REVISION A

REVISION B

REVISION C

REVISION D

DRAWN BY:

DATE:

SHOP ORD.#

DRAWING SIZE

TITLE

SHEET: OF: DRAWING NO:

PA

3/25/01

B

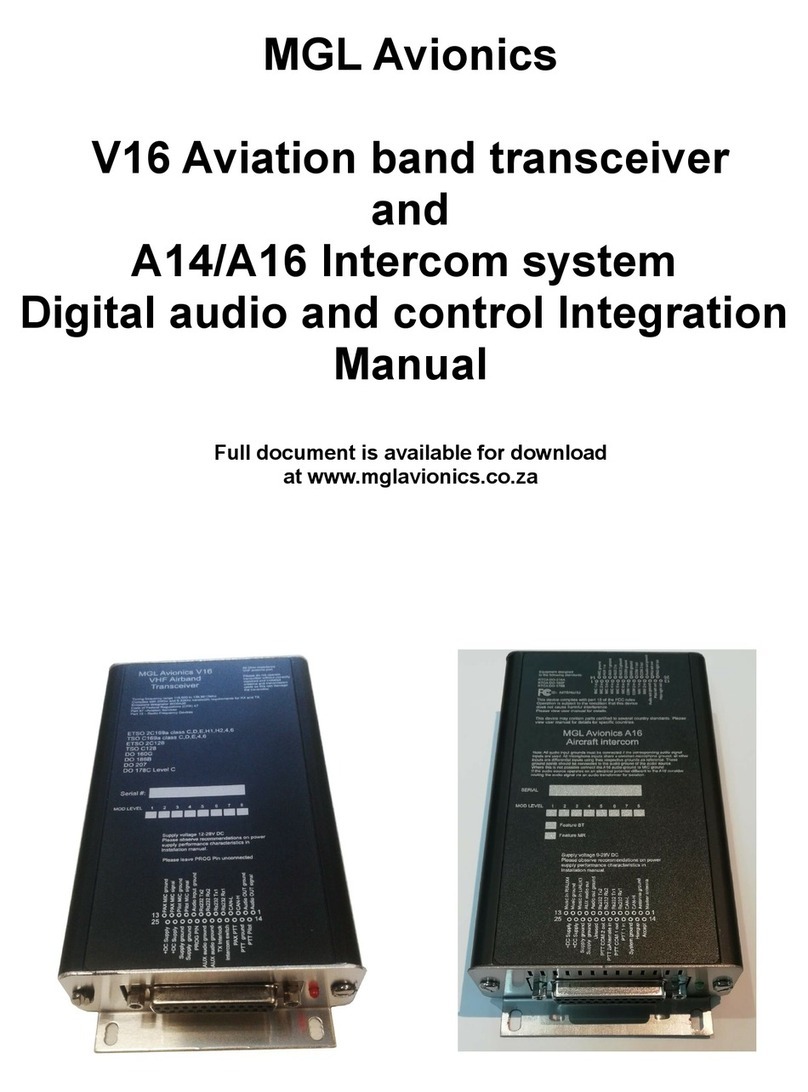

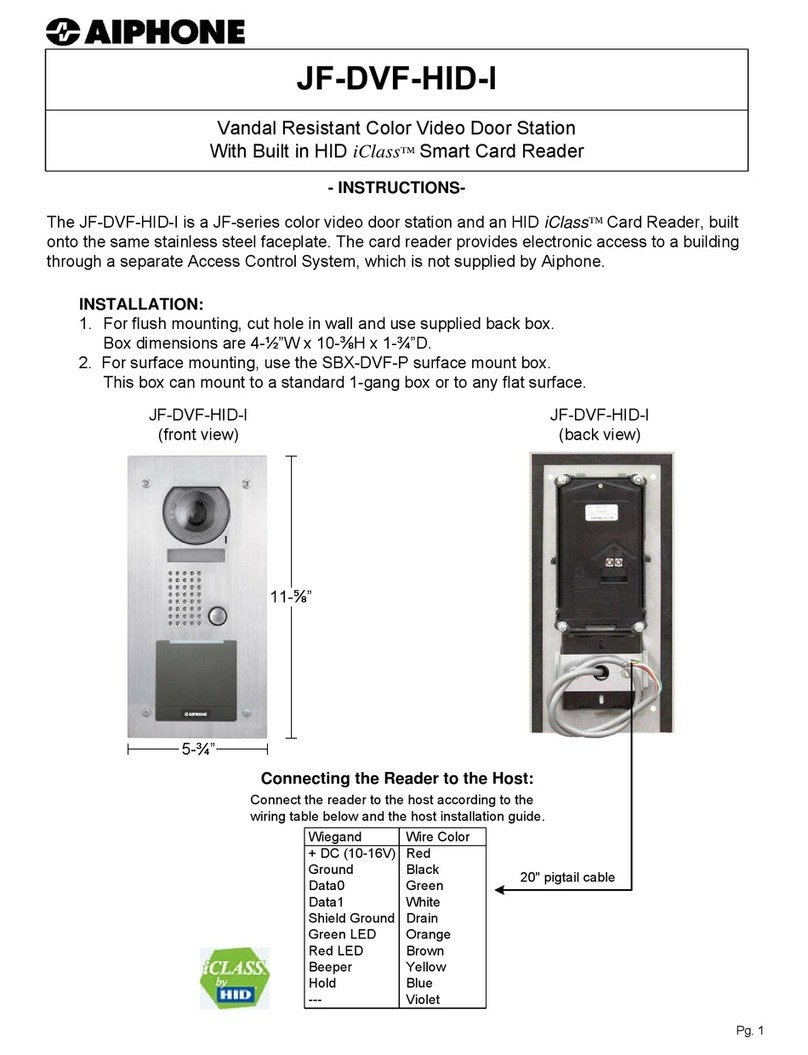

SAFETY-COMM # SC-100 INSTALLATION

5308B

1

AC ADAPTER

BOTTOMVIEWSIDE VIEW

AC ADAPTER

2

IMPORTANT NOTE:

MIN. 3.0" - MAX. 3.5" DIA. HOLE TOOLS REQUIRED

11/32" HEX NUT DRIVER WITH HOLLOW SHAFT

5/64" HEX KEY (INCLUDED WITH SC-100 UNIT)

1/8" TIP WIDTH SCREW DRIVER

(1)

(2)

(3)

3/8" DIA. HOLE

REAR VIEW OF CONTROL PLATE

OUTSIDE PLATE

REAR VIEW

FOUR #8-32

NUTS & BOLTS

2

1. With the tool provided, remove the four (4) tamper-resistant screws

located on the control plate.

2. Gently pull on the gooseneck to separate the control plate assembly from the main housing.

3. Remove cable harness connecting the outside plate and the control-plate assembly.

4. With a hollow-shaft nut driver (not included), remove the #8-32 mounting nuts

as shown. This will allow you to separate the outside plate from the main housing.

5. Remove the outside plate from the main housing unit and throw away the plastic

