OPERATING INSTRUCTIONS

When unpacking, be very careful ro 9o through all papers thorouqhly

as no+ to mi* any parts.

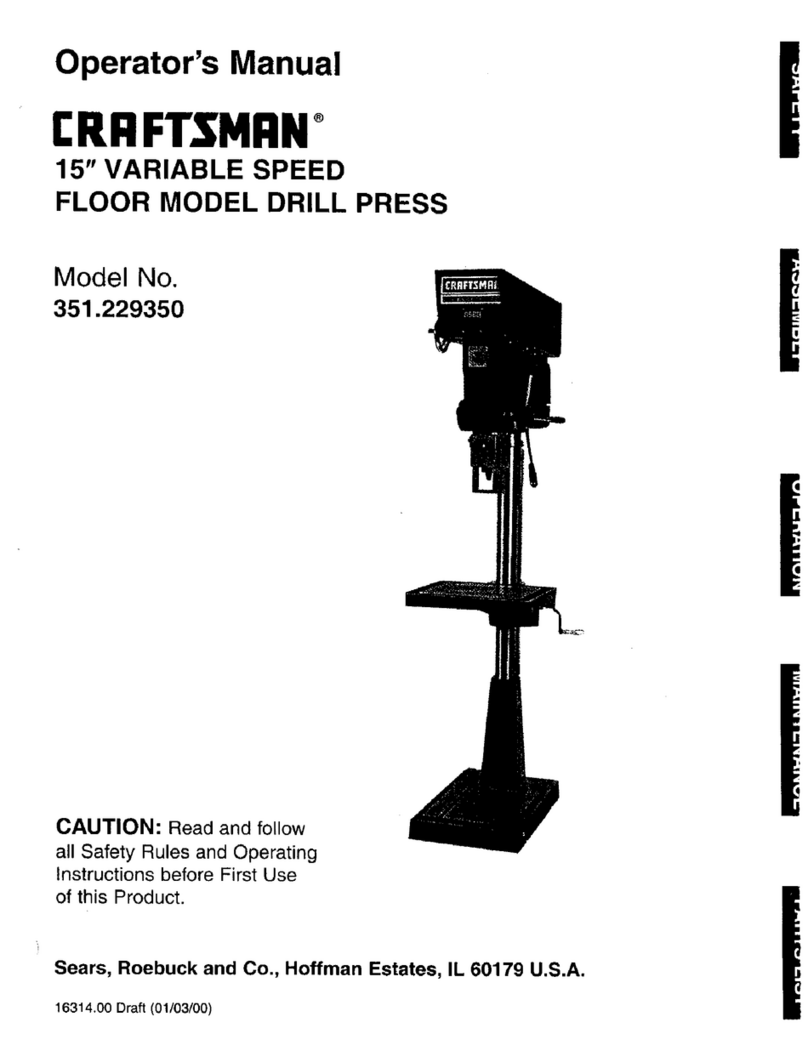

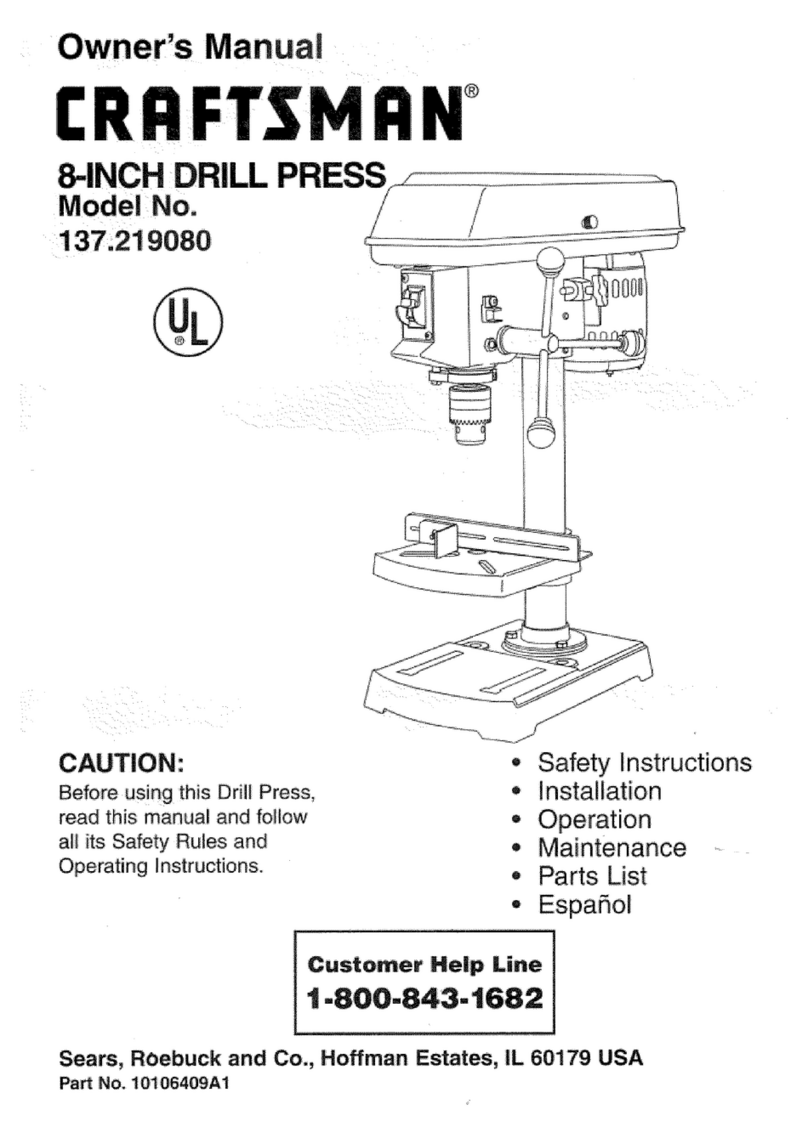

This drill press is desiened io be used {or all ordinary work with a

motor havinq " speed of approximately 1750 R.P,M. and with s,c\ a

mo+or will have n:ne dif{"rent speeds as {ollo*s: s80, 1300,2440dnd 5200

R.P.M. wilh moior in ro'mal pos;rion (pulleys in line); 1000, 1750 and

3300 R.P.M, with motor lowereo on molor base so thdt +op step o{

mofor pulley lines up wiih the secoid sreP on the spindle pulleyr 760

rnd 4,000 R.P.M. with motor .aised on moior base so rhai the top step

on tho spindle pulley lines r:p with the lhird s+eP on rho motor pulley.

l{ +he direct motor drive sef'up is r:sed, the moror should re'

'olve in a cloctwke dnection when facins ihe pulley end. lf it revolves

in the opposite directio., .everse this accordins to the manu{acturer's

instructions. When you are ,ure the motor revol"es properly, bolt it lo

ADIUSTMENTS AND CONTROLS DRILLING

(t) The eui k tocked in pos}ion by ru,n;rq rhe small lever located ,.,The prcper speed_ Ior drillins depends upo.' l. The malerial to be

"t +i,"'t.*", i,""i p"*-.iil" ti."a. drilled; 2. the size of the hole; 3. +he kind o{ drill. Generelly speakine,

(2) rhe rwo knurted nu*s on rhe.spindte srop sa!qe can be,er ar.aly li: lJjj;i. the material and the lareer the drill' the slower siould be

desired position and locked. ln this .ay a definite "mount of spindle

havel can be obtained ard dny rumoer of holes con be drilled +o a de-

sired deprh. Make sure tha+ the drill runs true when startin-g-ii may he necessary

