Cramaro FLIP TARP User manual

CRAMARO TS S.r.l. / COLOGNA V.TA (VR) VIA QUARI DESTRA 71 TEL. 0442/411688 / FAX 0442/411690

E-MAIL info@cramaro.com WEB : http://www.cramaro.com

CRAMARO TS

S.r.l. - 37044 COLOGNA VENETA (VR) – ITALY - VIA QUARI DESTRA, 71/G

TEL.+39 0442/411688 / FAX +39 0442/411690 - E-mail:

info@cramaro.com

WEBSITE:

http://www.cramaro.com

“ FLIP TARP “

MACHINERY DIRECTIVE 2006/42/EC

USER MANUAL

INSTALLATION-USE - MAINTENANCE - SAFETY

TRANSLATION OF ORIGINAL INSTRUCTIONS

MFT002- EN – ED07

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 2

Contents

PRESENTATION OF THE TARPAULIN ...................................................................................................................3

USING AND CONTROLLING THE MACHINE .........................................................................................................4

Operating temperatures........................................................................................................................................4

Wind action.............................................................................................................................................................4

Changes to the machine.......................................................................................................................................5

Areas where the machine cannot be used........................................................................................................5

Storage of the machine.........................................................................................................................................5

''Lifetime'' of the machine.....................................................................................................................................5

Demolition of the machine ...................................................................................................................................5

Hazard of falling from above or inside the container.......................................................................................6

Collision and crushing hazard for upper limbs when the tarpaulin is UNROLLED and ROLLED UP.....7

Hazard that may be caused by the wind............................................................................................................8

Ice hazard on the tarpaulin ......................................................................................................................................8

Hazard of unloading material when the tarpaulin is unrolled over the container..................................................8

Residual risk.............................................................................................................................................................9

WORKING UNDER SAFE CONDITIONS, SERVICES AND DOCUMENTS PROVIDED TO INSTALLERS...10

Training and support..............................................................................................................................................10

Installer manual......................................................................................................................................................10

WORKING UNDER SAFE CONDITIONS, SERVICES AND DOCUMENTS PROVIDED TO END USERS....10

Training, a session to gain familiarity with the machine.......................................................................................10

Delivery of manuals ...............................................................................................................................................10

Safety signs applied on the machine ....................................................................................................................10

PRESENTATION OF THE TARPAULIN .................................................................................................................11

ASSEMBLY PROCEDURE ......................................................................................................................................12

Preparing the container ......................................................................................................................................12

•

POSITIONING AND FIXING THE SIDE ARMS.....................................................................................14

PRE-TENSIONING THE SIDE ARMS.....................................................................................................................14

•

DRIVE UNIT INSTALLATION .................................................................................................................16

PRESENTATION OF THE TARPAULIN ................................................................................................................19

RADIO CONTROL (optional) ..........................................................................Errore. Il segnalibro non è definito.

TROUBLESHOOTING..............................................................................................................................................25

RULES APPLYING TO THE DELIVERY OF THE TARPAULIN TO THE USER (END user).............................26

HOW TO USE THE TARPAULIN (part devoted to the user)..................................................................................26

TROUBLESHOOTING..............................................................................................................................................27

ROUTINE MAINTENANCE ......................................................................................................................................27

EXTRAORDINARY MAINTENANCE.......................................................................................................................28

MACHINE CONTROL REGISTER...........................................................................................................................29

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 3

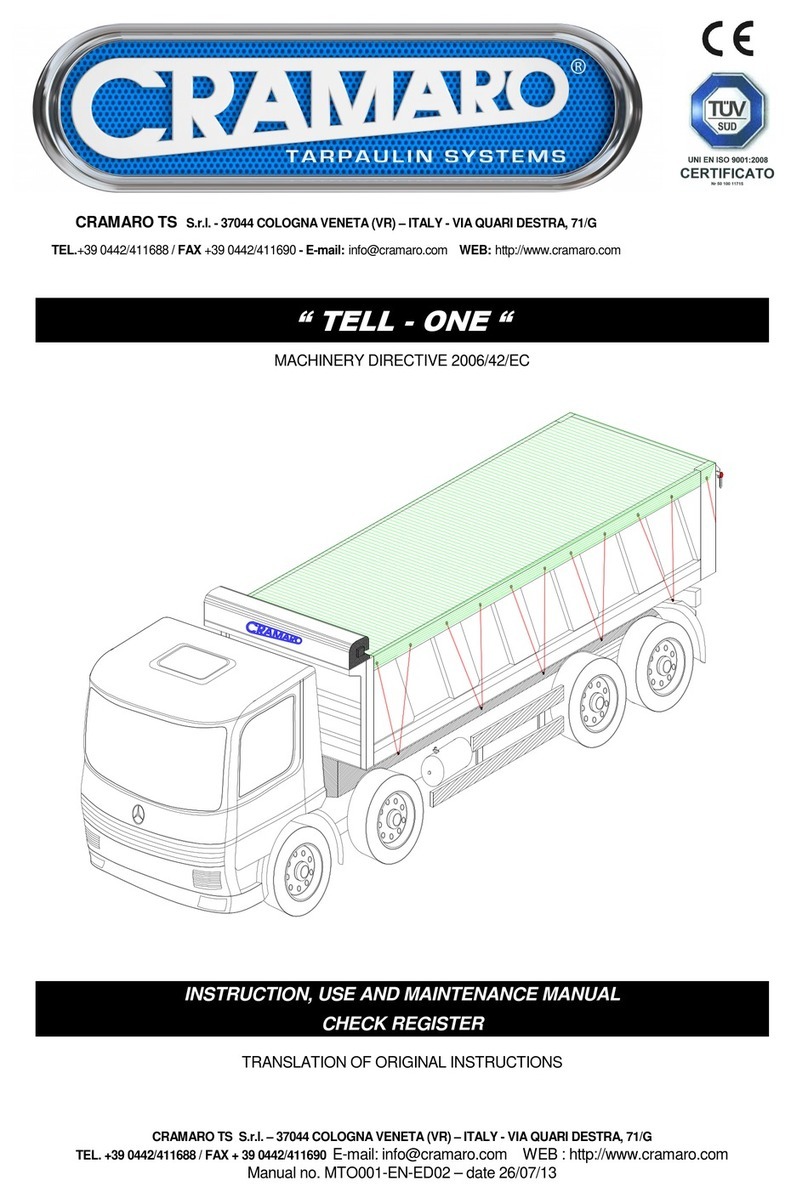

PRESENTATION OF THE TARPAULIN

This manually, electrically or hydraulically-operated tarpaulin, is mainly intended for farming vehicles, although it

can also be employed on road vehicles used to transport loose materials. It is also specifically designed to fulfil

both the need to cover the container and to provide quick access at the same time, for loading and unloading.

1. SIMPLE It is built with a housing that encloses the entire tarpaulin.

2. FUNCTIONAL It is extremely easy to use, just OPERATE the control handle or the remote

control and the tarpaulin covers or uncovers the vehicle's loading compartment.

3. LIGHTWEIGHT The SMALL size and ESSENTIAL DESIGN of the structure ensure REDUCED

WEIGHT.

4. VERSATILE Its extremely SIMPLE and COMPACT system is adaptable to any vehicle used

for transportation in the farming industry, or for the transportation of loose materials

5. ESSENTIAL Nothing can be taken off, ANYTHING NOT STRICTLY ESSENTIAL HAS

ALREADY BEEN ELIMINATED.

The manually, electrically or hydraulically-operated tarpaulin basically consists of:

1. A SHAPED HOUSING made with sheet metal measuring mm. 250 x 350 and MAX 2490 mm wide. It

contains the pipe to wind up the whole tarpaulin.

2. TWO ROTATING STEEL ARMS, which are length-adjustable based on the length of the container that

they are installed on

3. A TARPAULIN made with POLYURETHANE OR PVC

Although it has an essential design, the system ensures superior efficiency and unmatched reliability.

The simplicity of the system and the compact design of the TARPAULIN HOUSING make it easy to

install on almost any container currently on the market, without having to make any excessive

changes.

