SAFETY RULES ....................................................... 2

FULL SIZE HARDWARE CHART ............................ 3

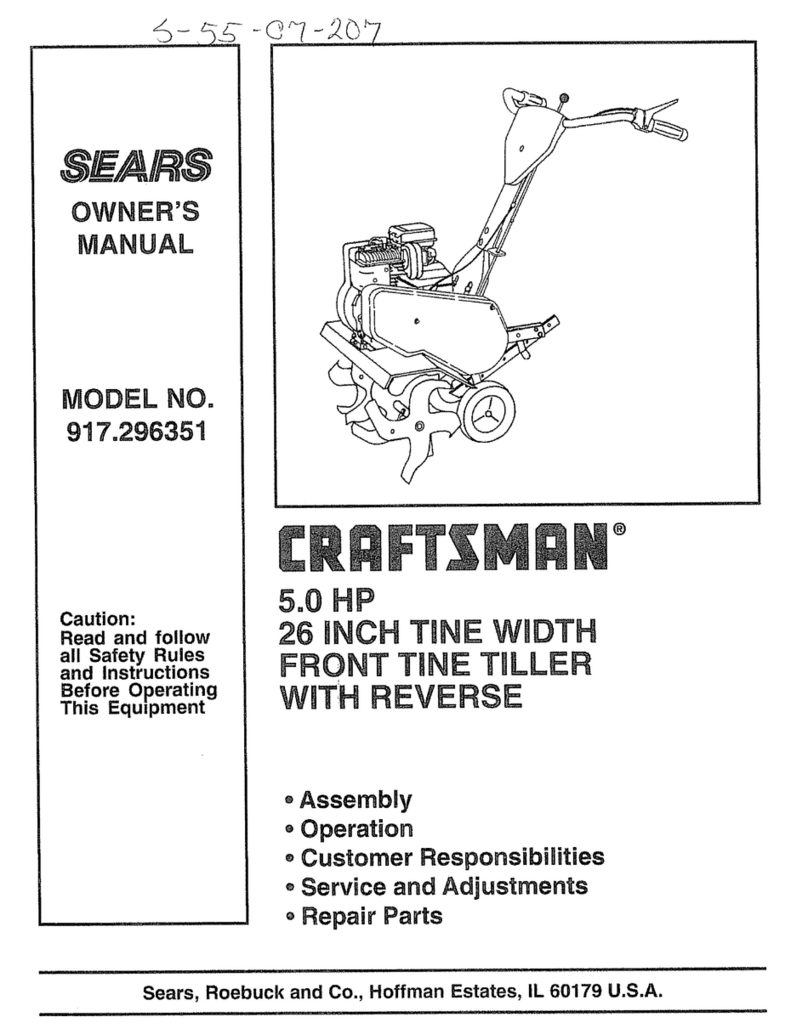

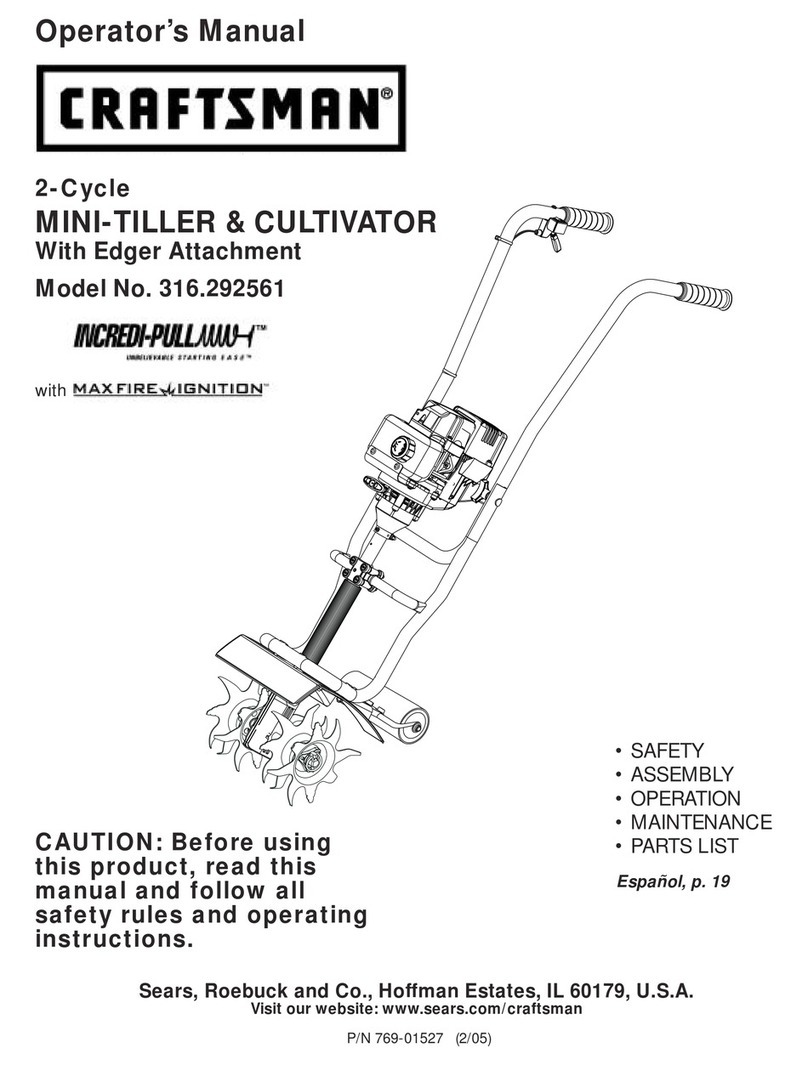

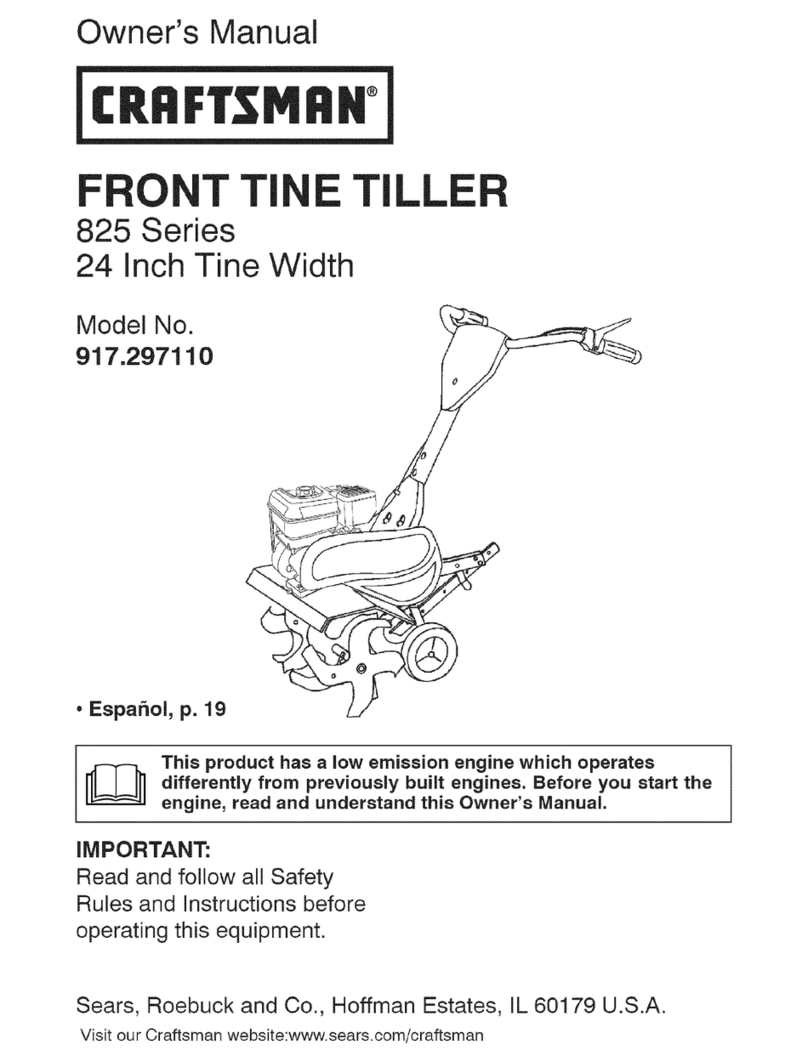

ASSEMBLY ............................................................... 4

OPERATION ............................................................. 6

MAINTENANCE ........................................................ 7

SERVICE AND ADJUSTMENTS .............................. 7

STORAGE ................................................................. 7

REPAIR PARTS ILLUSTRATION ........................... 8

REPAIR PARTS LIST ............................................... 9

PARTS ORDERING/SERVICE ................. Back Page

LIMITED ONE YEAR WARRANTY ON

For one yearfrom the date of purchase, when this aeratorismaintained and lubricated accordingto the operatingand

maintenance instructions in the owner's manual, Sears will repair any defect in material or workmanship free of charge.

If this aerator is used for commercial or rental purposes, this warranty applies for only 90 days from the date of purchase.

This warrantydoes notcoverrepairsnecessary because of operator negligenceor abuse,includingthe failure tomaintain

the equipment according to instructions contained in the owner's manual. ,

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT

IN THE UNITED STATES.

Thiswarrantyappliesonly whilethis productisinthe UnitedStates.

This warrantygives youspecificlegalrights,and you may alsohave otherrightswhichvaryfrom stateto state.

Sears, Roebuckand Co. D/817 WA. HoffmanEstates,Chicago, IL 60179

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate

the equipment. Exercise caution at all times, when using power equipment.

•Read the owners manual carefullyfor operatingand

