Before you begin—Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions with your Use and Care Book for future

reference.

This appliance must be properly grounded. See “Power Supply”, page 5.

Cet appareil doit être mis à la terre correctement. Voir la section « Alimentation

électrique » en page 5.

If you have a question concerning the

installation of this product, call the GE Answer

Center®Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged compactor, you

should immediately contact your dealer or

builder.

2

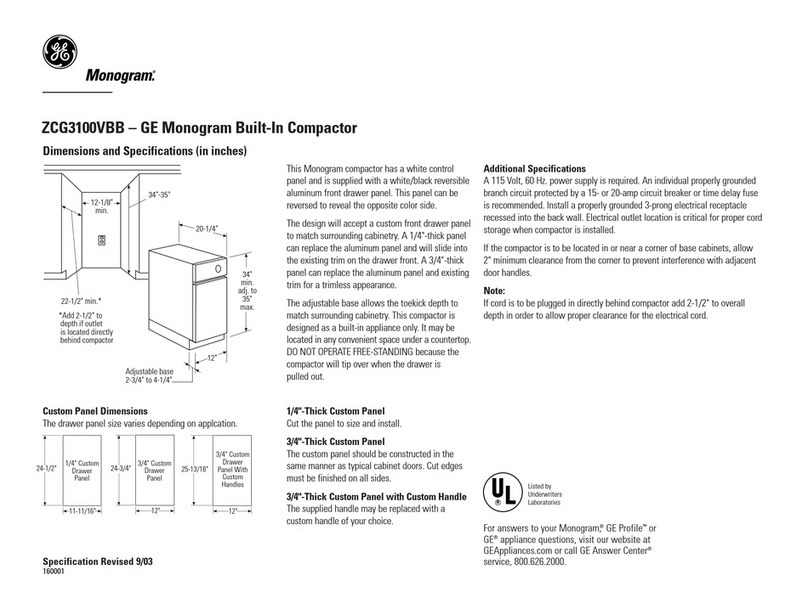

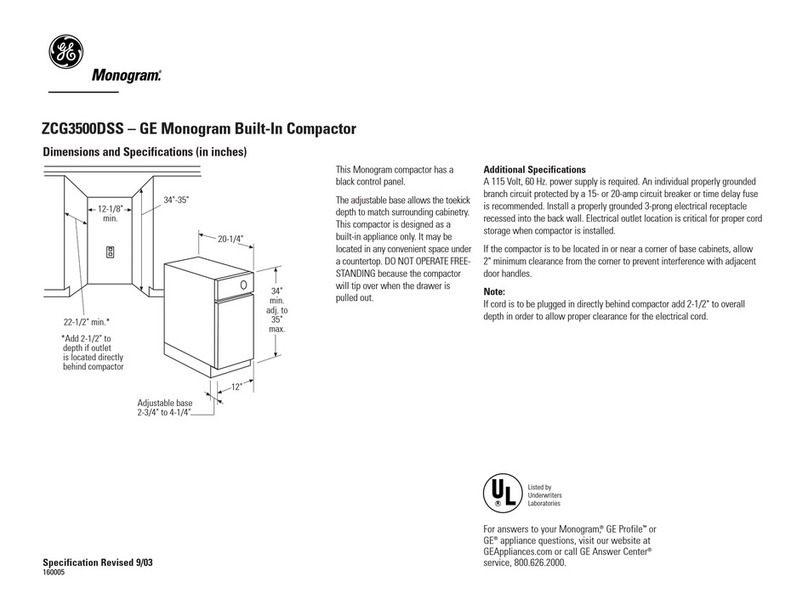

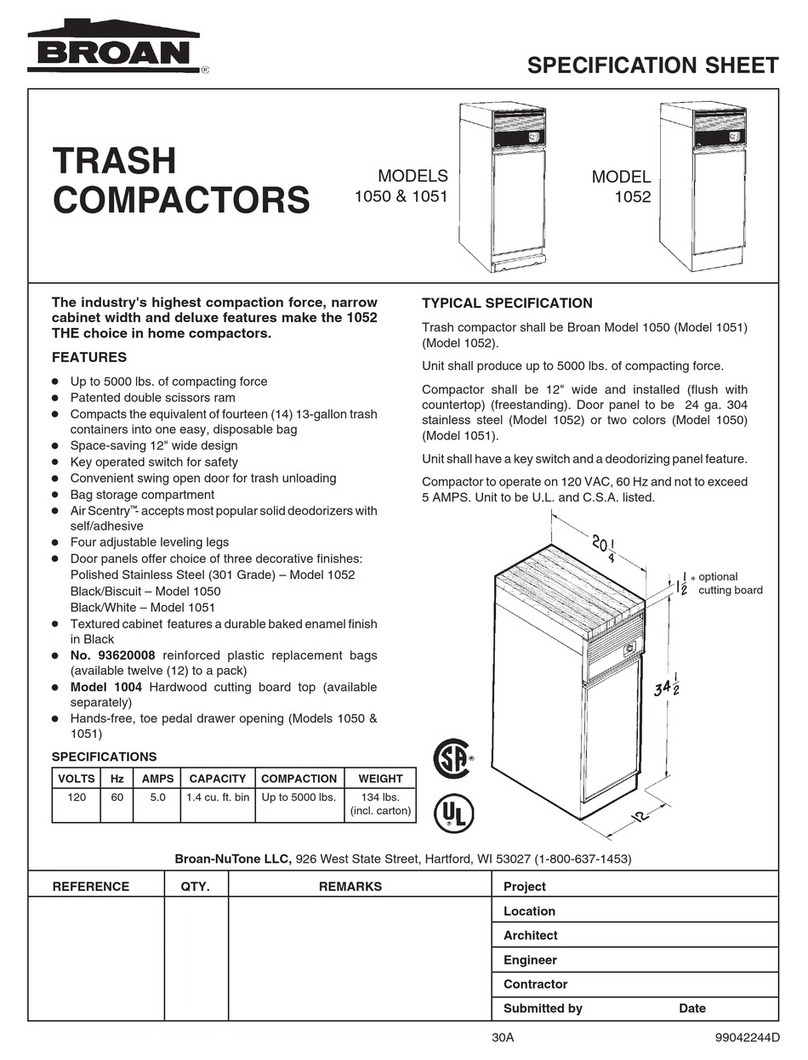

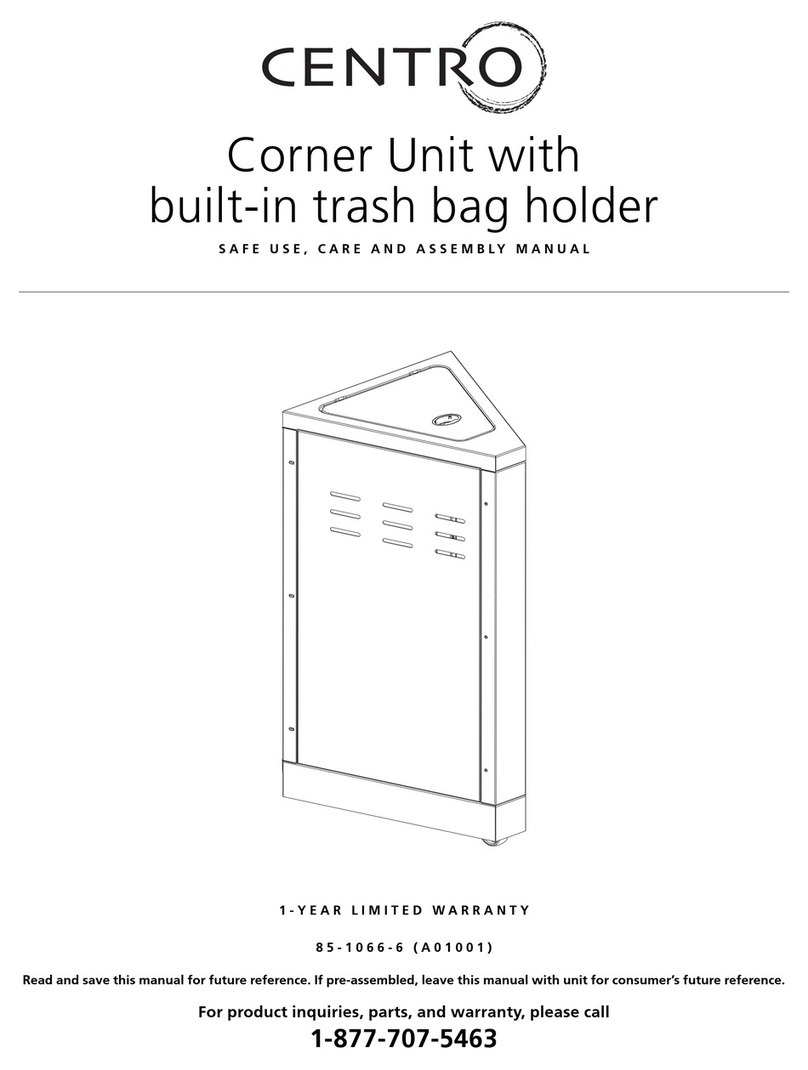

Design Information

Models Available ......................................................................................................................................................................3

