3

IOM-KHD-SGF-111_V1.4_EN

Copyright © 2022 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

V-Notch Segment Ball Valve

KHD-SGF

Chapter I

Introduction

The manual is provided to ensure proper installa-

tion, operation & maintenance for KHD-SGF, the

Wafer Type and Flanged V-notch Segment Ball Valve

with metal seat and soft seat, manufactured and

supplied by KLINGER DIE ERSTE INDUSTRY CO., LTD.

The valves are identified by marking on the body or

on a name plate or both.

1.1 Contact Information

For information concerning warranties, or for ques-

tions pertaining to installation, operation or mainte-

nance of KLINGER Die Erste products, contact:

KLINGER DIE ERSTE INDUSTRY CO., LTD.

5F-1, No.936, Sec. 4, Wen-Xin Road,

Taichung City, Taiwan 406

Phone: +886 4 22310059

Fax: +886 4 22360236

To order replacement parts, contact KLINGER Die

Erste sales at address listed above.

1.2 General Notes

The following instructions refer to KLINGER Die Er-

ste Wafer Type and Flanged V-notch Segment Ball

Valve with soft seat and metal seat as described in

the KLINGER Die Erste current catalog.

Keep the protective covers in place until the valve is

ready for installation. Valve performance depends

upon prevention of damage to ball surface. After re-

moving the cover make sure that the valve is com-

pletely open and free of obstructions, dirt, particles

or any materials that may cause seat or seal dam-

age.

Valves may contain a silicon-based lubricant for

transportation, which aids in the assembly of the

valve. Lubricant may be removed with a solvent if

found objectionable. Alternatively valves can be or-

dered free of lubricants upon request.

Certain ferrous valves contain phosphate material,

and are oil dipped during the course of manufac-

ture. However, the processes used are completely

non-toxic.

1.3 Precautions and Warnings

Choose the correct material of valve for different

applications before obtaining the valve. The user

should be aware of the operating situation, fluid

properties, and the possible outcomes when imple-

menting valves into the pipeline system. KLINGER

Die Erste suggests that the user should make esti-

mation beforehand.

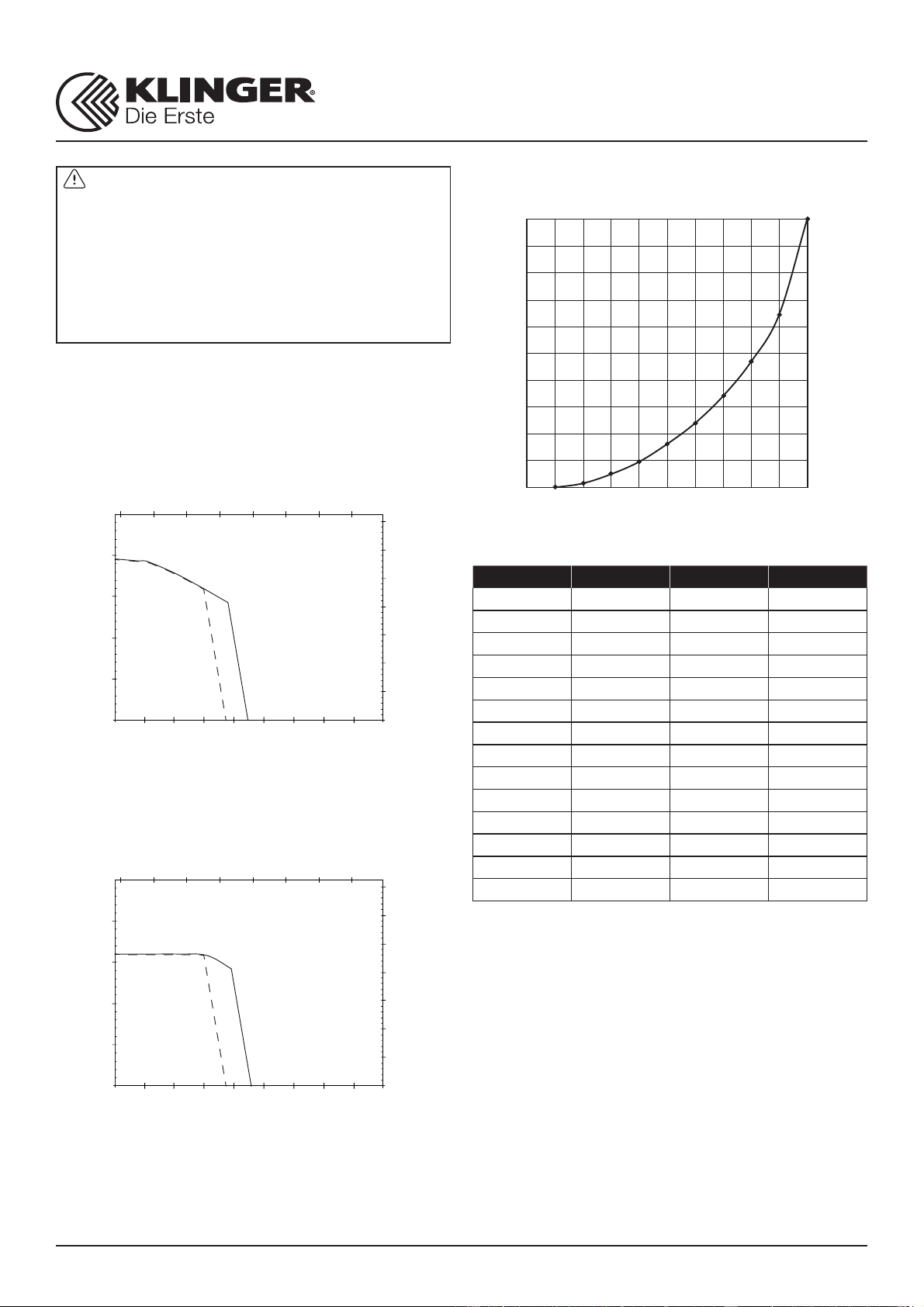

Fluid undergoes property changes with respect

to outside factors, particularly fluid left inside the

sealed cavity. When temperature and pressure ex-

ceed allowable value, valve failure may occur. User

should be aware of that excessive pressure and

temperature at nearby pipeline system can also

cause valve failure as well.

