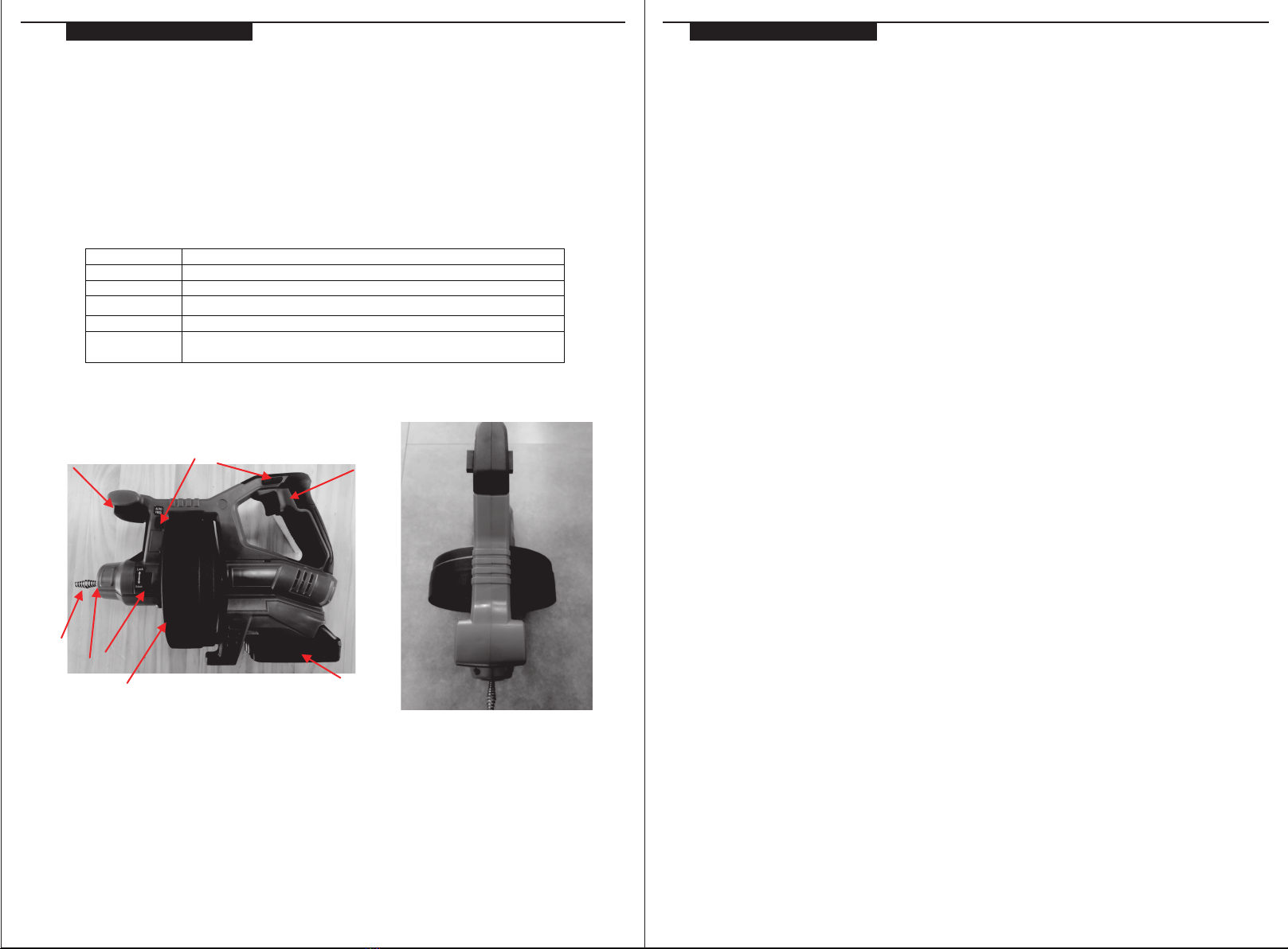

PRODUCT ASSEMBLY PRODUCT ASSEMBLY

c) Eviter tout démarrage intempestif. S’assurer que l’interrupteur est en position arrêt avant

de brancher l’outil au secteur et/ou au bloc de batteries, de le ramasser ou de le porter.

Porter les outils en ayant le doigt sur l’interrupteur ou brancher des outils dont l’interrupteur

est en position marche est source d’accidents.

d) Retirer toute clé de réglage avant de mettre l’outil en marche. Une clé laissée fixée sur

une partie tournante de l’outil peut donner lieu à des blessures de personnes.

e) Ne pas se précipiter. Garder une position et un équilibre adaptés à tout moment. Cela

permet un meilleur contrôle de l’outil dans des situations inattendues.

f) S’habiller de manière adaptée. Ne pas porter de vêtements amples ou de bijoux. Garder

les cheveux, les vêtements et les gants à distance des parties en mouvement. Des

vêtements amples, des bijoux ou les cheveux longs peuvent être pris dans des parties en

mouvement.

g) Si des dispositifs sont fournis pour le raccordement d’équipements pour l’extraction et la

récupération des poussières, s’assurer qu’ils sont connectés et correctement utilisés. Utiliser

des collecteurs de poussière peut réduire les risques dus aux poussières.

h) Ne laissez pas la familiarité acquise par l'utilisation fréquente d'outils vous permettre de

devenir complaisant et d'ignorer les principes de sécurité des outils. Une action imprudente

peut causer des blessures graves en une fraction de seconde.

4)Utilisation et entretien de l’outil

a) Ne pas forcer l’outil. Utiliser l’outil adapté à votre application. L’outil adapté réalisera

mieux le travail et de manière plus sûre au régime pour lequel il a été construit.

b) Ne pas utiliser l’outil si l’interrupteur ne permet pas de passer de l’état de marche à arrêt

et vice versa. Tout outil qui ne peut pas être commandé par l’interrupteur est dangereux et il

faut le réparer.

c) Débrancher la fiche de la source d’alimentation en courant et/ou le bloc de batteries de

l’outil avant tout réglage, changement d’accessoires ou avant de ranger l’outil. De telles

mesures de sécurité préventives réduisent le risque de démarrage accidentel de l’outil.

d) Conserver les outils à l’arrêt hors de la portée des enfants et ne pas permettre à des

personnes ne connaissant pas l’outil ou les présentes instructions de le faire fonctionner. Les

outils sont dangereux entre les mains d’utilisateurs novices.

e) Observer la maintenance de l’outil. Vérifier qu’il n’y a pas de mauvais alignement ou de

blocage des parties mobiles, des pièces cassées ou toute autre condition pouvant affecter le

fonctionnement de l’outil. En cas de dommages, faire réparer l’outil avant de l’utiliser. De

nombreux accidents sont dus à des outils mal entretenus.

f) Garder affûtés et propres les outils permettant de couper. Des outils destinés à couper

correctement entretenus avec des pièces coupantes tranchantes sont moins susc res et

exemptes d'huile et de graisse. Les poignées glissantes et les surfaces de préhension ne

permettent pas une manipulation et un contrôle sûr de l'outil dans des situations inattendues.

5) Utilisation et entretien des outils de la batterie

a) Recharge uniquement avec le chargeur spécifié par le fabricant. Un chargeur adapté à un

type de batterie peut créer un risque d'incendie lorsqu'il est utilisé avec une autre batterie.

b) Utilisez uniquement des outils électriques avec des batteries spécifiquement désignées.

L'utilisation de toute autre batterie peut entraîner un risque de blessure et de feu.

c) Lorsque le bloc-piles n'est pas utilisé, gardez-le à l'écart des autres objets métalliques, tels

que des trombones, des pièces de monnaie, des clés, des ongles, des vis ou d'autres petits

objets métalliques, qui peuvent établir une connexion d'un terminal à l'autre. Le fait de

raccourcir les bornes de la batterie peut provoquer des brûlures ou un incendie.

d) Dans des conditions abusives, le liquide peut être éjecté de la batterie; Éviter tout contact.

En cas de contact accidentel, rincer à l'eau. Si le liquide entre en contact avec les yeux,

recherchez en outre de l'aide médicale. Le liquide éjecté de la batterie peut provoquer une

irritation ou des brûlures.

e) Ne pas utiliser un bloc de batteries ou un outil fonctionnant sur batteries qui a été

endommagé ou modifié. Les batteries endommagées ou modifiées peuvent avoir un

comportement imprévisible provoquant un feu, une explosion ou un risque de blessure.

f) Ne pas exposer un bloc de batteries ou un outil fonctionnant sur batteries au feu ou à

une température excessive. Une exposition au feu ou à une temperature supérieure à 130 °

C peut provoquer une explosion.

NOTE La température "130 °C"peut être remplacée par la température "265 °F".

g) Suivre toutes les instructions de charge et ne pas charger le bloc de batteries ou l'outil

fonctionnant sur batteries hors de la plage de températures spécifiée dans les instructions.

Un chargement incorrect ou à des températures hors de la plage spécifiée de températures

peut endommager la batterie et augmenter le risque de feu.

Safety instructions for drain cleaners

a) Only grasp the rotating cable with gloves recommended by the manufacturer. Latex or

loose-fitting gloves or rags can become wrapped around the cable and may result in serious

personal injury.

b) Do not allow the cutter to stop turning while the cable is turning. This can overstress the

cable and may cause twisting, kinking or breaking of the cable and may result in serious

personal injury.

c) Use latex or rubber gloves inside the gloves recommended by the manufacturer, goggles,

face shields, protective clothing, and respirator when chemicals, bacteria or other toxic or

infectious substances are suspected to be in a drain line. Drains may contain chemicals,

bacteria and other substances that may cause burns, be toxic or infectious or may result in

other serious personal injury.

d) Practice good hygiene. Do not eat or smoke while handling or operating the tool. After

handling or operating drain cleaning equipment, use hot, soapy water to wash hands and

other body parts exposed to drain contents. This will help reduce the risk of health hazards

due to exposure to toxic or infectious material.

e) Only use the drain auger for the recommended drain sizes. Using the wrong size drain

auger can lead to twisting, kinking or breaking of the cable and may result in personal injury.

drain auger Safety Guidelines

WARNING The flexible shaft may wrap or break the fingers and palms, or cause damage

to other parts of the body.

Wear gloves with colloidal particle. Wear safety goggles.

Do not use damaged or failed cables.

Put the machine near the pipe opening.

Machine safety:

Do not use soft gloves or cloth to hold the rotating flexible shaft, which may cause serious

injury if twined in the flexible shaft.

Do not over-deliver the flexible shaft, excessive deliver due to blockage may cause the

winding or break off of flexible shaft and cause serious injury.