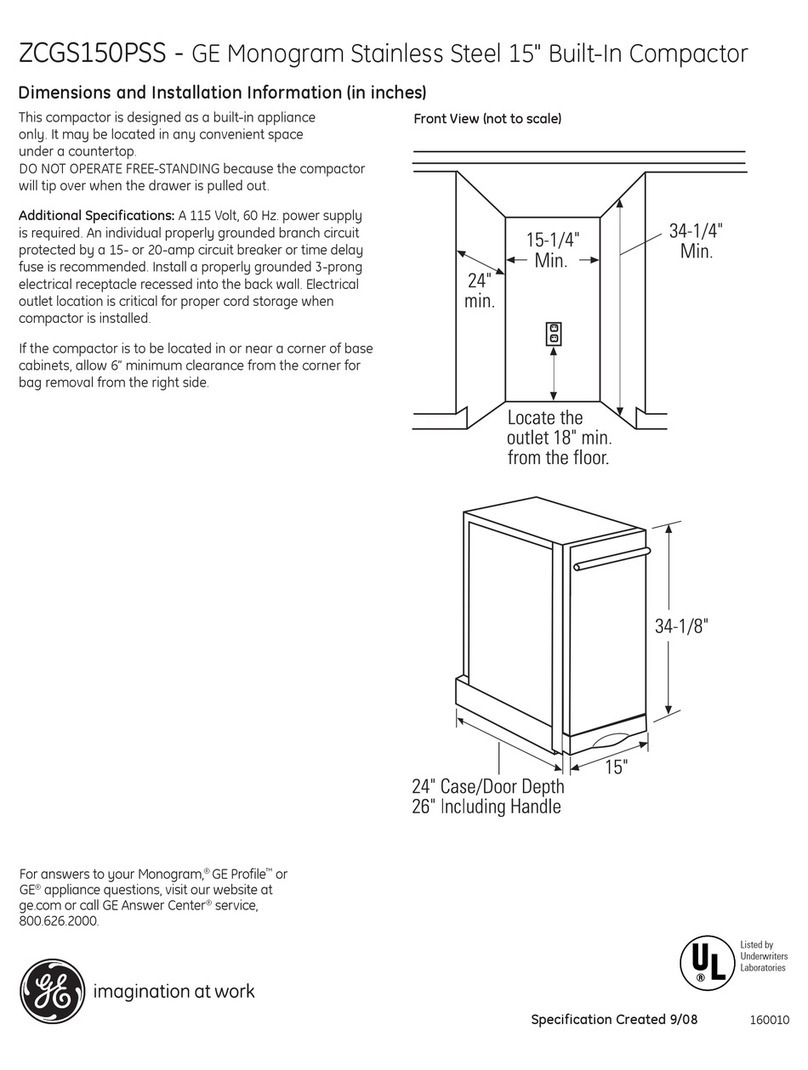

Dimensions and Clearances ....................................................................................................................................................3

Installation Preparation

Standard Appearance Panel Option ......................................................................................................................................4