(3) spindre Adiusrmenr-rr ronsi+udinar pr.y deveropes in rhe.spindre l:flll::ii!r-i:"';l;r"ti"1"';l''.,'1""'l',"T l;r"':l"".,tx,: :*;t:

it may be eliminared as foilows: {ll Re-mc,e spindle 9Lr..d a-n! the two hiqI a speed, 'esp.ciatty'*trh rhe la,ser d,ilts-exclssi'e speed wear ofl

lock nut5 on the {eed srop bracket, (21 Remove th; drill'coriex, dra*J th" +".per-"f rhe drill, and |n"v "*" f,ri .,

:prinq housinq by loosenine the set screw on the b.""k th. d,ili ii"-

unoe*:de of the boss, (3) Remove {eed lever and

pinion s[d{t d{ter roosening +he set screw in the

:ortar ad:acen+ -o +he heai, l4) putt spindle and Note: W[en drilline bruss, aluminum, lead and other so{t maierials

",rli a.-'"1",J "ia ,"-.," i.J.'r,""a. ist Loosen -hkh .cause. +he drill ro 'hoe-in", reduce_ the rEke dnel€ o+ the curtins

,J ,** r" ""rt", ai,""rrv "r.," qui d;d while edee by srindine rhe drill as shown in Fis. a. This reduced roke .nsle

i..i"s *. ,pindte up ag!in+ fhe Lolom of rhe is alrc delirable vhen,drillins very hard materials because i+ lessens the

o,rit, iioii." il" ."tt"'. ,p'.q"i,'+ rhe inner race of strain on the.drill. Thir chanee males drilline easier and ,esults in a

il" l1ifi s"",iis. o" -i .ll" this adius+dlent roo more accuratelv drilled hore'

fhs mounting braclet. localins it csntrally on lhe provided slots. Atlach

the molor pulley to +he shaft wi*h the large s+ep on top. Since +hk drill

press is a bench model, it should be securely bolted in+o position. l{ the

base does not iouch rhe bench top evenly, place shims whe,e requned.

lf +his p"ocedure is nof followed the Sase may be sprung, and unsatis-

iactory cond;tions may result.

