Page 2

Table of Contents

1 Safety

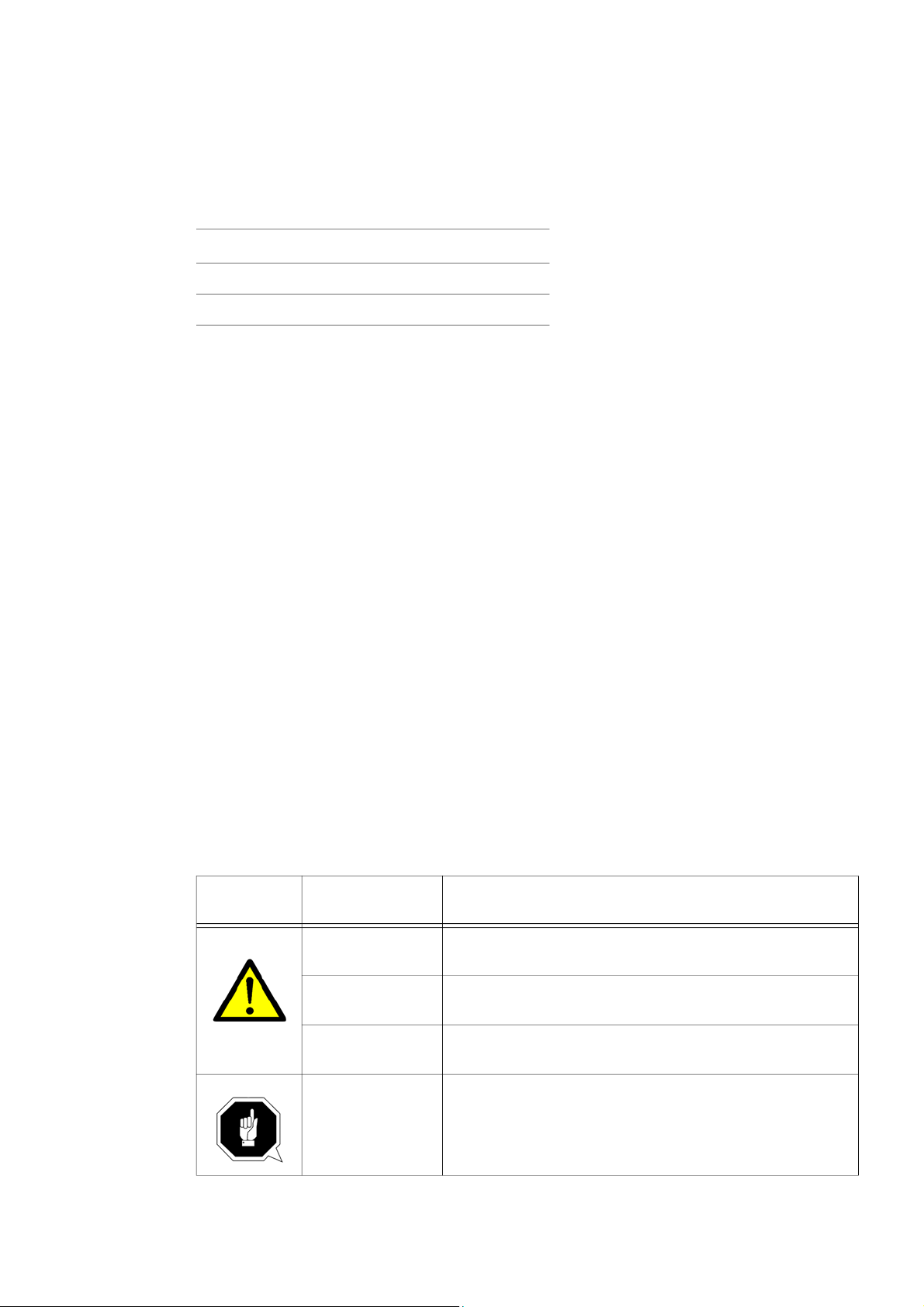

1.1 Safety warnings (warning notes)..............................................................................4

1.1.1 Classification of hazards ................................................................................4

1.1.2 Other pictograms............................................................................................5

1.2 Proper user...............................................................................................................6

1.3 Possible dangers caused by the circular metal saw.................................................6

1.4 Qualification of personnel.........................................................................................7

1.4.1 Target group...................................................................................................7

1.4.2 Authorised personnel .....................................................................................7

1.5 User positions...........................................................................................................8

1.6 Safety devices..........................................................................................................8

1.6.1 Prohibition, warning and mandatory labels ..................................................10

1.7 Individual protection gear .......................................................................................10

1.8 Safety during operation ..........................................................................................11

1.9 Safety during maintenance.....................................................................................12

1.9.1 Disconnecting the circular metal saw and making it safe.............................12

1.9.2 Using lifting equipment.................................................................................12

1.9.3 Mechanical maintenance work.....................................................................12

1.10 Accident report .......................................................................................................12

