CP Autosport SetupWizzard User manual

Wheel alignment system SetupWizzard

Year of manufacture: from 2015

Version 01

Edition: October 2019

© CP Tech GmbH

This operating manual and all illustrations contained herein are protected by copyright. Any use outside

the limitations of copyright law without our prior written approval is prohibited and liable to prosecution.

This applies especially to reproduction, translation, microfilming, saving, and editing in electronic

systems.

Wheel alignment system SetupWizzard I

Contents

1Introduction ......................................................................................................................................1

1.1 Notational conventions.............................................................................................................2

1.1.1 Section-related warnings ............................................................................................2

1.1.2 Embedded warnings ...................................................................................................3

1.1.3 Other notational conventions......................................................................................3

1.1.4 Symbols used in the manual ......................................................................................3

1.2 Warranty and liability................................................................................................................4

1.3 Copyright..................................................................................................................................5

1.4 Guarantee terms ......................................................................................................................5

1.5 Service / Customer service ......................................................................................................5

2Safety.................................................................................................................................................6

2.1 Intended use ............................................................................................................................6

2.1.1 Structural alterations to the measuring system ..........................................................7

2.1.2 Foreseeable misuse ...................................................................................................7

2.2 Personnel requirements...........................................................................................................7

2.2.1 Responsibilities...........................................................................................................8

2.2.2 Obligations of personnel.............................................................................................8

2.2.3 Unauthorized persons ................................................................................................8

2.2.4 Instruction ...................................................................................................................9

2.3 General safety information.......................................................................................................9

2.4 Safety measures for environment protection .........................................................................10

2.5 Special hazard signs..............................................................................................................10

2.5.1 Symbols used on the measuring system..................................................................10

2.5.2 Hazards due to electricity .........................................................................................11

2.5.3 Hazards due to hot surfaces.....................................................................................12

2.5.4 Hazards due to incorrect spare parts .......................................................................12

2.6 Personal protective equipment ..............................................................................................13

2.7 Safety devices and guards.....................................................................................................13

2.8 Information for emergencies ..................................................................................................14

2.9 Obligations of the plant operator............................................................................................15

3Description of the measuring system ..........................................................................................16

3.1 Scope of supply .....................................................................................................................16

3.1.1 Scope of supply of the system version Easy............................................................16

3.1.2 Scope of supply of the system version Basic ...........................................................17

3.1.3 Scope of supply of the system version Pro ..............................................................18

3.1.4 Accessories for system version Pro .........................................................................19

3.1.4.1 Rating plate ...............................................................................................19

3.2 Function .................................................................................................................................20

3.3 Technical data........................................................................................................................20

3.3.1 Measuring platform (System version Pro) ................................................................20

3.3.2 Camber sensor (System version Pro) ......................................................................20

3.3.3 Toe laser...................................................................................................................20

3.3.4 Leveling laser (see technical specification user manual) .........................................20

3.3.5 Transport box (flight case)........................................................................................21

3.3.6 Platform elevations (accessories).............................................................................21

3.3.7 Ambient conditions ...................................................................................................21

Contents

II CP Tech GmbH

4Transport and storage (by manufacturer)................................................................................... 22

5Transport and storage (by plant operator) ................................................................................. 23

5.1 Safety during transport .......................................................................................................... 23

5.2 Intermediate storage ............................................................................................................. 24

6Installation by manufacturer ........................................................................................................ 25

7Installation by plant operator ....................................................................................................... 26

7.1 Adjusting the universal stands of the setup wheel ................................................................ 26

7.2Replacing the wheel adapters............................................................................................... 30

7.3 Setting up the software.......................................................................................................... 31

7.3.1 Measuring platform operation .................................................................................. 33

7.3.2 Pairing the measuring platform ................................................................................ 34

7.3.3 PC software configuration........................................................................................ 35

7.3.4 Taring the wheel load scales ................................................................................... 36

8Commissioning.............................................................................................................................. 37

8.1 Safety measures to be taken before commissioning ............................................................ 37

8.1.1 Necessary operating and maintenance space......................................................... 37

8.1.2 Floor requirements ................................................................................................... 37

8.2 Setting up the measuring system.......................................................................................... 38

8.2.1 Installing the setup wheels....................................................................................... 38

8.2.2 Positioning the platforms/measuring platforms........................................................ 38

8.2.2.1 Using the positioning laser (optional) ....................................................... 39

8.2.3 Leveling the measuring platforms............................................................................ 39

8.2.4 Lowering the vehicle onto the measuring platforms ................................................ 40

8.2.5 Adjusting the toe laser ............................................................................................. 41

8.2.6 Functional testing of the toe lasers .......................................................................... 43

8.2.7 Adjusting the camber sensors (inclinometer)........................................................... 44

9Operation........................................................................................................................................ 46

9.1 Safety measures during normal operation ............................................................................ 46

9.2 Measuring the suspension .................................................................................................... 46

9.2.1 Measuring the wheel loads ...................................................................................... 46

