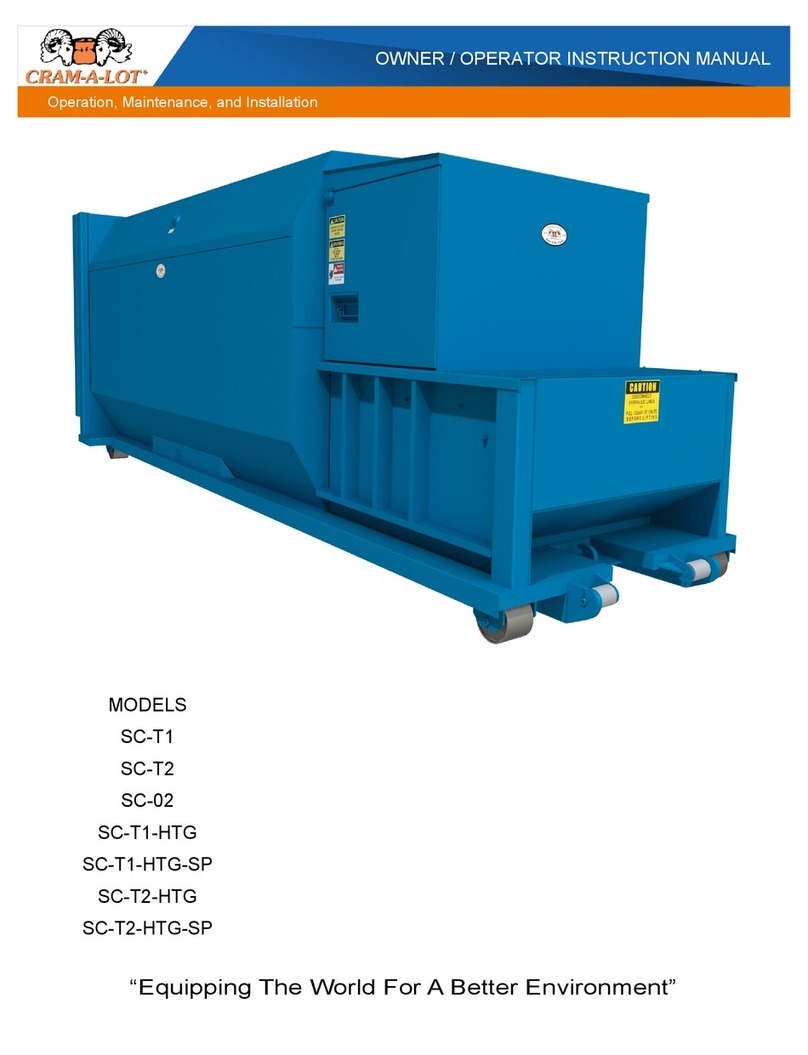

CRAM-A-LOT COR-02 Assembly instructions

“EquippingTheWorldForABetterEnvironment”

Operation,Maintenance,andInstallation

Operation,Maintenance,andInstallation

Operation,Maintenance,andInstallation

StationaryCompactor

OWNER/OPERATORINSTRUCTIONMANUAL

OWNER/OPERATORINSTRUCTIONMANUAL

MODELS

COR-02

CCR-02

CSR-02

CXR-02

C0-2.5

CH-2.5

CX-2.5

COR-03

CHR-03

CXR-03

COR-04

CHR-04

CXR-04 UL

LISTED

CRUS

2

Congratulations

You have just purchased a quality designed and manufactured CRAM-A-LOT®Compactor.

Manufacturing compactors and balers since 1978, JV Manufacturing offers quality workmanship, factory trained installa-

tion and a national service network. Advanced features have been designed into the compactor for modern waste dis-

posal operations.

As with any investment, a return is expected, and the return received from this investment will be in the form of maximum

performance during many years of dependable service.

In order to maintain quality performance and safe operation of your new compactor, it is necessary to observe and prac-

tice the operation and maintenance information provided in this manual.

The employer involved in the operation, maintenance, and installation of the compactor should read and understand the

most current version of the following applicable standards.