•PACKAGING WEIGHT AND SIZE

Shipped parcels no. - - - - - - - - - - - - - - - - - - - -

Size cm. - - - - - - - - - - - - - - - - - - - -

Weight Kg. - - - - - - - - - - - - - - - - - - - -

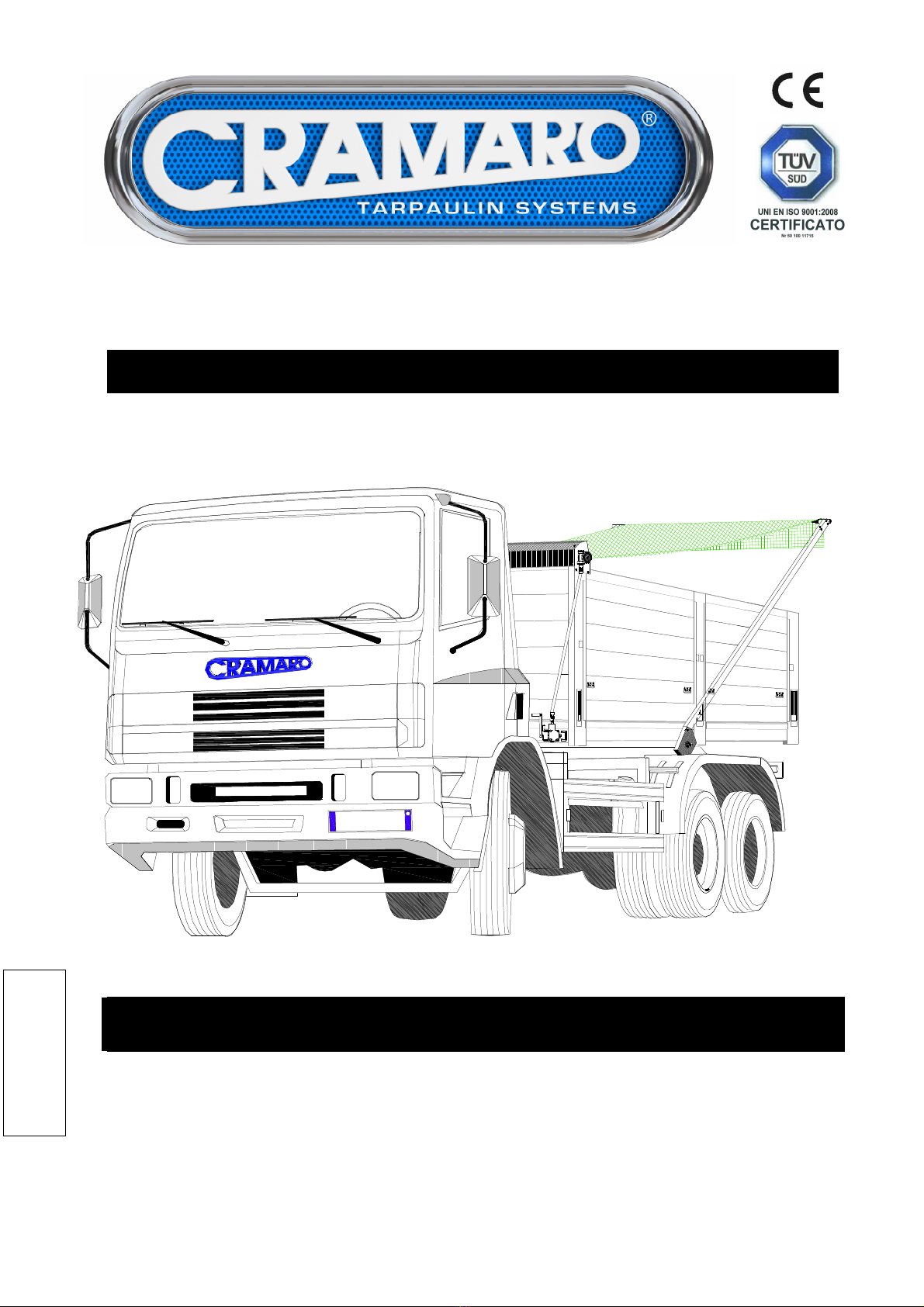

•LIFTING AND HANDLING THE TARPAULIN

WARNING!

The tarpaulin cannot be lifted and moved by one person alone.

It must be handled with suitable lifting and transport means by making sure it is stable

when it is moved.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 4

CRAMARO TARPAULIN SYSTEMS s.r.l.

37044 COLOGNA VENETA ( VR ) - ITALY

37044 COLOGNA VENETA ( VR ) - ITALY

VIA QUARI DESTRA 71 G

Tel + 39 0442 411688 Fax +39 0442 411690

www.cramaro.com Mail [email protected]

MODELLO TIPO MODEL TYPE :

N° SERIE SERIAL N° :

ANNO YEAR OF BUILT :

RUMOROSITA' SOUND PRESSURE :

VIBRAZIONI VIBRATIONS :

FLIP TARP

ASSENTE NO

ASSENTE NO

If it is moved with a forklift truck. Make sure the gap between the forks is suitable

to ensure the load is stable and the vehicle must be driven by an operator authorised

to use it.

During the assembly stage, the tarpaulin must be supported by a suitable lifting device until it is

steadily anchored onto the container.

•

CE MARKING

Each machine has a CE marking shown by the nameplate required by

Machinery Directive 2006/42/EC.

•MACHINE FUNCTIONS – INTENDED USE

The specific function of FLIP TARP

is to quickly cover and uncover a container for loading and unloading.

•NOT ALLOWED “IMPROPER” USE

Not allowed improper use refers to:

•any kind of use other than the one specified in the previous paragraph.

WARNING!

Do not use the machine to cause injury to your health and the health of other persons.

•SOUND EMISSIONS

The machine does not produce a sound pressure that can cause damage to human hearing.

•VIBRATION

Minimum, as for operation strictly associated with the action of the operator for the MANUAL version and the

slow rotation of the guiding arms for the ELECTRIC or HYDRAULIC version

USING AND CONTROLLING THE MACHINE

Operating temperatures

The machine is designed to operate in environments with temperatures ranging between –15° and +40°;

please contact the manufacturer to operate under other temperature conditions.

Wind action

The action of wind at ground level must be added to the speed of the vehicle the tarpaulin is mounted on, as it

exponentially amplifies its effects.

WARNING!

DO NOT OPERATE WITH WIND FORCE OVER 6 OF THE BEAUFORT SCALE (38.5 – 49.7

km/h)

if there is no air speed indicator, this can be detected by:

-

large branches moving, you start hearing the whistling of wind, it is difficult to use an

umbrella.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 5

Changes to the machine

WARNING!

DO NOT PERFORM MODIFICATIONS ON THE MACHINE.

In the event of work performed by unauthorised personnel, the warranty is voided and the

manufacturer is relieved from liability for damage to property and the environment and

injury to persons and animals.

The replacement of components called “spare parts” is not considered a modification.

Areas where the machine cannot be used

•Land where there might be unexploded war equipment.

•Closed or semi-closed environments where the dust of materials moved may be harmful to health.

•Environments where a fire hazard exists.

•Environments with vapours deriving from chemical processes.

•Areas adjacent to nuclear plants.

•Environments with the characteristics of an “Explosive atmosphere” (explosion hazard)

•With poor visibility.

•In environments with dangerous animals (not pets).

•Noise levels that reduce concentration and cause stress.

•In environments with a considerable amount of exhaust gases from other machines.

•In environments where there is an uprising or war.

Storage of the machine.

In the event of long periods of inactivity, the machine must be “stored” in a covered area not accessible to

people not authorised to use it.

-Protect any exposed metal parts with a suitable lubricant.

-Protect the machine with a tarpaulin made with breathable material.

''Lifetime'' of the machine

CRAMARO TS s.r.l. makes machines designed to “last over time”, but their “lifetime” is subject to the storage and

maintenance carried out by the owner.

Demolition of the machine

ENVIRONMENT!

To protect the environment, please follow the instructions below.

At the end of the machine's life cycle, dismantle it and separate the materials based on their nature. Materials

can be grouped by:

- construction steel; plastic material,

- lubricant oil; lubricant grease; rubber and rubber by-products; paint; etc.

All the above components must be sent to the Bodies specifically authorised to dispose of or recycle them

(metal materials can be disposed of as waste).

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 6

•MACHINE HAZARDS AND RESULTING RISKS

Hazard of falling from above or inside the container

HAZARD DESCRIPTION

Fig. 1

MEASURES ADOPTED TO TRY AND REDUCE THE HAZARD

-Information and recommendations for the user during the meeting designed to gain familiarity with the

machine, to be provided by the installer at the time of delivery.

-Supply of this manual, which reports the presence of the hazard and reports prohibitions and instructions.

WARNING!

Regardless of the work you are conducting (a stop, extension or unrolling) NO ONE MUST

STAND ON THE TARPAULIN.

The manufacturer declines any responsibility!

INSTRUCTION!

Please contact the manufacturer to solve the problem.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 7

CRAMARO TARPAULIN SYSTEMS s.r.l.

PRINCIPALI NORME E DIVIETI

E' ASSOLUTAMENTE VIETATO SOSTARE IN

PROSSIMITA' DEI BRACCI LATERALI DELLA

COPERTURA DURANTE IL SUO FUNZIONAMENTO

PERICOLO

LA DITTA CRAMARO T.S. DECLINA OGNI RESPONSABILITA'

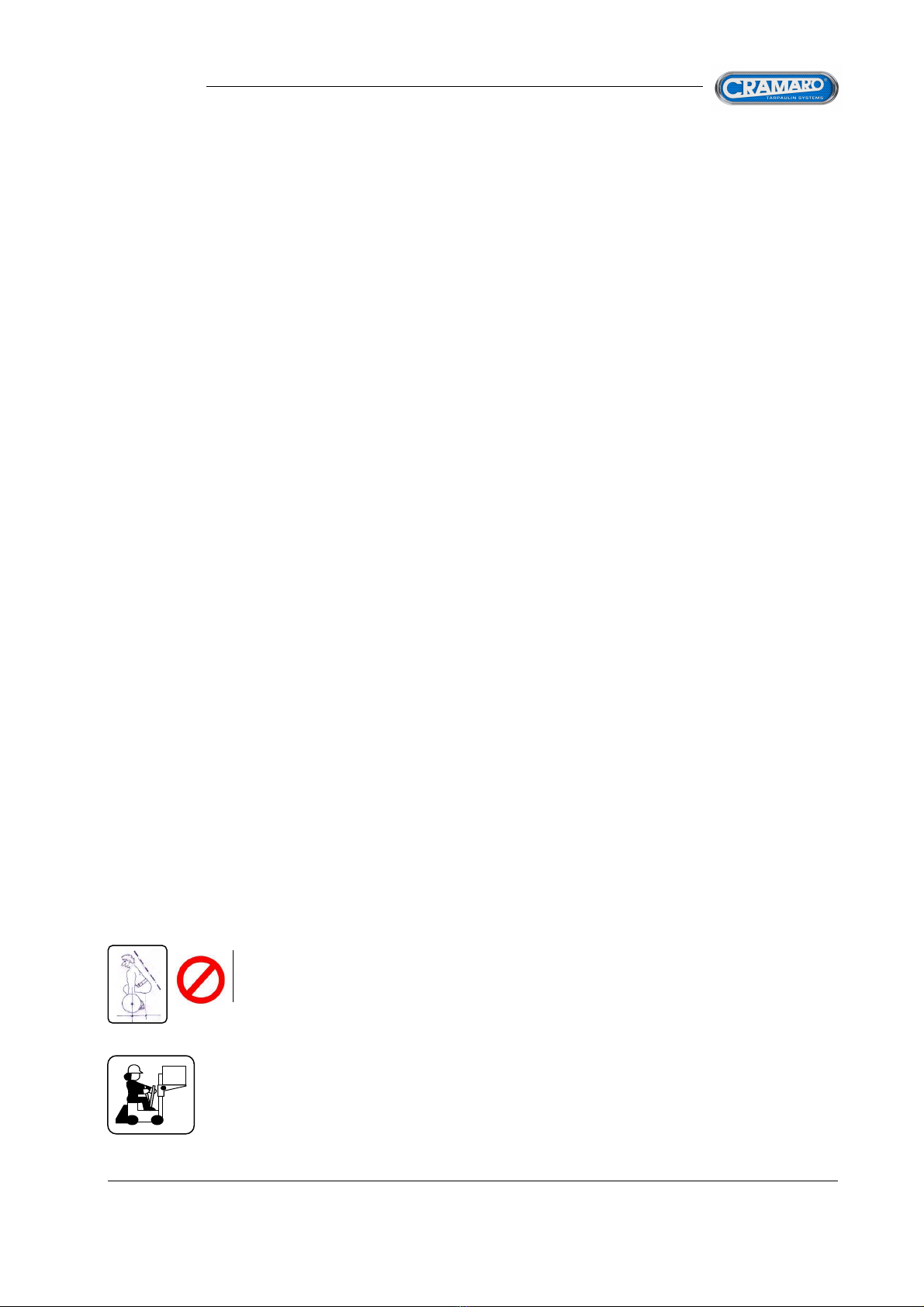

Collision and crushing hazard for upper limbs when the tarpaulin is UNROLLED

and ROLLED UP

HAZARD DESCRIPTION

When the tarpaulin is unrolled, the SIDE ARMS move to the side of the container by

rotating around the pin located underneath the lower edge of the container itself.

As they move, the arms slightly touch the sides of the container and if anyone

accidentally puts their hand between the arms and the side of the container it would

certainly cause an injury.

MEASURES ADOPTED TO TRY AND REDUCE THE HAZARD

-Information and recommendations for the user during the meeting designed to gain

familiarity with the machine, to be provided by the installer at the time of delivery.

-Supply of this manual, which reports the presence of the hazard and reports prohibitions and instructions.

WARNING!

Do not stand underneath the tarpaulin when it is being unrolled.

The manufacturer declines any responsibility!

-There is the obligation of reading and acquiring the content of the manual before using the machine for the

first time (sign shown on the machine).

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 8

Hazard that may be caused by the wind

THE HAZARD IS DESCRIBED BY THE TITLE

MEASURES ADOPTED TO TRY AND REDUCE THE HAZARD

-Information and recommendations for the user during the meeting designed to gain familiarity with the

machine, to be provided by the installer at the time of delivery.

-Supply of this manual, which reports the presence of the hazard and reports prohibitions and instructions.

WARNING!

DO NOT OPERATE WITH WIND FORCE OVER 6 OF THE BEAUFORT SCALE (38.5 – 49.7

km/h)

if there is no air speed indicator, this can be detected by:

-

large branches moving, you start hearing the whistling of wind, it is difficult to use an

umbrella.

The manufacturer declines all responsibility!

-There is the obligation of reading and acquiring the content of the manual before using the machine for the

first time (sign shown on the machine).

Ice hazard on the tarpaulin

THE HAZARD IS DESCRIBED BY THE TITLE

MEASURES ADOPTED TO TRY AND REDUCE THE HAZARD

-Information and recommendations for the user during the meeting designed to gain familiarity with the

machine, to be provided by the installer at the time of delivery.

-Supply of this manual, which reports the presence of the hazard and reports prohibitions and instructions.

WARNING!

Do not use the cover if there is a thick layer of ice on the tarpaulin.

Pieces of ice might be projected in unexpected directions and cause injury to persons or

damage to property.

The manufacturer declines any responsibility!

Hazard of unloading material when the tarpaulin is unrolled over the container

HAZARD DESCRIPTION

Stress and distraction cause everyone to make mistakes.

Lifting the container and unloading the material WHEN THE TARPAULIN IS UNROLLED OVER THE

CONTAINER WILL DEFINITELY DAMAGE THE TARPAULIN ITSELF and the parts that might come off it

might be projected in unexpected directions and cause injury to persons or damage to property.

MEASURES ADOPTED TO TRY AND REDUCE THE HAZARD

-Information and recommendations for the user during the meeting designed to gain familiarity with the

machine, to be provided by the installer at the time of delivery.

-Supply of this manual, which reports the presence of the hazard and reports prohibitions and instructions.

WARNING!

Do not unload material by lifting the container if the tarpaulin is not rolled up at the front.