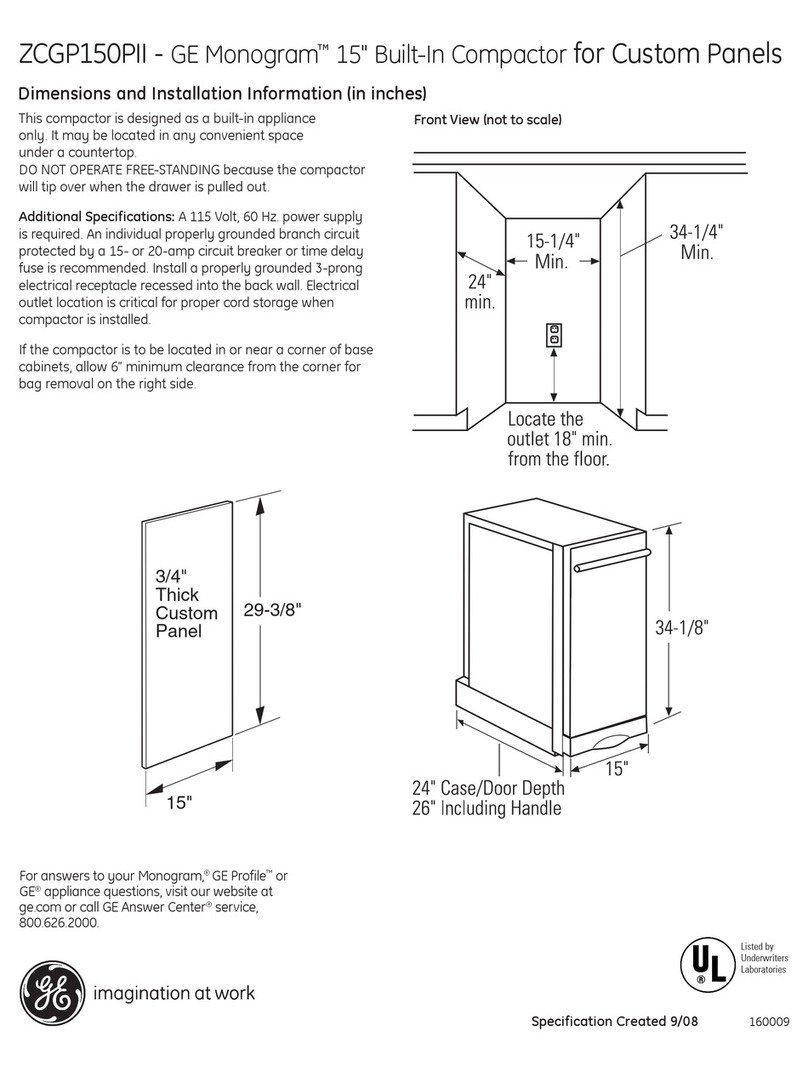

Custom Panels ..........................................................................................................................................................................4

Option 1: 1/4" Thick Wood Panel ..........................................................................................................................................4

Option 2: 3/4" Thick Wood Panel ..........................................................................................................................................4

Option 3: 3/4" Thick Wood panel with Custom Handle........................................................................................................5

Power Supply ............................................................................................................................................................................5

