6

FEED RAILS

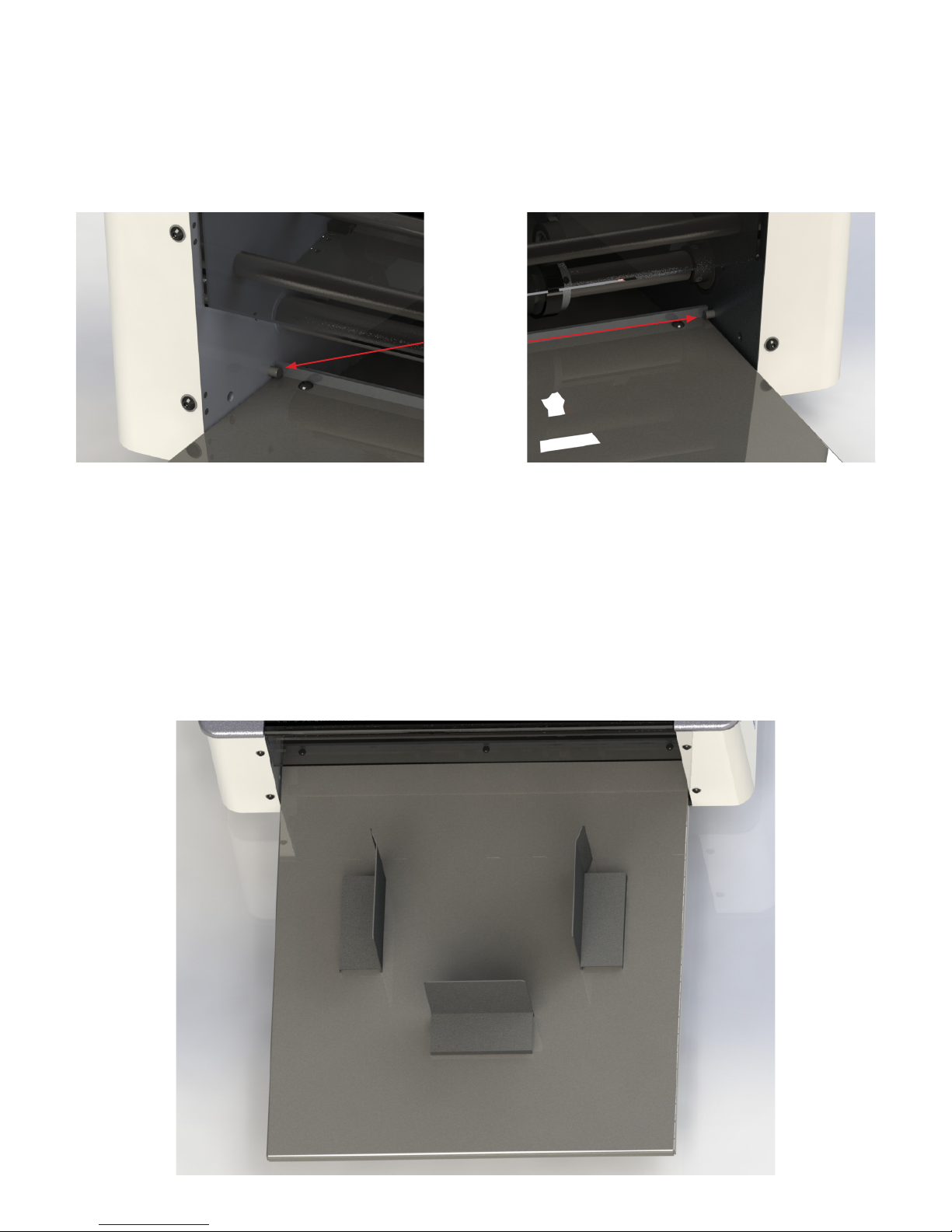

ADJUSTING FEED RAILS

The feed rails on this machine are designed to adjust easily in case of a problem with crooked

feeding. By loosening the feed rail alignment lock knobs you can move each rail independently

to square them to your stock. To maintain an accurate perf or score, it is important to get the

rails as aligned and snug to the sheet as possible without “squeezing” the sheet, as this will

create drag and cause the sheets to hang up in the rails.

To adjust this correctly, use one rail as your reference, the left (operator side). Place your

stock squarely against it then bring your right rail in and tighten, looking down it from the rear.

Adjust the rail with the skew adjustment knob so it is squared to the sheet. Then tighten the

lock knob. Set a sheet in the feeder, under the feed wheels, then run the machine. Check perf

by folding over and aligning the perfed edge.

