Craind Impianti KPO User manual

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

OF METERS

KPO

INTRODUCTION

A semi positive displacement rotary piston flow transducer type

KPO is situated in the liquid line, which detects the transfer of

very small volumes of liquid. A magnetically operated switch

converts the piston movement irato impulses which are transferred

along Mn screened wire to remote electronic counting/control

devices.

INSTALLATION

Location of Meter.

It is recommended that the meter be fitted irato a vertical section

of the pipe run wherever possible. With the meter fitted irato

horizontal pipe, it is possible that errors in registration can be

caused by the settling of the piston due to gravity within the

measuring chamber after shut off. The moviment of the piston after

metering has ceased can trigger the reed switch and create an extra

pulse. The meter should be fitted up stream of any flow control

device, thus preventing free discharge front the meter and

minimizing the risk of draining and vopour locking causing

erroneous reading on start up.

Preparation of Pipework.

Before fitting the meter irato position, the following points should

be checked:

That unions or flanges of correct size and spacification have

been fitted to the pipeline in the required position. Joints

requiring the application of heat must never be mode with !he

meter in position.

That the distance between unions or flanges is correct far the

meter to be fitted.

That the two unions or flanges are in line, and all local

pipework is unstrained and correctly supported. This is

particulary significant when using meters constructed in PVC.

The pipeline must be purged of al/ rust, swarf, welding slag

jointing compound by flushing or similar means before

putting the meter irato service.

Installation of Meter.

To prevent damage to the REED switch encapsulations, they

should beremoved belare fitting the meter fin to the fine.

As the meter are bi-directional (i.e. flow may take place in either

direction) direction arrows are not required and the meter may

be fitted directlyin to the system.

Pag.1

REED switch can now be replaced on the meter in the recesses

provided.

Excessive tightening of the reed switch securing screws should

be guarded against at all times.

Meters should not be fitted systems which are subjected to any

excessive hydraulic shock, or damage to the meter internals may

result.

Electrical Connections.

Electrical connections between the meter and the indicating of

control instrument shall be made using screened cable. Thereed

switch assembly is provided with a short length of flying lead. The

reed switch is encapsulatedin hermeticallyepoxyresin. The switch

withstand temperature up 100°C and is completely waterproofed

The maximum recommended lenght of cable is 100 metres.

Dismantling.

The meter has been designed to require the minimum of

maintenance. However, genera/ planned maintenance is

recommended and the following procedures maybe adopted

for alt maintenance purposes:

Isolate the meter from its source of supply and if possible drain

it.

Remove the REED switch.

Remove the meter from the pipeline by undoing the union nuts

and springing the pipework slightly to disconnect the

connections or with flanged version of the meter by undoing

flanged bolls and sliding the meter from belween the system

flanges.

Empityliquid from the meter.

Undo the socked head cap screws from one end of the meter

and remove the end port. Some resistance will be felt when

removingthe parte as an "O" ring seal is located on the end

place spigot.

Remove the piston chamber place by lifting vertical/y out of the

bodyusing the centreknob provided.

Remove piston bygently lifting from the body.

Pag. 2

Invert the meter and repeat.

Remove barrier plate from the slot in the body.

Havingcompletelydismantled meter al/ components maybe

thoroughlywashed in warm soapywater. On no account should

abrasive materials be used to clean the meter parts as meter

accuracy relies upon the maintenance of controlled clearances.

Inspection and Assembly

Inspect the barrier plate for wear, which if present will

manifest it self in the form of "waisting"or hollowing of the

barrier surface. Any reduction in barrier thickness will

permit the passage of un measuring liquid. If in doubt a new

barrier should be obtained and fitted

Examine the piston chamber plates for wear and scouring,

the latter will only occur in extreme cases when large

abrasive particles have passed through the measuring

chamber. Any mild signs of scouring ascertained be

polished out with metal polish and self cloth. Plates

displaying heavy signs of wear should be replaced and the

cause of scouring ascertained and a suitable strainer fitted

up-stream of the meter before re-installation of the meter in

the pipework system.

Examine the meter end plates and in particular the "O" ring

seal. It is recoininended that new "O" rings be fitted on

assembly as used rings tend to take a permanent set and

leakage could occur due to the "rings"inability to reseal

(This is particulary true with PTFE "O" rings). If an "O"

ring has been damaged during fit must be replaced

A piston chamber plate may now be re-assembled to the

body taking care to line up the radial barrier slot with the

axial slot in the body.

