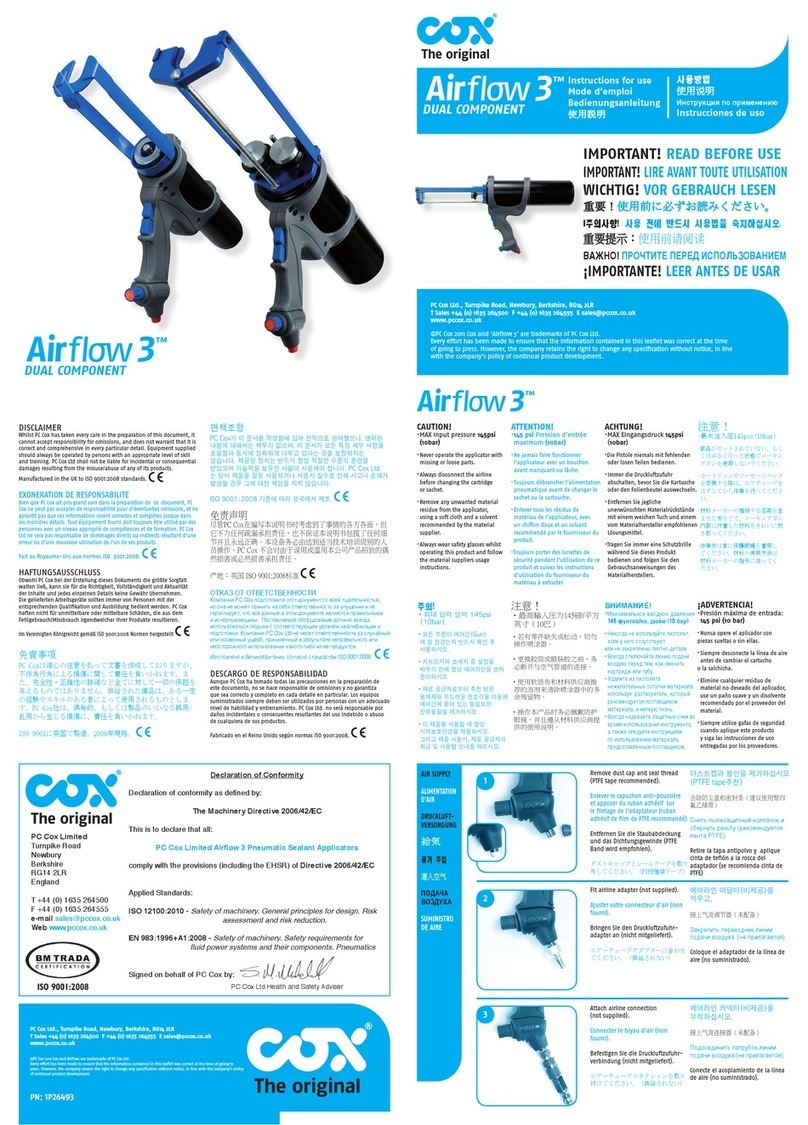

COX Airflow 1 User manual

SAFETY

This applicator is a quality product for the professional user; it is designed for

high duty cycles over long operating periods. As compressed air is used as the

power source, operator fatigue is minimal, but it must be remembered that

compressed air can be dangerous when used incorrectly. The user should take

time to read and understand these operating instructions fully. Failure to do so,

could lead to serious bodily injury.

ALWAYS

• USE PROTECTIVE EYE EQUIPMENT WHEN OPERATING.

• DISCONNECT THE AIR SUPPLY BEFORE STARTING ANY MAINTENANCE/CLEANING TASKS.

NEVER

• CONNECT THE APPLICATOR TO AN AIR SUPPLY WHICH CAN EXCEED 145 psi (10 BAR)

• IMMERSE THE GUN IN SOLVENT.

• OPERATE THE GUN WITH LOOSE, BROKEN OR MISSING PARTS.

• CARRY THE GUN BY THE AIR PIPE.

• USE DAMAGED CARTRIDGES OR THE WRONG TYPE OF CARTRIDGE IN THE APPLICATOR.

• FIT A REGULATOR WITH A HIGHER PRESSURE VALUE.

It is recommended that ear protection is used for Mk5b type guns.

