DIGITAL DELAY Mega 300 User manual

1

2036 Fillmore Street

Davenport, Ia. 52804

563-324-1046

www.racedigitaldelay.com

MEGA 300/400

WARRANTY AND DISCLAIMER

DIGITAL DELAY INC. WARRANTS THE PRODUCTS IT

MANUFACTURES AGAINST DEFECTS IN MATERIALS AND WORKMANSHIP

FOR A PERIOD LIMITED TO 1 YEAR FROM THE DATE OF SHIPMENT,

PROVIDED THE PRODUCTS HAVE BEEN STORED, HANDLED, INSTALLED,

AND USED UNDER PROPER CONDITIONS.

The company’s liability under this limited warranty shall extend only to the

repair or replacement of a defective product, at the company’s option. DIGITAL DELAY

INC. disclaims all liability for any affirmation, promise, or representation with respect to

the products.

The customer agrees to hold DIGITAL DELAY INCORPORATED harmless

from, defend, and indemnify DIGITAL DELAY INC. against damages, claims, and

expenses arising out of subsequent sales of or use of DIGITAL DELAY INC. products, or

products containing components manufactured by DIGITAL DELAY INC. and based

upon personal injuries, deaths, property damage, lost profits, and other matters which

BUYER, its employees, or sub-contractors are or may be to any extent liable, including

without limitation, penalties imposed by the Consumer Product Safety Act (P.L. 92-573)

and liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L.

93-637), as now in effect or as amended hereafter.

No warranties expressed or implied, are created with respect to the company’s

products except those expressly contained herein. The customer acknowledges the

disclaimers and limitations contained and relies on no other warranties or affirmations.

2

2036 Fillmore Street

Davenport, Ia. 52804

563-324-1046

www.racedigitaldelay.com

Mega 300 and 400

Instructions

Digital Delay, the company that invented and patented the Crossover, designed and manufactured the Mega 300 and

400 simply to be the best and most advanced multi-function box on the market. The Mega 300 and 400 both have four

separate outputs, four separate push-button inputs, and a tach input. This combination of inputs and outputs allows the Mega

300 and 400 to be tailored to fit a variety of roles.

Some of the special functions of the Mega 300 and 400 are, the ability to Tap either up or down, subtract time from

the stage timers, enter a programmable starting line enhancer time, shift up to five times on either Time or RPM, and to select

one or two push-buttons to start the delay times. Some other special features include a Replay Tach (Mega 400 only) that

samples the engine RPM 100 times a second, and a Driver’s Reaction Tester that allows a driver using the buttons mounted in

the vehicle to test his or her reaction time.

Contents:

Warranty and Disclaimer............................................................................…. Page 1

Features, and Specifications.....................................................................…… Page 3

The Terminal Strip......................................................................................…. Page 4

The Keypad.................................................................................................….. Page 5

Setting Dial-Ins and Delay Times..............................................................…… Page 6

Setting and Displaying the Tap Up/Down.................................................……. Page 6

How Late.....................................................................................................…… Page 6

Setting Push-button Mode and Interrupt Time...........................................……. Page 7

Setting the Selectable Function Output Mode (S.F.O.).............................……. Page 7

Setting Starting Line Enhancer Time (S.L.E.).............................................…… Page 7

Setting the Programmable Throttle Stop Override (P.T.S.O.)...................…….. Page 8

Setting Throttle Modes and Throttle Ranges...........................................………. Page 8

Setting Stage Times...................................................................................……… Page 8

Setting Shift Modes, Shift Output Mode, and Shift Points........................……….Page 9

Setting Number of Cylinders .....................................................................…….. Page 9

Understanding the Drivers Reaction Tester.............................................………. Page 9

Explanation of the Peak RPM......................................................................……. Page 10

Explanation of the 4-Stage Timer & Starting Line Enhancer.....................………Page 10

How the Programmable Throttle Stop Override Works............................………. Page 11

Understanding Time and RPM Mode and the Replay Tach....................……….. Page 11

Understanding the Selectable Function Output ( S.F.O. ).........................………. Page 12

Understanding the Line Lock push-button.................................................……… Page 12

Understanding and Connecting a By-pass push-button.. .............. .........……….. Page 12

Understanding and Connecting Two or More Outputs Together .............………..Page 12

Accessories................................................................................................………. Page 13

Mounting and Wiring the Unit....................................................................... Page 14

3

Features and Specifications

Features:

• Microprocessor controlled timing

• Discrete I/O (input - output) construction

• Retains all numbers even with power disconnected from unit

• Large illuminated display for easy reading of information day or night

• Self-test mode on all display functions

• Dust & splash-proof key pad with detent (positive feel)

• Hit the tree twice with one or two separate buttons

• Line Lock push-button input

• Can run two separate throttle stops at once

• High and low range settings for the 4 Stage Timers

• Instant timing cycle reset

• Programmable push-button interrupt time

• Built-in digital tachometer

• Time or RPM switch

• Works on 4, 5, 6, 8, 10, and 12 cylinder engines

• Selectable Function Output (S.F.O.) with four separate functions

• Secondary transbrake

• Second throttle stop timer

•Starting Line Enhancer (S.L.E.)

