SGH Series

380V/400V/415V

REVISION # 0003

DATE: 08/27/2021

1

CONTENTS

IMPORTANT INSTALLATION INSTRUCTIONS ................................................................................. 2

SPECIFICATIONS ............................................................................................................................... 3

TYPES AND SIZES OF DOORS ......................................................................................................... 4

INSTALLATION INSTRUCTIONS ....................................................................................................... 4

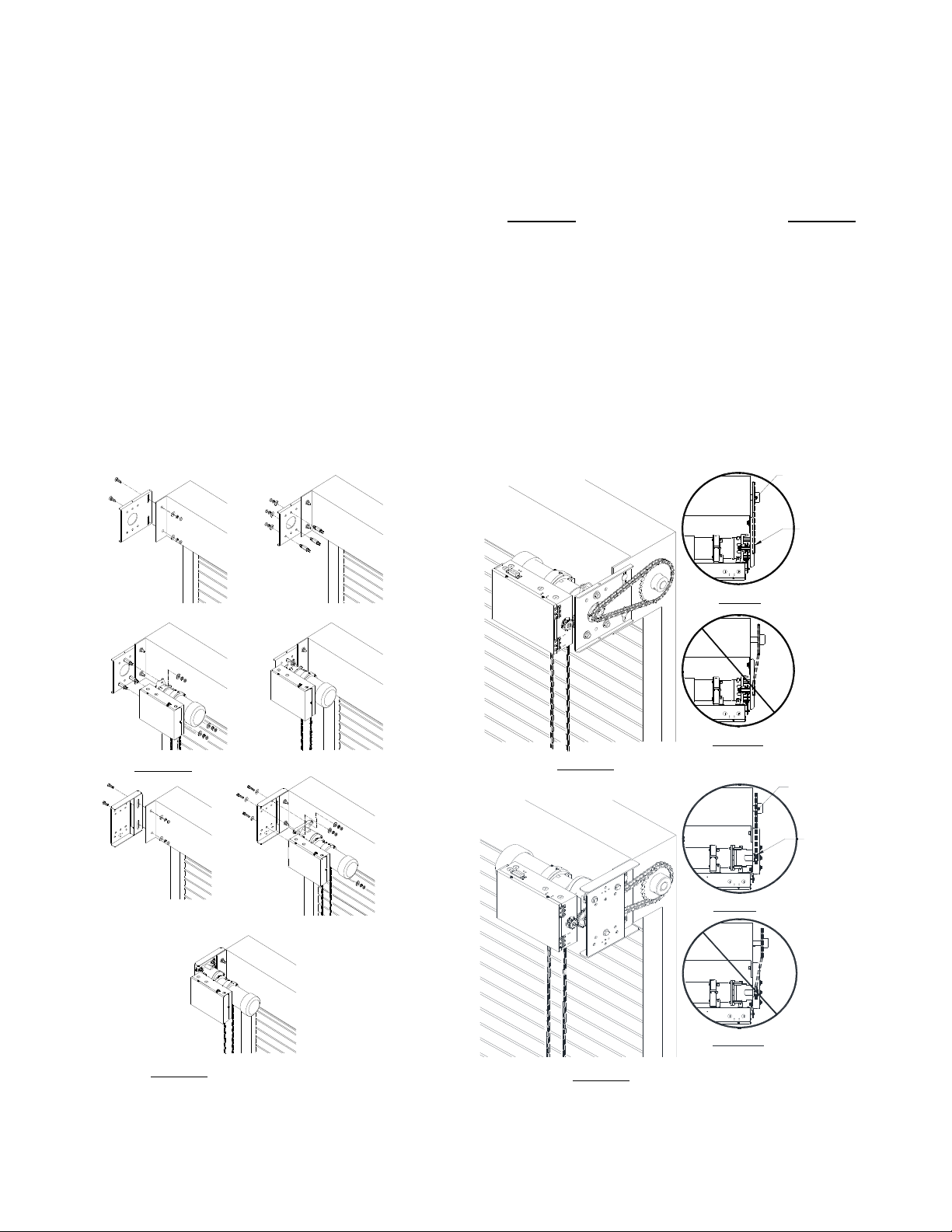

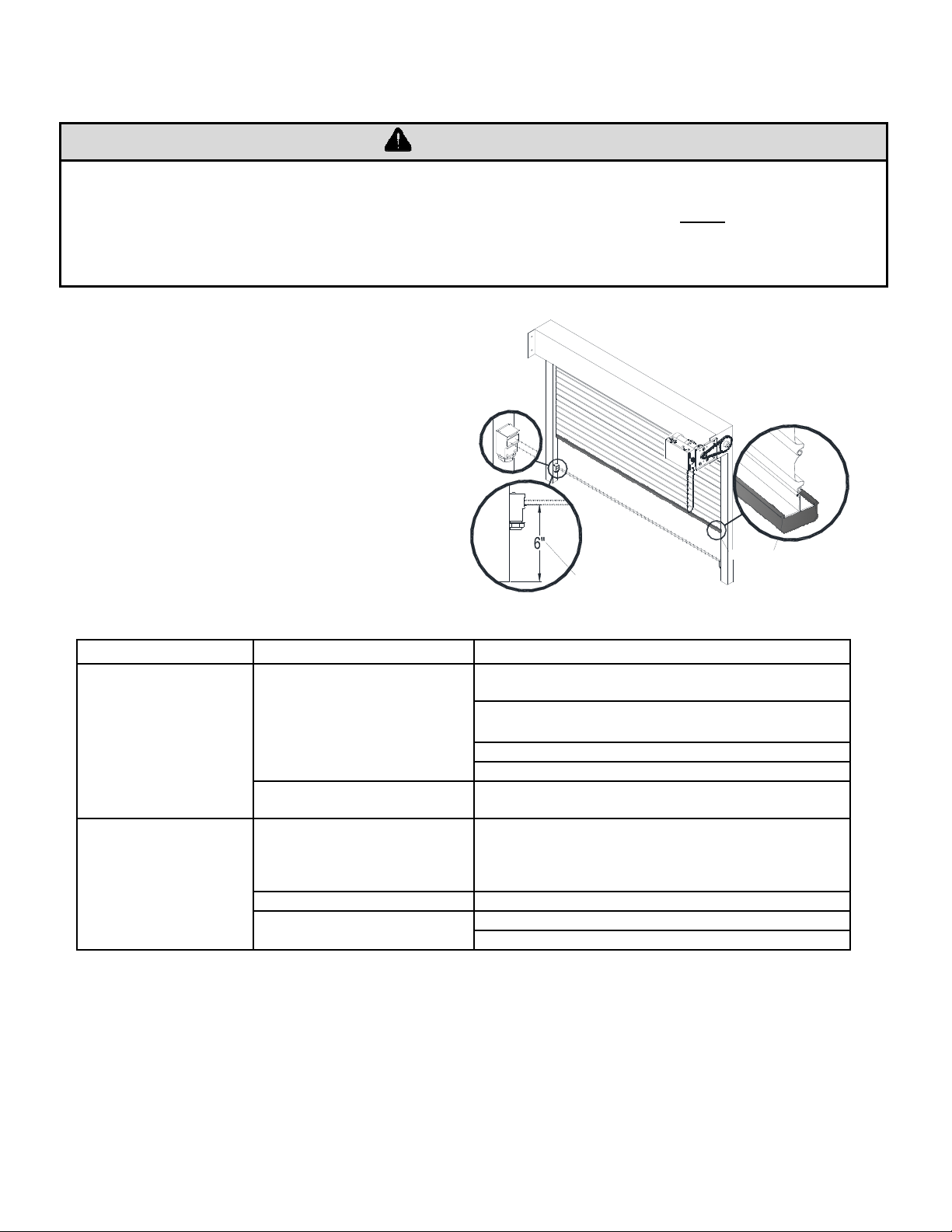

OPERATOR MOUNTING POSITIONS (for 1/2hp and 3/4hp) ....................................................... 4

OPERATOR MOUNTING POSITIONS (for 1hp, 1½hp and 2hp) .................................................. 4

OPERATOR MOUNTING ............................................................................................................. 5