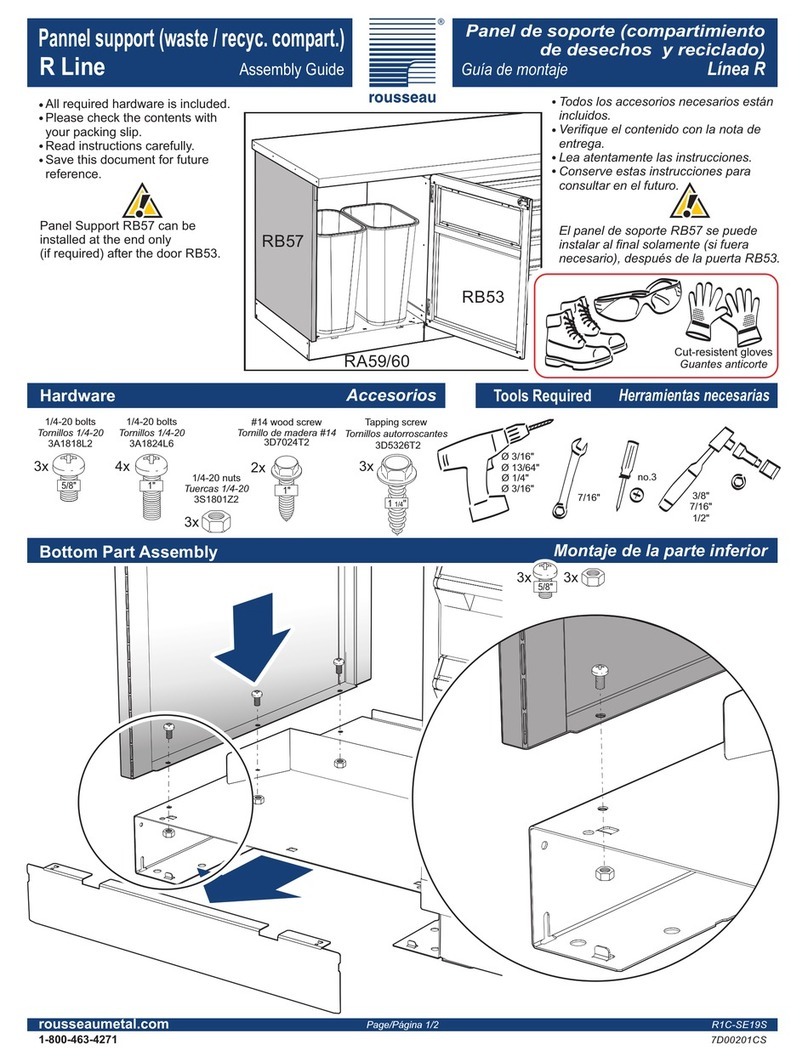

Installation

Technical Data ..........................................................................................................................................................................6

Choosing the Location ............................................................................................................................................................6

Installation in a Corner ............................................................................................................................................................7

Level the Opening ....................................................................................................................................................................7

Step 1 Determine Toekick Depth ............................................................................................................................................8

Step 2 Adjust Movable Base ....................................................................................................................................................8

Step 3 Positioning the Compactor Backstop ..........................................................................................................................9

Step 4 Setting the Height ........................................................................................................................................................9

Step 5 Attach Tip-Over Brackets ............................................................................................................................................10

Step 6 Optional Custom Toekick ..........................................................................................................................................11

Step 7 Changing Front Panel ................................................................................................................................................12

Optional Custom Panels ........................................................................................................................................................13

NOTICE

• Compactor is shipped with ram in “Down” position.

Trash container compartment cannot be opened until

the ram is restored to normal “UP” position. See label

on compactor.

• Compactor has adjustable base to set toekick depth

to match cabinets. This adjustment must be made

prior to installing unit under countertop. See page 8.

• Compactor is designed for BUILT-IN applications

ONLY.

• Consideration must be given to provide adequate

clearances for installation and servicing.

• Do not use an extension cord or adaptor plug with

this appliance.

Proper installation is the responsibility of the installer.

Product failure due to improper installation is not covered

under the GE Appliance Warranty. See the Owner’s

Manual for warranty information.

For Monogram local service in your area, 800.444.1845

For Monogram Parts and Accessories, call 800.626.2002.

Contents

WARNING

AVIS

• À l’expédition, le bras de compression du compacteur se

trouve à la position « Down ». Il est impossible d’ouvrir le

compartiment du récipient à déchets tant que le bras de

compression ne revient pas à la position normale « UP ».

Lire l’étiquette sur le compacteur.

• Le compacteur est doté d’une base réglable permettant

d’adapter la profondeur du coup-de-pied à l’armoire. Ce

réglage doit être effectué avant de monter l’appareil sous le

comptoir. Voir la page 8.

• Le compacteur est conçu pour être ENCASTRÉ

SEULEMENT.

• Les dégagements appropriés doivent être prévus pour le

montage et l’entretien.

• N’utilisez pas de rallonge ou de fiche d’adaptation avec cet

appareil.

AVERTISSEMENT

MISE EN GARDE