-There is the obligation of reading and acquiring the content of the manual before using the machine for the

first time (sign shown on the machine).

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page 9

Residual risk

As with any machine, and for this tarpaulin, it is impossible to eliminate at the design stage all the risks associated

with correct use and incorrect use. As a result, it is also impossible for the manufacturer to provide all the safety

systems.

However, the most important factor that guarantees safety is the correct use of the machine by the operators

working on the machine at different times.

Perfect knowledge of accident-prevention standards, methodical use of personal protective devices and a good amount of

common sense help keep the machine in good condition and prevent accidents or hazardous situations.

However, conditions referred to as “RESIDUAL RISK” may occur due to:

•Failure to comply with the instructions reported in this manual, which means the manufacturer is relieved from

any responsibility.

•Imponderable factors for which the manufacturer is relieved from any responsibility.

Some of the main imponderable risk factors:

•Natural disasters for which one cannot provide for suitable evacuation routes such as EARTHQUAKES,

FLOODS, WHIRLWINDS, HURRICANES, STRONG WIND, ETC.

•Sudden fires.

•Lightning.

•Toxic gas leaks.

•Radiation leaks from nuclear areas.

•Fall of bodies from outer space, such as satellites falling from orbit, meteorites, missiles, etc.

•Loose war material.

•Injury to persons, animals or damage to property or the environment caused by persons responsible for

stealing the machine.

•Injury to persons, animals or damage to property or the environment caused by tampering of the tarpaulin by

rivals in an uprising or war.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

10

WORKING UNDER SAFE CONDITIONS, SERVICES AND DOCUMENTS PROVIDED TO

INSTALLERS

Training and support

All retailers and installers of CRAMARO TS tarpaulins are provided with professional training and online support for any

doubts or problems related to assembly.

Installer manual

All machines are delivered with this manual.

WORKING UNDER SAFE CONDITIONS, SERVICES AND DOCUMENTS PROVIDED TO

END USERS

Training, a session to gain familiarity with the machine

When the vehicle on which the CRAMARO TS is mounted is delivered, the retailer/installer provides the owner (or

appointed operated) with a session to gain familiarity with the machine and explains user and routine maintenance

procedures.

At this time, also operating instructions and instructions to protect operators' health and the health of persons

operating with them are provided as well.

Delivery of manuals

All tarpaulins installed are delivered with this manual.

When the manual is provided, the user is informed of the presence of the control register inside the manual and

explanations on how it works and is used are given.

Safety signs applied on the machine

ATTENTION!

The presence of the signs does NOT exempt operators from attending training on how to use

the machine (provided by the employer). Operators must imperatively read the content of this

manual in its entirety.

WHEN YOU SEE THE FIRST SIGNS OF DETERIORATION, CONTACT CRAMARO TS OR

RETAILERS FOR ORIGINAL REPLACEMENT SIGNS.

WARNING!

The employer must not let employees use the machine if the signs are worn, unreadable