• Line Lock Controller

• Programmable Tap Up/Down feature for the delay

• Programmable Throttle Stop Override for the 4-Stage Timer

• An additional second 4-Stage Timer

• Programmable Starting Line Enhancer

• Built-in drivers reaction tester

• Built-in Replay Tach (Mega 400 only)

• Digital data port for down loading (Mega 400 only)

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Specifications:

•Input Voltage Range: 10 to 18 Volts DC ( 16 Volt compatible )

•Operating Temperature Range: 0 to 150 degrees F.

•Push-button Current: .1 AMPS at 12 VDC

•Tach and RPM Switch Range: 800 to 12750 in 50 RPM increments

• Four Separate Output

•Transbrake

• Selectable Function Output ( S.F.O.)

• Throttle Stop

• Shifter

• Five Separate Inputs

•P.B.1

•P.B.2

•TapP.B.

• L.L. P.B.

• Tach

4

The Terminal Strip

+12VDC Terminal: Connect the +12VDC terminal to a switched +12 Volt source with enough amperage

capable of driving all outputs at the same time.

Transbrake Terminal: Connect the Transbrake terminal to the Transbrake solenoid. Connect the low

side of the 2-Step here, if used.

S.F.O. Terminal: Connect the S.F.O. (Selectable Function Output) to a device that is to function in one of

the following four ways.

1) A device to be used as the Starting Line Enhancer, usually a linkage style throttle stop.

2) A device to be controlled by the second four stage timer.

3) Connect to the Line Locks, if the Line Locks are to be engaged when the Transbrake is

engaged or the Line Lock push-button is pressed.

4) Connect to the Transbrake solenoid, this is to be used only as a temporary back-up output.

Make sure that the S.F.O. mode setting is correct for the device being used.

Incorrect settings will cause undesirable results.

Throttle Stop Terminal: Connect the Throttle Stop terminal to a stop to be used down track. This is the

main or first four stage timer (Throttle 1).

Shift Terminal: Connect the Shift terminal to the shifter.

Ground Terminal: Connect the Ground terminal to the Neg. terminal on the battery or to a good steel

ground, not aluminum.

Button-1 Terminal: In single Push-button Mode the push-button connected to Button-1 terminal is used

to control the primary delay and the secondary delay in sequence. In dual Push-button Mode

the push-button connected to Button-1 terminal is used to control the primary delay only.

Button-2 Terminal: In single Push-button Mode this terminal is disabled and has no affect on the

operation of the unit. In dual Push-button Mode the push-button connected to Button-2 terminal is

used to control the secondary delay only.

Line Lock Terminal: To use the optional Line Lock terminal connect to an additional push-button. This

button functions as listed below.

1) If the Line Lock push-button is pressed and the S.F.O. is set to 3 (Line Lock Control), any

Line Locks hooked to the S.F.O. Terminal will be engaged.

2) If the Line Lock push-button is pressed the Replay Tach Record function will be armed

(Mega 400 only).

Tap P.B. Terminal: To use the optional Tap P.B. terminal connect to an additional push-button. This

button can control three different operations.

1) If the Starting Line Enhancer is on and before the Transbrake is applied, if the Tap push-

button is pressed the throttle will close allowing the car to be staged at a preset RPM.

2) After a Transbrake push-button has been released, every time the Tap push-button is

depressed a programmable amount of time is either added to, or subtracted from, the first

delay time started until the Transbrake is released.

3) A quarter of a second after the Transbrake releases and for every time the Tap push-

button is depressed a programmable amount of time is subtracted from the second or fourth

stage times.

Tach Terminal: Connect the Tach terminal to the tach output on the ignition. On the Mega 400 this

terminal must be connected for proper operation of the Replay feature.

5

The Keypad

The keypad is made up of numerical and function keys that are used to control the information that is either entered

into the unit or shown on the displays. The numerical keys 0-9 are used in conjunction with the function keys A and B to enter

new information. While the numerical keys 1-5 and the function keys C-F are used to control what information is shown on

the display.

Function Keys A and B

The function keys A and B correspond to the A and B shown on the displays and are used when changing either

setting or value. When either the A or B key is pressed the numbers to the right of the respective A or B on the display will be

blank. This allows a new setting or value to be entered using the numerical keys.

Example:

1) Select the Dial-Ins by pressing the C key until the letters A and B are next to the Dial-Ins.