9.2.2 Measuring the camber ............................................................................................. 47

9.2.3 Measuring the toe .................................................................................................... 47

9.2.4 Measuring the ride height ........................................................................................ 49

9.3 Operating the accessory components................................................................................... 50

9.3.1 Caster measurement ............................................................................................... 50

9.3.2 Platform elevations .................................................................................................. 52

9.3.3 Longer platform stands ............................................................................................ 52

9.3.4 CAN charger ............................................................................................................ 53

10 Faults and remedial measures..................................................................................................... 54

11 Service ............................................................................................................................................ 55

11.1 Safety measures when carrying out service ......................................................................... 55

11.2 Inspection and service work.................................................................................................. 56

11.2.1 Revision SetupWizzard............................................................................................ 56

11.2.2 Accumulators ........................................................................................................... 57

11.2.3 Batteries .................................................................................................................. 58

Contents

Wheel alignment system SetupWizzard III

11.2.4 Special service intervals ...........................................................................................58

11.2.4.1 Electrical equipment..................................................................................58

11.2.5 Service of third-party components............................................................................58

12 Decommissioning and disposal ...................................................................................................59

12.1 Decommissioning / Dismantling the machine ........................................................................59

13 Appendix .........................................................................................................................................60

13.1 EC Declaration of Conformity / Declaration of incorporation .................................................60

13.2 Attached documents ..............................................................................................................61

Contents

Wheel alignment system SetupWizzard 1

1 Introduction

Dear customer,

Thank you for deciding in favour of the SetupWizzard.

This operating manual provides all the information you need to operate the Wheel

alignment system SetupWizzard properly.

All persons responsible for operating, maintaining, cleaning, and troubleshooting the

measuring system must read, understand and heed the operating manual. This applies in

particular to the safety information that is given.

After reading the operating manual you will be able to

–Operate the measuring system safely

–Clean the measuring system according to the rules and regulations

–Take the necessary action in the event of a fault.

In addition to this operating manual, it is necessary to comply with the general laws and

other regulations concerning accident prevention and environmental protection in the

country of use.

This operating manual must always be kept at the measuring system’s point of deployment.

Contents

2CP Tech GmbH

1.1 Notational conventions

Passages of this operating manual that require special attention or are a direct hazard

warning are shown as follows:

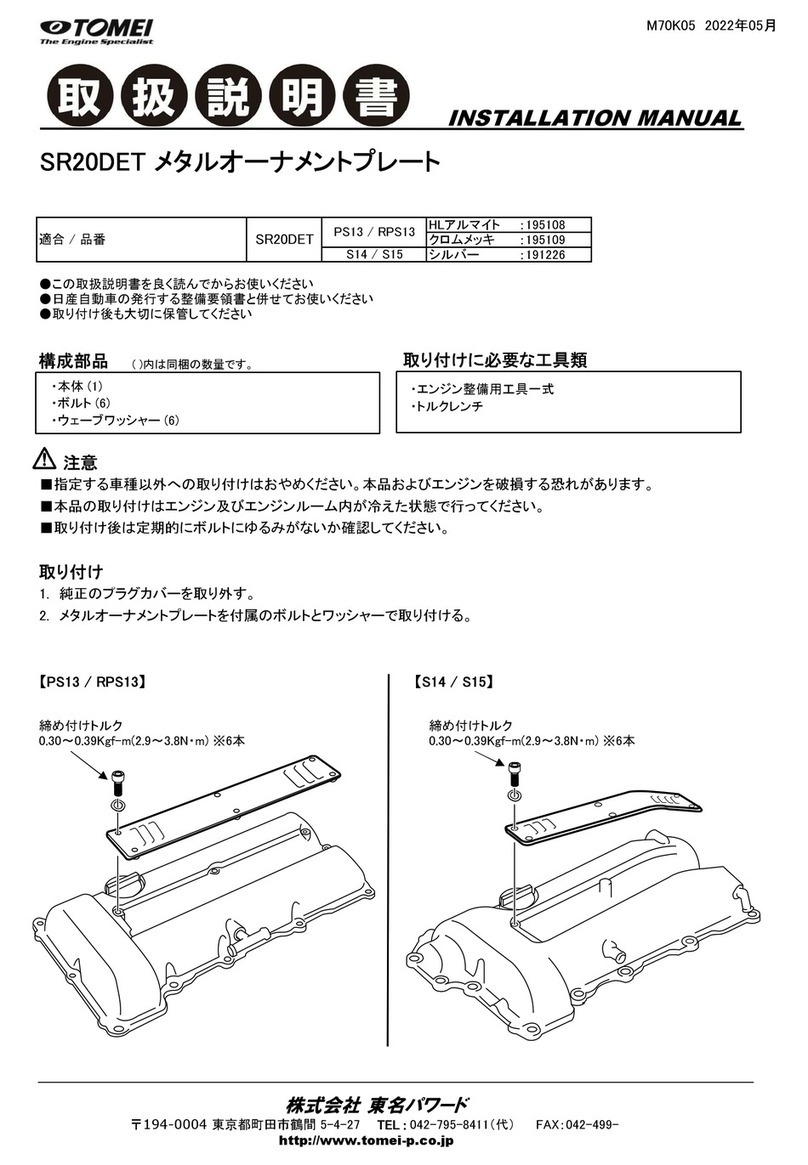

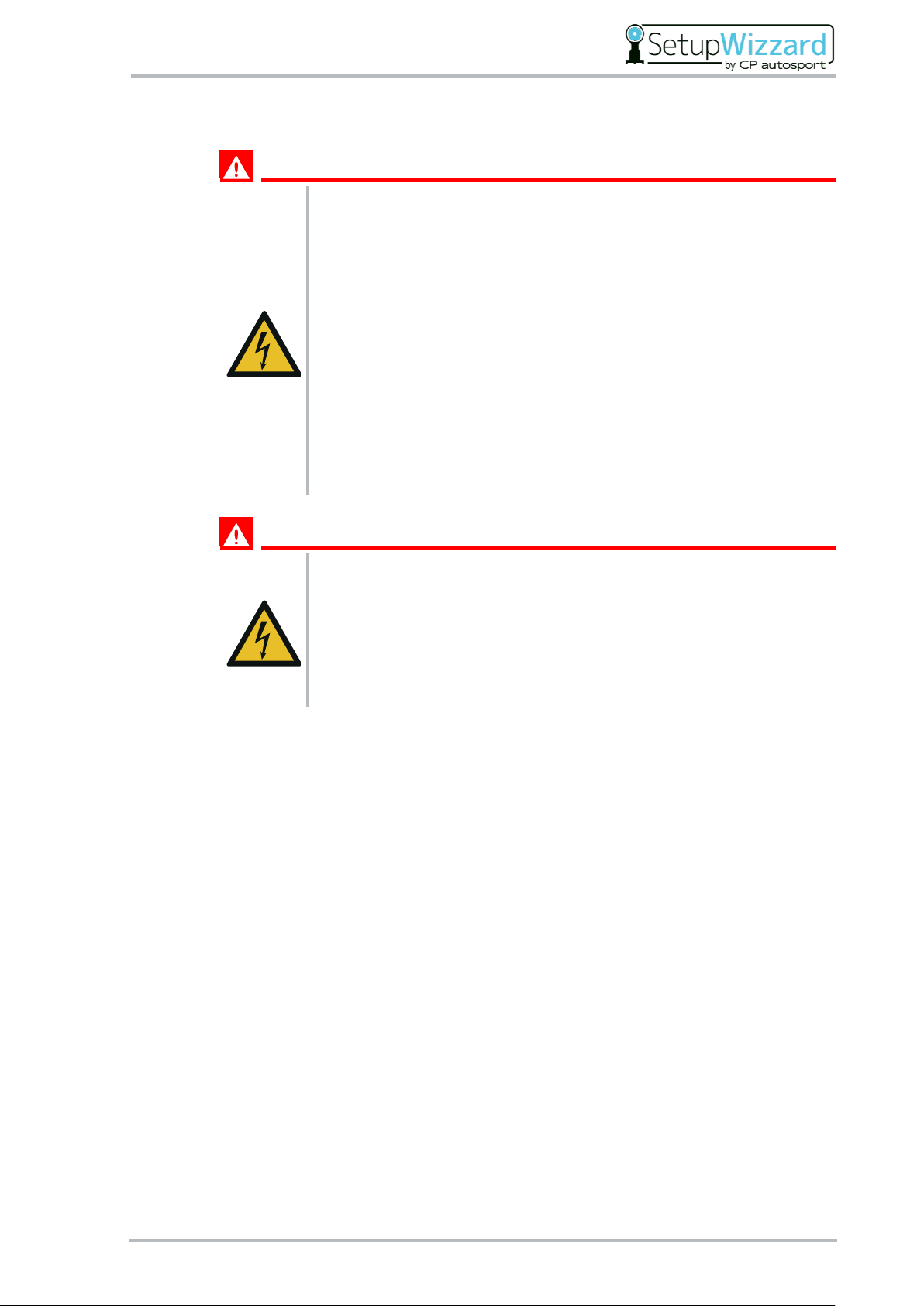

1.1.1 Section-related warnings

Section-related warnings are not limited to just one specific action but apply to all the

actions performed within a section.

Structure

SIGNAL WORD

Symbol

that

describes

the danger

in more

detail

Type and source of danger

Possible consequence(s) of failure to comply

–Measure(s) to avoid the danger

Danger levels

DANGER

Hazard which, unless avoided, may involve a high risk of death or serious

injury.

WARNING

Hazard which, unless avoided, may involve a medium risk of death or

serious injury.

CAUTION

Hazard which, unless avoided, may involve a minor risk of negligible or

moderate injury.

NOTE

Hazard which, unless avoided, may involve a low risk of material damage.

