Crane Source Spacevector SV200 User manual

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

2

SpaceVector™ Variable Frequency Drives

Congratulations on the purchase of a SpaceVector™ SV200 Series drive. This is the most

advanced drive on the market today specifically designed and programmed for the overhead

material handling industry by the leader in the industry, Columbus McKinnon Corporation.

SpaceVector™ drives have many advantages and features to meet the very specific and

demanding needs of the crane and hoist industry. Features such as:

•An energy efficient drive, resulting in less heating of the motor.

•Cooler running motors last longer saving on downtime and maintenance costs.

•Efficient utilization produces more torque, resulting in better load control.

•Reduced motor harmonics, which improve motor performance and lengthen life.

•Easy macro quick set programming for faster start-up and servicing.

•Plain English programming and service manual saves time.

Before proceeding any further, please read the following important information regarding the

drive and its proper handling and use:

•Please read this manual completely before working with the drive.

••

••

•Thedriveoperatesonandcontainshighvoltagethatcancauseelectricshockresulting

in personal injury or loss of life. Handle the drive with the same care and caution as

all other high voltage electrical components.

••

••

•Be sure to disconnect all AC input power to the drive before servicing. Lock and tag

the main switch in the de-energized position per ANSI Z 244.1.

••

••

•Wait at least 3 minutes after disconnecting the AC input power to the drive.If the bus

capacitor discharge circuit fails, high voltage can remain in the drive for a period of

time after the AC power is disconnected.

••

••

•Do not perform high voltage tests such as Megger testing.

••

••

•Only qualified personnel should perform service.

••

••

•Insure unit is properly grounded.

••

••

•Disconnect drive before performing any welding on the bridge crane structure. Do

not weld the hook, to the hook or to a load suspended from the hook.

Onthefollowing pages arespecificationandselection tables forthedrives and dynamicbraking

resistors. Please check to insure you have the proper equipment for your application.

IMPORTANT! PLEASE READ!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

3

SV200

Table Of Contents

Introduction ...........................................................................................................2

Chapter 1: Installation

Section 1.1: Inspection of Drive .....................................................................8-11

Section 1.2: Mounting the Drive...................................................................12-17

Section 1.3: Wiring the Drive .......................................................................18-25

Chapter 2: Start Up Programming

Section 2.1: Keypad Layout.........................................................................28-29

Section 2.2: Keypad Operation

2.2.1: Definitions ..................................................................................30

2.2.2: Moving through the Program .....................................................30

2.2.3:View a Specific Function Using Jump Code Location ...............32

2.2.4:Viewing all Functions within a Group Level ...............................33

2.2.5: Change Control from Pendant to Keypad..................................34

Section 2.3: Initial Setup Programming

2.3.1: Programming the Drive for a Specific Application ................41-43

2.3.2: Programming the Speed Selection.......................................44-46

2.3.3: Drive Operation Checks.............................................................46

Chapter 3: Programming

Section 3.1: Passwords and Group Access Levels

3.1.1: Passwords .................................................................................48

3.1.2: Entering a Password..................................................................48

3.1.3: Changing a Password................................................................48

Section 3.2: Programming Function Data

3.2.1: Customizing the Programming ..................................................51

Section 3.3: Establishing Motor Parameters ...............................................52-53

Chapter 4: Trouble Shooting

Section 4.1: Fault Trip Descriptions, Causes and Solutions

4.1.1: Monitoring Frequency................................................................56

4.1.2: Monitoring Current.....................................................................56

4.1.3: Monitoring Speed.......................................................................56

4.1.4: Monitoring Fault Trips ................................................................57

4.1.5: Fault Codes ..........................................................................58-59

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

4

Section 4.2: Problem Flow Charts ...............................................................60-63

Section 4.3: Testing Power Components..........................................................64

Section 4.4: Pushbutton Pendant Test..............................................................65

Section 4.5: Multi-Function Output Test............................................................66

Chapter 5: Function Code Information

Section 5.1: User Level Functions

5.1.1: Frequency Output Monitor.........................................................70

5.1.2: Frequency Reference ................................................................70

5.1.3:Accel / Decel ..............................................................................71

5.1.4: Drive Status Monitoring .............................................................72

Section 5.2: Service Level Functions

5.2.1: Command Reference (Run / Stop Selection) ............................73

5.2.2: Accel / Decel Patterns...........................................................73-74