or have been removed.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

11

C

T

B

B

M

B

M B

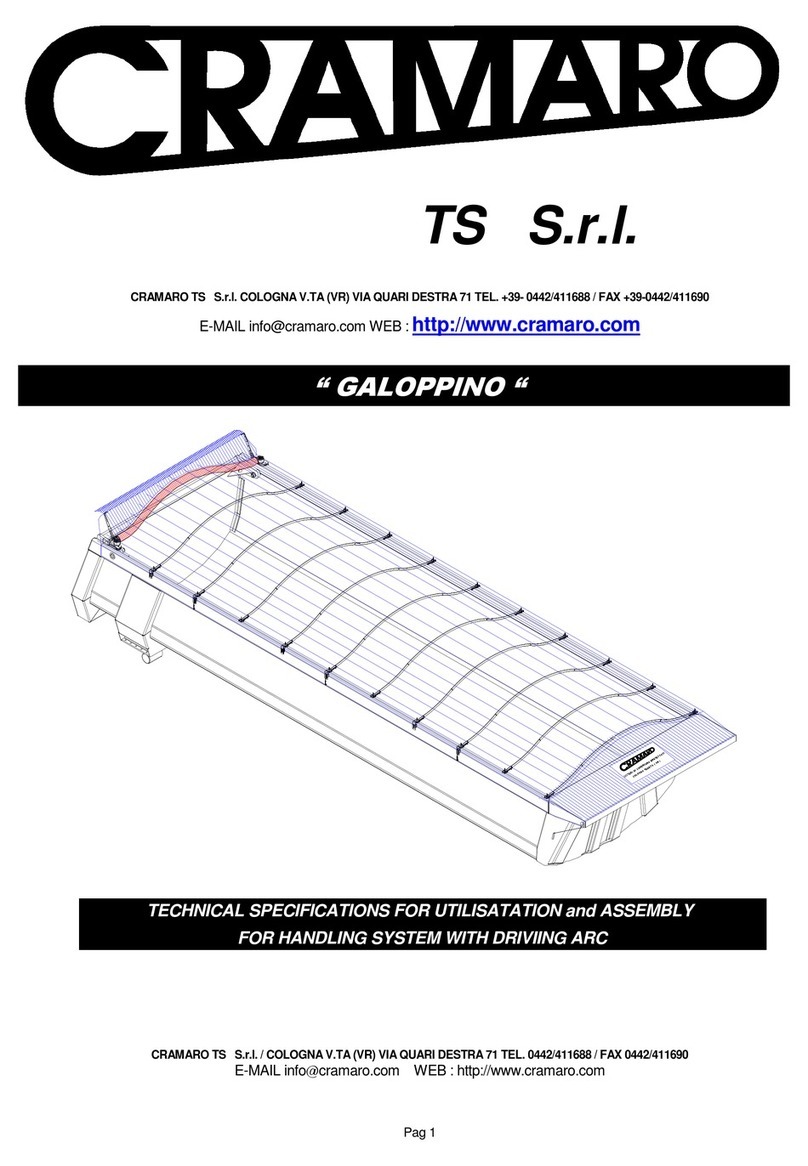

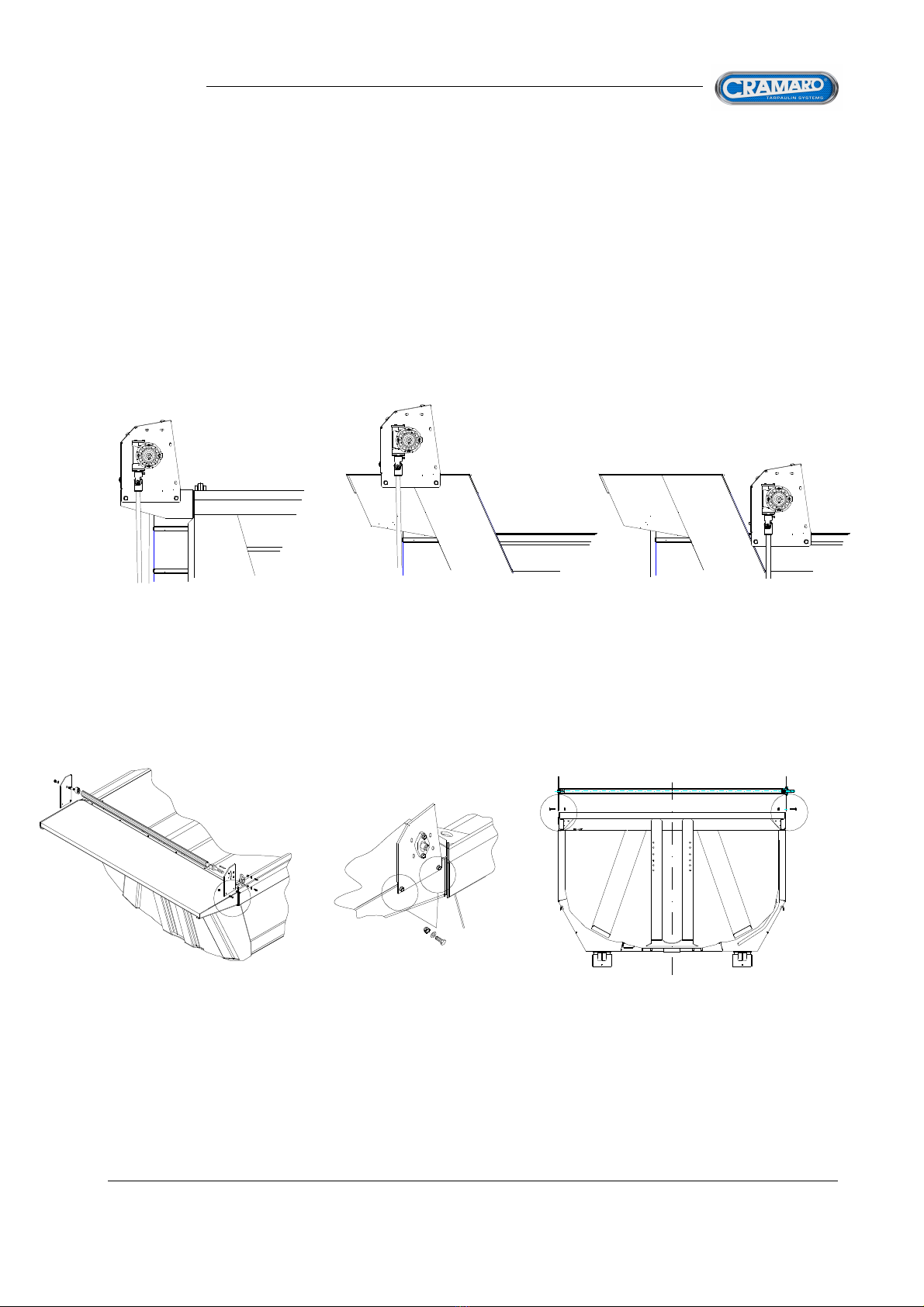

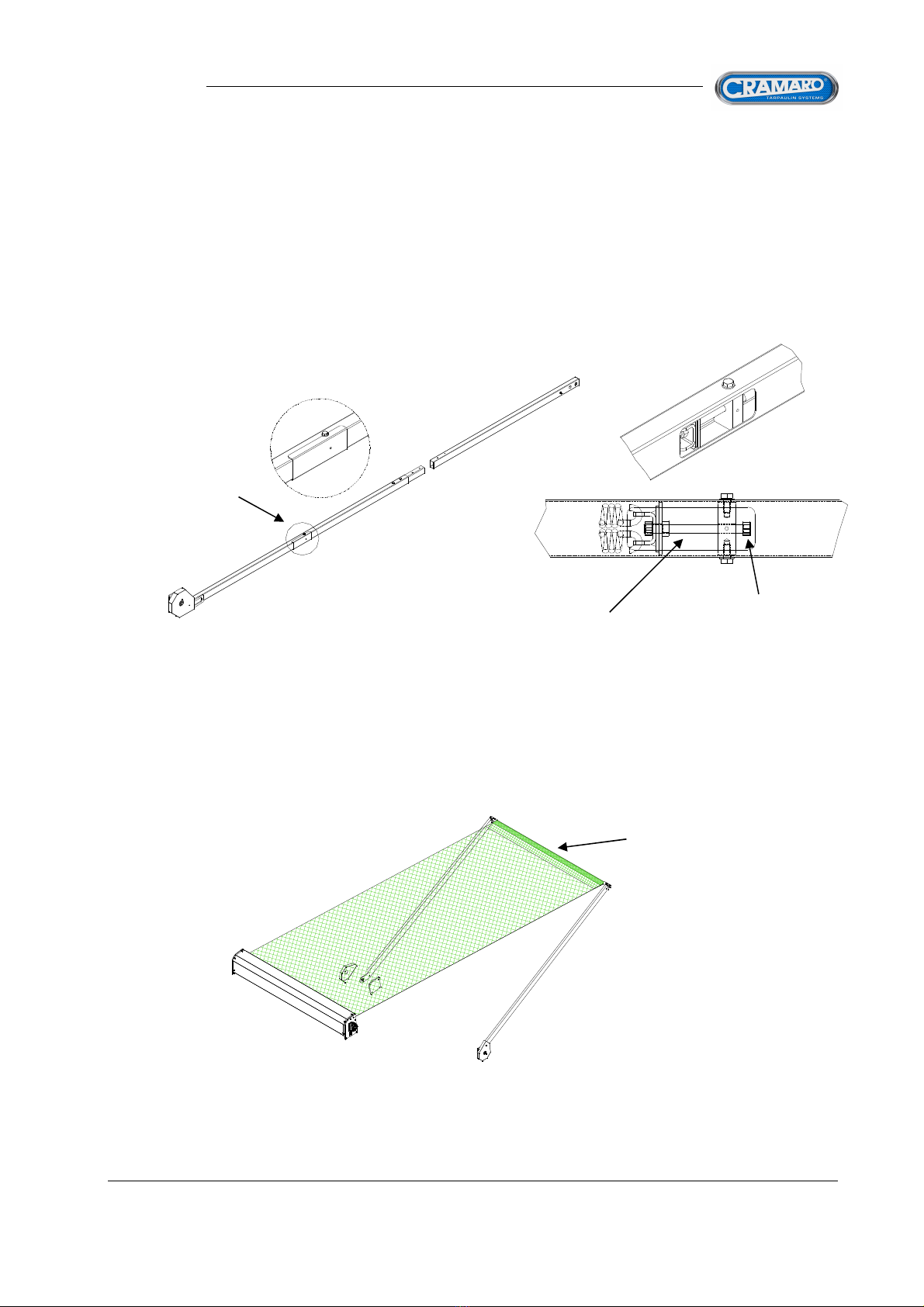

PRESENTATION OF THE TARPAULIN

FOR CONTAINERS MEASURING LESS THAN 7M IN LENGTH

The tarpaulin is delivered ready for installation and is composed of a series of elements that need to be

attached to each other, to adapt it to the measurements of the container that it will be installed on.

C) Tarpaulin housing

M) Crank with adjustable operating rod

B) Adjustable side tarpaulin-guiding arms

T) Tarpaulin

STRAIGHT STD

ARMS

Fig. 2

SHAPED ARMS

FOR HYDRAULIC DOORS

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

12

123

ASSEMBLY PROCEDURE

Preparing the container

1. Level and/or repair any uneven areas and/or crushed or broken areas on the upper edges of the sides

(ATTENTION: SHARP IMPERFECTIONS MAY CUT THE TARPAULIN!)

2. Any sharp angle the tarpaulin might come in contact with by resting on it must be rounded (see detail A), as

it might block and/or damage the tarpaulin

Positioning and attaching the front tarpaulin housing

Position and secure the tarpaulin housing on the front portion of the container.

It is possible to position the front tarpaulin housing either on the overhanging portion of the cab-shield, or behind

the front wall of container

Fig. 3

After positioning the two side covers and the tube used to roll the tarpaulin in the desired position and carefully

make sure it is PARALLEL to the front profile of the container. It can be secured to the cab-shield with the M8

screws supplied in the assembly kit.

Fig. 4

the tarpaulin housing can be mounted at a later stage by attaching it to the two side covers of the housing itself

with special M8 convex screws supplied for this purpose.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

13

Fig. 5

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

14

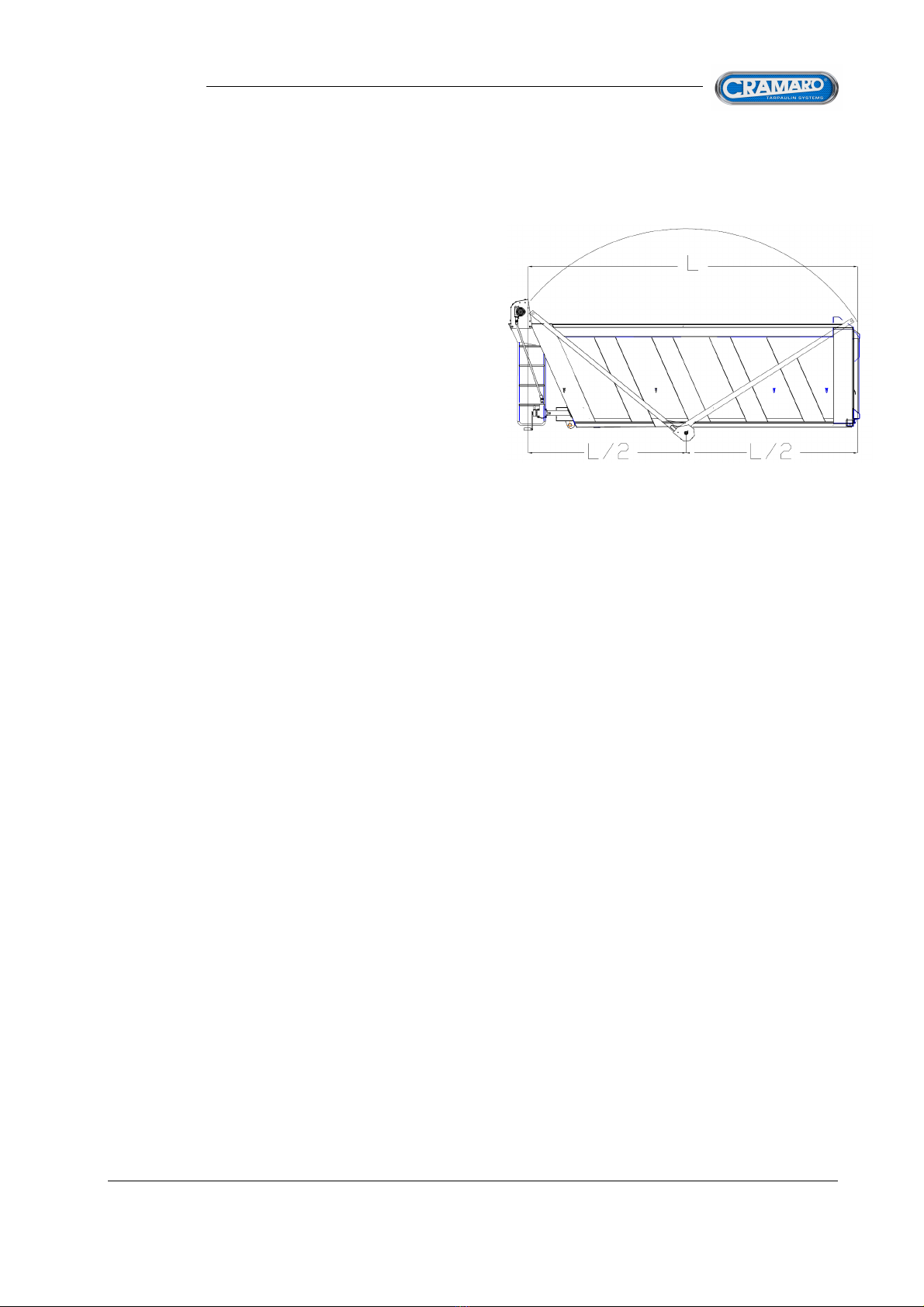

•POSITIONING AND FIXING THE SIDE ARMS

Fig. 6

The side arms are not

very difficult to position. Once you have measured

the distance between the tarpaulin housing

and the front portion of the container, just divide this

measurement

and position the plate acting

as a fulcrum for the tarpaulin operating arms halfway along

the measurement.

The option of adjusting the length

of the arms (only the lower

portion of the arms comes as standard) will make it fairly

easy to position the arms themselves.

IMPORTANT: The fulcrum must be positioned as low as possible and parallel to the container

PLEASE NOTE When the tarpaulin is not used, leave it in the unrolled position (covered container); less

stress is applied on the springs, which ensures greater durability.

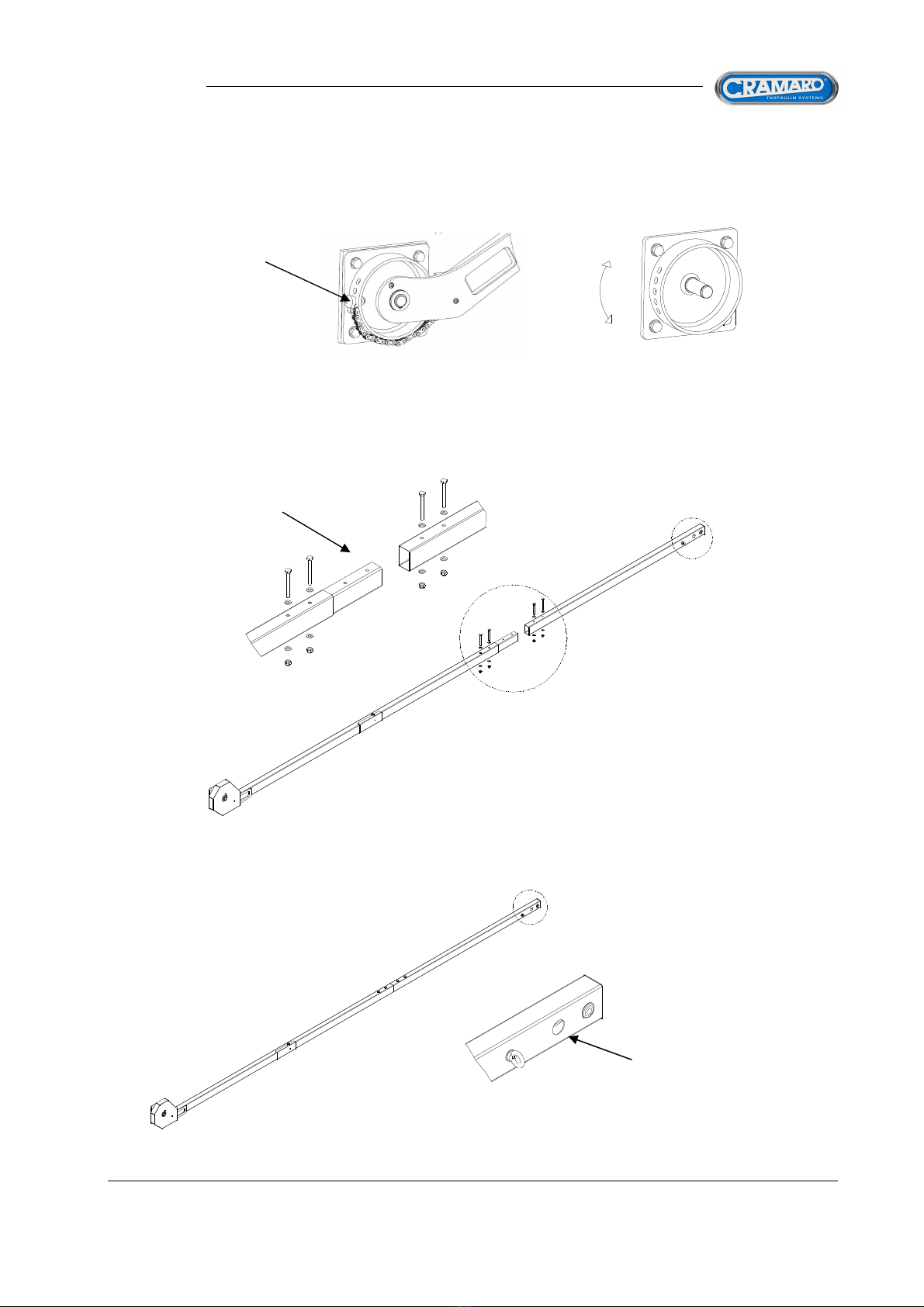

PRE-TENSIONING THE SIDE ARMS

The side arms are usually pre-assembled as far as their lower portion is concerned and with the tensioning

springs inserted, connected and ready to operate when the assembly is completed.

However, in relation to the kind of assembly and geometrical features of the container (length, height, etc.), the

pre-tensioning of the springs carried out by the manufacturer is probably not enough to ensure the tarpaulin

works properly.

Therefore, before completing the assembly of the tarpaulin and therefore permanently attaching the upper

portion of the rotating arms in their operating operation, check whether the springs are well-tensioned to ensure

the arms move smoothly during their whole stroke.

To adjust the tension of the springs, take out the upper portion of the arms and use the special nut at the top of

the lower arms (the ones connected to the container). Turn it clockwise or anticlockwise to increase or reduce

the restoring force of the arms. An additional adjustment is provided by the chain located on the lower part. By

attaching it in the highest hole, the restoring force increases, while it decreases in the lowest hole.

After completing the assembly of the sheet, check again whether the springs are well-tensioned to ensure the

arms move smoothly during their whole stroke. If not, adjust the control chain again as described above.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

15

ARMS WITH SPRINGS IN STAND-BY

Fig. 7

Spring

tensioning threaded bar

Spring tensioning

holes

Spring tensioning chain

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

16

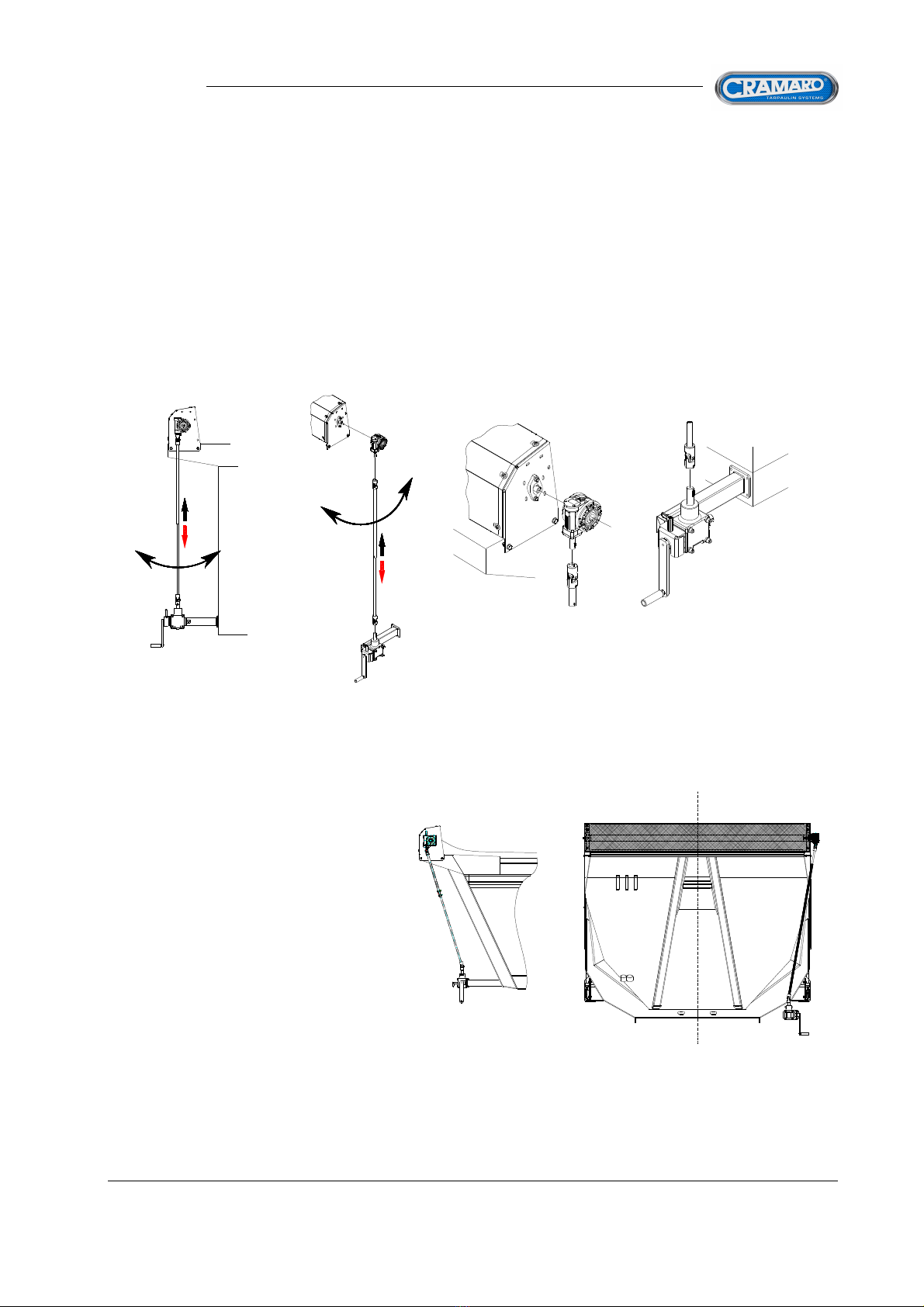

•DRIVE UNIT INSTALLATION

The front drive unit of the tarpaulin can be manual, electric or hydraulic.

In any case application is quite simple and intuitive.

The only exception being the application of the control unit in the electrically-operated version.

MANUAL OPERATION

Fig. 8

The connecting rod between the upper REDUCER and the lower corner STOPPER, which is connected to

the roll operating handle, consists of two pipes sliding into each other to adapt the length of the rod itself in order

to adapt to all the heights of the containers the tarpaulin might be installed on.

The two folding JOINTS at the ends of the

rod can also be used to vary the position of the

lower handle considerably, so that it is not

positioned out

of the maximum overall dimensions of the

container itself

as clearly indicated in the figure to the side

Fig.9

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

17

ELECTRICAL OPERATION

As for the ELECTRICAL system used to operate the FLIP TARP

tarpaulin, the motor's installation method is fairly similar to the method used for MANUAL operation,

as the electric motor and its mechanism are also applied on the small shaft protruding

from the side of the tarpaulin housing.

In this case, a connecting BUSHING will

be placed between the GEARED MOTOR and the housing

Fig. 10

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

18

HYDRAULIC OPERATION

The operation of the hydraulic system is similar to the electric one. The

reducer with the hydraulic motor is applied on the small shaft protruding from

the tarpaulin housing. The kit is supplied with a pressure valve and two

hydraulic pipes that connect this valve to the motor. The valve must be

connected near the motor.

PAY ATTENTION TO THE CALIBRATION OF THE VALVE.

ADJUSTMENT STEP:

- Before sending the oil to the motor, make sure the pressure valve is set to

minimum. To do this, use the designated spanner to turn the screw anticlockwise (see figure).

Perform this step on both directions of flow.

MOTOR

SUPPLY

- With the arms positioned as shown in figure 12, increase the pressure of the delivery circuit through the valve.

Turn the screw clockwise until the motor has enough force to bring the arms in the open position and discharge

the valve (Fig.13). Also position the screw of the return circuit in the same position as the delivery one.

Fig.12

Fig.13

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

19

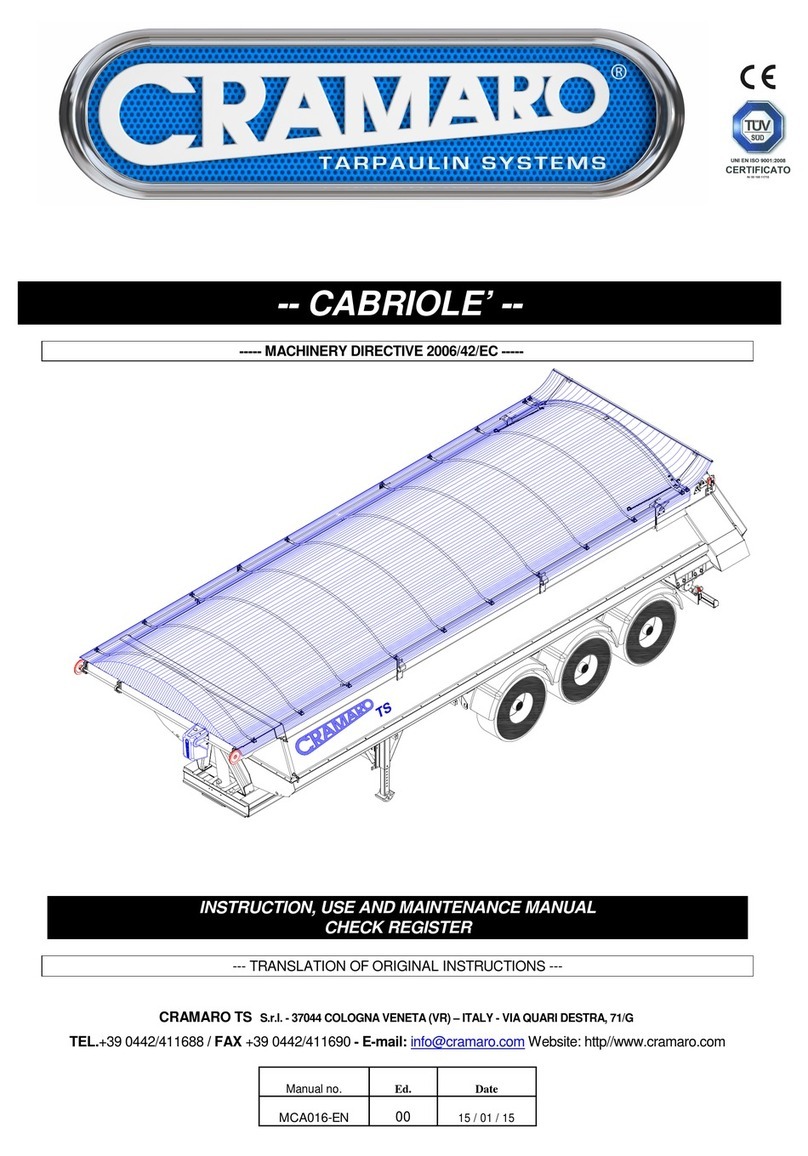

PRESENTATION OF THE TARPAULIN

FOR CONTAINERS MORE THAN 7 M IN LENGTH

This configuration involves some components that differ from those in the previous configuration. The side arms

consist of 80x50 tubular elements inside which move springs of various sizes.

The adjusting system for the latter is based on the same operating principle: they are tensioned using the

designated spanner and adjusting rod (refer to the diagram). Remove the protective cover to access the

adjusting rod.

PROTECTIVE

COVER

TENSIONING NUT

ADJUSTING ROD

This operation must be done with the arms fixed to the rotation fulcrum plate and connected to the tarpaulin with

the designated transversal pipe.

During the operation, make sure that the tension of the springs is practically the same to the left and to the right,

ensuring that the side arms can turn in a uniform manner and that the tarpaulin can be rolled up correctly.

TRANSVERSAL PIPE

JOINING THE ARMS

After making the adjustment, put the protective cover correctly in place again.

FLIP TARP

CRAMARO TS S.r.l. – 37044 COLOGNA V.TA (VR) - VIA QUARI DESTRA, 71/G TEL. +39 0442/411688 / FAX + 39 0442/411690

E-MAIL info@cramaro.com WEBSITE: http://www.cramaro.com - Manual no. MFT002-EN-ED07 – date 02/05/2017

Page

20

+

-

The chain at the base of the arm (available also in the other version) can also be used to adjust the springs.

Attach it to the highest hole to increase pressure or to the lower one to decrease pressure (refer to the diagram).

CHAIN FOR

TENSIONING

.

The arms are joined using the ARM JOINT and the designated fixing screws. (refer to the diagram)

JOINT

There are two holes in the UPPER ARM for inserting the transversal pipe that holds the tarpaulin. The lower

hole should normally be used; the other one is to be used when moving the rotation fulcrum or when moving the

pipe into a position other than the predefined one. If using the upper hole, remove the sealing caps and put

them on the lower hole.

HOLE TO BE USED

FOR THE TRANSVERSAL PIPE

Table of contents

Other Cramaro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ATD Tools

ATD Tools SPI-77100 user manual

C-Tech Manufacturing

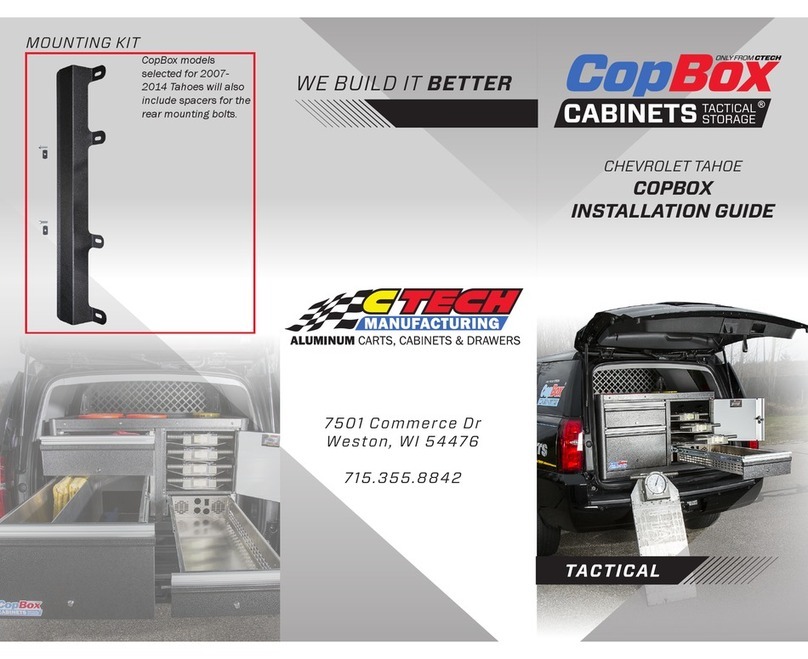

C-Tech Manufacturing CopBox installation guide

Witter

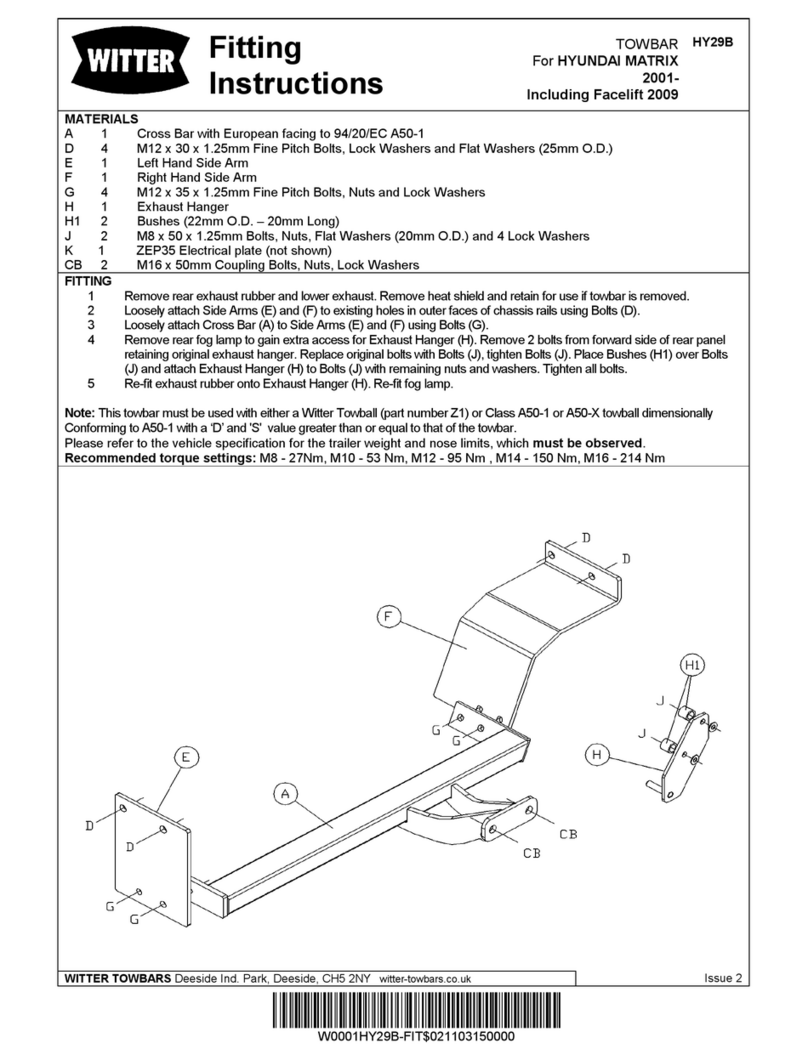

Witter HY29B Fitting instructions

Subaru

Subaru TRAILER HITCH HARNESS instructions

Abrams

Abrams SlickEye Visor Installation and configuration manual

Barker

Barker TOTE-ALONG Owner's instructions