(or aluminum) spacers.

6. Align the outside plate over the opening in the barrier.

7. From the inside, reinstall the main housing unit on the bolts indicated in step 4 above.

8. Reattach the control plate to the main housing units with the four (4) tamper-resistant

screws .

TM

Step

2

1

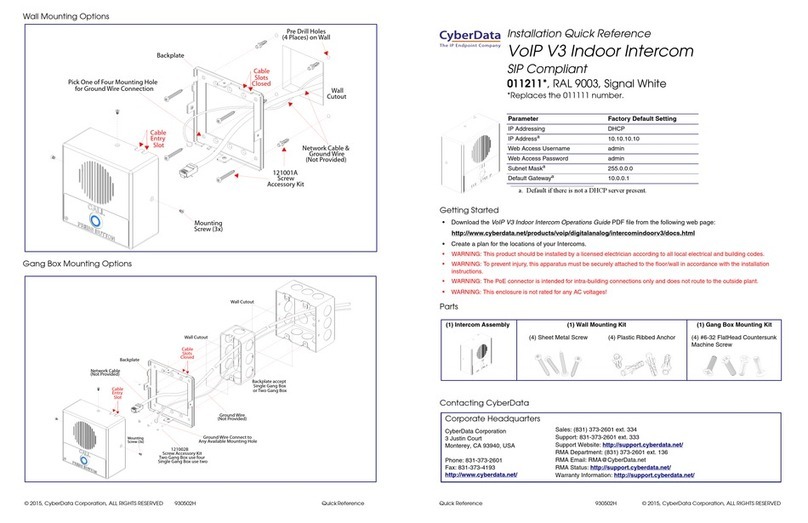

1. Turn "power" switch off.

2. Make sure the AC adapter is plugged in.

3. Turn "power" switch on. The green LED will illuminate.

4. Adjust "listen" and "talk" controls to the desired level. [note: ideal

speaking distance for the customer-side (outside) plate is 4" to 8" away.

Ideal speaking distance from the gooseneck microphone is 3" to 5"].

TM

Reconnect the cable from the outside plate to the control plate assembly. See wiring diagram.

BLACK W/ WHITE STRIPE (+)

BLACK (-)

CABLE HARNESS

OUTSIDE PLATE

REAR VIEW

CONTROL SIDE

PARTITION(GLASS)

MODEL #SC-100

CUSTOMER SIDE

FRONT VIEW

CONTROL PLATE

ASSEMBLY SCREWS

FOUR #6-32

1

INSTALLING MODEL #SC-100 :

IS REQUIRED IN BARRIER.

ADJUSTING MODEL #SC-100 :

WIRING DIAGRAM

PAGE -3-

MODEL: SC-100 AC