2) Press the A key on the keypad, the numbers to the right of the A on the screen will blank

out indicating it is ready to accept a new time.

3) Use the numerical keys to enter Your Dial-In, leading zeros do not have to be entered. As

the numbers are entered they will appear on the display indicating that the number was

accepted and stored into memory.

Note: If an error is made while entering, press the appropriate A or B key to erase the last digit.

This can be repeated as many times as necessary until the display is blank.

Function Keys C, D, E, and F

The function keys C, D, E, and F are used to select what information is shown on the display. For example, if the

Dial-Ins and Delays are wanted and the Throttle 1 stage times are being displayed, the C key would be pressed to display the

Dial-Ins and Delays with the letters A and B next to the Dial-Ins (this is C1). If the C key was then pressed again the A and B

would move down next to the Delays (this is C2).

Display with C-F key Change with A key Change with B key

C1 YourDial-in TheirDial-in

C2 Delay1 Delay2

D1 Sub/Add HowLate

D2 P.B.Mode. S.F.O. Mode

D3 *S.L.E. P.T.S.O.

D4 Throttle Stop 1 Mode *Throttle Stop 2 Mode

E1 Stage1 Throttle 1 Stage2 Throttle 1

E2 Stage3 Throttle 1 Stage4 Throttle 1

E3 *Stage 1 Throttle 2 *Stage 2 Throttle 2

E4 *Stage 3 Throttle 2 *Stage 4 Throttle 2

F1 Tachor **Peak RPM ShiftPoint

F2 #of Cylinders Timeor RPM Mode

F3 _Display Test Mode -Drivers Reaction Tester

F4 __**Replay Mode **Replay Mode

* Will only be displayed if S.F.O. is set to corresponding mode.

** Will only be displayed if engine is off.

_ Test mode A and B keys have no affect.

__ Optional Feature.

Note: The “F” key can also be used to cancel a timing cycle.

6

Setting Dial-In Times

To set a new Dial-In time into either Your Time or Their Time press the C key until the A and B letters are shown

next to the

Dial-Ins (C1). To enter a new number press the corresponding letter key (A or B) for the Dial-In time to be changed. The

selected display row will go blank indicating the unit is ready to accept the new Dial-In time. Enter the new Dial-In time using

the numerical keys, leading zeros do not have to be entered. For example if 9.90 for a Dial-In time is desired 990 would be

entered on the keypad. As the numbers are entered they are shown on the display, indicating the numbers are accepted and

entered into memory. If a mistake is made while entering the number, depressing the corresponding letter key (A or B) again

will erase the last digit entered. This can be repeated as many times as necessary until the display is blank.

Setting Delay Times

To set a new Delay time into either Delay 1 or 2, repeatedly press the C key until the letters A and B are shown next

to the Delays (C2). Then follow the same procedure for entering a new number as instructed in setting new Dial-In times.

Setting and Displaying the Delay

Tap Up/Down (Sub-Add) Information

To display the Tap Up/Down information, repeatedly press the D key until the letters A and B are shown next to the

Sub/Add and How Late (D1). The Sub/Add information is shown to the right of the letter A. The left most digit shows the

number of times the Tap Up/Down push-button was pressed. The two right hand digits show the programmable time (0 to 9

hundredths of a second) to be subtracted from or added to the delay time every time the Tap Up/Down push-button is pressed.

Above the two right digits the word Sub or Add will be shown, this indicates what will happen when the Tap Up/Down push-

button is pressed (Add = Tap up and Sub = Tap Down). To change the number, press the A key and enter the new number (0-

9). To switch between the Sub and Add modes press the A key repeatedly, once the far right digit is blank the unit will toggle

between the Sub and Add modes each time the A key is pressed. Once the mode is selected enter the new Sub/Add amount.

The Tap Up/Down will only affect the first delay time started.

Understanding the How Late

To display the How Late information, repeatedly press the D key until the letters A and B are shown next to the

Sub/Add and How Late (D1). The How Late information is shown to the right of the letter B. If the Transbrake is released on

Delay-2 (4-Digit) the left most digit will display an “2”, if not, it will be a “1”. The remaining digits display the How Late

time. For example if the number displayed is “2.012” and your reaction time was .510 on the time slip, add the How Late time

to the .510 for a total reaction time of .522 on the crossover delay.

NOTE: Both How Late and Tap Up/Down information are stored in memory until either a new How

Late or Tap Up/Down number replaces the old one or the B key is pressed while the Tap

Up/Down and How Late information is displayed, they will then both be cleared to all zeros.