Wafer Type and Flanged V-notch Segment Ball

Valves are generally recommended for throttling

services as well as on-off functions.

Do not touch the valve surface when high tempera-

ture fluid is flowing through the valve.

Do not attempt to open the bonnet and the cap

during operation, especially with the presence of

high pressure in the pipeline system.

For safety concern, unstable fluid should not be

used in the pipeline system, unless otherwise spec-

ified with the category III in Declaration of conformi-

ty.

NOTE:

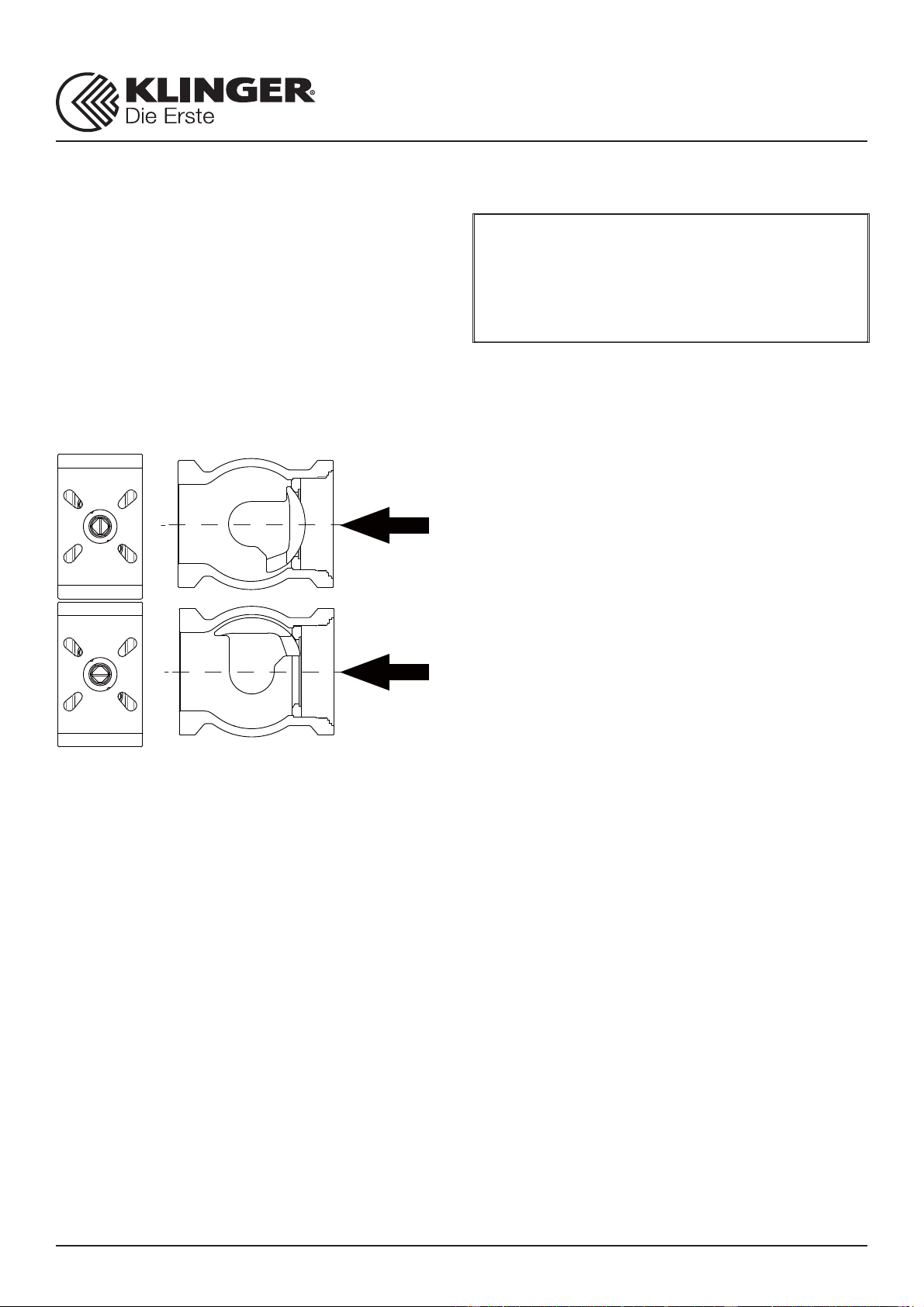

1. KHD-SGF Wafer Type and Flanged V-notch Seg-

ment Valves are installed between flanges. The

body is in one part; the shaft and segment ball are

separated.

2. The valve is either soft or metal seated. De-

pending on customers' requirement, the structure

of the supplied valve may be different.

3. The valve is designed for both control and shut-

off applications.

4. Actuators and accessories are only discussed

briefly. Please refer to individual manuals for fur-

ther information on their IOM manuals.

CAUTION:

Before removing valve from pipeline, operator

should be aware of that: media flowing through

the valve may be corrosive, toxic, flammable, or

of a contaminant nature. Where there is evidence

of harmful fluids having flowed through the valve,

the utmost care must be taken. It is suggested