CONNECTION

Check the supply pressure. For optimum performance the supply pressure must

be greater than 100 psi (6.8 bar) and less than 145 psi (10 bar).

The applicator will work at lower supply pressures, but flow rates could be

reduced and may vary.

Connect the applicator to a suitable compressed air source using the nut and tail

supplied, or with a suitable tting. All applicators are tted with a male ¼” BSP

thread.

OPERATION/CONTROLS

A - Internal Pressure Regulator

The internal pressure regulator controls the material flow rate and ensures a

stable flow of sealant is maintained. To increase the flow of sealant, turn the

knob in a clockwise (+) direction. To decrease the ow, turn the knob in an

anticlockwise (-) direction.

The regulator is colour coded to designate the maximum pressure that will be

allowed in to the applicator barrel, regardless of the line in pressure.

Blue = 50 psi (3.4 bar) Yellow = 75 psi (5.1 bar) Orange = 100 psi (6.8 bar)

B - Trigger

By pulling the trigger, a cushion of compressed air is built up inside the

applicator, which initiates the ow of material. On releasing the trigger, the

sealant flow ceases as the compressed air escapes rapidly by a quick exhaust

valve at the rear of the gun.

C - Plunger Return Button (Where tted)

Press and hold the plunger return button (C), then pull the trigger (B).

This will pull back the plunger rods automatically ready for the next cartridge.

If the applicator is not tted with the air return button, manually pull back the

plungers using the indicator knob (D).

D - Indicator/Return Knob

This gives a visual indication of how much material is remaining in the cartridge

during use. For guns not fitted with air return, the return knob is used to

manually pull the plungers back.

MAINTENANCE

DAILY: Wipe the applicator using the adhesive manufactures recommended

solvent before it has time to set. Special care should be taken to make sure no

residue is left on the rods.

WEEKLY: Check the plungers and all external bolts/screws are tight. Tighten if

found to be loose.

MONTHLY: Place a small amount of oil in the air pipe to keep the internal seals

and pistons lubricated.

NOTE

Tested in accordance with European Machinery Regulations (1.1.95)

Mk5b pneumatic applicator has A-weighted sound pressure levels in

excess of 70dB (A).

Series 2 pneumatic applicator has A-weighted sound pressure levels

less than 70dB (A).