service instructions before attempting to assemble or

operate this equipment. Be thoroughly familiar with

the proper use of this equipment.

• Read the vehicle owners manual and vehicle safety

rules, and know how to operate the vehicle before

using this equipment.

• Never allow children to operate the tractor or spike

aerator attachment, and do not allow adults to operate

withoutproper instructions.

• Wear eye protection when operating the aerator.

• Wear substantial footwear when operating the

aerator.

• Do not allow anyone to ride or siton spike aerator

attachment frame or on towing vehicle.

• Keep the area of operation clear of all persons,

particularly small children, and also pets.

•Alwaysbegin with the transmission in first (low)gear

and engine at low speed, and graduallyincrease

speed as conditionspermit.

• The vehiclebrakingand stabilitymay be affectedwith

the attachmentof thisequipment. Beaware of

changingconditionsonslopes. Refer to safety rulesin

the vehicleowner'smanual concerningsafe operation

on slopes.STAY OFF OF STEEP SLOPES.

• Always operateup and down a slope, never across

theface of a slope

• This equipmentshouldbe operated at reducedspeed

on roughterrain,alongcreeks and ditchesand on

hillsides,to preventtippingand lossof control.Do not

drivetoo closeto a creek or a ditch.

• Do nottow thisequipmenton ahighwayor anyother

publicthoroughfare.

•Followthe maintenance instructionsas outlinedinthis

ownersmanual.

Look for this symbol to point out important safety precautions. It mean--Attention!!

Become alert!! Your safety Is involved.

The model number and serialnumber will be found on a

decal attached to the spike shield.

You should record both the serial number and the date of

purchase and keep in a safe place for future reference.

I

MODEL NUMBER: 486.24372 I

I

SERIAL NUMBER:

DATE OF PURCHASE: