Table of Contents

1/ 135

0 Table of Contents

1IMPORTANT SAFETY INSTRUCTIONS...................................................... -5

1.1 Warnings and symbols in this document................................... 5

1.1 Markings on the product.............................................................. 6

2Overview...................................................................................................... -8

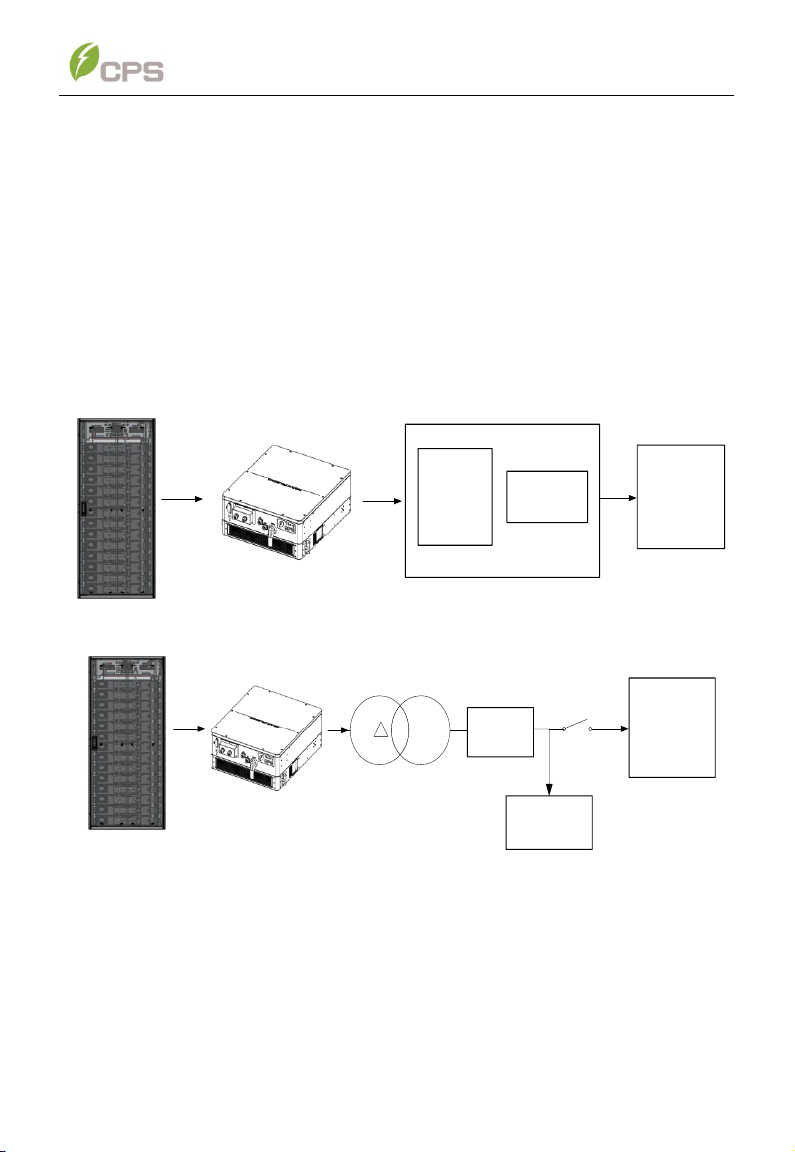

2.1 PCS for energy storage systems ................................................ 8

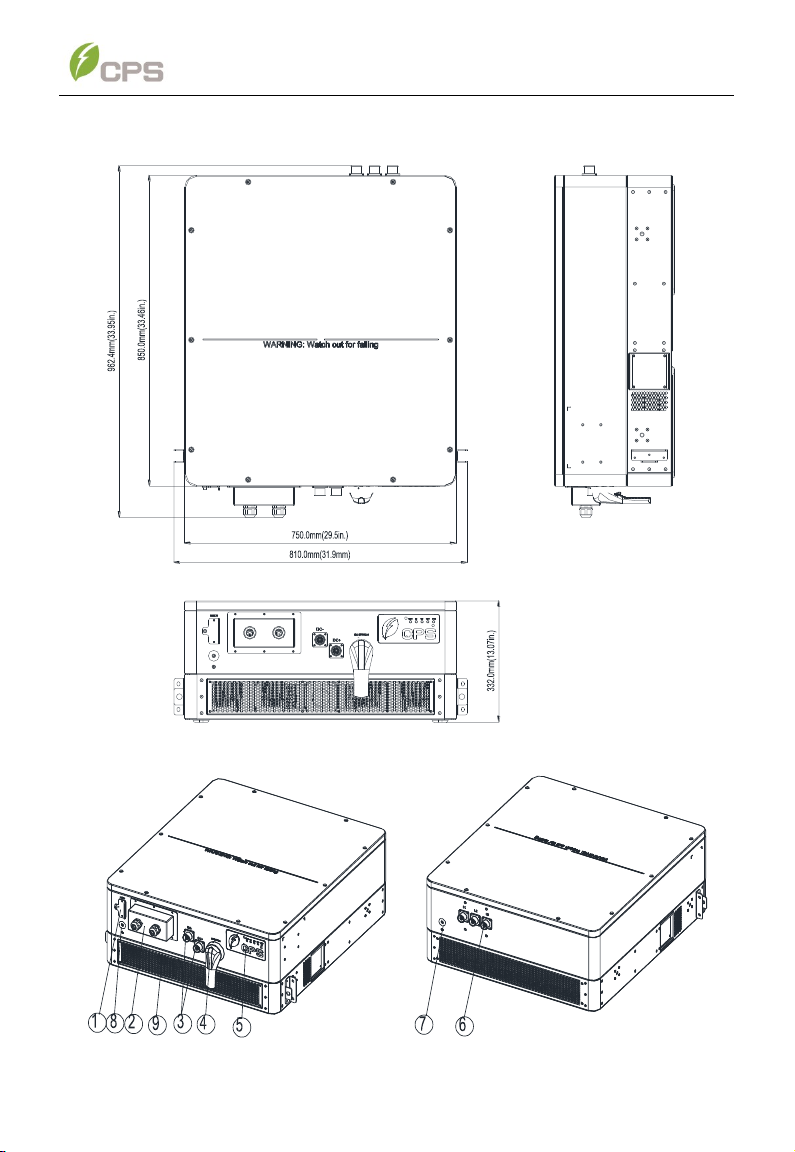

2.2 Appearance and Dimensions ...................................................... 9

2.3 Nameplate ..................................................................................... 10

2.4 Product features............................................................................11

2.5 Protection functions......................................................................11

2.6 Circuit structure design................................................................11

3Mechanical Installation ............................................................................-13

3.1 Unpacking for Inspection............................................................. 13

3.2 Installation Precautions ............................................................... 13

3.3 Installation Requirements............................................................ 14

3.3.1 Environment Requirements............................................. 14

3.3.2 Installation Modes ............................................................ 14

3.3.3 Space Requirements ........................................................ 14

3.4 Installation process...................................................................... 16

3.4.1 Prepare the mounting bracket......................................... 16

3.4.2 Lifting Instruction ............................................................. 18

3.4.3 Install the PCS .................................................................. 21

4Electrical Installation................................................................................-22

4.1 Cables specifications................................................................... 22

4.2 Tools Required and Torque Values ............................................. 22

4.3 Connection interface.................................................................... 22

4.4 AC and Ground connection ......................................................... 24

4.5 DC and Ground connection ......................................................... 25

4.6 Communication connection ........................................................ 26

4.6.1 Communication interfaces and cards............................. 26

4.6.2 LINKIT module Installation .............................................. 31

4.7 Connect with a CPS FlexOM Gateway ........................................ 32

5Commissioning.........................................................................................-37

5.1 Pre-commissioning Checklist ..................................................... 37

5.2 Commissioning steps .................................................................. 37

6User Interface............................................................................................-38

6.1 LED lights and indication............................................................. 38

6.2 Mobile application functions ....................................................... 39

6.2.1 APP download................................................................... 39

6.2.2 APP Setting ....................................................................... 39

6.2.3 Main menus of APP page................................................. 46

6.3 Web application functions ........................................................... 89

6.3.1 Ethernet connection and setting..................................... 89

6.3.2 Web application setting ................................................... 91