7

Setting Push-button Mode and the

Push-button Interrupt Time

To set the Push-button Mode, repeatedly press the D key until the letters A and B are shown next to the P.B. Mode

and the S.F.O. Mode (D2). The Push-button Mode is shown next to the letter A. The left most digit shows “1” or “ 2” to

indicate which Push-button Mode the unit is in, when in 1 Push-button Mode, the First P.B. starts both the primary and

secondary delays. When in 2 Push-button Mode, one or both push-buttons can be used in any sequence, the First P.B. starts

the primary and Second P.B. starts the secondary delay. The two right digits show the programmable amount of time (00 to 99

seconds) that after the Transbrake releases, Button 1 and Button 2 push-button inputs are disabled. To change either the

Button Mode or the Interrupt Time first press the A key, then enter a “1” or “2” for the Push-button Mode followed by a two

digit number representing the Push-button Interrupt Time. For example “1 10” would indicate 1 Push-button Mode with a 10

second Interrupt Time. If no Push-button Interrupt Time is wanted enter “00” after pressing a “1” or “2” for the Push-button

Mode.

Setting Selectable Function

Output Mode (S.F.O.)

To set the Selectable Function Output Mode, repeatedly press the D key until the letters A and B are shown next to

the P.B. Mode and the S.F.O. Mode (D2). The S.F.O. Mode is shown next to the letter B. There are five different modes (1-5)

which are listed below, to change the S.F.O. mode repeatedly press the “B” key, each time the B key is pressed the S.F.O.

mode will increase by one until it reaches five at which time it will revert back to one on the next press of the B key.

1) This sets the S.F.O. terminal up to Function as a Starting Line Enhancer (S.L.E.).

2) This sets the S.F.O. terminal up to function as a second Throttle Stop.

3) This sets the S.F.O. terminal up to function as a Line Lock Control.

4) This sets the S.F.O. terminal up to function as a second Transbrake output.

5) This turns the S.F.O. terminal completely off (no voltage out).

Setting Starting Line

Enhancer Time

If the S.F.O. mode is set to mode one the Starting Line Enhancer will be turned on, if the S.F.O. mode is set to any

mode other than mode one, the Starting Line Enhancer will be turned off. To set the Starting Line Enhancer Time, repeatedly

press the D key until the letters A and B are shown next to the S.L.E. and the P.T.S.O. (D3). If there are two dashes and the

word off is shown at the top of the screen, the Starting Line Enhancer is turned off. If the Starting Line Enhancer is turned on,

the time is shown to the right of the letter A. The four digits show the amount of time that the throttle will open up before the

TRANSBRAKE RELEASES.

When the Starting Line Enhancer is turned on, to enter a new time do the following. Press the A key, the four digits

to the right of the letter A will go blank. Then use the numerical keys to enter a new Starting Line Enhancer time. All number

from 00.00 to 99.99 can be entered, with the exceptions of 11.11 and 22.22 which are described below. If the Starting Line

Enhancer time is greater than the delay time, the throttle will open as soon as a Transbrake push-button is released. If this is

desired simply enter all nines (99.99). If all zeros (00.00) are entered the throttle will open up when the Transbrake releases.

Using all ones (11.11) will pre-set the release of the throttle at eight tenths of a second before the Transbrake releases.

This means that two tenths of a second after your top yellow the throttle will open up. The benefit of the throttle opening up at

this time is that it will not be a distraction when using your top yellow for a second hit at the tree.

Using all twos (22.22) will set the S.L.E. to Pro mode. When in Pro mode the release of the throttle will occur when

the transbrake is engaged. This means that the throttle must be closed using the Tap P.B. before staging.

Note: Use Throttle Stop Mode two (D4) to change output voltage of the S.F.O. for the type of Throttle

Stop being used as a Starting Line Enhancer.

8

Setting the Programmable

Throttle Stop Override (P.T.S.O.)

To enter a new Programmable Throttle Stop Override amount, repeatedly press the D key until the letters A and B are

shown next to the S.L.E. and the P.T.S.O. (D3). The Programmable Throttle Stop Override information is shown to the right

of the letter B. If the P.T.S.O. is turned off, two dashes and the word “OFF” will be to the right of the letter B. If a number is

displayed the P.T.S.O. is turned on and the number shown is the current P.T.S.O. time. To change the amount of time press

the B key, the four digits to the right of the letter B will go blank and the word “OFF” will be shown just below and to the left

of where the digits had been. At this point if no numbers are entered the P.T.S.O. will be turned off. If any number greater

than zero is entered the P.T.S.O. will automatically be turned on. Enter the new P.T.S.O. amount using the numerical keys,

leading zeros do not have to be entered. Any number from 00.01 to 99.99 seconds can be used.

Setting Throttle

Modes and Throttle Ranges

To set the Throttle Modes or Throttle Range, repeatedly press the D key until the letters A and B are shown next to

Throttle 1 and Throttle 2 (D4). The Throttle 1 mode and Range are shown to the right of the letter A and Throttle 2 mode and

Range are shown to the right of the letter B. To the right of the letter A either “lo” or “Hi” will be shown, this is the Throttle

Range and only affects the first and second stages. The first and second stage times can be set to any number from 0.000 to

9.999 seconds when in “lo” Range and from 00.00 to 99.99 seconds when in “Hi” Range. Above the Throttle Range setting

the words “off on off on” or “on off on off” this is the Throttle Mode. To change either Throttle 1 Range or Mode repeatedly

press the A key until the desired Range and Mode combination is shown on the display. Throttle 2 works in much the same

way as Throttle 1 does except for two differences. First the S.F.O. Mode must be set to a “2” or Throttle 2 is turned off.

Second is the Throttle Mode indicators are below the Range settings and only “on off” or “off on” will be shown. It must just

be understood that the Throttle Mode would simply repeat for stages 3 and 4.

If the S.F.O. mode is set to any number other than a “1” or a “2”, two dashes will be shown along with the word

“OFF” below the dashes indicating Throttle 2 is off.

Setting Stage Times

To set a new stage time, repeatedly press the E key until Throttle 1 is shown on the display and the letters A and B are

shown next to Stage 1 and Stage 2 (E1). To change stages 3 or 4 press the E key again so the letters A and B are shown next

to Stage 3 and Stage 4 (E2). The stage times can be changed by following the same procedure for entering a new number as

instructed in Setting New Dial-In Times. Entering all zeros into any stage turns that stage off.

To set a new stage time for Throttle 2 the S.F.O. Mode must first be set to a 2. Then repeatedly press the E key until

Throttle 2 is shown on the display and the letters A and B are shown next to Stage 1 and Stage 2 (E3). To change stages 3 or 4

press the E key again so the letters A and B are shown next to Stage 3 and Stage 4 (E4). The stage times can be changed by

following the same procedure for entering a new number as instructed in Setting New Dial-In Times. Entering all zeros into

any stage turns that stage off.

If the S.F.O. mode is set to any other mode other than 2 the access to Throttle 2 stage times will be denied.

9

Setting Shift Modes,

Shift Output Mode, and Shift Points

The Mega 300 and 400 can handle up to 5 shifts on each pass. These 5 shifts can be either made on time, RPM, or a

combination of both. The shifts occur when the Shift Point setting is reached for each of the five shifts in sequence. The 5

Shift Points can all be set to different values and shift modes. When looking at the Shift Points, at the bottom of the screen the

Shift Mode and shift number will be displayed. To look at all of the Shift Points, repeatedly press the F key until the letters A

and B are shown next to # of CYL and Shift Mode (F2). To the far right of the letter B is the shift number (1-5). To change

the shift number, press the number on the key pad for the desired shift number. For each shift number the Shift Point will be

displayed towards the top of the screen and the Shift Mode will be shown at the bottom of the screen by the word “RPM” or

“TIME”. To change the Shift Mode repeatedly press the B key. Each time the B key is pressed the Shift Mode toggle between

either RPM or Time Mode. As the Shift Mode is changed, the decimal will either be added, Time shift, or removed, RPM

shift, from the Shift Point. Only when viewing Shift Number 1 can the shift output be seen or changed. The Shift Output is

displayed as either “LO” or “HI” along with the Shift Mode and Shift Number. When the Shift Output is set to “HI” (normally

open) it means the every time a Shift Point is reached the Shift terminal will go from a low (0 Volts) to a high (12 Volts).

When the Shift Output is set to “LO” (normally closed) it means the every time a Shift Point is reached the Shift terminal will

go from a high (12 Volts) to a low (0 Volts). Setting the Shift Output is done at the same time the Shift Mode is set for Shift

Number 1.

To set a Shift Point, first make sure the Shift Number is set correctly then repeatedly press the F key until the letters A

and B are shown next to Tach and Shift Point (F1). Then press the “B” key the digits to the right of the letter B will go blank.

Then follow the same procedure for entering a new number as instructed in setting new Dial-In times. Numbers from 00.02 to

99.99 can be entered for time mode and from 1000 to 9950 in 50 RPM increments for RPM mode.

The shifts will occur for a 20 second time period, only after the transbrake has been released.

Setting Number of Cylinders

To set the Number of Cylinders, repeatedly press the F key until the letters A and B are shown next to # of CYL and

Shift Mode (F2). To the right of the letter A will be a two digit number representing the number of cylinders. To change the

number of cylinders press the A key. Each time the A key is pressed the unit will advance to the next cylinder setting.

Cylinder settings of 4, 5, 6, 8, 10, and 12 are all available.