ANSI Standard No. Z245.2, “Stationary Compactors-Safety Requirements for Installation, Maintenance and Operation”.

A copy of this standard may be obtained from:

ENVIRONMENTAL INDUSTRIES ASSOCIATION

4301 Connecticut Avenue, NW

Washington D.C. 20008

Website http://www.wastec.org

If, after thoroughly reading this manual, there are questions about the operation or repair of your compactor, please con-

tact J.V. Manufacturing, Inc., and our Customer Support Team will provide assistance.

CRAM-A-LOT® Customer Support

Tel: 800-754-4290

Fax: 479-751-7870

Hours: 7:00 am - 5:00 pm CST®

Monday - Friday

JV Manufacturing Corporate Philosophy

It is the stated goals of J.V. Manufacturing, Inc. to build equipment of uncompromising quality, provide the absolute best

customer service in our industry, and to conduct all business with honesty and integrity, whether it be with customers,

vendors, fellow employees or members of the community.

J.V. Manufacturing, Inc. encourages positive change. Change will provide opportunities for future growth and new direc-

tions as we move into the future.

3

4

Table of Contents

Manual0005 Rev. B. Effective 01-12-06

Introduction

Congratulations.................................................................................................................................3

Table of contents...............................................................................................................................5

Specifications .................................................................................................................................6-9

Operation Section

Decals .............................................................................................................................................12

Safety Decal Placement..................................................................................................................13

Compactor Operation

Safety Orientation.....................................................................................................................14

Owner/employer Responsibilities.............................................................................................15

Operator and Employee Responsibilities .................................................................................16

Procedure for control of hazardous energy sources.................................................................16

Safety and Training program....................................................................................................17

General Training.......................................................................................................................17

Compactor Controls .................................................................................................................18

Standard Operation Sequence.................................................................................................19

Emergency Procedures............................................................................................................19

User Preventive Maintenance ..................................................................................................20

Maintenance Section

Lockout & Tag-out Instructions........................................................................................................22

Hydraulic Safety ..............................................................................................................................23

Preventive Maintenance..................................................................................................................24

Checking and adding oil...........................................................................................................25

Pressure Setting Procedure .....................................................................................................25

Electric Schematics....................................................................................................................26-27

Hydraulic Schematics.................................................................................................................28-29

Trouble-Shooting Chart...................................................................................................................30

Installation Section

Installation Requirements

Concrete Pad..........................................................................................................................34

Positioning..............................................................................................................................34

Anchoring ...............................................................................................................................34

Electrical & Hydraulic Installation............................................................................................35

5

3-10

11-20

21-30

33-36

Warranty Policy & Procedures Section 37-40

Warranty Policy...........................................................................................................................38-39

Warranty Procedures.......................................................................................................................40

Parts Section

Safety Decal Placement ..................................................................................................................32

31-32

6

Specifications

DISCHARGE HEIGHT

B

(OAH) DISCHARGE WIDTH

A

(OAW)

C

(OAL)

MODEL A (OAW) B (OAH) C (OAL) DISCHARGE WIDTH DISCHARGE HEIGHT

COR-02 73-7/8” 59” 121-5/8” 60” 38”

CCR-02 73-7/8” 59” 121-5/8” 60” 38”

CSR-02 69-3/4” 59” 83” 60” 39”

CXR-02 73-7/8” 59” 121-5/8” 60” 38”

CX-2.5 73-3/8” 49” 138-3/8” 60” 36-3/4”

COR-03 74-1/2” 62” 168” 60” 41”

CXR-03 74-1/2” 62” 168” 60” 41”

CHR-03 74-1/2” 62” 168” 60” 41”

COR-04 74-1/2” 64” 167-7/8” 60” 41”

CHR-04 74-1/2” 64” 168” 60” 41”

7

J.V. MANUFACTURING, INC

COR-02, CCR-02, CSR-02, CXR-02 AND CX-2.5 SPECIFICATIONS

General Equipment Specifications COR-02 CCR-02 CSR-02

Wastec Charge Box Rating 1.5 cu/yd 1.5 cu/yd 1.52 cu/yd

Clear Top Opening 40”x58-3/8” 40”x58-3/8” 40”x57”