Re-fit the end plate and loosely screw home the socket head

cap screws.

Invert the meter and replace the barrier into its slot.

Inspect the piston for signs of wear and ensure that no

particles are embedded in the piston wall. The points of

greatest wear are the outside diameter and the incide

diameter of the piston , and rise jaws of the radial pear shaped

can slot.

Replace the piston fin to chamber, feeding the can slot over

the barrier plate and check that for al/ positions of the piston

within the chamber, the ainount of "sfide play" or free

movement is not excessive and that the piston rotates within

the chamber.

Replace the second chamber plate and end cover.

To check that small meters are operating correctly after

assembly, place meter to lips and blow into the connection. The

rotation of the piston within the chamber should be apparent.

Pag.3

OPERATION

Commissioning

immediately after installation or after long periods of shut

down the meter must be slowly purged of air. This is most

effectively achieved by allowing the liquid to be metered !o

flow through the meter at a slowly increasing rate until the

maximum through put is achieved

The inter is now ready to be put fin to service and will

accurately in measure all liquid passing through it, provided it

is not operate outside the limits.

METER DIMENSIONS

Pag.4

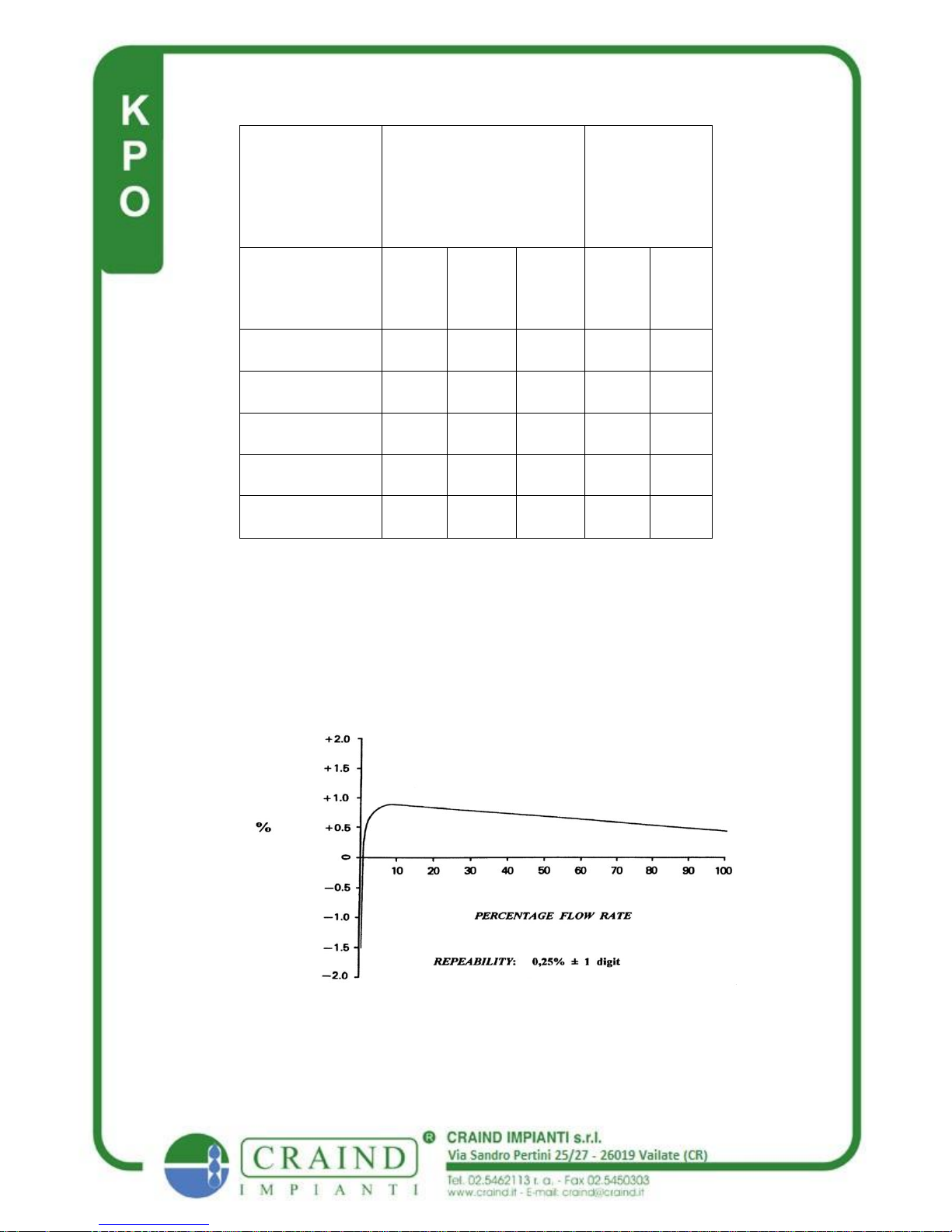

TYPICAL ACCURA CY CURVE

Pag.5

METER

DIMENSIONS

(mm)

WEIGHT

(N)

TYPE

A

B

C

AISI

PVC

0 KPO 'A"

86

60

12

1

0,4

KPO 0 1"

122

95

13

4

1 ,5

KPO 0 1 '/z"

145

145

18

13

2,7

KPO 0 2"

171

205

19

21

3,8

KPO 0 3"