Understanding the

Driver’s Reaction Tester

This new feature in delay boxes allows a driver using the buttons mounted in the vehicle to test their reaction time.

This can also be used to test different kind of buttons and locations that they are mounted in the vehicle for the quickest release

possible.

To select the Driver’s Reaction Tester, repeatedly press the “F” key until everything on the screen turns on at once,

this can also be used to check for proper screen operation. Once in Reaction Test Mode, if a push button connected to either

PB.-1 or PB.-2 is pressed and held down, the screen will go blank. After 2 seconds all eights will be shown on the screen, at

which time the driver releases the push button being held. The display will now show the amount of time from when the

eights where displayed to when the push button was released, this is the driver’s reaction time. If the driver lets go of the

button too soon, before the display turns on, dashes will be shown on the screen to indicate a red light. If the driver does not

let go of the button within .75 seconds after the eights are displayed, the display will show reaction time of all nines to indicate

a missed light. To exit the Driver’s Reaction Test Mode press any function key C - F on the keypad. If neither PB.-1 or PB.-2

push-button is pressed, the unit will automatically exit the Driver’s Reaction Test Mode after 30 seconds. Each time a push-

button is pressed the 30 second resets.

NOTE: When in the Driver’s Reaction Test Mode, the Transbrake solenoid will not be activated when

a

push button is pressed. This is to prevent any damage to the solenoid from over heating.

10

Explanation of the Peak RPM

The Peak RPM is shown on the display in place of the Tach any time the engine is off. The Peak RPM value will be

the highest RPM the engine has reached since the last time the Peak RPM cleared. To clear the Peak RPM, repeatedly press

the F key until the letters A and B are shown next to the Tach and Shift Point.

If the words “Peak RPM” are being shown on the screen, press the A key and the Peak RPM will be set to zero. If the engine

is on when the A key is pressed nothing will happen.

Explanation of the 4-Stage Timer

This is to help the racer understand the 4-Stage Timer when controlling a throttle stop. The 4-Stage Timer can also be

used to control other timed devices, nitrous, or timing retarders.

Stage 1 represents when the throttle stop turns on. Stage 2 represents the amount of time (duration) the throttle stop

will stay on. Stage 3 represents when the throttle stop will turn on the second time during the run. Stage 4 represents the

amount of time (or duration) the throttle stays on the second time. Both Stage 1 and Stage 3 start counting from the release of

the Transbrake. Stage 2 starts counting after the amount of time set in Stage 1 is completed. Stage 4 starts counting after the

amount of time set in Stage 3 is completed.

Possible 8.90 S/C pass

Timer 1= 1.000

Timer 2= 2.000

Timer 3= 08.00

Timer 4= 00.50

Explanation of the Starting Line Enhancer

This is to help the racer understand how the Starting Line Enhancer works. When turned on, the Starting Line

Enhancer will close the throttle under two different conditions, first if the Tap push-button is pressed before a Transbrake

button and second when the Transbrake Push Button is pressed. After the throttle has been closed the Starting Line Enhancer

will open the throttle at the programmed amount of time before the Transbrake is released.

Crossover Delay = 01.35

Starting Line Enhancer = 00.40

Timer 1 = 1.000

Timer 2 = 2.000

Timer 3 = 08.00

Timer 4 = 00.50

11

How the Programmable

Throttle Stop Override works

The Programmable Throttle Stop Override allows a programmable amount of time to be subtracted from either or

both Stages 2 and 4 by pressing the Tap push-button. After the Transbrake releases there is a quarter of a second disable time

before the Programmable Throttle Stop Override is enabled. This is to insure that a late delay Tap is not registered as a

Programmable Throttle Stop Override. If the Programmable Throttle Stop Override is turned on and after the Programmable

Throttle Stop Override is enabled, every time the Tap push-button is pressed while in either Stage 1 or 2 the Programmable

Throttle Stop Override amount will be subtracted from Stage 2. And every time the Tap push-button is pressed while in either

Stage 3 or 4 the P.T.S.O. amount will be subtracted from Stage 4.

NOTE: Only the main 4 Stage Timer (Throttle 1) is affected by the P.T.S.O.

Understanding Time and RPM Mode

The Mega 300 and 400 can handle up to 5 shifts each pass. These 5 shifts can be either made on time, RPM, or a

combination of both. The shifts occur in sequence starting with Shift Number 1 and progressing to Shift Number 5. When a

shift occurs the Mega 300 and 400 checks to see if the next Shift Point setting is valid. If the next Shift Point is an RPM, the

only invalid setting is zero. If the next Shift Point is a Time, the unit checks to make sure that the Shift Point time setting is

greater than the amount of time that has gone by since the release of the Transbrake. If the amount of time is greater the unit

waits for the next Shift Point to occur. If the amount of time is not greater, the next Shift Point is invalid. If an invalid Shift

Point is reached, further shifting of the vehicle is terminated. This means that for vehicles that require only one shift, the

driver should set the second Shift Point to zero.