Cycle Time (sec) 63 63 42

System Pressure (psi) Normal 1,600 2,000 2,000

Maximum 2,000 2,400 2,400

Compaction Force (lbs) Normal 45,200 56,560 42,700

Maximum 56,500 67,850 51,300

Ram Face Pressure (psi) Normal 26.4 33.0 24.6

Maximum 33.0 39.7 29.5

Ram Penetration 13” min 13” min 7-1/2”

Motor (hp) 10 10 10

Motor (voltage) 208/230/480 3ph 208/230/480 3ph 208/230/480 3ph

Pump (capacity) (gpm) 10.5 10.5 10.5

Reservoir capacity (gal) 22 22 22

Cylinder

Bore 6” 6” 4” (2)

Stroke 54” 54” 34”

Rod 3.5” 3.5” 2”

Construction

Floor

1/2” steel plate 1/2” steel plate 1/2” steel plate

4” “C” Channel 4” “C” Channel 4” “C” Channel

Sides

3/16” steel plate 3/16” steel plate 3/16” steel plate

2”x6”x3/16” steel tube

4” “C” Channel 4” “C” Channel 4” “C” Channel

Breaker Bar 6”x6”x1” steel angle 6”x6”x1” steel angle 6”x6”x1” steel angle

Ram

Top 3/16” steel plate 3/16” steel plate 3/16” steel plate

Sides 1/4” steel plate 1/4” steel plate 3/16” steel plate

Bottom 1/2” AR steel plate 1/2” AR steel plate 1/2” AR steel plate

Face 1/2” steel plate 1/2” steel plate 1/2” steel plate

Guides UHMW pads UHMW pads UHMW pads

Weight (lbs) 3,900 4,200 4,000

CXR-02

1.5 cu/yd

40”x58-3/8”

52

2,000

2,400

77,000

92,400

45.0

54.0

13” min

10

208/230/480 3ph

10.5

33

7”

54”

4”

1/2” steel plate

4” “C” Channel

3/16” steel plate

2”x6”x3/16” steel tube

4” “C” Channel

6”x6”x1” steel angle

3/16” steel plate

1/4” steel plate

1/2” AR steel plate

1/2” steel plate

UHMW pads

4,500

8

J.V. MANUFACTURING, INC

COR-03, CXR-03, CHR-03, COR-04 AND CHR-04 SPECIFICATIONS

General Equipment Specifications CX-2.5 COR-03 CXR-03

Wastec Charge Box Rating 1.97 cu/yd 2.4 cu/yd 2.4 cu/yd

Clear Top Opening 52”x60” 62”x58-1/2” 62”x58-1/2”

Cycle Time (sec) 54 54 64

System Pressure (psi) Normal 2,000 2,000 2,000

Maximum 2,400 2,400 2,400

Compaction Force (lbs) Normal 76,970 56,500 76,900

Maximum 92,300 67,900 92,300

Ram Face Pressure (psi) Normal 43.5 31.9 43.4

Maximum 52.1 38.4 52.1

Ram Penetration 13” 13” min 13” min

Motor (hp) 15 10 15

Motor (voltage) 208/230/480 3ph 208/230/480 3ph 208/230/480 3ph

Pump (capacity) (gpm) 12 10.5 12

Reservoir capacity (gal) 33 33 33

Cylinder

Bore 7” 6” 7”

Stroke 64” 76” 76”

Rod 4” 3.5” 4”

Construction

Floor

1/2” steel plate 1/2” steel plate 1/2” steel plate

C-4 x 5.4 Channel 4” “C” Channel 4” “C” Channel

Sides

3/16” steel plate 1/4” steel plate 1/4” steel plate

2”x6”x3/16” steel tube 2”x6”x3/16” steel tube 2”x6”x3/16” steel tube

4” “C” Channel 4” “C” Channel 4” “C” Channel

Breaker Bar 6”x6”x1” steel angle 6”x6”x1” steel angle 6”x6”x1” steel angle

Ram

Top 1/4” steel plate 1/4” steel plate 1/4” steel plate

Sides 1/4” steel plate 1/4” steel plate 1/4” steel plate

Bottom 1/2” AR steel plate 1/2” AR steel plate 1/2” AR steel plate

Face 1/2” steel plate 1/2” steel plate 1/2” steel plate

Guides UHMW pads UHMW pads UHMW pads

Weight (lbs) 5,100 5,620 6,100

CHR-03

2.4 cu/yd

62”x58-1/2”

47

2,000

2,400

56,500

67,900

31.9

38.3

13” min

15

208/230/480 3ph

12

33

6”

76”

3.5”

1/2” steel plate

4” “C” Channel

1/4” steel plate

2”x6”x3/16” steel tube

4” “C” Channel

6”x6”x3/4” steel angle

1/4” steel plate

1/4” steel plate

1/2” AR steel plate

1/2” steel plate

UHMW pads

5,700

9

J.V. MANUFACTURING, INC

COR-03, CXR-03, CHR-03, COR-04 AND CHR-04 SPECIFICATIONS

General Equipment Specifications COR-04 CHR-04

Wastec Charge Box Rating 2.8 cu/yd 2.8 cu/yd

Clear Top Opening 60-3/16”x57” 60-3/16”x57”

Cycle Time (sec) 54 64

System Pressure (psi) Normal 2,000 2,000

Maximum 2,400 2,400

Compaction Force (lbs) Normal 56,550 76,900

Maximum 67,900 92,300

Ram Face Pressure (psi) Normal 27.3 37.1

Maximum 32.8 44.6

Ram Penetration 13” min 13” min

Motor (hp) 10 15

Motor (voltage) 208/230/480 3ph 208/230/480 3ph

Pump (capacity) (gpm) 10.5 12

Reservoir capacity (gal) 33 33

Cylinder

Bore 6” 7”

Stroke 76” 76”

Rod 3.5” 4”

Construction

Floor

1/2” steel plate 1/2” steel plate

4” “C” Channel 4” “C” Channel

Sides

3/8” steel plate 3/8” steel plate

3”x6”x1/4” steel tube 3”x6”x1/4” steel tube

4” “C” Channel 4” “C” Channel

Breaker Bar 8”x6”x1” steel angle 8”x6”x1” steel angle

Ram

Top 1/4” steel plate 1/4” steel plate

Sides 1/4” steel plate 1/4” steel plate

Bottom 1/2” AR steel plate 1/2” AR steel plate

Face 3/4” steel plate 3/4” steel plate

Guides UHMW pads UHMW pads

Weight (lbs) 7,240 7,420

10

11

Operation

Section

12

SAFETY DECALS

13

SAFETY DECALS

14

Compactor Operation

Safety Orientation

Safe Operation

CRAM-A-LOT®compactors meet or exceed all safety standards set by ANSI. Although we have included many safety features in

the design and construction of your compactor, safe operation of the equipment depends on the operator's adherence to certain

guidelines. To prevent accidents to personnel or damage to the compactor, the operator must NEVER VIOLATE ANY OF THE

FOLLOWING SAFETY PRECAUTIONS.It is the owner / employer’s responsibility to ensure these guidelines are known and

followed by all operators of the compactor.

NOTE: Publication of these safety precautions does not imply or represent an inclusive list.

NEVER place hands or arms in the compactor while it is operating.

NEVER allow anyone except qualified electrical or hydraulic repair persons to work on the equipment.

NEVER disable any safety switch.

NEVER overload the compaction chamber.

NEVER place concrete, heavy steel plate or castings, explosive materials, liquids, nor hazardous waste in the compactor .

NEVER climb in or on the compactor, nor perform any maintenance/repairs unless the power is disconnected and locked /

Tagged out.

NOTE: Hydraulic oil is the primary element of power transmission on the compactor. Remember that hydraulic systems can

remain pressurized even after the motor has stopped and or the power disconnected. Refer to the Lock Out / Tag Out instruc-

tions found elsewhere in this manual for instructions concerning the neutralization of these energy sources.