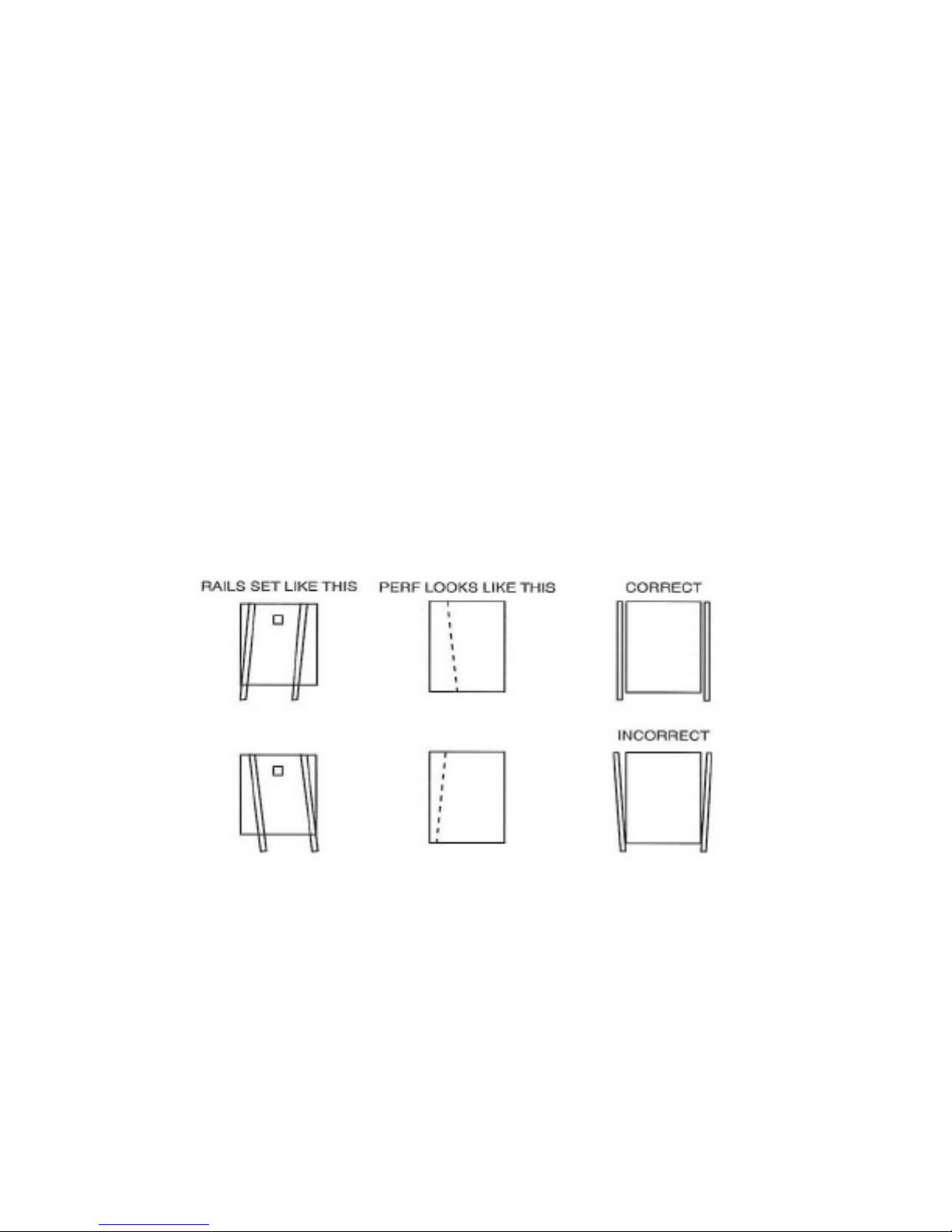

Perf holes should line up within a blade’s width. If they do not line up, adjust rails accordingly,

moving your left rail rst and then adjusting the right rail to square the sheet. This may take a

few attempts, but this adjustment is important to produce quality perf and score jobs

FEED RAIL EXAMPLE

SQUARING THE FEED RAILS

The constant ne tuning of the rails will make it necessary to bring the rails back to true

“square”. To do this, take a sheet of 8 1/2 x 11” cover stock and place it in the feed table

against the operator side guide. Pressing the sheet against the rail, slide the rail over so that

the front edge of the stock lines up to the front edge of the feed table. Loosen the feed rail

adjustment lock knob, and use the skew adjustment knob to adjust the rail so that the sheet

is aligned with the left to right with the edge. Once this is done, slide the opposite side guide

into position and adjust it to the edge of the sheet. Your rails should now feed the sheet

perfectly aligned, providing a straight perf or score.