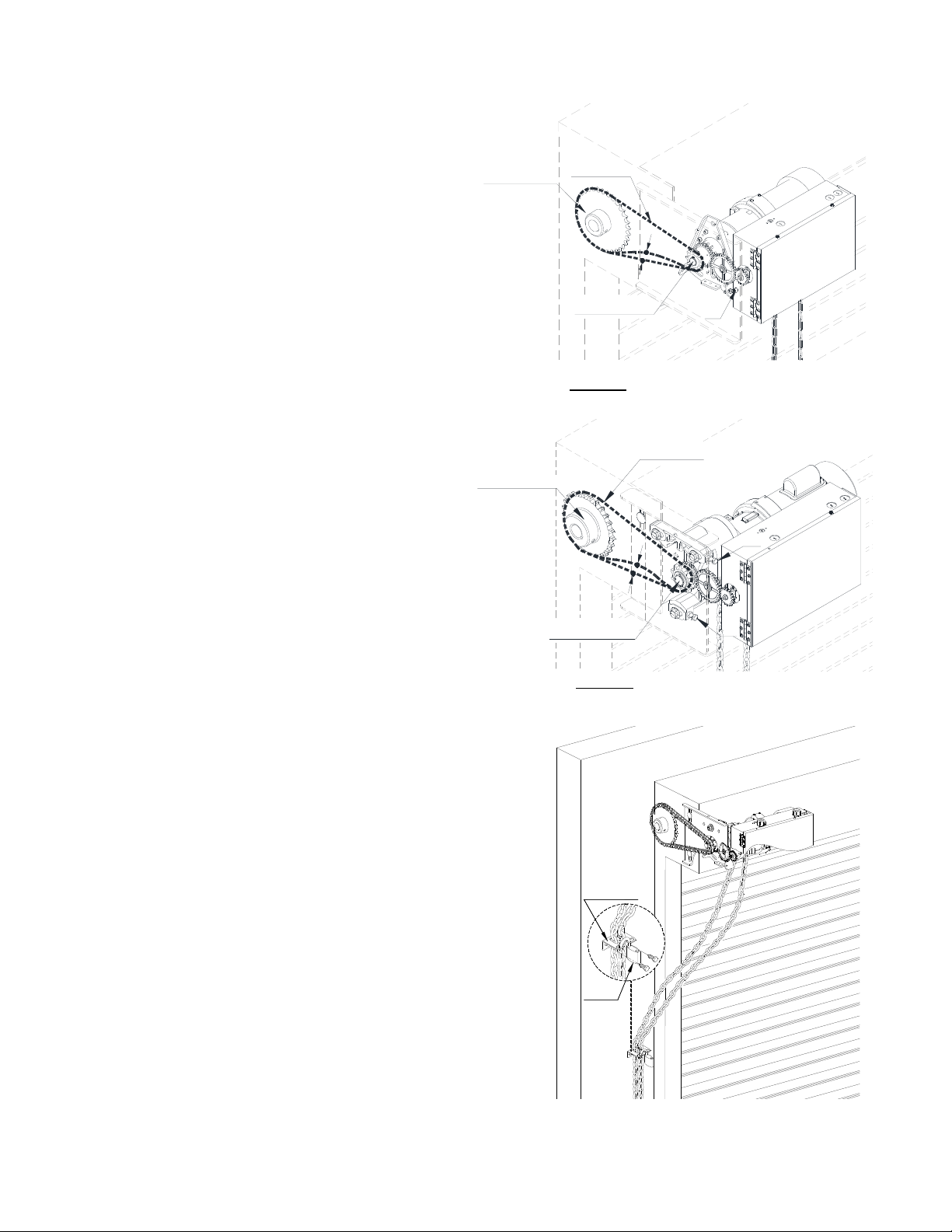

DRIVE CHAIN ADJUSTMENT ...................................................................................................... 6

HAND CHAIN ADJUSTMENT ....................................................................................................... 6

WIRING INSTRUCTIONS .................................................................................................................... 7

CONTROL WIRING ...................................................................................................................... 8

ENTRAPMENT DEVICES WIRING .............................................................................................. 9

INPUT POWER CONNECTIONS ...................................................................................................... 10

LIMIT SWITCH ADJUSTMENT ......................................................................................................... 11

CONTROL SETTINGS ...................................................................................................................... 12

CONTROL FUNCTION ............................................................................................................... 12

AUXILIARY FUNCTION .............................................................................................................. 13

TIMER INSTRUCTION ............................................................................................................... 14

LCD DISPLAY INSTRUCTION ................................................................................................... 16

LIGHT INDICATION .......................................................................................................................... 17

WIRING DIAGRAMS ......................................................................................................................... 18

TERMINAL CONNECTIONS ...................................................................................................... 22