Z245.2—2004

Stationary compactors—safety requirements for installation, maintenance and operation.

Obtain a copy of this standard (ref: http//www.wastec.org) and become familiar with specific responsibilities and guidelines.

Safety Terminology

The accident prevention decals on your CRAM-A-LOT®compactor meet or exceed standards set by ANSI and OSHA. It is im-

portant that you are familiar with the terminology used on the decals and the varying degrees of hazards that are associated with

this terminology.

DANGER—Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. This signal

word is to be limited to the most extreme situations. The signal word Danger should not be used for property damage hazards

unless personal injury risk appropriate to the level is also involved.

WARNING—Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. This signal

word should not be used for property damage hazards unless personal injury risk appropriate to this level is also involved.

CAUTION—Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices that may also cause property damage.

NOTICE—Indicates a statement of company policy directly or indirectly related to the safety of personnel or protection of property.

This signal word should not be associated directly with a hazard or hazardous situation.

Compactor Operation, cont.

Owner/employer responsibilities for compactors The employer/owner shall provide properly

Maintained stationary compactors that meet all applicable regulatory safety requirements and requirements of ANSI Z245.2-2004.

A Ensuring that the installation of the compactor conforms to local codes, ordinances, and manufacturer’s recommendations.

If installing into a system, examine prevailing safety standards of associated equipment.

B Providing to employees instruction and training in safe work methods before assigning them to operate , clean, service,

maintain, modify, or repair the compactor. Such instruction and training shall include procedures provided by the manufac-

turer. The employer will maintain records as to the names of employees and the dates of training.

C Providing instructions for addressing abnormal situations (e.g., bridging of the loading chamber or feeding chute, jam of

materials).

D Assigning only trained employees to work on (which includes operating, loading, cleaning, servicing, maintaining, or repair-

ing) the compactor.

E Monitoring the employee’s operation of the compactor and take appropriate action to insure proper use, including adher-

ence to safe practices and the employee requirements of Z245.2-2004.

F Repairing, prior to placing the compactor into service, any mechanical malfunctions or breakdowns that effect the safe op-

erations of the compactor.

G Establishing and following a program of periodic and regular inspections of all compactors to insure that all parts, compo-

nent equipment, and safeguards are in safe operating condition, and adjusted, in accordance with the manufacture’s rec-

ommended procedures. This shall include keeping all malfunction reports and records of inspections and maintenance

work performed.

H Implementing a program for the maintenance of the compactor which will incorporate the following elements:

1) Requirements for trained, competent maintenance employees or contractors to perform inspection and repair

work;

2) Providing for the cleaning, inspection and repair of the compactor in accordance with the manufacture’s recom-

mendations. Including periodic maintenance;

3) Ensuring that all required safety features are operational and functioning, and repairing, prior to placing into ser-

vice, any reported malfunction or defect that affects the safe operation of the compactor;

4) Ensuring that all caution, warning and danger markings required are installed and legible, or are replaced if dam-

aged, defaced or missing.

I Utilizing the manufacturer’s recommended procedures for the control of hazardous energy sources (lockout/tag-out) in a

program complying with Part 1910.147 of the Title 29 of the Code of Federal Regulations (OSHA).

J Utilizing the manufacture’s recommended procedures for access control for permit-required confined spaces as part of the

employer’s program;

K Protecting any person by one of the methods in 5.9.1, AMERICAN NATIONAL STANDARD Revision of ANSI Z245.2-

2004, or by other means as effective as those means of protection.

L For compactors fed by means of a loading pit conveyor, reciprocating floor or push pit that is flush with or below the facility

floor, provide;

1. Protection for employees by means of ;

a) Limiting access within 6 feet (183) of the edge of the pit to authorized employees;

b) Training authorized employees to recognize and avoid the hazards associated with the pit area;

c) Requiring that others whose employees use the pit area provide assurance of such training;

d) Limiting access by unauthorized persons by installing signs, such as:

“RESTRICTED AREA - AUTHORIZED EMPLOYEES ONLY”

2. Providing a device to the extent practicable, which prevents trucks or other motor vehicles that unload directly into

the loading pit from rolling into the pit.

