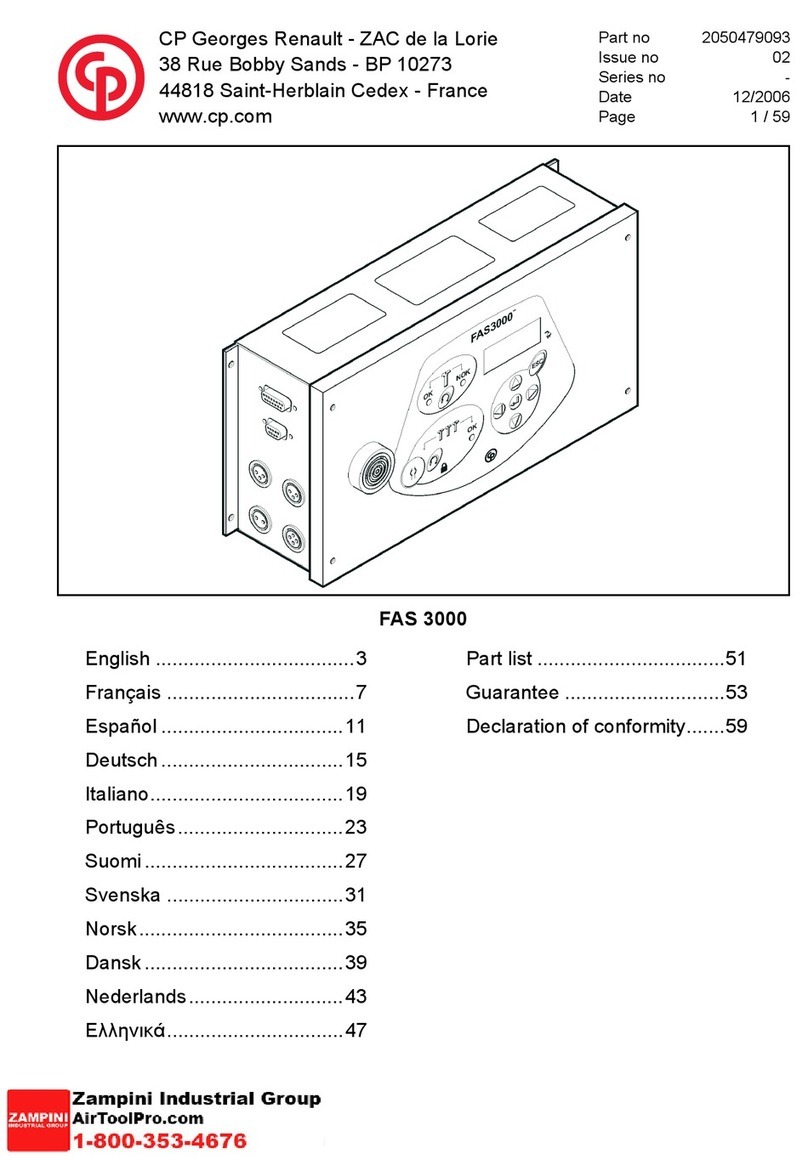

CP Desoutter FAS 3000 User manual

Part no

Issue no

Series no

Date

Page

CP Georges Renault - ZAC de la Lorie

38 Rue Bobby Sands - BP 10273

44818 Saint-Herblain Cedex - France

www.cp.com

2050479303

02

-

12/2006

1 / 218

English.................................... 3

Français................................ 21

Español................................. 39

Deutsch ................................ 57

Italiano .................................. 75

Português ............................. 93

Suomi ................................. 111

Svenska.............................. 129

Norsk .................................. 147

Dansk ................................. 165

Nederlands ......................... 183

ǼȜȜȘȞȚțȐ ............................. 201

FAS 3000 Flow Chart

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 3 / 218

OPERATION

Normal operation of the FAS3000 is depicted below. On power-up, the unit will display a series of identifiers, code

revisions, etc. and then remain on the "count» window. The count window displays the current parameter set and the

current number of fasteners completed toward a GROUP. Other statistics are also available to the operator without a key

or password by pressing the arrow keys on the keypad. These options are described below.

Power-up sequence

Parameter set Count The count is the number of completed

fasteners in the batch. When the count equals

the batch, the count will go back to zero and a

GROUP ACCEPT output will be generated.

Product identification

Firmware revision numbers

Pressing the left or right arrows will

advance the display to the next or

previous screen respectively.

If this button is pressed, the

operator will be prompted for a

four-digit password before entering

the program menu.

During screen changes, a description of the

next value to be displayed will be shown

momentarily.

This number denotes the number of fasteners

to be completed to get a GROUP ACCEPT.

The max group is 255.

The TOTAL represents the number of

completed groups. If the total exceeds 9999,

the total will begin to scroll to show all five

digits. The max total is 65,535. After 65,535 is

reached, the total will reset to zero.

Number of sensors (1 or 2)

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 4 / 218

SECURITY

The advanced settings and the GROUP RESET features of the FAS3000 are governed by a key-switch on the front of

the unit. Alternatively, a password may be used to enter the program menu or perform a GROUP RESET.