lr +he coun+erehaf+ and idle. pulley are +o be used rl,e motor

should revol'e ii d counreFcloclwise direc+ion when {acin9 +he pulley

end. Bolt rhe Drill Press to the bench 6nd attach the counterohafl

in position as shown. Locate the molor pulley on the sh.ft wirh +he

large end oul and directly under the counrersha{t. Bolt the motor +o

lhe bench, put +he belt in the desired groove, and the Drill Press is

roady for operation. When usinq the belr in one of rhe smaller motor

pulley 9roc,ves, pull out the counfershaft +o keep the bel+ tigh+.

ihe quilr bearine. Do not maIe thk adius+ment loo more dccurarerv drrrred hc

tishr, (6) Put spindle back inio rhe drill head and Lubrication: A cultins compound is

reassemble. essenrial when drillins pracfically any

lal To Reno,e ChucL {'or Spirdre-See Fieure me+al- The {ollowing compor:nds will

l. Use the -edqe pro,ided fo' this pr:rpose. grve best r.u'ts:

Fio. I ,N.r\,k'Ar\,-.rev'e,.abu,e yoL, a,,., e,.t,,"i; I *':1"::""t '' 31---t""n'Ftin" d l"-'

- Do no+ strike ;+ wi+h d h6mne", bump rt, or drop rt - -

ar any time. u* *" *,"""i i,,ii't"a *iri ri" "t',"1. sofrer sreels-lard oil or equivalent.

ls) To adiust tension on Quill Return Spring-Turn the spring hous AJuminum 'nd other so{t al'ovs-kero-

r"o '*,"+.,"r.j"1,r'" i. i"",""i" +" tensionj To',elease +he tensiin. pull

,ri*".J "" +.-,"tli"r-p."t 1,.u. Brass-drill dry or use parafiin oil.

l6) T.ole Adi,r#,-ert-To ti t the ble, pul. ou+ the krurled \an e Die canings-drill drv or use le'osene'

r"""ili i"""rir- i""""ii rr," r"si.'""a rernserf afrer ad;u*ment ras casr iron-drilr dry.

been made. If the rable is tilted 90 desrees right or left, t}e knuled Do not aftemPt to make large holes

shourd the followins repla:e.m.ent.e.yel bicome necessarv, +he fottow- '".,"']r'";:L"'ftil:;:il;t.:;:r,;!

ine irstalra+ioi c199ed19 s!r91ld 1._.f9ll.iy:d, ,pi,ar" a"", ".+ .:u" enrir;ty ouroflhe

( I I QUILL BUMPER REPLACEMEN I:-

l.'nJ..," +i",pr"Jr"-q,irr ,"it +.- *" r""a as described ,"r". :l1li,; ?fl"l":l::'*il"Jfll #ll:i

section 4 of "spindle adiusrmen+.' ,",,triu* .sr"i"ua by ;,i"s .,; ";b. Remo,e old bunper and {orce ne" bumPer ;nto Posiiion bv ,io"-ro""a "++""t.."t showri inria.z.

m"ars of d lone, slir .od. Maie.sure. rhe. bunper seats ilselt ProPerrv This "'ri"+;""1 ;,;,td; " i.;;p1;;

belore re-installins tle spindle quill unit inio the head. o{ 200 R.p.M. t+ can be a*ached o.

"i" "."-s" t,,"*.a in Ihe holes p-"ia.i. io: iny internediate are e in a smali pieco or in thin -rarerial Fig'

il,e tubt" -,+ he locled in pldce by tishten:ns the nu'. wilhoL,t first clampins the .ork securely

to the table. For ma:rimum accuracy,

IMPORT'ANT_LUBRICATION derached in ress rhan iwo minures.

USE S.A.E. No.20 MACHINE OIL

A. Upper Spindle Pulley Bear;n9-Oil l'e- DRILLS: Afrer the drill point is dulled {or ihe lirst lime, i+s ,)ffs..

.'eness depends entirely upon how :r is .e9roLnd. For clean. accurate

drilling, the operator rusr rerharpen tre d,i.l prope,ly. The cone+haped

su{ace dt the end o{ the drill is cdlled the "point', and the edqe at

rhe extreme rip end is.ihe "dead center'.

c.

D.

E.

Quill Bedrincs-Oil frequenlly. (Note:

Sp ndle must be in lowes+ posi+io. tc

unccver oil hole)-

Pinion Sha{+ Hub-Oil occasionally.

Lower Quill Bearine-Oil {requenily.

Lower Spindle Pulley Bearins-Fill erease

cup with Lubrico M-6 Grease every+hree

Quill Surface-Oil should frequently be:p

plied to the olrlside sur{ace of +his quill. The

spindle cap .hould 6e removed frequen+ly end

oil applied to tie splined spindle also.

FIG.3

DEAD

BODY

-2 -