M When compactor equipped with automatic start/cycling controls are provided, allowing their use only in locations where a

startup alarm is utilized or it is demonstrated that automatic starting does not result in a risk of injury to persons;

N Providing guard railings for dock ramps that meet U.S. Occupational Safety and Health Administration requirements. These

shall be located around the loading chamber if walk on ramps are used to deposit refuse into the loading chamber. Guard

railings and toe boards shall be provided on the sides of docks and ramps;

O Providing for an adequate work area around the compactor for safe maintenance, servicing, and cleaning procedures.

P Keeping all surrounding walking areas and floor free from obstructions, and from accumulations of waste matter, grease, oil

and water;

Q Specifically inspecting safety interlocks, switches, and other protective devices to ensure that these devices are not dis-

abled or bypassed, and not to permit the compactor to be operated unless these devices are fully functional. These inspec-

tions shall be in accordance with ‘G’;

R Ensuring that containers supplied are capable of withstanding the maximum forces generated by the compacting system;

S Ensuring that loaders are aware of hazards and safety requirements;

T Ensuring that only authorized employees (18 years or older) operate, inspect, or maintain compactors;

U Ensuring that only authorized employees (16 years or older) load, but do not operate compactors; and

V Incorporating compactors into the employer’s safety program.

15

16

Compactor Operation, cont.

Operator and employee responsibilities for compactors Operators who work on and around

the compactor shall be responsible for the items listed below:

A. Using all applicable safety features provided on the compactor;

B. Using the compactor only after receiving instructions;

C. Reporting any damage to, or malfunction of the compactor by submitting a report to the employer or responsible authority

when the damage or malfunction occurs;

D. Ensuring that access doors and service openings covers are in place, secure, and/or locked before operation begins;

E. Ensuring that the area of operation around container/cart lifting systems and the container will be clear of persons during all

phases of the lifting operation prior to energizing the dumping system;

F. Ensuring that all persons are clear of the compactor point of operation before actuating any compaction cycle controls or con-

tainer/cart lifting system controls and being prepared to stop the compaction cycle or container dumping operation if neces-

sary;

G. Insuring that all persons are clear of the tailgate (on compactor-container combinations so equipped) before the tailgate is

opened or shut. The operator shall warn all persons not to cross behind or under an open tailgate;

H. Using the compactor in accordance with the manufacture’s instructions, including ensuring the proper position of all locks,

doors, guards, etc.;

I. Ensuring that no one disables or bypasses safety interlocks, switches, or other protective devices and that the compactor is

not operated unless these devices are fully functional;

J. Locking out the unit when inspecting malfunctions, jams, or other problems arising from daily operations, servicing, or per-

forming maintenance (except maintenance testing). The affected employee shall identify the type and magnitude of the en-

ergy that the compactor uses, shall understand the hazards, and know the methods to control the energy;

K. Coupling and securing a compatible container to a compactor frame as specified by the compactor and container manufactur-

ers);

L. Operating, inspecting, and maintaining the compactor only if 18 years old or older and being properly instructed and trained;

M. Loading, but not operating, the compactor only if 16 years old or older.

Procedure for the control of hazardous energy sources. (lockout/tag-out)

1. The owner/employer shall have a hazardous energy control (lockout/tag-out) procedure to follow when performing servicing

and maintenance on compactors where the unexpected energization or startup of equipment, or release of stored energy

could cause injury to employees.

2. The owner/employer shall utilize the instructions provided by the manufacturer for the control of hazardous energy sources.

The lockout/tag-out procedure shall isolate and render safe all energy sources including electrical, mechanical, hydraulic,

pneumatic, chemical, thermal or other potential energy sources (e.g., gravity, etc). It shall be used to ensure that the compac-

tor is stopped, isolated from all potentially hazardous energy sources and locked out before employees perform any servicing

or maintenance where the unexpected energization or startup of the compactor or release of stored energy could cause in-

jury.

