WarTar'ity ....................................... 2

Salety Rules .................................. 2-3

Unpacldng ..................................... 3

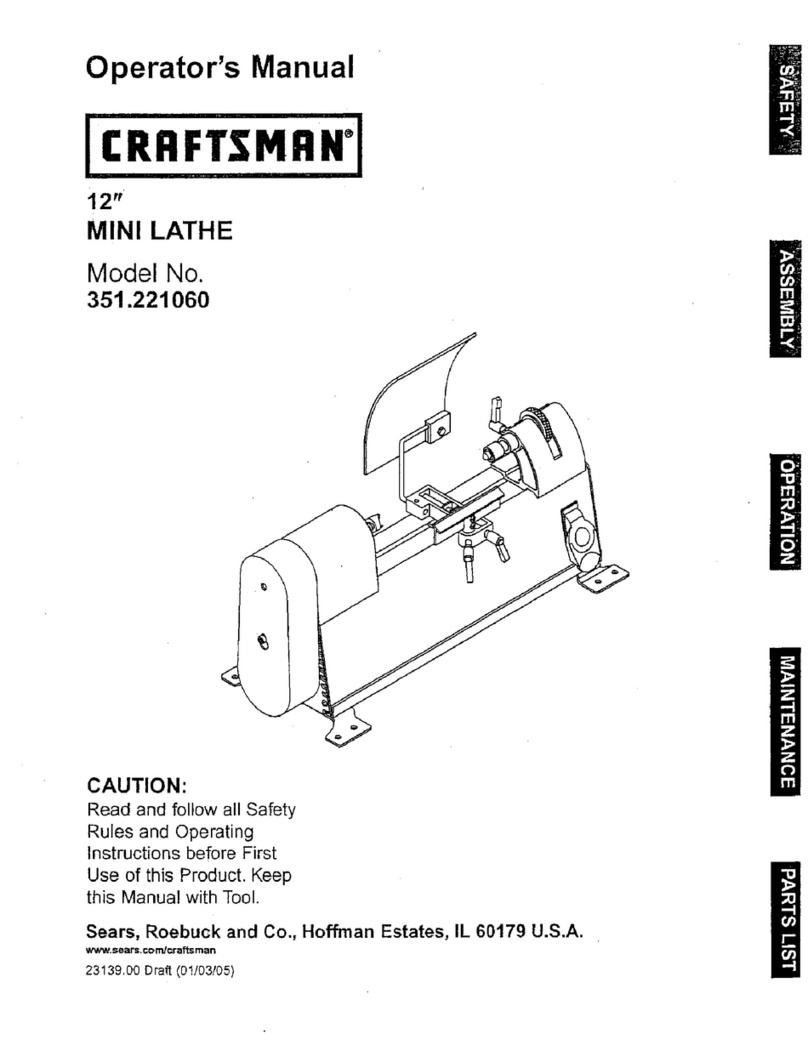

Assembly ...................................... 4

Installation .................................... 4,-6

Operation ................................... 8-19

Maintenance ................................... 20

Troubleshooting ................................ 21

Parts Illustration and Ust ....................... 24-27

Esp_of .................................... 28-51

FULL ONEYEAR WARRANTY ON CRAFTSMAN

VARIABLE SPEED WOOD LATHE

If this productfallsdue to a detectin materialor workmanship

withinone year fromthe date oi purchase,Sears will at its

optionrepair or replaceit tree dcharge. Contactyour near-

est Sears Service Center (1-800-4-MY-HOME) to arrangefor

productrepair,or return thisproductto place d purchasefor

replacement.

Ifthis productis usedfor commercialor rental purposes,this

warrantywill applyfor 90 days from the date of pumhase,

This warrantyappliesonly while thisproductis usedin the

UnitedStates.

This warrantygives you specificlegal rights, and you may

also have othar rightswhichvary from stateto state.

Sears, Roebuck and Co., Dept. 817WA, Hottman Estates,

IL 60179

CAUTION: Alwaysfollowproper operating proceduresas

definedin this manual-- even ifyou are familiarwith use of

this or similartools.Remember that being carelessfor even a

fractionct asecond can rasuit in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel.Do not wear loose dnthing,gloves,

neckties,rings,bracelets or other jewelry whichmayget

caught in movingpads of machine.

• Wear protectivehaircevedng tocontain longhair.

•Wear salety shoeswith non.aiipsoles.

•Wear saletyglasses onmplying with United StatasANSI

Z87.1. Everydayglasses have only impactresistantlens-

es.Thay are NOT safetyglasses.

•Wear face mask or dustmask it operationis dusty.

•Be alert and think dearly. Never operate power toolswhen

tired, intoKleatedor when taking medicationsthatcause

drowsiness.

PREPARE WORK AREA FOR JOB

Keepwork area dean. Clutteredworkareas ioviteacci-

dents.

Do not use power toets in dangerous environments. Do

not use power tools in damp or wet locations. Do nOt

expose power tools to rain.

•Work area should be properly lighted.

oSears, Roebuck and Co.

Keepvisitorsat a sate distancefrom workarea.

Keep childrenoutoi workplace.Make workshopchild-

proct.Use padlocks,master switchesor removeswitch

keysto preventany unintentionaluse of powertools.

Keep powercordsfrom coming in contactwith sharp

objects,oil, grease, and hOtsurfaces.

TOOL SHOULD BE MAINTAINED

Alwaysunplugtoolprior to inspection.

Consultmanualforspecificmaintainingand adjustingpro-

ceduras.

• Keep toollubricatedand clean for safest operation.

• Keep all pads in worldngorder.Check to determinethat

the guard orOtherpartswilloperate propertyand perform

their intendedfunction.

•Checkfor deranged parts.Check for alignment oi moving

pads, binding,breakage, mountingand any othercondi-

tionthatmay affecta tool'soperation.

•A guard or Otherpad that is damaged shouldbe properly

repairedor replaced.Do nntpedorm maksshiftrepairs.

(Use parts listprovidedto order replacementparts.)

•Never adjustattachments while running.Disconnectpower

to avoid accidentalstart-up.

•Havedamagedorworn powercordsreplacedimmediately,

• Keep cuttingtoolssharpfor efficientand s_est operation.

KNOW HOW TO USE TOOL

•Use righttoolforjob. Do notIorce toolor attachment to do

ajob forwhichit was notdesigned.

•Disconnecttoolwhen changingattachments.

•Avoidaccidentalstart-up.Make surethat the toniis in the

=off"positionbefore pluggingin, turning on satelydiscon-

nector activatingbreakers.

• Do not force tool.It willwork most efficientlyat the rate for

whichit was designed.

• K,_ephandsswayfromchuck,centers and Otharmoving

pads.

•Never leave toolrunningunattended.Turnthe power off

and do not leovetooluntilit comes to acompletestep.

•Do not overreach.Keepproper lootingand balance.

•Never stand ontool,Serious injury could occurit toolis

tippedor i' centers are unintentionallycontacted.

•Knowyourtool.Learnthe leers operation, application and

specificlimitations.

•Handleworkpiececorrectly.Mountfirmly in holding

devices.Protect handsfrom possibleinjury,

•Turnmachineoff ifworkplece splitsor becomesloose.

•Use cuttingtonleas recornmendedin =Operation."

WARNING: Forysurown salety,donot operateyOUrwood

latheuntilitiscompletelyassembledand installedaccordingto

instructions.

PROTECTION: EYES, HANDS, FACE, BODY, EARS

If any part ct your lathe is missing, malfunctioning,or has

been damaged orbrahen,cease operating immediately

untilthe particularpad is properlyrepaired or replaced,

•We="saletygogglesthatcomplywih UnitedStatesANSI

7R7.1 anda face sttaldordustmask it operatlen isdusty,

Wearear plugsor muffsduring _,.'tandedperiodsct operation.

Small loosepieces ofwood or other objectsthat contacta

spinning workplececan be propelledat very highspeed.

Thiscan be avoided by keeping the latheclean.