Showa Denki Mistresa CRM-S Series User manual

0371(E)

−

E

Operation Manual & Cautions

CRMH

−

SSeries CRHSeries

CRM

−

SSeries CRM

−

VSeries

Originalinstructions

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Cautionary information indications used in this manual .................

Meanings of symbol marks used in this manual .............................

Using the Mistresa in a safe manner ..............................................

Items to check at product delivery ..................................................

Internal component names and layout ...........................................

Product labels .................................................................................

Ambient conditions in the area of installation .................................

Suction port cautions ......................................................................

Product installation .........................................................................

Piping ..............................................................................................

Operating cautions .........................................................................

Maintenance and inspections .........................................................

Warranty .........................................................................................

Contact information ........................................................................

About Disposal ...............................................................................

Specifications .................................................................................

[Contents]

Thank you for purchasing the Mistresa from Showa Denki. This manual explains the

specifications for the [Mistresa units from CRM-S Series, CRM-V Series, CRMH

Series, and CRH (High Temperature Types) Series].

The Mistresa collects the mist generated while components are manufactured by machine tools.

Please read the operating instructions and cautionary information carefully to ensure that the

Mistresa is used in a safe and efficient manner. Special attention should be given to

cautionary information which bears the [ ] mark.

Keep this manual in a secure location

where it can be easily accessed.

1

1

1

3

4

8

8

9

10

18

20

21

31

32

32

33

−1−

All warnings and instructions must be strictly observed.

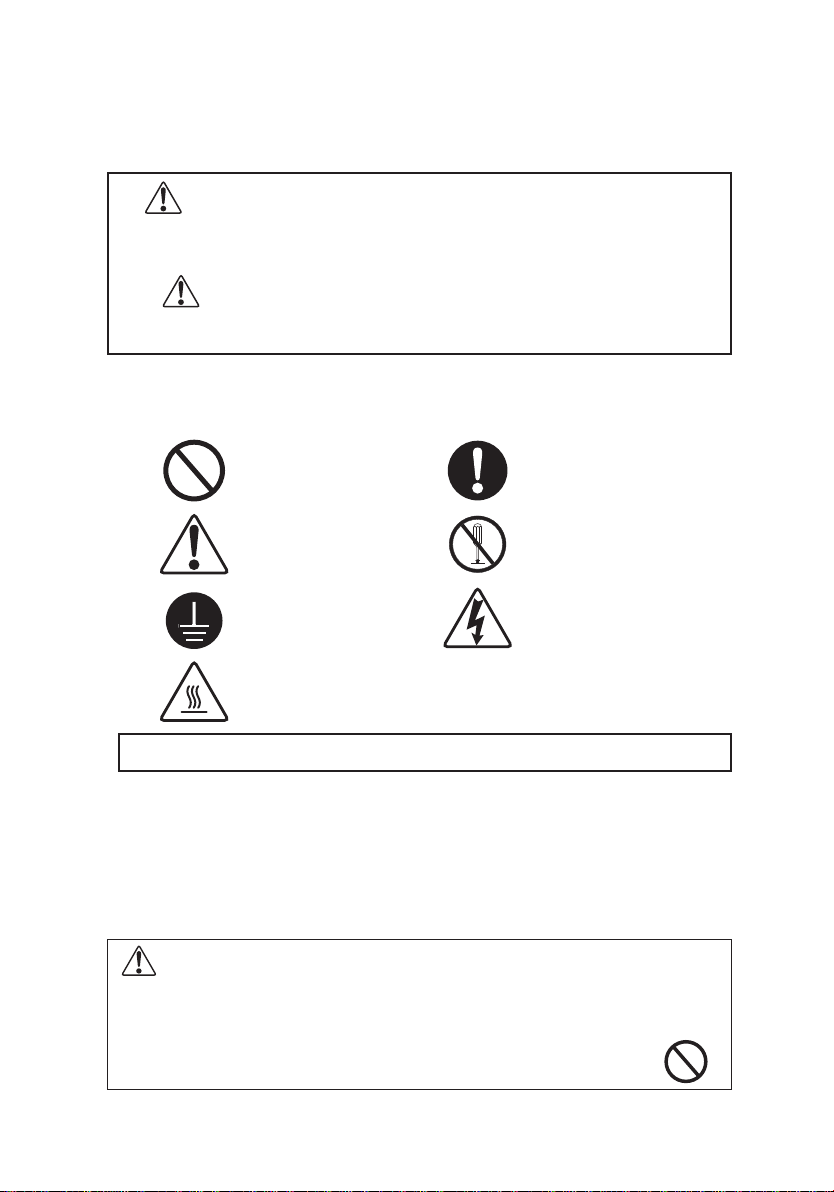

A prohibited action

(Target is unspecified)

Failing to heed the

instructions could

result in accidents

Follow instructions

carefully

Disassembly prohibited

Electrical shock hazardElectrical ground required

1.