3. The lockout/tag-out procedure shall include but is not limited to the following:

a) Shutting down all power sources;

b) Removing keys or other devices that enable the compactor;

c) Installing a tag on an appropriate location, using a non-reusable fastener, or installing a similar warning device;

d) Placing operating components in such a position so as not to be subject to possible free fall and/or installation of addi-

tional blocking devices to prevent such free fall of any raised or elevated component;

e) Relieving stored hydraulic or pneumatic pressure, after blocking devices are installed, if maintenance is to be done to the

hydraulic or pneumatic system.

4. The procedure shall address the following:

a) Sequence of lockout for the compactor;

1. Notify all affected employees that servicing or maintenance is required on a compactor and that the compactor must

be shut down and locked out to perform the servicing or maintenance.

2. The authorized employee shall refer to the company procedure to identify the type and magnitude of the energy that

the compactor utilizes, shall understand the hazards of the energy, and shall know the methods to control them.

3. If the compactor is operating, it must be shut down by the normal stopping procedure (depress stop button, open

switch, close valve, etc.).

4. De-activate the energy isolating device(s) so that the compactor is isolated from the energy source(s).

5. Lock out the energy isolating device(s) with assigned individual lock(s).

6. Stored or residual energy must be dissipated or restrained by methods such as grounding, repositioning, blocking,

bleeding down, etc.

7. Ensure that the compactor is disconnected from the energy source(s) by first checking that no personnel are ex-

posed, then verify the isolation of the equipment by operating the push button or other normal operating control(s) or

by testing to make certain the equipment will not operate.

Caution; Return operating control(s) to neutral or “off” position only after verifying the isolation of the equipment.

NOTE: The machine or equipment is now locked out.

17

Compactor Operation, cont.

b) Restoring the compactor to service. When the servicing or maintenance is completed and the compactor is ready to re-

turn to normal operating condition, the following steps shall be taken:

1. Check the machine or equipment and the immediate area around the machine or equipment to ensure that all non-

essential items have been removed and the machine or equipment components are operationally intact.

2. Check the work area to insure that all employees have been safely positioned or removed from the area.

3. Verify that the controls are in neutral.

4. Remove the lockout devices and re-energize the machine of equipment.

NOTE: The removal of some forms of blocking may require re-energizing of the machine before safe removal.

5. Notify affected employees that the servicing or maintenance is completed and the machine or equipment is ready for

use.

5. Procedures for work in confined spaces:

a) The owner/employer shall have a written procedure for work in confined spaces meeting the criteria of “permit required

confined spaces," such as integrated power units. The procedure shall utilize the manufacturer’s instructions for the haz-

ardous energy control (lockout/ tag-out) procedure which shall isolate and render safe energy sources, including electri-

cal, mechanical, hydraulic, pneumatic, chemical, thermal or other potential sources of energy (e.g., gravity, kinetic, etc.),

which may create a hazard during entry into each of those confined spaces

b) These instructions shall include the requirement to affix a sign to the compactor, at or near the entrances to those con-

fined spaces for which hazardous energy control procedures are provided, such s, “Warning — Follow lockout/tag-out

procedures.”

c) These instructions shall include the requirement to affix a sign to the stationary compactor, at or near the entrances to

those confined spaces for which hazardous energy control procedures are provided, such as, “Danger — Confined

Space.”

Safety and training program

General: Employers shall evaluate and manage safety issues related the operation of compaction equipment as part of

their safety program

Safety Program

The employer’s program shall include at a minimum the following elements:

a) A hazard assessment in which the employer conducts a review of the various types of compaction equipment that

the employer utilizes and the hazards associated with them and, review and assess the capabilities, qualifications

and training of any person who may potentially encounter these hazards.

b) An evaluation of the means and methods of controlling the hazards identified in the hazard assessment, including

information such as industry and regulatory requirements, instructions for the operation, inspection, and mainte-

nance of compactors, and other information appropriate to the hazards that are identified.

c) A written program, based upon the hazard assessment and evaluation, to include procedure for the operation, in-

spection, and maintenance of compactors, prohibited practices, record keeping, training requirements, and norma-

tive references to documents, such as operating manuals, that are relied upon and may be required as part of that

program.

d) Periodic review and program revisions as necessary to ensure the effectiveness of the safety program.

General training

Employers shall ensure all employees, including supervisors, contract laborers, and all other persons engaged in the opera-

tion, cleaning, maintenance, service or repair of compacting equipment are properly trained appropriate for their assigned

jobs and tasks. Contractors who may be engaged to operate or maintain the employer’s compactor shall be advised of the

unique hazards related to the equipment that may affect the activities in which the contractor’s employees will engage.

18

Compactor Operation, cont.

Compactor Controls

KEY START SWITCH

EMERGENCY STOP/

PULL TO REVERSE

LOW OIL

(OPTIONAL)

75% SOLID

100% FLASHING

(OPTIONAL)

19

Compactor Operation, cont.

Emergency Procedures

Should an emergency occur while operating the compactor, press the RED EMERGENCY STOP BUTTON and the

compactor will terminate all functions and shut down. EVERYONE AUTHORIZED TO OPERATE THE COMPACTOR SHOULD

KNOW THIS EMERGENCY PROCEDURE.

Standard Operation

1) Open chamber door (If not chute fed.)

2) Fill charge chamber with material to be compacted.

3) Close chamber door.

4) Turn the “Start Key Switch”

5) Compactor will start and complete one cycle of operation.

6) The Compactor will continue to operate in this manner until the “Push to Stop” button is pressed or a door is opened.

If the Compactor is stopped it must be restarted with the “Start Key Switch”.

7) Repeat steps #1 thru #5 until the container attached to the compactor is full. Contact hauler for dumping.

Conditions During Standard Operation

• The ”Push to Stop” button may be pressed at any time during the cycle to stop operation to shut down the system. If

this button is pulled at any time during the cycle or when the compactor is stopped with the ram forward away from the

retracted position, the ram will return to the retracted position and the compactor will stop.

• When the HAULER SAFETY SWITCH is turned to the ON position, all compactor functions are disabled to facilitate

removal of the container.

It is unlawful to operate this machine if you are under 18 years of age!

20

Compactor Operation, cont.

We recommend the user of CRAM-A-LOT®compactors adopt a program of regularly scheduled maintenance procedures. This

schedule should be followed to insure against premature failure of mechanical or hydraulic components.

1. INITIAL CHECK:

a. All nuts and bolts during the first week of use, and then monthly thereafter.

b. Hydraulic reservoir should be at the mid to upper range of the sight glass with ram retracted. Use a good quality

5W-20 Hydraulic fluid.

c. Hydraulic lines for leaks.

d. Hydraulic hose condition. (Check for damage, kinks, etc.).

e. Access covers to be sure fasteners are in place.

f. Power unit. Remove dust and dirt from outside of control box. Wipe off any dirt or grease, oil or moisture.

2. MONTHLY CHECK:

a. Check external hoses for chafing, rubbing, or other deterioration and damage.

b. Check for any obvious unsafe conditions, such as electrical lines or operator obstructions, in compactor area. If

any unsafe conditions are found, they should reported immediately to an authorized maintenance technician.

c. Check oil level in hydraulic reservoir.

d. Check functional operation of standard controls and options (stop button, timers, lights, etc.).

USER PREVENTIVE MAINTENANCE

This manual suits for next models

12

Table of contents

Other CRAM-A-LOT Trash Compactor manuals

Popular Trash Compactor manuals by other brands

GE

GE Monogram GCG1000 manual

Mikasa

Mikasa MVH-100 Service manual

Electrolux

Electrolux EI15TC65HS - Undercounter Trash Compactor Technical & service manual

AmazonBasics

AmazonBasics B091TZJG1L manual

KitchenAid

KitchenAid KUCS180 Use and care guide

Electrolux

Electrolux E15TC75HSS - ICON Designer Specifications