WARNING

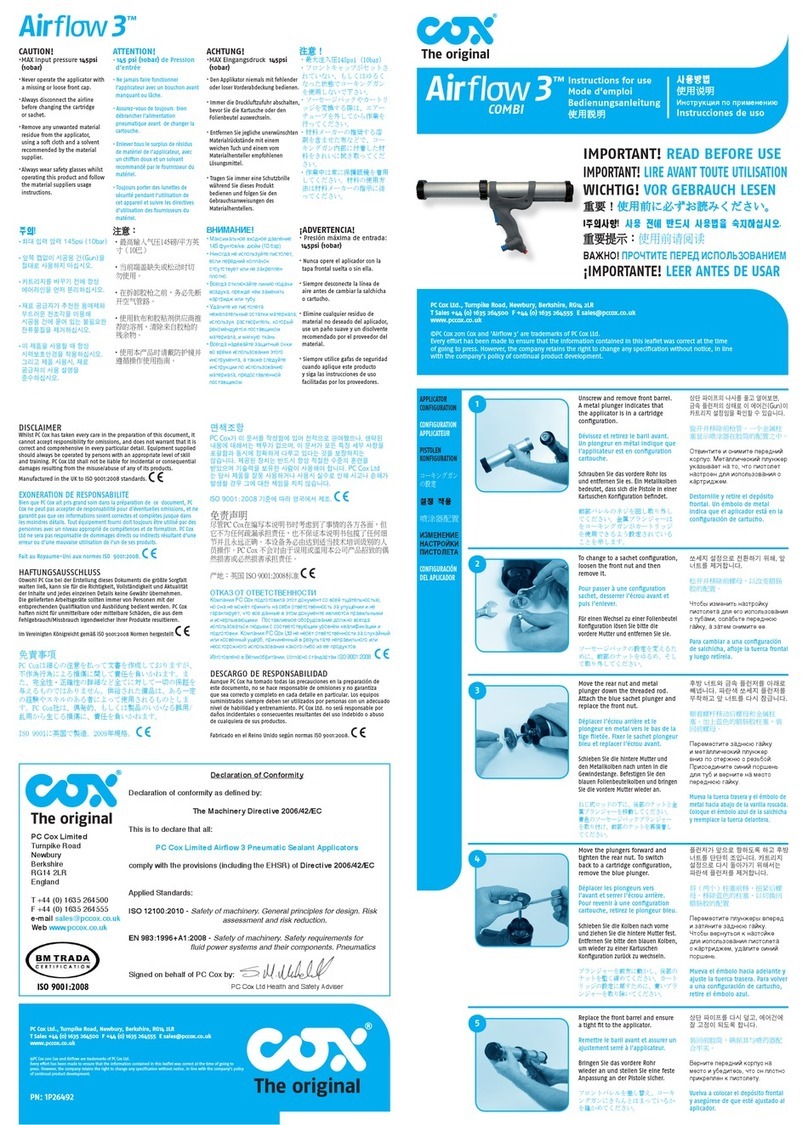

Two Component Applicators with cartridge locators

1. Ensure rods are fully retracted towards the barrel.

2. Locate rear of cartridge over plungers and onto cartridge locators.

3. Push back rmly until the front of the cartridge can be located into the

frame assembly.

4. Check that the cartridge is correctly located before operating the trigger.

Two Component Applicators with support straps

1. Ensure rods are fully retracted towards the barrel.

2. Place cartridge into frame assembly making sure the front of the cartridge

locates in the frame assembly slot.

3. Check that the cartridge is correctly located before operating the trigger.

Two Component Applicators with hinged frame assembly

1. Ensure rods are fully retracted towards the barrel.

2. Swing frame assembly open.

3. Load cartridge/sachet into sleeve and t manifold (if required).

4. Close frame assembly.

5. Check that the cartridge/sachet is correctly located before operating

the trigger.

Two Component Applicators with hinged cartridge sleeve

1. Manually retract plungers using the indicator rod (not shown).

2. Twist sleeve downwards

3. Load the cartridge in the sleeve.

4. Close sleeve fully.

5. Check that the cartridge is correctly located before operating the trigger.

Co-Axial Applicators with hinged frame assembly

1. If gun is tted with air return, fully retract plungers.

2. Swing the frame assembly open.

3. Load the cartridge in the sleeve. NOTE – This will push back the plungers on

guns not fitted with air return.

4. Close frame assembly fully. Rotate cartridge if required.

5. Check that the cartridge is correctly located before operating the trigger and

the frame is fully closed.

CARTRIDGE LOADING

Airflow 1 and Airflow 2 Operating Instructions

2 Component Pneumatic Sealant and Adhesive Dispensers

Noise Emission

• Sound pressure level, A weighted (LwA) = 89.96dB

• Sound pressure level at work station, A weighted (LpA) = 78.96dB

• Peak emission sound pressure level, C weighted (LpC, peak) = 109.54

• Average daily exposure (based on 8 hours continuous use) = 78.96dB

Vibration Emission

Hand arm vibration = 0.04m/s2

Two Component AF1/AF2 - Tool Weights (empty)

Safety Instructions for pneumatic sealant and

adhesive dispensers

General

•Please make sure you read and fully understand all the

instructions provided in this manual, before attempting

to use the tool.

•Do not discard the safety instructions. These should be

stored in a safe place, and should be read and referred

to regularly, to ensure the safe use of this tool.

•The user, or the user’s employer, shall carry out a risk

assessment before using the tool each time, to ensure

that it is safe to apply material.

•This tool is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities. Operators who lack experience or knowledge

of the tool, must be given thorough training first before

being allowed to use the tool.

•This tool should only be used to dispense sealants and

adhesives from conventional material packaging systems.

The dispensing of other material types, or the use of

customer modified packaging systems, is strictly forbidden.

•The tool should be inspected periodically, to ensure that

the text and graphics on the labels are still clearly legible.

If not, the user shall contact the manufacturer and request

replacement labels.

•Do not modify this tool in any way. Modications can

reduce the eectiveness of safety measures, and increase

the risks to the operator.

Tool Use

•Always wear gloves and safety glasses, before attempting

to dispense any materials with this tool.