Understanding the

Replay Tach (Mega 400 Only)

The Mega 400 has a built-in replay tach that records the engine RPM every hundredth of a second for fifteen seconds

after the Transbrake releases. To start the unit recording, the unit must first be armed. This is done by pressing and releasing

the push-button that is connected to the Line Lock terminal. After the unit is armed, either P.B. 1 or P.B. 2 can be pressed and

released starting its corresponding delay timer. Then after either the Delay 1 or the Delay 2 timer times out and releases the

Transbrake, the Mega 400 will start recording. While the Mega 400 is recording, the words ” RECORDING” will be shown

on the display.

Once the engine is shut off the Replay Tach information can be viewed on the screen. This is done by repeatedly

pressing the F key until the letters “ PL” or the word “REPLAY” is shown on the screen. The top row of digits is the engine

RPM, with the next row down being the time. The time is relative to the release of the Transbrake. Use the A key to scroll the

time up and the B key to scroll the time down. The longer the key is held down the faster the scrolling will go. If any shifts,

up to five, occurred during the time the unit was recording, the time and RPM of each shift will also have been recorded. To

recall the Shift Points press the number key corresponding to the shift desired. An example would be to press the 2 key, if

there were at least two shifts the Mega 400 will now display the time and RPM that the second shift occurred. If there was not

a second shift the Mega 400 will display the RPM at the time the Transbrake released, which is at 00.00 on the time row of

digits. Another way to show the RPM at the time the Transbrake released is to press the number zero on the keypad.

The Mega 400 also has a Digital Data port located on the side of the unit opposite the terminal strip. This Digital

Data port is used to download a recorded pass to a hand-held unit called a Digital Viewer (Part # 1025-DV). Once the

recorded pass has been downloaded it can viewed on the screens of the Digital Viewer or printed out on an IBM compatible

DOT matrix printer. When a recorded pass is printed there will be several lines showing all of the Mega 400’s settings at the

time the pass was recorded. A sample print-out of a recorded pass is shown on the next page along with a drawing of the

Digital Viewer.

The shifts will occur for a 20 second time period, only after the transbrake has been released.

12

Selectable Function Output (S.F.O.)

The Selectable Function Output is a single output that can be programmed to function in four separate ways. Each of

the separate functions is listed below with an explanation of the setting basic function. Once the basic understanding of the

settings is understood, additional uses may be thought of by the driver.

1) When the S.F.O. is set to a one, the S.F.O. Functions as a Starting Line Enhancer (S.L.E.). This

means a Throttle Stop connected to the S.F.O. will control the starting line RPM.

2) When the S.F.O. is set to a two, the S.F.O. Functions as a second Four Stage Timer. This means

that a Throttle Stop with dual solenoids, can have a separate Four Stage Timer driving each

solenoid. Another function would be to control a stage of NOS.

3) When the S.F.O. is set to a three, the S.F.O. Functions as a Line Lock Control. This means that

the Line Lock solenoids will engage when either the push-button connected to the Line Lock

terminal is pressed (burn out) or when the Transbrake is engaged (starting line).

4) When the S.F.O. is set to a four the S.F.O. functions as a second Transbrake output. This means

that if the main Transbrake output has been damaged in some way, the S.F.O. can be used as a

spare until the box can be shipped back for repairs.

5). When the SFO is set to a five the output is turn off.

To disable the safety circuit that is designed in the unit, when power is first applied, or after you have taken

the SFO out of mode 3 or 4 a delay cycle must be run, by engaging and releasing either pushbutton 1 or 2.

When SFO is in mode 3 or 4 a safety circuit is enabled to prevent false engagements.

Understanding

Line Lock push-button

The push-button connected to Line Lock terminal is mainly used to engage the Line Lock solenoids that are

connected to the S.F.O. terminal. This is typically done for a burn out when the Transbrake solenoid should not be engaged.

Only the Mega 400 has a second use for the Line Lock push-button, which is to arm the Replay Tach for recording a pass.

If the S.F.O. terminal is not to be used as Line Lock control, it is not necessary to connect either the Line Lock push-

button or the Line Lock solenoids to the unit. However for the Mega 400 a Line Lock push-button is required to arm the

Replay Tach for recording a pass. If the vehicle has Line Lock solenoids, the Line Lock push-button and the Line Lock

solenoids can both be connected to the Line Lock terminal. This will automatically arm the Replay Tach recording feature,

when a burn out is done using the Line Locks and eliminate the need for a separate record push-button.

Understanding and Connecting a By-pass

push-button or Two or More Output Together

A by-pass push-button is used to engage the Transbrake solenoid without starting a timing cycle. This can be helpful

if the vehicle needs the Transbrake engaged to back up. If a by-pass push-button is desired, connect one side of a push-button

to the Transbrake terminal and the other side of the push-button to +12 Volts.

Applying 12 Volts to any of the outputs will not damage the unit. Connecting one or more outputs together will also

not damage the unit. An example of this would be connecting the S.F.O. and the Throttle Stop terminals together. This would

be done if the same Throttle Stop was to used as a S.L.E. Stop and a down track Stop.

Connecting or shorting any output terminal directly to ground will cause damage to the unit. This damage will

not be covered by the warranty. It is strongly recommended that a 15 Amp fuse is put in each of the wires coming from

the output terminals.

13

Accessories (Mega 400 Only)

Shown smaller then at actual size

14

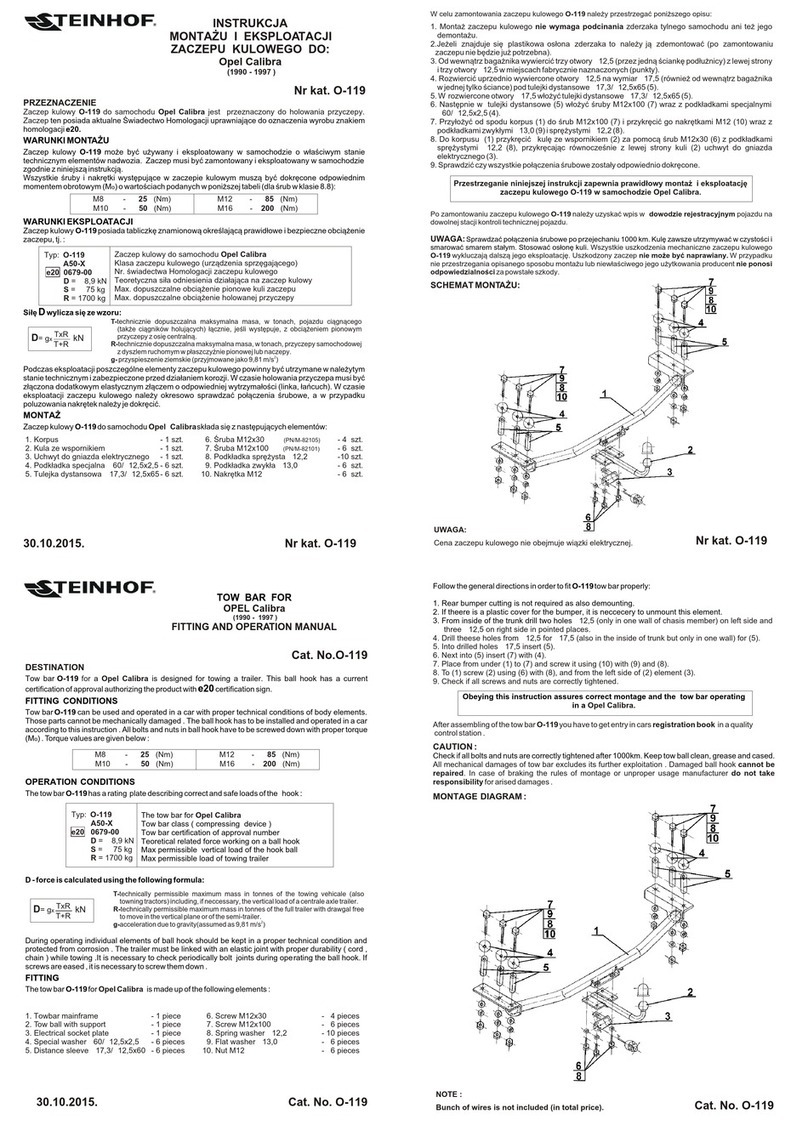

Mounting the Mega 300/400

For complete viewing of the large LCD, care should be taken when mounting the unit to make sure that the display is

angled towards the driver’s eyes. Before mounting the Mega 300/400, place the box in the desired location and check the

legibility of the display in both day and night conditions. As shown below, the lower the box is placed below eye level, the

more the angle amount needs to increase for viewing.

Wiring the Mega 300/400

Dri

ver

D

as

h

Box

Dri

ver

D

as

h

Box

This manual suits for next models

1

Table of contents

Other DIGITAL DELAY Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

WILLTOO

WILLTOO BC39 user manual

Prime Design

Prime Design VRR3-GM31G-ST Assembly instructions

Brodit

Brodit ProClip 804400 installation instructions

Code 3

Code 3 Pursuit 25 Series installation manual

Navistar

Navistar SmartDrive SR4 International LT 625 Series installation guide

Polaris

Polaris Mazda BT50 RW-50/15 installation instructions