Contents

Wheel alignment system SetupWizzard 3

1.1.2 Embedded warnings

Embedded warnings apply to specific actions and are integrated directly in the action.

Structure

KEY WORD Type and source of the danger

Possible consequences of non adherence

–Measures to avoid the danger

Danger levels

–DANGER / WARNING / CAUTION

–NOTE

For explanations of the danger levels, see „1.1.1 Section-related warnings”.

1.1.3 Other notational conventions

The info symbol provides useful information.

–

Text following this mark represents an item in a list.

•

Text following this mark describes actions to be performed in the specified order.

„”

Text in double quotation marks refers to other chapters or sections.

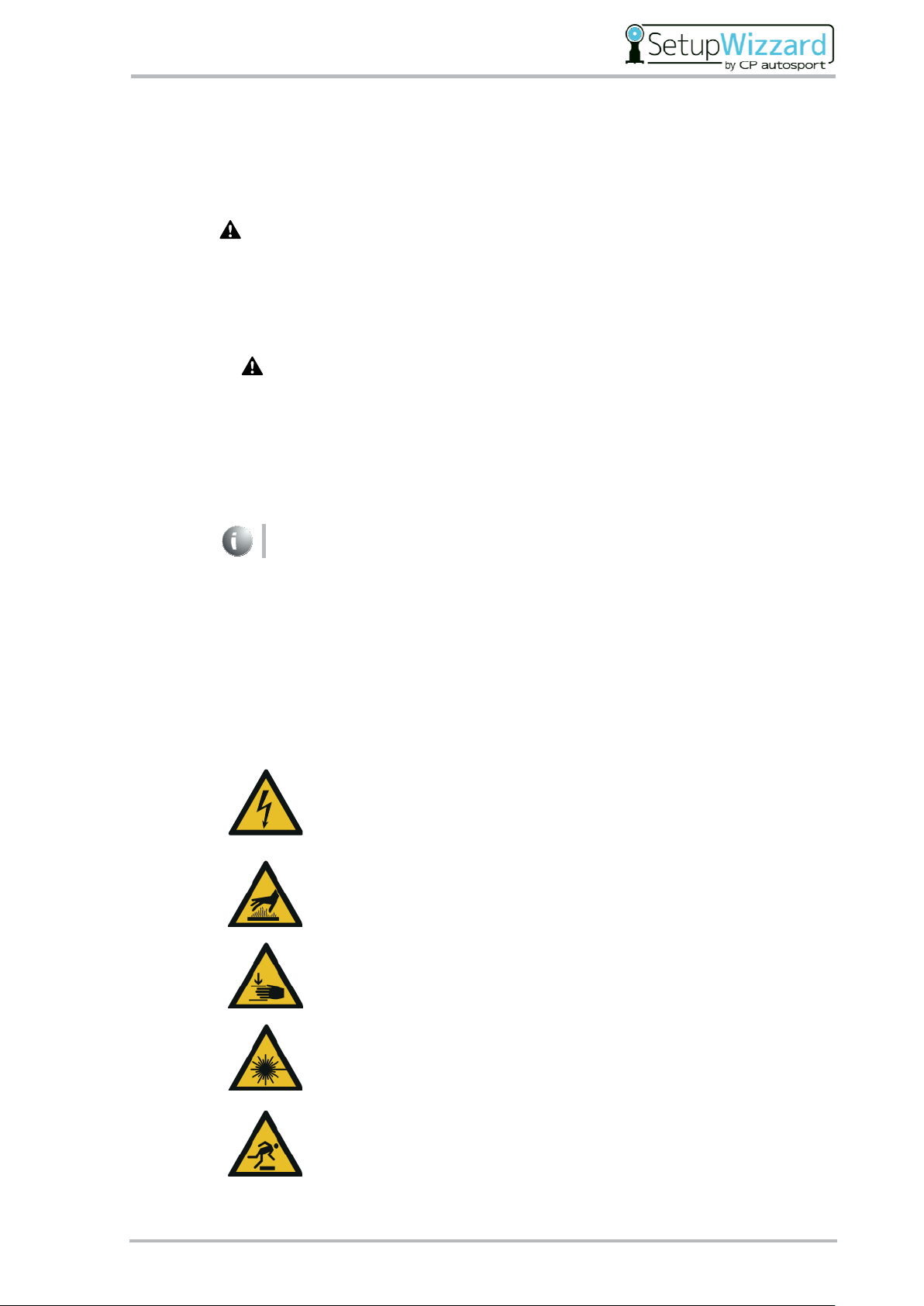

1.1.4 Symbols used in the manual

Particular hazards in connection with hazard warnings are shown in addition as follows:

Fatal injury hazard due to electricity

This symbol warns of a fatal injury hazard due to electricity.

Contact with live parts is a direct fatal injury hazard.

Warning of hot surface

This symbol warns of a burn hazard due to hot surfaces.

Warning of hand injury

This symbol warns of hand injuries when setting up the measuring system.