•Please ensure that the material packaging system is the

correct size for this tool, and that it has been adequately

secured to the tool, before attempting to dispense any

material.

•Before using the tool each time, please check the airline

to ensure that it is not damaged. There should be no loose

connections, or excessive lengths of hose left lying in areas

that could create a trip hazard.

•Never exceed the maximum air pressure stated on the tool.

•To prevent projectile hazards, please ensure the tools are

never operated with open ended frames or barrels.

Accessories should also be adequately secured to the tool

and the material packaging system. If the mixing nozzle

becomes blocked during use, it should be replaced.

•Never aim the tool at yourself or anyone else during use.

•Always disconnect the compressed airline from the tool,

when loading/re-loading the tool with material.

•Always disconnect the tool from the air supply after use.

Sicherheitshinweise bei Druckluftpistolen für

Dichtungsmaterialen und Klebstoe

Allgemeines

•Stellen Sie bitte sicher, dass Sie alle in dieser Betriebsanleitung

angegebenen Instruktionen lesen und verstehen, bevor Sie das

Werkzeug verwenden.

•Verwahren Sie die Sichheitshinweise an einem sicheren Platz

auf und werfen Sie diese nicht weg. Um einen sicheren Gebrauch

dieses Werkzeugs zu gewährleisten, ist eine regelmäßige

Durchsicht und der Verweis auf die Sicherheitshinweise

notwendig.

•Der Werkzeugnutzer oder dessen Arbeitgeber sollte vor jedem

Einsatz des Werkzeugs eine Risikobewertung ausführen, um eine

gefahrlose Anwendung sicherzustellen.

•Dieses Gerät ist nicht zur Verwendung durch Personen

(einschließlich Kinder) mit eingeschränkten körperlichen,

geistigen oder sensorialen Fähigkeiten. Werkzeugbediener, denen

es an Erfahrung und Wissen im Umgang mit dem Werkzeug

mangelt, müssen vor der Nutzung zunächst eine umfassende

Schulung zum Gerät erhalten.

•Dieses Werkzeug sollte nur mit herkömmlichen Dichtungs- und

Klebstogebinden verwendet werden. Das Aufbringen anderer

Materialien oder der Gebrauch von kundenmodizierten

Gebinden ist strengstens verboten.

•Um sicherzustellen, dass der Text und die Grak auf den

Etiketten noch klar leserlich sind, sollte das Werkzeug regelmäßig

geprüft werden. Sollte dies nicht mehr gegeben sein, werden auf

Anfrage neue Ersatzetiketten vom Hersteller bereitgestellt.

•Modizieren Sie dieses Werkzeug in keinster Weise. Jegliche

Änderungen am Gerät können die Wirksamkeit von

Sicherheitsmaßnahmen reduzieren und die Gefahren für den

Maschinenbediener erhöhen.

Bedienung des Werkzeugs

•Tragen Sie immer Handschuhe und Sicherheitsbrille bevor Sie

beginnen, Materialien mit dem Werkzeug aufzutragen.

•Bevor Sie das Werkzeug verwenden, stellen Sie bitte sicher,

dass die Verpackungsgröße des zu verarbeitenden Gebindes

(Kartusche/ Schlauchbeutel) die richtige Größe für dieses

Werkzeug aufweist. Prüfen Sie, dass vor der Nutzung das zu

verarbeitende Gebinde korrekt gesichert im Werkzeug eingesetzt

wurde.

•Die Pressluftzuleitung muss vor jedem Gebrauch des Geräts auf

Mängel geprüft werden. Lose Anschlüsse sowie lange Kabel, die

Stolperfallen bilden können, müssen vermieden werden.

Überschreiten Sie nie den auf dem Werkzeug maximal

angegebenen Luftdruck.

•Um geschossähnliche Gefahren zu verhindern, stellen Sie bitte

sicher, dass das Werkzeug nie mit geönetem Rahmen bzw.

Gebinderohr benutzt wird. Auch jegliche Zubehörteile sollten

sicher mit dem Werkzeug oder dem Gebinde verbunden sein.

Sollte sich die Düse während des Arbeitsganges verstopfen,

muss diese ausgewechselt werden.

•Richten Sie das Werkzeug während des Gebrauchs nie auf sich

selbst oder gegen jemand anderen.

•Trennen Sie das Werkzeug stets von der Druckluftleitung wenn

Sie eine neue Verpackung des Verarbeitungsmaterials einsetzen

•Trennen Sie das Werkzeug nach Ende der Nutzung immer von

der Druckluftzufuhr.

Règles de sécurité pour nos pistolets d’extrusion de

mastics et colles de type pneumatique

Conseils de sécurité générale

•Assurez- vous d’avoir bien lu et compris cette notice

d’instructions avant de mettre le pistolet sous tension.

•Conservez bien ces instructions pour référence ultérieure.

Consultez ces instructions à chaque fois qu’il est nécessaire

afin de vous assurer du bon emploi et de la mise en marche

du pistolet en toute sécurité.

•L’utilisateur doit impérativement vérier que le pistolet

est en bonne état de fonctionnement et accomplir les

vérications d’usage avant d’utiliser le pistolet pour éviter

les risques d’accident.

•Ces vérications doivent se faire avant toute mise en marche

du pistolet.

•Cet outil n’est pas conçu pour les personnes ou enfants dont

les capacités physiques, sensorielles ou mentales sont réduites

ou pour les personnes novices ayant aucune

expérience ou connaissance du ce produit à moins qu’elles

ont pu bénécier, par l’intermédiaire d’une personne

responsable de leur sécurité, d’une surveillance et d’instructions

préalables concernant l’utilisation de cet outil.

•Ce pistolet est conçu pour l’extrusion de produits d’étanchéité

et de colles fournis dans les emballages

standards de types cartouches ou poches. L’extrusion de toute

autre type de produits, ou type de packaging est strictement

interdit.

•Vériez régulièrement que toutes les étiquettes qui

apparaissent sur le pistolet sont toujours lisibles. Des étiquettes

de remplacement sont disponibles sur demande auprès du

fabricant.

•Ne pas modier ce pistolet d’aucune façon. Ceci pourrait

avoir des conséquences néfastes sur le bon fonctionnement de

l’appareil et donc aecter la sécurité de l’utilisateur.

Usage

•Le port de gants et de lunettes de sécurité est recommandé

•Assurez- vous que vous avez le bon outil pour la taille de votre

cartouche poches.

•Placez votre cartouche/poche correctement votre cartouches ou

poches dans le pistolet avant de commencer à extruder votre

produit.

•Vériez que la ligne d’arrivée d’air n’est pas endommagée

avant toute mise sous tension. Tous les composants doivent

être en bon état et xés correctement, et prendre les

mesures nécessaires pour s’assurer que personne ne se prenne

les pieds dans le câble d’arrivée d’air.

•Le produit ne doit pas être sous tension ou relier à la ligne

d’arrivée d’air lorsque l’utilisateur recharge le pistolet.

•Après utilisation, n’oubliez pas de débrancher le pistolet du

compresseur à air.

P C COX LTD, TURNPIKE INDUSTRIAL ESTATE, NEWBURY, BERKSHIRE, RG14 2LR, UNITED KINGDOM

T Sales +44 (0) 1635 264500 | F +44 (0) 1635 264555 | E sales@pccox.co.uk | www.pccox.co.uk