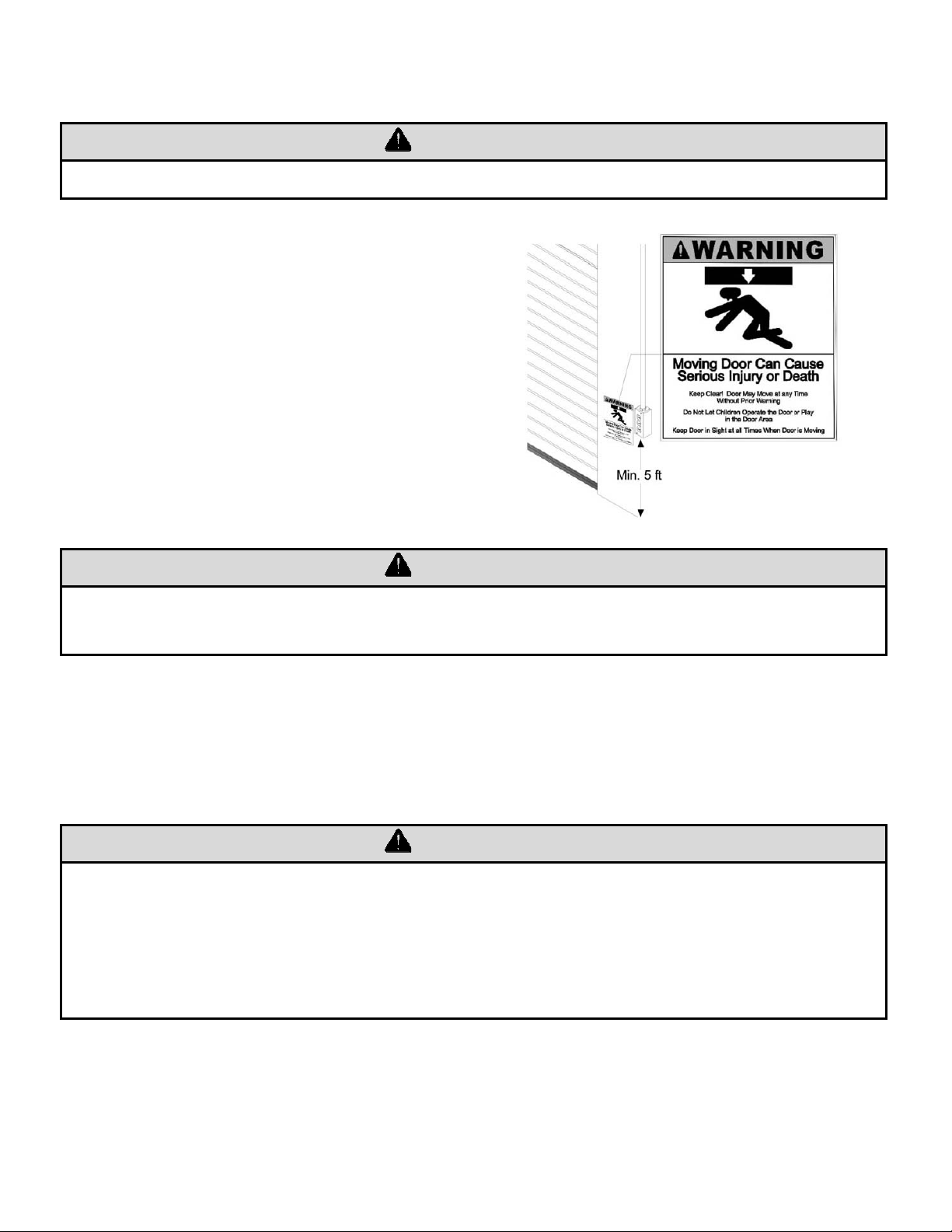

IMPORTANT SAFETY INSTRUCTIONS ........................................................................................... 23

TESTING ........................................................................................................................................... 24

PUSH BUTTON STATION TESTING ......................................................................................... 24

EMERGENCY MANUAL OPERATION ....................................................................................... 24

MAINTENANCE INSTRUCTIONS ..................................................................................................... 25

APPENDIX 1: Multiple Sensing Devices Connection Instruction ................................................. 26

APPENDIX 2: Control Connections Diagrams ............................................................................... 27

APPENDIX 3: Control Connections Diagrams ............................................................................... 28