Warning of laser beams

This symbol warns of laser beams (leveling laser, toe laser, positioning

laser).

Warning of obstacles on the ground

This symbol warns of obstacles on the ground (cables, tools, ...).

Contents

4CP Tech GmbH

1.2 Warranty and liability

The obligations under the supply contract, the general delivery terms and conditions of the

measuring system and the legal regulations in force at the time the contract was signed will

apply.

All information in this operating manual has been compiled in line with the applicable

standards and regulations, the state of the art, and our longstanding knowledge and

experience.

Warranty and liability claims for personal injury and material damage are excluded if they

are attributable to one or more of the following causes:

–Unintended or inappropriate use of the measuring system

–Inappropriate installation, commissioning, operation, maintenance or cleaning of the

measuring system

–Operation of the measuring system with defective safety devices or with improperly

fitted or non-functional safety devices and guards

–Failure to heed information in the operating manual regarding installation,

commissioning, operation, maintenance, and cleaning of the measuring system

–Use of unqualified or inexperienced personnel

–Structural alterations to the measuring system (conversions or other alterations to the

measuring system are not allowed to be made without prior written permission from

CP Tech GmbH. Any breach of this causes the measuring system to lose its EC

conformity).

–Improperly executed repairs

–Use of non-permitted spare parts or of spare parts that do not satisfy the technically

established requirements

–Disasters, effects of extraneous elements and force majeure

We reserve the right to make technical alterations in the course of further development and

improvement of features.

Contents

Wheel alignment system SetupWizzard 5

1.3 Copyright

This operating manual is protected by copyright and intended for internal use only.

This operating manual or parts thereof must not be passed or disclosed to any third party

or be reproduced or exploited in any form without the prior written consent of

CP Tech GmbH except for internal use.

Contravention results in liability for damages. Further claims remain reserved.

1.4 Guarantee terms

The guarantee terms are contained in the general terms and conditions of CP Tech GmbH.

1.5 Service / Customer service

Our Customer Service department is at your disposal for any technical queries you

may have.

CP Tech GmbH

Dornierstraße 7

33142 Büren / Germany

Phone: +49 (0) 2955 / 4849-553

www.setupwizzard.com

In addition, our employees are consistently interested in new information and

experiences resulting from the application that may be of value in improving our

products.

Contents

6CP Tech GmbH

2 Safety

Failure to observe the safety information below may have serious

consequences:

–Risk to persons due to electrical, mechanical or chemical effects

–Failure of important functions

–Environmental damage due to leaking hazardous substances

Read the safety and hazard information in this section thoroughly before putting

the measuring system into operation.

In addition to the information specified in this operating manual, always comply with

general safety and accident prevention regulations.

Follow internal rules and regulations.

In addition to the information specified in this operating manual, the plant

operator/system operator must comply with national occupational, health and

safety regulations.

2.1 Intended use

The safety of the measuring system is only ensured if it is used as intended.

The measuring system is only intended for the measurement of vehicle suspension.

The measuring system is not intended for use other than as described here; other use

counts as inappropriate. In addition, the measuring system is only approved for vehicles

with a total vehicle weight of up to 2000kg or 500kg/wheel.

Intended use also includes:

–Observing all information from the operating manual

–Complying with the inspection and maintenance intervals

–Complying with the operating conditions

The technical specifications mentioned in the technical data must be complied with without

exception.

Only use the measuring system as intended; otherwise there is no guarantee of

safe and reliable operation.

It is not the manufacturer but the plant operator who is responsible for any and all

personal injuries and material damage resulting from unintended use.

Contents

Wheel alignment system SetupWizzard 7

2.1.1 Structural alterations to the measuring system

Construction and manufacturer's acceptance are based on the German Product Safety Act

(ProdSG). The measuring system is not allowed to be converted or otherwise altered

without prior written permission from CP Tech GmbH.

Any breach of this causes the measuring system to lose its EC conformity. Such a breach

absolves the manufacturer of the measuring system from warranty. This also applies to

welding work on components.

Any parts not in a perfect state must be replaced immediately.

Use original spare/wearing/accessory parts only. These parts have been specifically

designed for the measuring system. For parts from other sources there is no guarantee

that they have been designed and manufactured in line with load and safety requirements.

Parts and special features not delivered by CP Tech GmbH have not been released for use

with the measuring system.

2.1.2 Foreseeable misuse

Any use exceeding the concept of intended use and/or other use of the measuring system

can lead to severe injuries.

–Only use the measuring system for its intended purpose.

2.2 Personnel requirements

The measuring system is only allowed to be operated, maintained, and repaired by persons

who have been qualified and/or trained for this. These persons must know the operating

manual and act in accordance with it. The respective authorizations for personnel must be

defined clearly.

Personnel require the following qualifications for the various activities:

Qualified, instructed personnel (in this case, e.g., automotive mechatronics technicians)

Qualified personnel are able to do their work and recognize/avoid potential hazards on their

own as a result of their training, knowledge and experience and their familiarity with

regulations.