A four digit password may also be used to enter

the program menu or perform a GROUP

RESET.

The key-switch is used to unlock the advanced

features of the FAS3000.

When the key is in the locked position, the padlock-

shaped symbol will be illuminated, the program

menu will not be accessible, and the GROUP

RESET will not be available.

When the key is in the unlocked position, the

padlock-shaped symbol will not be illuminated and

all the afore mentioned features will be available.

This button can be used to enter the program

menu when unlocked, or to display the

password prompt when the unit is locked.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 5 / 218

SELECTING PARAMETER SETS

The FAS3000 has eight different parameter sets that can be used to store the qualification conditions for eight differing

fasteners. The parameter sets are referred to as sets A through H. The current parameter set can be selected using the

steps below:

Indicates the parameter set (A-H) that will

be used to qualify the fastener.

Use the arrow buttons on the keypad to

change parameter sets.

Press this key to switch to the selected

parameter set.

Press this key to exit the menu option

without making the change.

Allows external selection of parameter sets

with 15-pin sockets.

Do not use

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 6 / 218

PROGRAM MENU

The program menu provides access to all the setting, features, and qualification parameters of the FAS3000. The

illustration below shows the location of each of the menu options. Each menu option will be expanded in detail on the

following pages.

These messages will each be displayed

momentarily to indicate to the operator that

he or she is now entering the program

menu.

Use the Up and DOWN buttons on the

keypad to navigate the PROGRAM

MENU.

Press this key to select an item to edit

from the menu.

Press this button to exit or "go back" from

a selected menu item. If the program

menu was accessed with the password,

press this key to exit the program menu

and return to normal operation. The

FAS3000 will again be locked, and a

password or key will be needed to re-

enter the program menu.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 7 / 218

AUTO-CALIBRATION

Auto-Calibration allows the operator to record the signature of a properly tightened fastener by which to qualify

succeeding fasteners. On the FAS3000, the process will be performed as follows:

Indicates the parameter set that will be

calibrated, i.e. parameter set A.

Press this key any time to exit the Auto-

Cal process.

These statements will repeat until the proper

button is pressed to continue to the next step.

or

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 8 / 218

GROUPS

The group setting is the number of fasteners that need to be completed before the FAS3000 issues a GROUP-ACCEPT

output. If the sequencing feature is turned on, the group setting represents the number of fasteners that must be

completed before switching to the next parameter set in the sequence. A GROUP ACCEPT will be issued after the final

parameter set in the sequence is completed.

This number represents the number of fasteners in a GROUP.

One of the digits will be flashing. Use the up and down arrow

keys to increment or deincrement the flashing digit. Use the left

and right arrow keys to select the next digit for editing. The

maximum GROUP is 255.

Use these buttons to edit the next digit.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

increment or deincrement the flashing digit.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 9 / 218

CLEARING THE TOTAL

The total count is the number of GROUP ACCEPTs that have accumulated for the selected parameter set. The maximum

total is 65,535. The total can be cleared by selecting TOT in the program menu and following the steps below.

This message will scroll until the ENTER or ESC key is

pressed.

Press this key to set the total to zero and exit

the menu option.

Press this key to exit the menu option

without making the change.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 10 / 218

EXTERNAL SOLENOID DRIVER

The FAS3000 has a +24VDC output that can be enabled to shut off an air tool in the event of a NOK. The output can be

connected to an external solenoid to close an air valve, and in turn, disable the tool. The solenoid driver can be enabled

or disabled from the program menu as follows:

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to turn the

solenoid driver ON or OFF.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 11 / 218

SEQUENCING

The FAS3000 can be set to sequence through up to eight different parameter sets before issuing a GROUP ACCEPT.

Under SEQU in the program menu, the operator can choose the number of parameter sets to include in the sequence.

The FAS3000 will start in parameter set A. Upon completion of all the fasteners in group A, the FAS3000 will advance to

parameter set B and so on. The parameters in the sequence will have to be set up individually, i.e.: Auto-Cal, number of

fasteners in the group, etc. A GROUP RESET operation will also reset the sequence.

Press this key to save the change

and exit the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

select the number of parameter sets

in the sequence.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 12 / 218

BEEP ON ACCEPT

The FAS3000 will sound a double beep on GROUP ACCEPTS. This feature can be turned off in the program menu. The

FAS3000 will still beep on REJECTs.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to turn the

"beep on ACCEPT" feature ON or OFF.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 13 / 218

GROUP TIMER

The FAS3000 is equipped with a group timer that is enabled and started by applying +24VDC to the Group Timer Start

input. The group timer is stopped by a GROUP ACCEPT. If the group timer is allowed to expire, the OK LED will flash on

and off, and the error code ER06 will be displayed until the GROUP is complete or the GROUP RESET is activated. The

Group Timer Start input must be maintained in order for the timer to run. Also, the group timer must be disabled and

enabled in order to restart the timer. The maximum group time is 99.9 seconds.

When the cycle timer expires, this message will appear on the

display until the GROUP is complete or a GROUP RESET is

activation.

Use these buttons to edit the next digit.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

increment or deincrement the flashing digit.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 14 / 218

TIME LIMITS

The FAS3000 uses four time limits to qualify the fastening cycle. These time limits are set by the Auto-Cal process, but

are also available for editing in the program menu. Each timer has a maximum value of 64.00 seconds.

Use these buttons to edit the next digit.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

increment or deincrement the flashing digit.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 15 / 218

THRESHOLDS

The FAS3000 uses two thresholds to qualify the fastening cycle. These thresholds will be set during the Auto-Cal process,

but are also available for editing in the program menu. The thresholds are displayed as percent of full scale

(approximately PSI). The values range from 0 to 99.

Use these buttons to edit the next digit.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

increment or deincrement the flashing digit.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 16 / 218

PASSWORD

The password can be used to access the program menu without using the key-switch. The FAS3000 will ship with a

default password that should be changed by the customer. The password consists of a four-digit number that can be

changed in the program menu. The password may also be used to perform a GROUP RESET.

Use these buttons to edit the next digit.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to

increment or deincrement the flashing digit.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 17 / 218

ANALOG INPUT CHANNELS

The two analog input channels can be viewed if a trouble-shooting tool is needed. They are displayed as two percentages

from 0 to 99. These are the live readings from the two pressure trasducers.

Press this key to exit the menu option.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 18 / 218

NUMBER OF SENSORS

The FAS3000, version F1.11, B3.35 and higher, can be used with either 1 or 2 sensors. Select the number of sensors

via the "SENS" parameter. The number of sensors programmed is displayed at power up after the version screen.

Press this key to save the change and exit

the menu option.

Press this key to exit the menu option

without making the change.

Use these buttons on the keypad to select

the number of sensors

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 19 / 218

RESET OPERATION

In the event of a NOK, an error code will be displayed and the beeper will sound. The FAS3000 will need to be reset in

order to continue operating. The RESET button will clear the error status and allow the operator to finish the group of

fasteners. If the solenoid driver is enabled, the solenoid output will no longer source +24VDC.

GROUP RESET OPERATION

In the event of a NOK, an error code will be displayed and the beeper will sound. The FAS3000 will need to be reset in

order to continue operating. The GROUP RESET will clear the error code and reset the count to zero. If sequencing is

enabled, the FAS3000 will also go back to the beginning of the sequence. If the solenoid driver is enabled, the solenoid

output will no longer source +24VDC.

In the event of a NOK, a cycle reset can be

performed by pressing this button.

In the event of a NOK, a GROUP RESET can be

performed by unlocking the unit with the key or

password and pressing this button.

FAS 3000 FLOW CHART

Part no 2050479303

Issue no 02

Series no -

Date 12/2006

Page 20 / 218

ERROR CODES

The FAS3000 has seven error codes. The function and description of each error code are described below. In the event

of a NOK, the error code will be displayed and the beeper will sound until the operator performs a RESET. If the solenoid

driver is enabled, the solenoid output will source +24VDC until a RESET is performed.

"Screw Pre tightened".

This occurs if the clutch operates immediately within time t0.

Typical causes - Fastener is already tightened or cross threaded. The operator has "blipped" the

trigger/lever.

"Clutch operated too early".

This occurs if the clutch operates before time t1 and indicates the clutch has operated too early.

Typical causes: Screw is too short, has become cross threaded or is too tight. (i.e. Component

characteristics have changed, possible batch related problem), hole is not deep enough, screw too

long in a blind hole.

This problem could also occur if the air supply pressure has increased since the tool was last set

up. Alternatively, if the tool has just been serviced and or torque re-adjusted.

"Clutch operated too late".

This occurs if the clutch operates after time t2. Typical causes: Screw is too long in a through hole,

is too small a diameter, no thread, hole too large. It can also occur if the air supply pressure has

dropped and or the tool is becoming slow. Alternatively, if the tool has just been serviced and or

torque re-adjusted.

"Trigger/lever released too quickly after clutch operated".

This occurs if the trigger/lever is released too quickly after the clutch has operated. The check is

carried out with time t3.

Typical causes: Operator has released the trigger/lever too quickly after the clutch has operated

(But for a greater time then Timer t0).

Operators should be made aware of this feature.

"Trigger released before clutch operates".

This occurs if the trigger/lever is released before time limit t2 and before the clutch has operated.

Typical causes: Operator has released the trigger too early. (i.e. due to high ambient noise, may

sense that the tool has tightened and releases the trigger/lever).

Operators must wait for the Green OK LED to illuminate before releasing the trigger.

Problem with sensors, electrical Signals did not change.

This occurs if there is no change in the trigger/lever or clutch signals at the start of the cycle.

Typical causes: Defective sensor, broken sensor cable, tool requires repair or service.

In extreme cases, could be due to poor air supply to the tool.

When the cycle timer expires, this message will appear on the display until the GROUP is

complete or a GROUP RESET is activated.

Other manuals for Desoutter FAS 3000

1

Table of contents

Languages:

Other CP Power Tools manuals