210

250

25

26

6

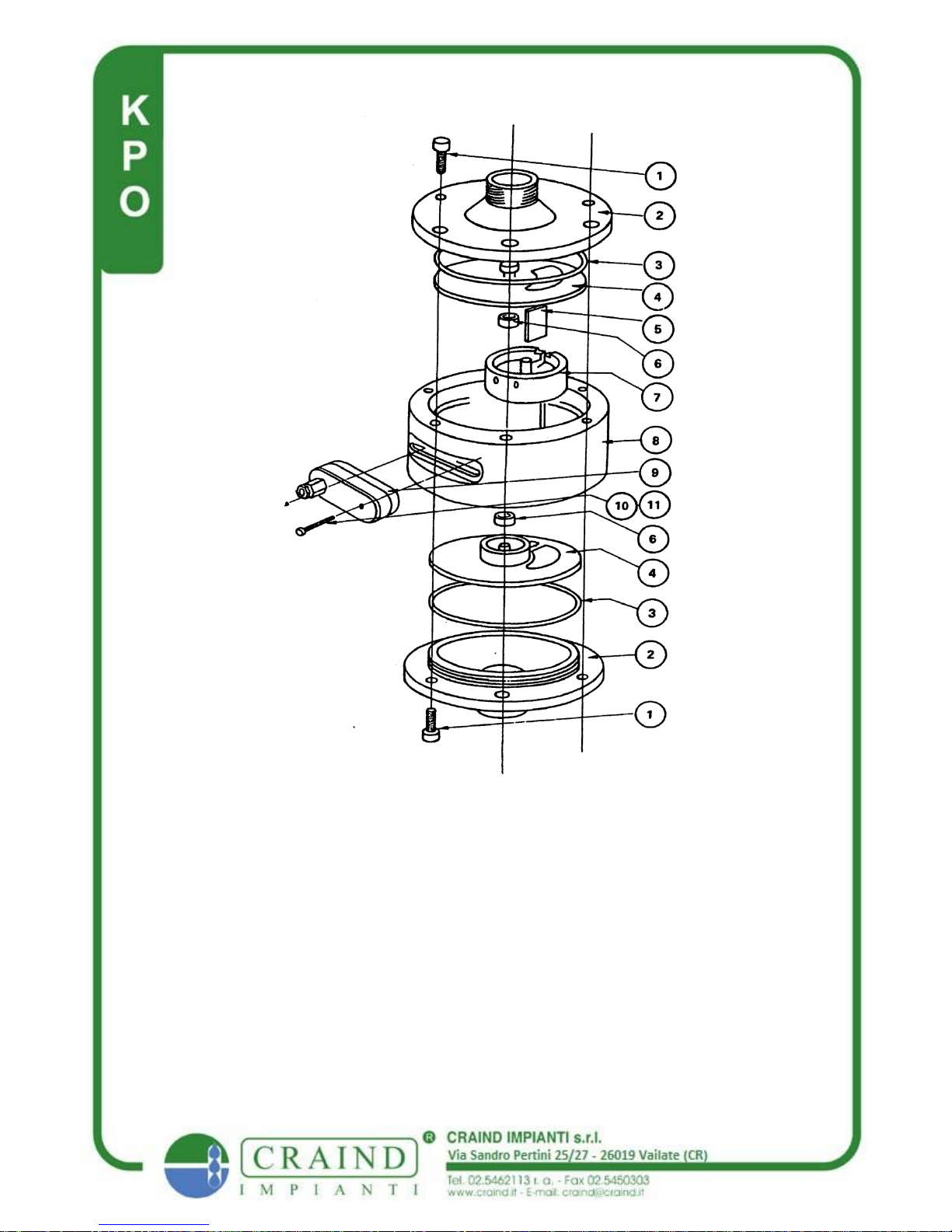

Bodyscrew 9)reed switch Screw

1)End Nate 10)Reed switch Washer

2)'O' Ring

3)Plate Assd.

4)Barrier

5)Roller

6) Piston

7)Body

8)Reed Switch Pag.6

Spare parts

It is recommende that the following parts be held in stock as

spares:

N. piston

N.1 Reed switch

N.2 roller (only for 2" and 3"meters)

N.1 barrier plate

N.2 'O"rings seal

ASSOCIATED EQUIPMENT

Filters

In order to guard against seizure of the meter working parts, due to

the ingress of oversized particles too large to be swept through the

meter, it is recommended that filter be fitted up-stream of the meter

to filterout particles in excess of 0,1 mm in diameter. For further

infomation do not exitate to contact our Technical Department in

CRAIND IMPIANTI

Valves

Remotely controlled valves, when fitted, should be of the fast

closingtype to minimized the effect of over-run at the end of a

batch delivery. Generally, pneumatically operated valves are

recomended. Our Technical Department in CRAIND IMPIANTI

will be pleased to offer a suitably spiced valve to suit your

requirements.

Pumps

Use pumps free from pulsation (centrifugal or volumetric types).

Positive displace rent pumps inherently produce pulsations which

can cause measurement errors.

Air Separation

If thereis danger of entrained air being present in the liquid then a

suitable de-aeration device must be installed upstream of the meter

otherwise air will be measured as liquid.

Pag.7

HYGIENICDESIGN

The body components (s.s. version) are manufactured from

AISI 316 stainless steel and are ready dismantled for

maintenance and cleaning. Due to the hygienic design and

self-flushing action, the mete, lends itself to in-line steam

sterilization. As a result the CRAIND IMPIANTI KPO meter

is used in a wide renge of applications in the brewing,

distilling, food ,drinks and pharmaceutical industries.

CLEANING IN SITE

When a system is to be cleaned in place, sterilized or purged

without removal of the meter from the line, it is advisable to

provi de the meter with a by-pass to prevent damage

occurring to the internal working parts unless the following

reccommenations can be adhered to:

Liquid detergent temperatures in excess of the maximum

stated in the meter speciation should not be used for

cleaning purposes or distortion and expansion of the piston

will result, causing the piston to "bind"within the chamber.

Check that cleaning fluid will not attack or corrode the

material of the meter.

Sterelization with steam is not admitted. If it is necessary

the pressure of the in-coming steam to the meter must be

carefully controlled so that the velocity of the piston

within the chamber is kept below 75% of its maximum

velocity when metering with liquids. The sane must be

done when purging the system with air.

After steam sterilization or air purging during re-charging

of the pipe with fluid, care must be taken to avoid impact

of high speed fluid re-entering the empty measuring

chamber.

Pag.8

ATTENTION:• It is very dangerous to empty the mete,

by using air, nitrogen or steam. If it !s necessary be very

careful during the operation. Moment emptying will

inevitably damage the piston

TECHNICAL CARATTERISTCHS AND MATERIALS

MODEL

LO

MODEL

PORTATA

FLOW RATE

IMPULS

I

PULSES

AISI316

PVC

POLIPRO

P.

PVDF

Min Max

I/b

cc x imp

T

max

°C

P

max

bar

T

max

°C

P

max

bar

T

max

°C

P

max

bar

T

max

°C

P

max

bar

KPO'/:"

30 400

8,5

80

10

KPO1"

200 2.200

50

80

10

35

3,5

45

3,5

60

3,5

KPO1'/"

400 6.000

220

80

10

35

3,5

45

3,5

_60

3,5

I~O 2"

500 9.000

500

80

10

35

3,5

45

3,5

60

3,5

KPO 3"

800 20.000

500(2

reed)

80

10

35

3,5

45

3,5

60

3,5

emitted pulses number is theoretical and it refers to water

PISTONS MATERIALS : PTFE - PVC -

ALLUMINIO - PIK MOD.

