CD65ServiceManual: Ver.1.2,Page 8

Clean-up

The GustoPurge tank (Page#32) is usedto cleanhoses, mixers, hosemanifolds, valves,and other components

exposedto catalyzed resin. Complete steps 1 and 2 below tocharge theGusto Purgetank beforestarting injection.

Itisa precaution thatallows clean-up inthe event theairsupply islostdue to compressorfailure. Withthe Gusto

Purgetank fully chargedwithair,there is sufficientenergywithin the tank tocleanupthemajorcomponents.

1. Vent the tank by rotating theselector valveso thatit pointsaway fromthe adapterblock,

andtowardsthe bronzefilter. Removethe lid andpour about one-halfgallon of Acetoneor

MethylEthylKetone (MEK) solventinto the tank. Donot use petroleumbasedsolvents

suchastoluol,xylol,mineralspiritsor naptha, as theywilldestroythelidseal. Donot fill the

tank,asthiswillreducethevolumeofair available for anemergencyclean-up.

2. Replacethe lidand secure it with itsbale. Rotate theselector valve 90 degrees sothat it

isclosed to theinlet and outlet. Connectthe airsupply and pressurizethe tankat the maxi-

mumpressureavailable. Setthe tank asideuntiltimeto clean up.

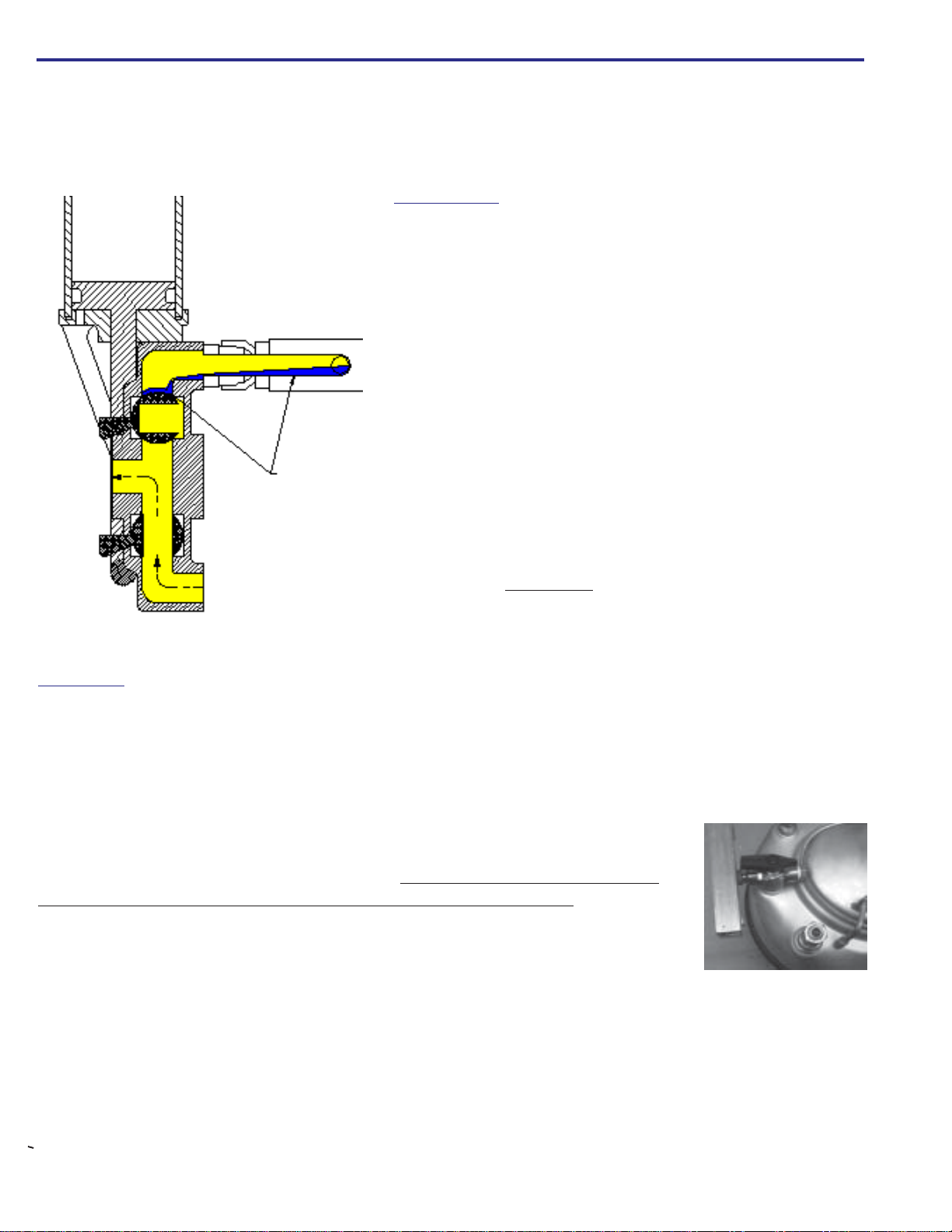

Mostepoxyresinscanbeleftwithinasystemindefinitely. How-

ever,there isa very important step to be takenat shut-downif (a),

alowviscosityresinis being used, and(b), amixerormanifoldis

fixeddirectlytothe outletfittingsofthe Cocomodule. Theproce-

dureiscalled“burping”.

Burpingisnecessary because thebase and catalystcomponentsof

mostthinresinshaveamuchdifferentspecificgravity. Likevinegar

andoilin saladdressing, one isheavierthanthe other,andquickly

sinksto the bottom: the base component tends to sink beneath the

catalyst.Whenthecomponentshovertogetherwithinamixer or

manifoldfixedtotheoutletvalves,itispossiblewithina very few

minutesforthe base topond out beneaththecatalyst, entering the

catalystoutletvalvewithcostlyresultsasithardensovernight.

Toburp the unit,simplydispenseafew ounces ofmaterialintoa

wastecontainerimmediatelyafterremovingthemixerormanifold.

Thiswillflushanybaseresinwhichmayhaveenteredthe catalyst

fittingorvalve.

Heavier base

resin ponded

into catalyst

valvefrommixer

Shut Down

OPERATION cont.

Becausetheresincomponents arenotjoinedwithin thedispenser, no internalclean-upis required. And unlessyouare

usingasingle outlethosewith aSSOControl Valve, or a mixerthat is notdisposable, there isno external clean-up

otherthan those minor tasks cited on Page 7, and you can proceed directly to Page10 forfurther information. Youdo

notneedtheinformationbelow. Butifyouare dispensing throughasinglehose or anon-disposablemixer, you need

thefollowinginformation.