Cautionary information indications used in

this manual

2.

Meanings of symbol marks used in this manual

"[ ] WARNING" mark indicates cautionary information that, if not

heeded, could result in serious injury or death, and could also

pose a fire hazard.

A "[ ] CAUTION" mark indicates cautionary information that, if not

heeded, could result in injury and/or equipment damage.

WARNING Do not install in hazardous locations

3.

Using the Mistresa in a safe manner

The Mistresa does not have a pressure and explosion-proof construction.

Operating the Mistresa in areas where explosive gases, etc., are present

could result in an explosion in the event of an electric motor burnout.

(CRH-□□E Series except.)

CAUTION! HOT

This product collects oil mist generated by equipment such as machine tools

to ensure and maintain a comfortable working environment. Do not use the

product for any purpose other than the originally intended.

The high efficiency motor (IE3) used with the Mistresas of the CRM-S (H02

excluded), CRM-V (H02 excluded) and CRMH-S series is designed with a lower

winding resistance than the standard motor (IE1 and equivalent), in order to reduce

loss. Since this design feature requires a higher starting current than the

standard motor, replacing your existing motor may require that you also

replace the circuit breaker, thermal relays and other parts.

−2−

CAUTION Cautionary notes on using Mistresas of the

CRM-S, CRM-V and CRMH-S series

WARNING Fire and electrical shock prevention

WARNING Maintenance and inspections prohibited

during impeller rotation

The Mistresa wiring work must be performed by a qualified electrician, and must

conform to the relevant electrical engineering standards and

internal wiring standards.

CAUTION For after installation transport

If you want to transport by installing the product on the device, please

fix firmly with as rope hanging. It may cause malfunction or damage.

Do not hold the Mistresa by the terminal box when moving the unit.

This may deform or damage the unit. Hold the Mistresa somewhere

other than the terminal box or attach the included hanger bolts to lift and

relocate the unit.

Always wait at least 2 minutes after a power OFF before performing

filter replacement work or inspections (to allow the impeller's inertial

rotation to come to a complete stop).

WARNING Fire and explosion prevention

Never allow explosive gases , organic solvents , or flames to be sucked

into the suction port. (CRH-□□E series, please use in the range of 8 page

described.)

Do not touch the product main body or the inside during the operation or

a short while after stopping the operation. Otherwise, "burn" may result.

CAUTION Burn (CRH, CRMH-S Series)

CAUTION Relocating the Mistresa (CRM-V series)

−3−

4.

Items to check at product delivery

Although all our products are thoroughly tested and inspected prior to

shipment, the customer should nonetheless check the following items when

taking delivery of the Mistresa.

• Verify that the delivered product (model, etc.) is the same as

that which was ordered.

• Verify that the product has not been damaged or deformed,

etc., during shipment.

• Verify that all the product accessories are present.

Operation & Cautions Manual

Front

(Primary)

filter

(for replacement)

Drain tube 2.5m

Hose band

(for drain tube)

Anti-vibration pads

Duct companion flange

Packing

(for duct companion flange)

Bolts + nuts

Hanger bolts

Crimp terminals

(1 spare)

Standard Accessories Type

1 copy

1 piece

2 pieces

2 pieces

4 pieces

1 piece

1 sheet

4 sets

2 sets

7 sets

S2□only S2□only V2□only

* Two duct companion flanges come with the product – one for installing

the product and the other for connecting with the next machine. The

packings (for duct companion flanges) for CRM-S, CRMH-S Series are

affixed to the duct companion flanges.

CRM

−

S

Series CRMH

−

S

Series CRM

−

V

Series CRH

Series

—

—

—

—

—

—

—

——

——

**

If necessary, store the Mistresa in ambient conditions below.

・Indoor avoiding direct sun beams

・Temperature between 0°C to 40°C

・Humidity between 10% to 90% (No condensation)

Follow the instructions below if it is necessary to stop the operation or store

the Mistresa for 3 months or longer.

(1) Storing Mistresa in the original packaging

Store the Mistresa in a dry area indoor where the temperature does not

change much.

(2) Not operating the Mistresa after installation

Keep the Mistresa free from "significant vibration" and "heat" from

other machines and equipment.

It is recommended that the Mistresa be covered with a plastic sheet or the

like to keep it free from water, oil and dust.

This manual suits for next models

29

Table of contents

Other Showa Denki Industrial Equipment manuals