O.R MATERIALS:VITON - Pl I-E - EPDM –

NITRILE

SENSOR TYPE

following types of sensor are available

REED

HALL EFFECT

HALL EFFECT

Pag.9

CYCLE OF OPERATION

FIG.1

The piston is over the inlet port, the inflowing liquid has

entered the incide wall of the piston and is causing it to start

its semi-rotary movement, sliding down the division piece,

displacing the neutral liquid which becomes the out owing

liquid as it is expelled through the outlet port.

FIG.2

Shows the above operation taking place with the inflowing

liquid both inside and outside the piston

FIG.3

Shows the inflowing liquid on the inlet ride of the chamber

with the neutral liquid on the incide of the piston and with the

out owing liquid passing to the outlet port.

FIG.4

Shows the completion of the exhaust period and the

commencement of the inlet period.

FAULT FINDING

If the metering system is not functioning correctly:

First check the operation of the indicator or control instrument

correctly:

Disconnect the signal input connections to the instrument and

simulate the pulsations of the reed switch at the meter by

intermittently short circuiting the input signal terminals at the

rear of the instrument. If the appropriate pulses are not

received on the indicating or control equipment, then these

units must be checked as described in the appropriate

instruction manual. If pulses are received and indicated then

re-connect a signal input cable.

Check that the interconnection cable is satisfactory by:

Disconnecting the other end of the cable from the reed switch

connection. Short circuit the conductors and see whether or

not pulses are received on the control equipment at the other

end of signal cable. If pulses are not received then there is a

break somewhere in the interconnection cable and it should be

replaced. If pulses are received re-connect the cable.

Pag.10

Check the operation of the reed switch by:

Remove the reed switch assembly from the meter and

connect a battery ohm meter.

Pass a normal magnet across of the reed switch and if the

resistance changes from at least I mega ohm to less than I ohm

due to the movement of the magnet, the reed switch is

operative.

To check that the piston is rotating whilst liquid is flowing:

1)Hold an ordinary magnetic compass near the reed switch

recess in the meter body. If the needle oscillates wildly the

piston is moving.

2)A visual ( check can be made on the quantity of liquid

flowing through the system with the control device fully

open. If the flow rate is drastically below that normally

delivered the piston could be stationary and helping to

produce a prohibitive head loss across the meter.

3)Adjust the system flow rate to its maximum and check for

a slight vibration of the meter caused by a rotating piston. If

all the previouslymentioned checks prove satisfactory then

the meter must be removed front the line and dismantled and

inspected as detailed in maintenance sections.

Possible causes of imperfect operation are:

1)A fractured piston allowing the passing of unmetered

fluid.

2)Resistance to motion of the piston due to:

- Particles of foreign matter embedded in the working

surfaces of the meter.

- A "gummed up "meter due to ineffective

temperature control or. settling out during "shut or.

- A distorted piston due to operation at

temperatures in excess of the maximum allow .

- Worn barrier or rollers allowing the piston to "cock"

during operation are not in the right position.

- Bent piston pegs due to excessive pressure drop

across the meter.

Pag.11

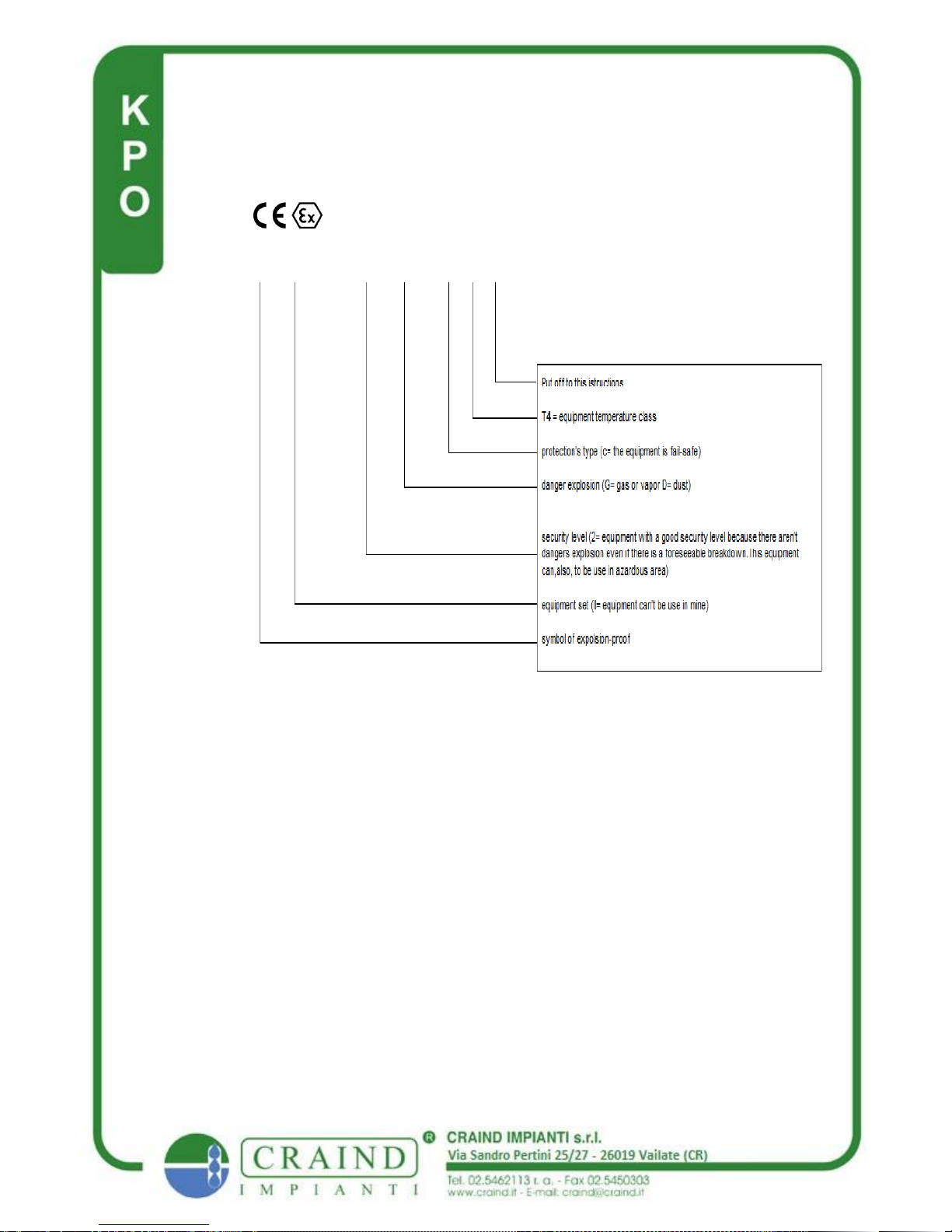

This addict istructions and informations completate the

istruction’s manual and the standard’s service.

1- What operating

features have

Your equipment?

1.1 - Marking and

esplications.

All of Yours equipment have this label

Pag.12

ATEX: ADDICT

ISTRUCTIONS AND

IN FORMATION

II 2 GD c T4 X

2- THE DATAS THAT YOU MUST CONTROL DURING

THE OPERATION

DANGER EXPLOSION!

The observance of the instruction contained in this chapter can

be produce severe damages to the people,

or it can be cause the death! This instructions don’t prescind

from an appropriate utilization of the equipment

and from the istructions on the generic instruction’s manual.

Pag.13

Note 1: refer to the individual instructions for the other

accessory united to the meter.

Note 2: all meters must be assembled with this follow addict

precaution

Pag.14

ATEX: ADDICT

ISTRUCTIONS AND

IN FORMATION

Table of contents

Other Craind Impianti Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Mgl

Mgl Blaze AHRS-2 operating manual

Campbell

Campbell 109B instruction manual

Pessl Instruments

Pessl Instruments METOS LoRAIN NBIoT user manual

CORNING

CORNING ONE OIU Quick installation sheet

Mirion Technologies

Mirion Technologies TelePole II user guide

Endress+Hauser

Endress+Hauser Prothermo NMT 538 operating manual

Hama

Hama 00137289 operating instructions

PCB Piezotronics

PCB Piezotronics IMI SENSORS 637A06 Installation and operating manual

ADVANTEST

ADVANTEST R3267 series Operation manual

ALCO

ALCO AL-82933 Installation and use instruction

Honeywell

Honeywell Enraf 977 instruction manual

PIETRO FIORENTINI

PIETRO FIORENTINI MODUS Series Technical manual