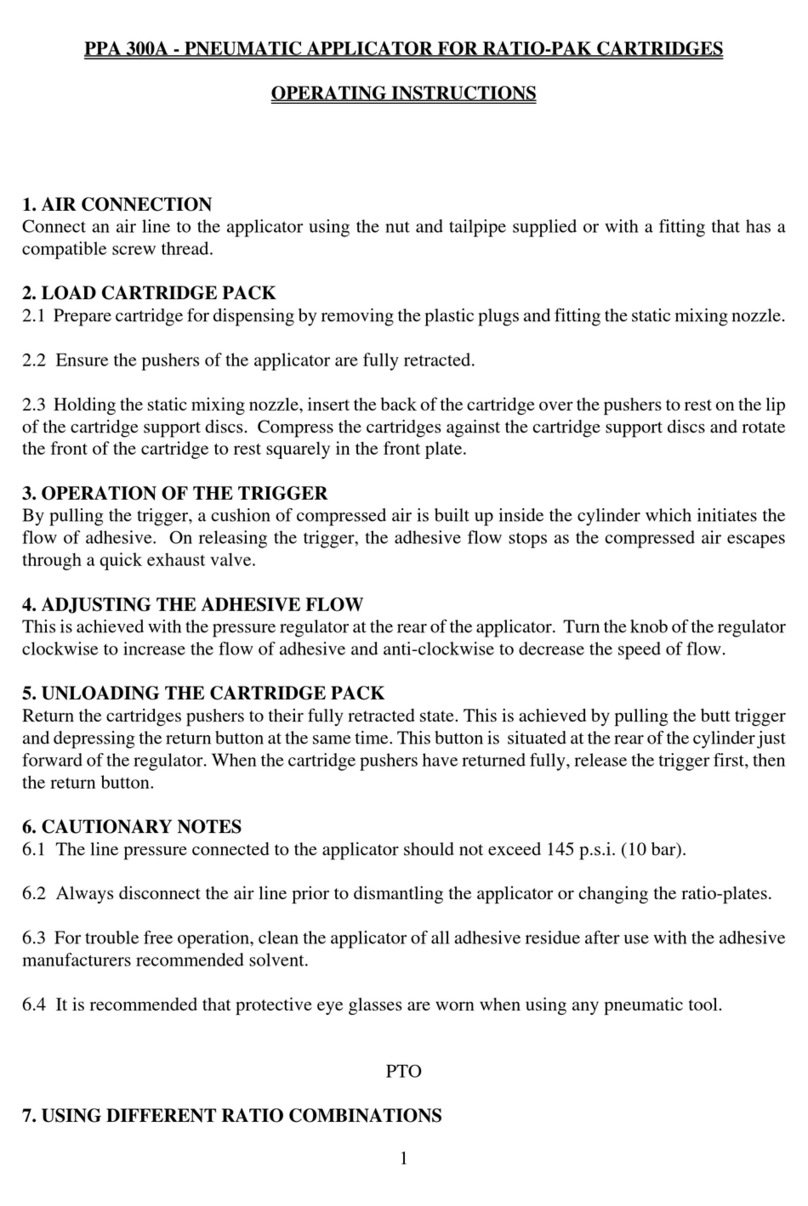

CBA 25 0.8

CBA 50 0.8

CBA 200 C 2.8

CBA 310 C 3.1

CCA 380 A 3.3

CCA 380 B 2.6

PPA 75 LP 1.2

PPA 75 HP 1.6

PPA 150 LP 1.6

PPA 150 HP 1.9

PPA 300 A 3.3

PPA 300 B 2.3

Product Type Weight (kg)

PPA 600 A 3.6

PPA 750 A 3.8

RBA 100 LP 1.4

RBA 100 HP 1.7

RBA 200 B 1.9

RBA 300 B 2.2

TBA 100 LP 1.6

VBA 100 HP 1.7

VBA 200 A 2.9

VBA 200 B 2.2

VBA 400 A 3.1

VBA 400 B 2.6

Product Type Weight (kg)

PC Cox Ltd.

Turnpike Industrial Estate

Newbury, Berkshire

RG14 2LR

United Kingdom

Tel: +44 (0) 1635 264500

Fax: +44 (0) 1635 264555

www.pccox.co.uk

DECLARATION OF CONFORMITY

This is to declare all Airow 1 pneumatic dispenser tools including models

PPA300A PPA600A PPA750A PPA1200A PPA1500A

Manufactured by P C Cox Ltd are in compliance with the following Directives:

The Machinery Directive 2006/42/EC,

Pressure Equipment Directive 97/23/EC

Applied Standards:

EN ISO 11148-6:2010 - Hand held non-electric power tools

- Part 1 Assembly power tools for non-threaded mechanical fasteners.

EN ISO 15744:2008 – Hand held non-electric power tools

– Measurement of noise.

EN ISO 8662-11:2009 - Hand held non-electric power tools

– Measurement of vibration at the handle.

Technical Data:

Air pressure 6.8 bar (max)

Thrust 5.1 kN (max)

Tool Data:

Noise emissions 109dB(A) Peak

Hand Arm Vibration 0.04 m/s2

Signed for & on behalf of P C Cox by:

Date: 30 November 2014

C Beckett: Engineering Director

This manual suits for next models

1

Other COX Dispenser manuals