Electrical specialists

Electrical specialists are able to work on electrical equipment and recognize/avoid potential

hazards on their own as a result of their training, knowledge and experience and their

familiarity with standards and regulations.

Electrical specialists have been trained for their specific point of deployment and know the

relevant standards and regulations.

Contents

8CP Tech GmbH

2.2.1 Responsibilities

Inappropriate handling can lead to severe personal injury and material damage.

All activities must therefore be carried out by qualified personnel only.

–Personnel must consist of individuals who can be expected to perform their work

reliably. Individuals whose response is impaired by drugs, alcohol, medication, and the

like must not work on the measuring system.

–All persons working on the measuring system must read the operating manual and

confirm with their signature that they have understood it.

–Initially, personnel requiring training are only allowed to work on the measuring system

under the supervision of qualified personnel. The completion and success of instruction

must be confirmed in writing.

The plant operator is responsible for training and instructing personnel.

2.2.2 Obligations of personnel

Before working on or with the measuring system, all persons undertake the following:

–To comply with basic regulations concerning health and safety and accident prevention.

–To read the safety information and warnings in this operating manual and to confirm

with their signature that they have understood the issues.

2.2.3 Unauthorized persons

Unauthorized persons who do not have the required qualifications are not aware of the

hazards in the work area.

–Keep unauthorized persons away from the work area.

–Address persons in case of doubt and eject them from the work area if applicable.

–Interrupt work while any unauthorized persons are in the work area.

Contents

Wheel alignment system SetupWizzard 9

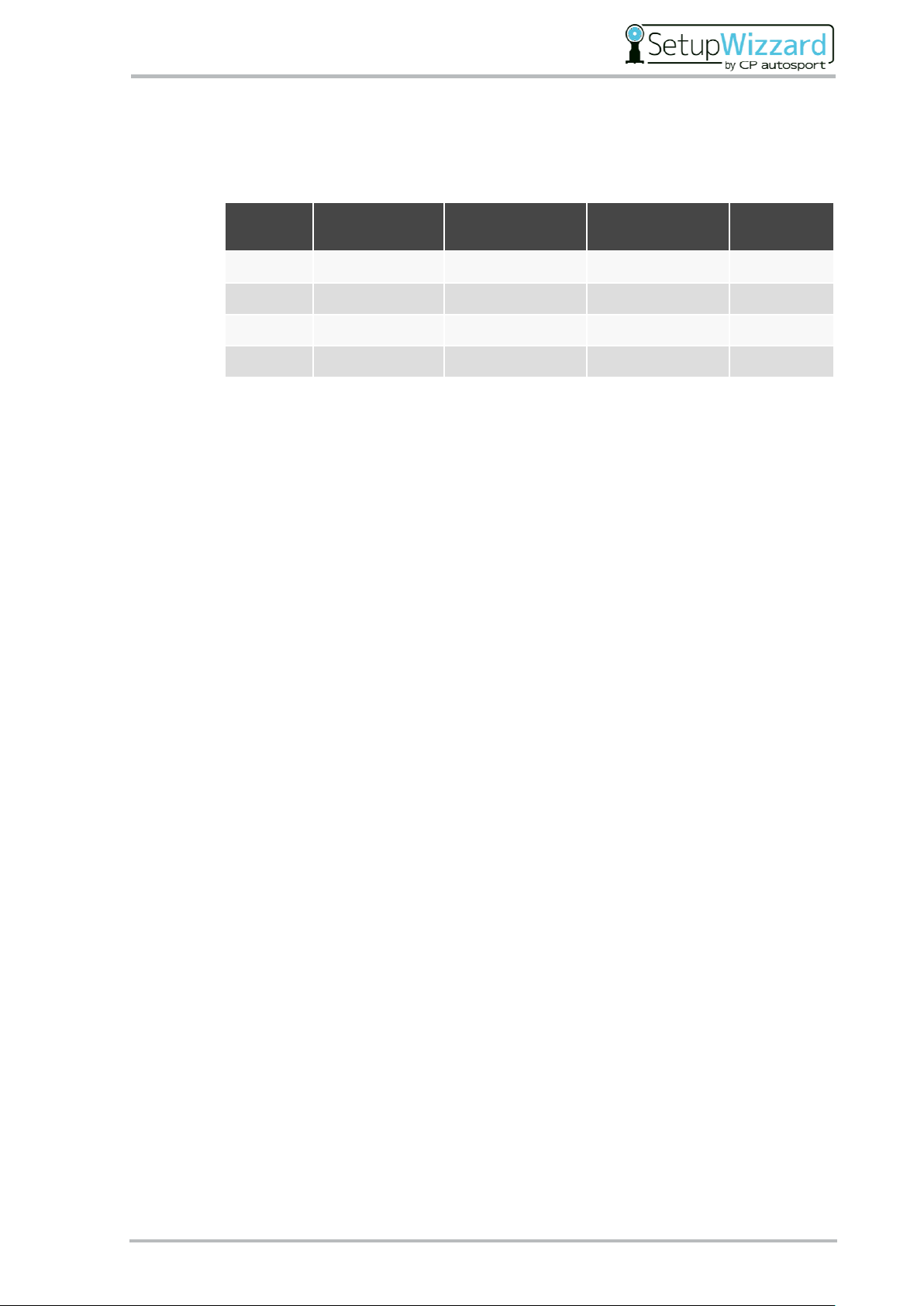

2.2.4 Instruction

The plant operator must instruct personnel at regular intervals. Keep a record of all

instructions given in order to keep track of matters.

Date

Name

Type of

instruction

Instruction given

by

Signature

2.3 General safety information

–Always read and understand the operating manual before operating and maintaining

the measuring system.

–Only use the measuring system for its intended purpose

(see „2.1 Intended use”).

–Do not work on the measuring system when other persons are present in the danger

zone.

–Refrain from any act which is likely to compromise the health and safety of people and

safe operation of the measuring system.

–Never operate the measuring system without the associated guards and safety devices.

Never take installed safety devices out of operation.

–Always keep the work area around the measuring system clean and tidy to prevent

hazards due to dirt and things lying around.

–Do not exceed the technical data (see „3.3 Technical data”).

–Keep all safety and hazard signs on the measuring system in a legible state and renew

them if necessary.

–Only qualified or trained personnel are allowed to operate or work on the measuring

system (see „2.2 Personnel requirements”).

–Take the measuring system out of operation immediately if a fault occurs. Have faults

rectified by appropriately trained specialists or by CP Tech GmbH.

–Always keep the operating manual at the measuring system’s point of deployment. It

must be ensured that all personnel working on the measuring system can view the

operating manual at any time.

Contents

10 CP Tech GmbH

2.4 Safety measures for environment protection

In all work obey the regulations for waste avoidance and proper waste disposal/recycling.

In the course of installation, maintenance and decommissioning, in particular, it must be

ensured that materials which could jeopardize the groundwater –such as greases, oils,

coolants, solvent-containing cleaning fluids and the like –do not pollute the ground or get

into the drains. These materials must be caught, kept and transported in suitable containers

and disposed of in compliance with national regulations.

2.5 Special hazard signs

2.5.1 Symbols used on the measuring system

Fatal injury hazard due to electricity

This symbol warns of fatal injury hazard due to electricity.

Contact with live parts is a direct fatal injury hazard.

Warning of hot surface

This symbol warns of a burn hazard due to hot surfaces.

Warning of hand injury

This symbol warns of hand injuries when setting up the measuring system.

Warning of laser beams

This symbol warns of laser beams (leveling laser, toe laser, positioning laser).

Warning of obstacles on the ground

This symbol warns of obstacles on the ground (cables, tools, ...).

Keep all safety and hazard signs on the measuring system in a legible state. Renew

the signs if necessary.

Contents

Wheel alignment system SetupWizzard 11

2.5.2 Hazards due to electricity

DANGER

Voltage

There is a hazard of electric shock from contact with live parts.

–Make sure electrical components are always fully closed.

–Have work at electrical equipment only be carried out by electrical

specialists who, as a result of their training, knowledge and experience,

are able to recognize and avoid potential hazards.

–Observe the five golden safety rules:

1. Disconnect completely

2. Secure against reconnection

3. Verify that it is disconnected

4. Carry out grounding and short circuiting

5. Project against live parts

DANGER

Voltage

An electric shock may have a number of secondary effects that lead to

additional injury (e.g. falling if working at height).

–Always observe the five golden safety rules when working on electrical

equipment.

–Only have electrical specialists carry out work on the electrical equipment.

–Before working on electrical equipment, switch off the measuring system and prevent

unexpected restoration of power.

–Only electrical specialists - e.g. plant electricians - are allowed to work on the electrical

equipment.

–Regularly check the electrical equipment for defects such as loose connections or

scorched cables. Have any defects rectified immediately.

–Have the electrical equipment and fixed electrical apparatuses tested by an electrical

specialist every 4 years at least.

Fixed electrical apparatuses are permanently installed apparatuses or apparatuses that

do not offer any carrying device and which, due to their weight, are difficult to move.

This also includes electrical equipment that is fitted on a temporary basis and operated

using movable device cabling.

–Have portable electrical equipment and extension and device cabling with plugs and

sockets tested by an electrical specialist, or by a trained person using suitable

inspection facilities, every 6 months at least.

Equipment is portable if, by its nature and in its normal use, it is moved while under

power. This includes, for example, electric floor cleaners.

–Alterations at electrical equipment made after testing must comply with DIN EN

60204-1.

Contents

12 CP Tech GmbH

–Check correct functioning of all the measuring system’s safety devices regularly.

–Only use original fuses.

–Have a damaged housing and pipes/hoses/cables repaired or replaced immediately

before switching on the measuring system.

–Ground the measuring system.

2.5.3 Hazards due to hot surfaces

Contact with hot parts can cause burns.

–Always wear protective clothing and safety gloves when working near hot parts (wheel

support, brake discs, brake caliper).

–Before maintenance and repair work, let all machine components cool down to the

ambient temperature.

2.5.4 Hazards due to incorrect spare parts

Incorrect or faulty spare parts may cause damage, malfunctioning or total failure, and may

also give rise to safety hazards.

–Use original spare parts only.

–Procure spare parts via CP Tech GmbH.

For the ordering of spare parts our customer service is at your disposal:

CP Tech GmbH

Dornierstraße 7

33142 Büren / Germany

Phone: +49 (0) 2955 / 4849-553

www.setupwizzard.com

In addition, our employees are consistently interested in new information and

experiences resulting from the application that may be of value in improving our

products.

Contents

Wheel alignment system SetupWizzard 13

2.6 Personal protective equipment

During measuring system operation, always wear personal protective equipment,

irrespective of the risk assessment at work, to minimize health hazards.

–Always wear the personal protective equipment required for the respective task when

carrying out work.

–Never wear rings, necklaces or other jewelry.

–In the work area, obey all signs relating to personal protective equipment.

Protective clothing

Protective clothing refers to tight-fitting working clothes that tear easily and

feature tight sleeves and no loose parts. They predominantly protect against

becoming entangled in moving machine parts.

Safety shoes

Wear non-slip safety shoes to protect yourself against heavy falling parts and

prevent you from slipping.

Safety gloves

Wear safety gloves to protect your hands against friction, abrasion, puncture

wounds or deeper injuries as well as against coming into direct contact with

hot surfaces or chemical substances.

The personal protective equipment must be provided by the plant operator and must be fit

for purpose.

It is also necessary to obey national regulations, the guidelines of the risk assessment at

work and, if applicable, the operator's internal instructions.

2.7 Safety devices and guards

–Before switching the measuring system on, always make sure that all safety devices

and guards have been fitted properly and are functional.

–When subcomponents are delivered, the plant operator must ensure that the guards are

fitted according to the rules.

Contents

14 CP Tech GmbH

2.8 Information for emergencies

Preventive measures

–Always be prepared for accidents or fires.

–Keep first aid equipment (first aid box, blankets etc.) and fire extinguishers at hand.

–Familiarize the personnel with accident reporting, first aid, fire-extinguishing, and rescue

equipment.

–Keep access routes for rescue vehicles clear.

Measures in the event of accidents

–Bring persons out of the danger zone.

–In the event of cardiac and/or respiratory arrest, initiate a resuscitation attempt

immediately.

–If anybody is injured, notify the first aid officer and the emergency medical service.

–Clear the access routes for rescue vehicles. If necessary, appoint a member of staff to

engage with fire and rescue services upon arrival and to provide them with the

appropriate information.

–Extinguish any burning oil/grease with a CO2or powder extinguisher.

–Use a CO2extinguisher to put out any fire in the electric control system.

Contents

Wheel alignment system SetupWizzard 15

2.9 Obligations of the plant operator

The measuring system is used in the commercial and private sector. The plant operator is

therefore subject to the legal requirements concerning health and safety at work.

In addition to the safety information in this operating manual, it is necessary to comply with

the safety, accident prevention and environmental protection regulations in force where the

measuring system is being used. The following applies in particular:

–The plant operator must ensure that the measuring system is only used as intended

(see „2.1 Intended use”).

–The plant operator must always keep the operating manual in a legible and complete

state at the measuring system’s point of deployment.

–The plant operator must clearly define and arrange the responsibilities for installation,

commissioning, operation and cleaning.

–The plant operator must verify that no individual working at the measuring system is

under the minimum age stipulated by law.

–The plant operator must only let suitably qualified and trained personnel work on the

measuring system.

–The plant operator must ensure that all personnel working on or with the measuring

system have read and understood this operating manual.

–Moreover, the plant operator must train staff and inform them about hazards at regular

intervals.

–The plant operator must provide personnel with personal protective equipment and also

ensure that this is used.

–The plant operator must make sure that individuals whose response is impaired by

drugs, alcohol, medication, and the like do not work on the measuring system.

In addition, the plant operator is responsible for keeping the measuring system in a perfect

technical state. So the following also applies:

–The plant operator must ensure compliance with the service intervals described in this

operating manual.

–The plant operator must regularly check that all safety devices are functioning correctly

and are complete.

–The plant operator must regularly check that all safety and warning signs on the

measuring system are legible and stay on the measuring system.

Table of contents

Popular Automobile Accessories manuals by other brands

Rainbow

Rainbow Experience Series installation manual

Hyundai

Hyundai 9999Z057196 Fitting instructions

ULTIMATE SPEED

ULTIMATE SPEED UAMM 12 B2 operating instructions

Federal Signal Corporation

Federal Signal Corporation CommCenter D1 Series Installation and service instructions

Yakima

Yakima K1249 instructions

ipf

ipf H4 installation manual