4

Before operating the machine, check that switches are in good operating

condition. Attention: the motor has no cut-off function. Do not use it for

overloads. If the machine is unable to lift an item, do not attempt to force it.

Switch the motor off to allow it to cool, reduce the load, and lift again.

Position-Limit Safety Device:

The position-limit safety device is designed to prevent capacity limits being

exceeded when lifting or lowering a load.

Do not use it as a travel switch and never dismantle. The hoist brake system

The hoist brake system is factory-adjusted to work within the rated load

conditions. After long use, the rubber in the brake system will become worn

and the brake will no longer work as it should. If you feel that your hoist can

no longer lift the load for which it is intended, please contact your dealer to

replace the friction plate.

The electric hoist features up and down limit-position safety devices. When

a load is hoisted to the limit-position level, the machine will stop lifting.

Conversely, if the downward movement is too fast, the safety switch will be

triggered and the machine will stop working. The down safety switch is installed

on the side of machine. There must be at least 2 turns of wire rope on the spool

when the down safety switch triggers. Otherwise, it is out of adjustment and

you should have it reset at your local dealer.

Please ensure that you check all easily-wearing parts as mentioned above every

6 months to ensure the safety of the operator and the machine.

EXTENSION LENGTH CABLE SECTION

Up to 20 m 1.5 mm

From 20 to 50 m 2.5 mm

3. MAINTENANCE

Periodically CHECK that the motor cut-off switch and push button switch are

in good working condition. Please check extent of wear and tear on the hoist

and perform regular maintenance. Check normally once a year.

Ensure that all moving parts are adequately greased or oiled: e.g. the hook,

drum shaft, gearbox and shaft etc. Do not grease the cable!

Note: Abrasion of the hook: Check abrasion of the hook at each maintenance; if the

wear/abrasion exceeds 10% of the original size, replace the hook with a new one.

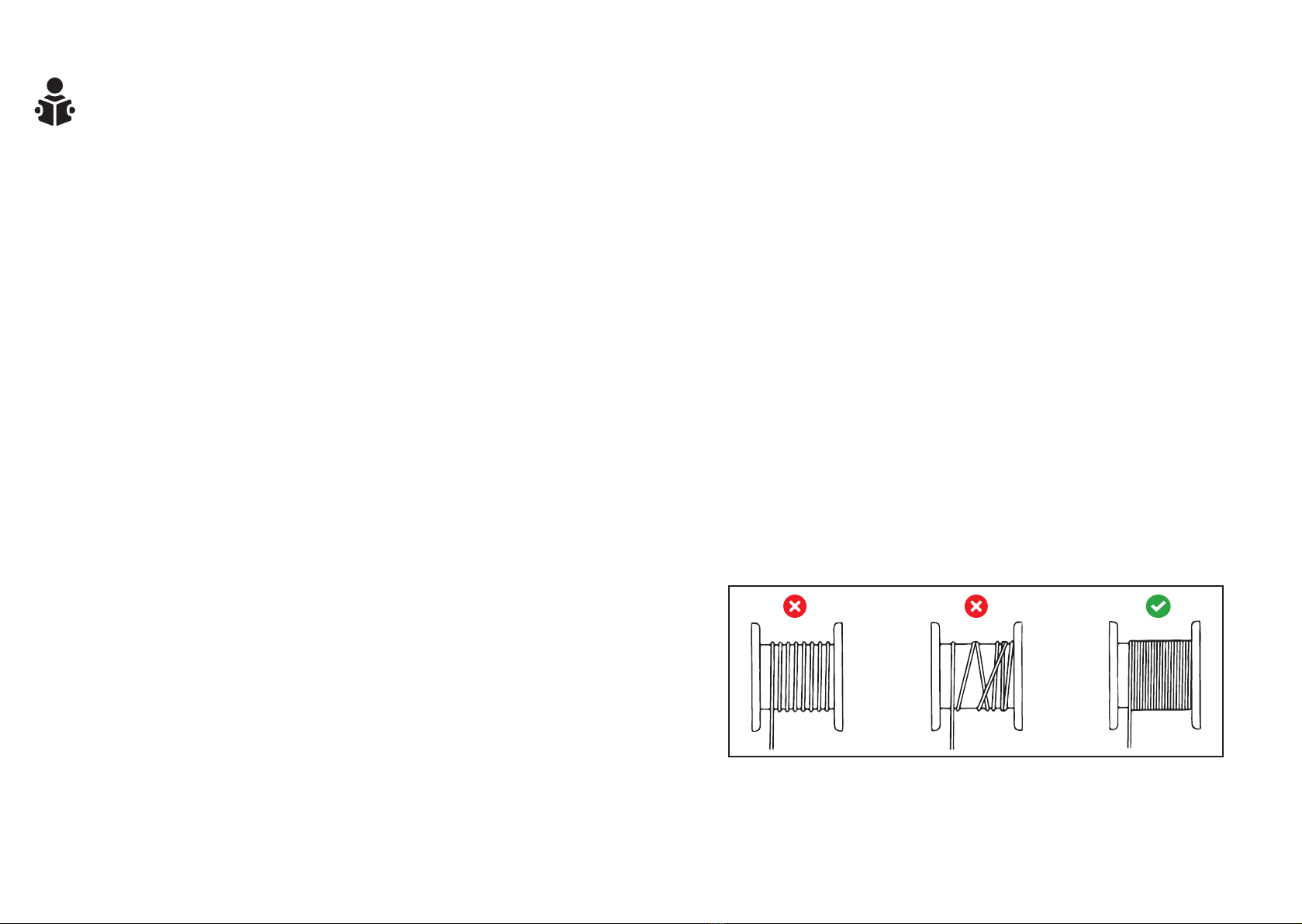

• Periodically CHECK that the steel cable is in

good condition.

• CHECK that the screws securing the brackets

and reduction gear are rmly tightened.

• CHECK THE CONDITION AND TIGHTNESS OF THE

NUTS securin the steel cable clamps.

1

1-2 replace

2

2. INSTALLATION

The hoist “standard version” is tted with a specially-designed bracket system

that enables it to be bolted to a round, square or rectangular shaped support.

4. TECHNICAL DATA

Model LH-PA-200G LH-PA-500G LH-PA-300G LH-PA-400G

Standard

version

Version

with

double

load cap

Standard

version

Version

with

double

load cap

Standard

version

Version

with

double

load cap

Standard

version

Version

with

double

load cap

Load capacity 100 kg 200 kg 125 kg 250 kg 150 kg 300 kg 200 kg 400 kg

Lifting height 12 m 6 m 12 m 6 m 12 m 6 m 12 m 6 m

Lifting speed 10m/

min

5m/

min

10m/

min

5m/

min

10m/

min

5m/

min

10m/

min

5m/

min

Cable length 12.5 m 12.5 m 12.5 m 12.5 m

Cable

diameter 3 mm 3 mm 3 mm 4 mm

Cable break

resistance 800 kg 800 kg 800 kg 1200 kg

Service S3-20%10min S3-20%10min S3-20%10min S3-20%10min

Main voltage 230V~50Hz 230V~50Hz 230V~50Hz 230V~50Hz

Motor

performance P1=450w P1=500w P1=550w P1=750w

First ensure that outlet specications (volt-hertz) correspond to those indicated

on the machine plate, and then insert the plug. If a cable extension is required,

it is of utmost importance to comply with the specications given in the tables.