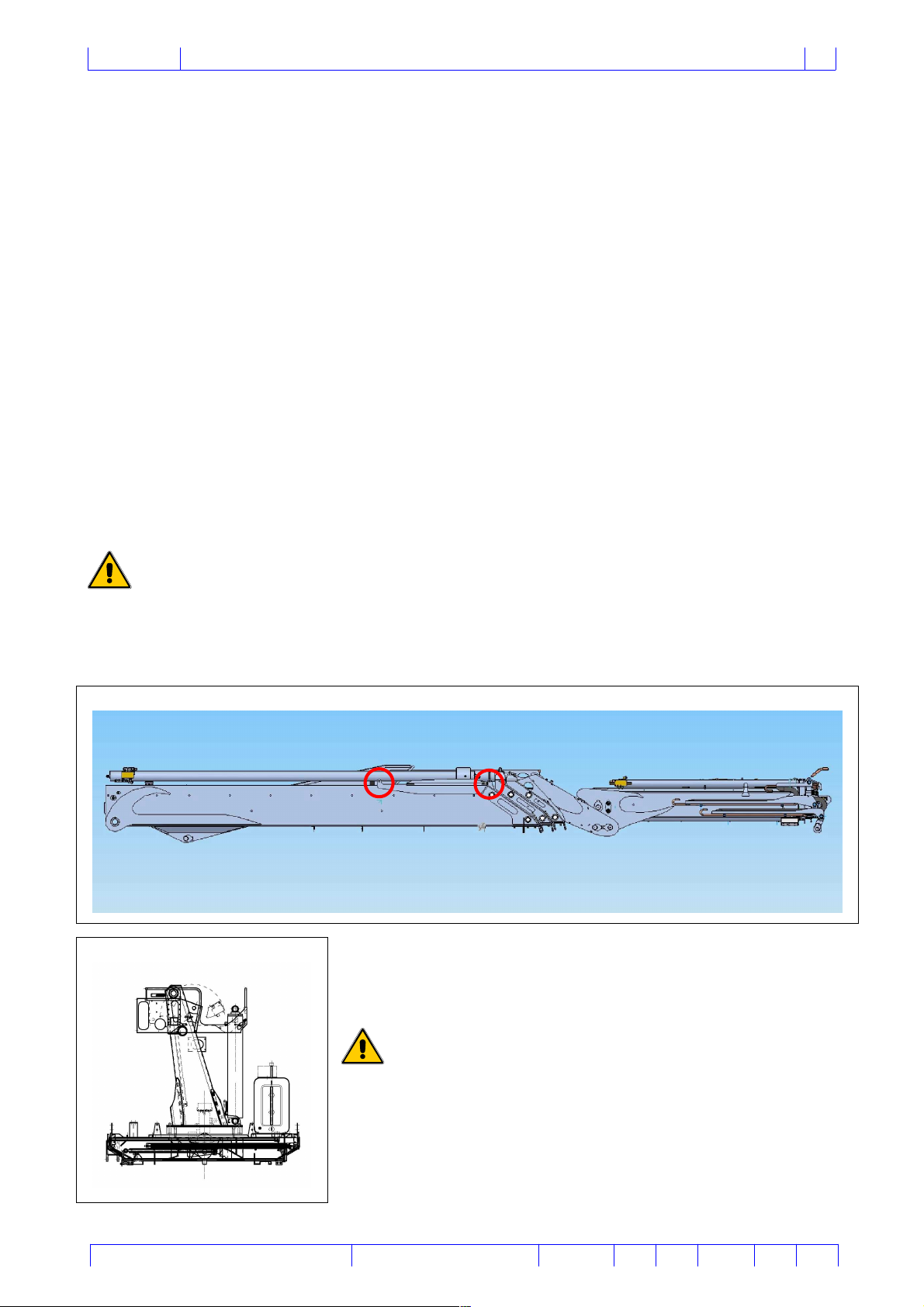

2.5 - EXTENDING THE BOOM .................................................................................22

2.6 - FOLDING OF THE BOOM ................................................................................25

2.7 - MANOEUVRING.............................................................................................25

2.8 - LOAD CAPACITIE ........................................................................................29

2.8.1 – TIME RE ET FUNCTION ............................................................................... 31

(CHAPTER 3) - ROUTINE MAINTENANCE.................................................................. 37

3.1 - AFTER THE FIR T 20 HOUR OF OPERATION....................................................37

3.2 - AFTER THE FIR T 300 HOUR OF OPERATION..................................................37

3.3 - PERIODIC MAINTENANCE ..............................................................................37

3.3.1 - EVERY 20 HOUR OF OPERATION.................................................................. 37

3.3.2 - EVERY 100 HOUR OF OPERATION ................................................................ 39

3.3.3 - EVERY 200 HOUR OF OPERATION ................................................................ 39

3.3.4 - EVERY 600 HOUR OF OPERATION OR AT LEA T ONCE A YEAR ........................ 39

3.3.5 - EVERY 1000 HOUR OF OPERATION .............................................................. 40

3.3.6 - EVERY 2000 HOUR OF OPERATION .............................................................. 40