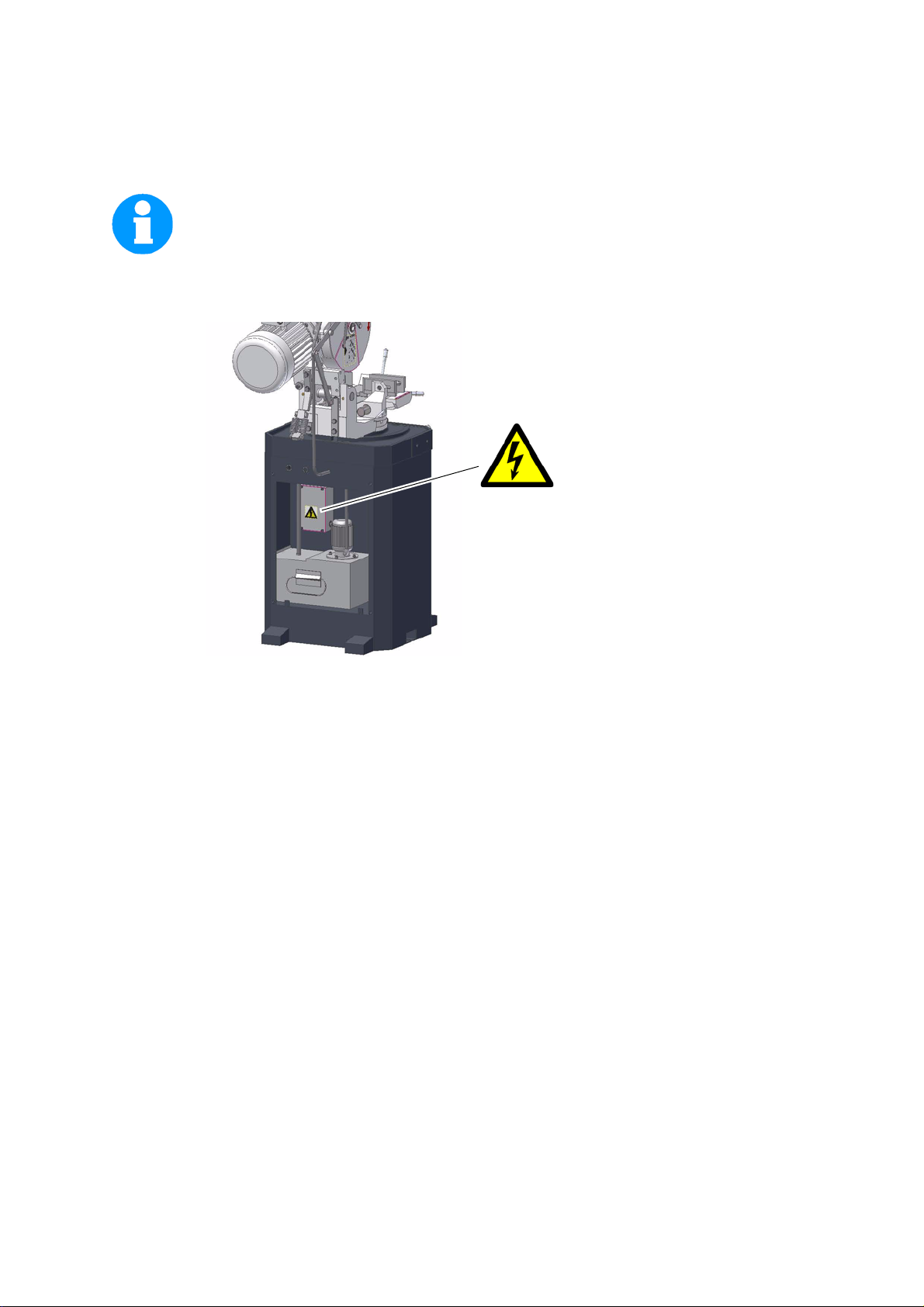

1.11 Electrical system.....................................................................................................13

2 Technical data

2.1 Type plate...............................................................................................................14

2.2 Power connection...................................................................................................14

2.3 Cutting range..........................................................................................................14

2.4 General...................................................................................................................14

2.5 Dimensions.............................................................................................................14

2.6 Speed of saw blade................................................................................................15

2.7 Environmental conditions .......................................................................................15

2.8 Operating material..................................................................................................15

2.9 Emissions...............................................................................................................15

3 Assembly

3.1 Extent of supply......................................................................................................16

3.2 Storage...................................................................................................................16

3.3 Installation and assembly.......................................................................................16

3.3.1 Requirements of the installation site ............................................................16

3.3.2 Fasten the substructure of the circular metal saw on the floor.....................17

3.3.3 Mount the saw on the machine substructure................................................18

3.3.4 Mount the lever arm .....................................................................................18

3.3.5 Mount the saw blade....................................................................................18

3.4 First use..................................................................................................................19

3.4.1 Checking ......................................................................................................19

3.4.2 Direction of the saw teeth.............................................................................19

3.4.3 Check the oil level in the worm gear ............................................................19

3.4.4 Fill in coolant ................................................................................................20

3.4.5 Power supply................................................................................................20

3.4.6 Check the running direction of the saw blade ..............................................20

4 Operation

4.1 Safety .....................................................................................................................21