3.4 - WHENEVER NECE ARY ................................................................................40

3.5 - MAINTENANCE TO BE CARRIED OUT AFTER A LONG PERIOD OF INACTIVIT .........41

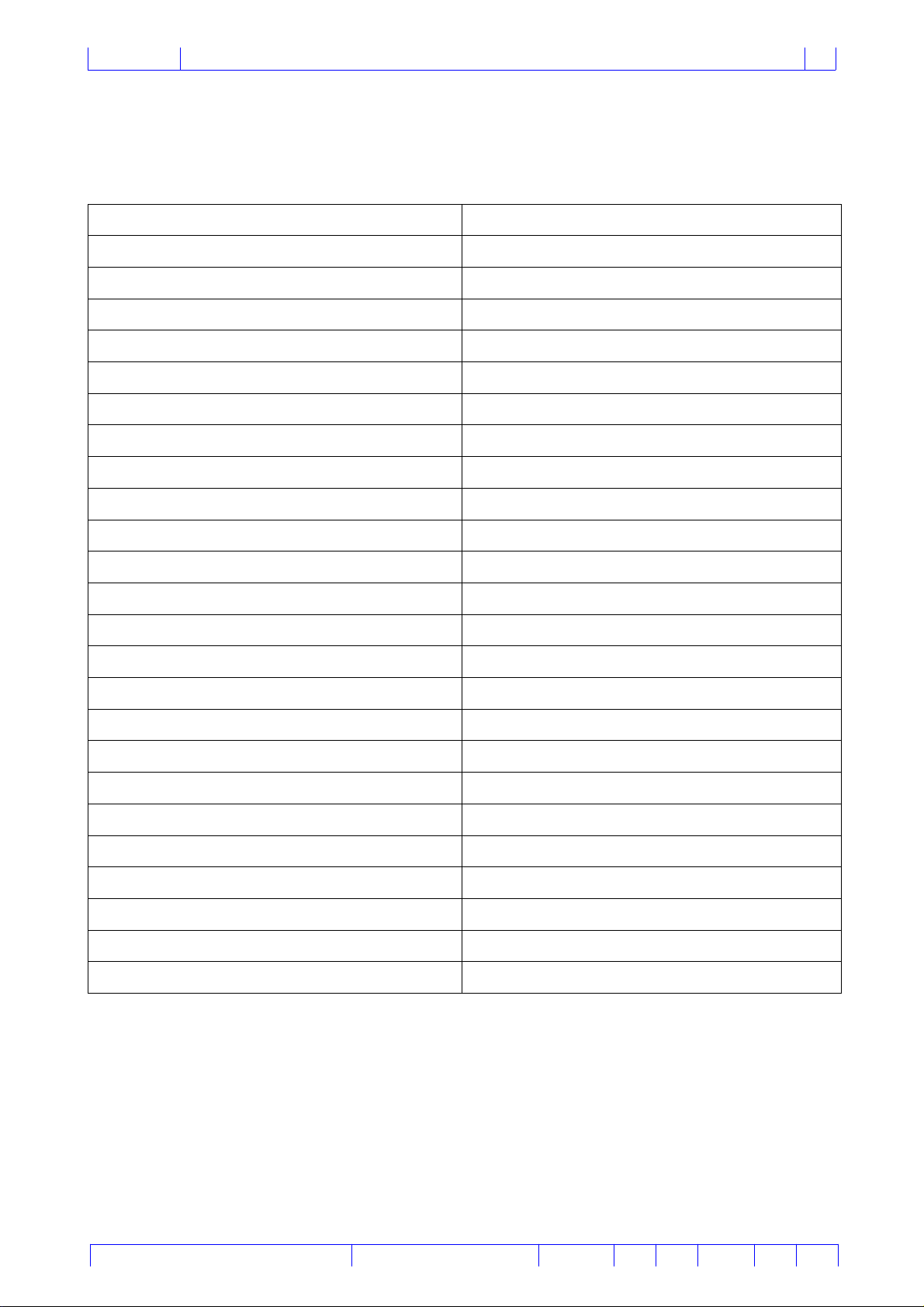

3.6 - CHEDULE OF IN PECTION AND PROGRAMMED MAINTENANCE TO BE CARRIED

OUT IN AUTHORIZED WORK HOP . .......................................................................42

3.7 - CHEDULE FOR WIRE ROPE AND CHAIN IN PECTION ..................................44

3.8 - NOTE FOR EXCEPTIONAL PART EXCHANGE ................................................45

(CHAPTER 4) - EXTRAORDINARY MAINTENANCE...................................................... 46

4.1 - THE CRANE DOE NOT WORK ........................................................................46

4.2 - THE CRANE MOVE BUT IT I NOT POWERED ..................................................46

4.3 - THE CRANE MOVE BY JERK AND VIBRATE ..................................................47

4.4 - THE MOVEMENT ARE PONGY ......................................................................47

4.5 - THE EXTEN ION CYLINDER VIBRATE WHEN MOVING OUTWARD OR INWARD

AND ARE OUT OF EQUENCE .................................................................................47

4.6 - THE EXTEN ION CYLINDER EXTEND UNCONTROLLEDLY ..................................47

APPENDIX A” ADDITIONAL RISKS .......................................................................... 48

SPECIAL NOTES - SPECIAL VERSION ........................................................................ 49