5.2.3: Multi-Function Inputs .................................................................75

5.2.4: Multi-Function Outputs...............................................................76

5.2.5: Drive Model Selection................................................................77

5.2.6: Frequency Settings....................................................................78

5.2.7: Dwell Function ...........................................................................79

5.2.8: V / F Pattern..........................................................................80-81

5.2.9: Torque Boost.........................................................................81-82

5.2.10: Voltage Control ........................................................................82

5.2.11: Motor Poles..............................................................................82

5.2.12: Brake Release .........................................................................82

5.2.13: Upload / Download from Keypad and Set Factory Defaults ....83

5.2.14: Braking.....................................................................................83

Section 5.3: Advanced Level Functions

5.3.1: Drive Mode ................................................................................84

5.3.2: Frequency Reference Source....................................................84

5.3.3: Energy Save ..............................................................................84

5.3.4: User V / F Pattern ......................................................................84

5.3.5: Analog Frequency Control ....................................................84-86

5.3.6: Maximum / Minimum Operating Frequency...............................87

5.3.7: Frequency to Bypass.................................................................88

5.3.8: DC Injection Braking ..................................................................89

5.3.9: Motor Data .................................................................................90

5.3.10: Drive and Motor Protections ...............................................90-93

5.3.11: Stall Prevention...................................................................93-95

5.3.12: Instantaneous Power Failure and Speed Search....................96

5.3.13:Restart After Reset .............................................................97-98

5.3.14: Carrier Frequency....................................................................98

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

5

5.3.15:Two Motor Applications............................................................99

5.3.16: Closed Loop Speed Control ....................................................99

5.3.17: Rotation Direction Prevention................................................100

5.3.18: Jog Frequency.......................................................................100

5.3.19: Output Current, Voltage and Frequency................................100

5.3.20: Frequency Detection..............................................................101

5.3.21: Speed Display Scaling Factor ...............................................101

5.3.22: LED Check.............................................................................101

5.3.23: Option Card ...........................................................................102

5.3.24: Reverse Plugging ..................................................................103

Chapter 6: Maintenance

Section 6.1: Maintenance........................................................................................106

Section 6.2: Precautions .........................................................................................106

Section 6.3: Routine Inspection ..............................................................................106

Section 6.4:Visual Inspection .................................................................................106

Appendix ....................................................................................................107-109

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

6

This page intentionally left blank.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

7

Section 1: Installation

Section 1.1: Inspection of Drive

Section 1.2: Mounting the Drive

Section 1.3: Wiring the Drive

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

8

1. Inspect the drive for any physical damage that may have occurred during its shipment.

If any parts of the drive are missing or damaged, contact your SpaceVector™distributor

immediately.

2. Verify the nameplate of the SV200 drive. Verify that the drive part number matches your

order and packing slip.

3. Verify that the Dynamic Braking Resistor part number matches your order and packing

slip.

4. If there are questions, referenceTables 1.1.1, 1.1.2, 1.1.3, 1.1.4 for Drive and Resistor

specifications.

WORKING IN OR NEAR EXPOSED ENERGIZED

ELECTRICAL EQUIPMENT PRESENTS THE DANGER

OF ELECTRIC SHOCK.

TO AVOID INJURY:

•Disconnect and lockout power to the drive per

ANSI Z 244.1

•Wait 3 minutes after disconnecting power for

capacitor to discharge before entering drive.

WARNING

Section 1.1: Inspection of Drive

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

9

Table 1.1.1: SV200 Drive Specifications for 230 Volts

SpaceVector™ Drive Specifications

(230 V)

epyTretrevnI )XX-584644( 01-11- 21-31- 41-51- 61-71-

elbacilppA rotoM

euqroTtnatsnoC]PH[ 35 5.701 5102 5203

euqroTtnatsnoC]Wk[ 2.27.3 5.55.7 1151 5.8122

sgnitaRtuptuO

euqroTtnatsnoC]AVk[ 2.41.6 1.92.21 5.715.22 2.822.33

euqroTtnatsnoC]ALF[ 1161 4223 64 95 4778

ycneuqerF.xaM.zH0.021

egatloVegatloVtupnI-0,esahP3

tupnI sgnitaR

egatloVtupnI)%01±(V032-002,esahP3

ycneuqerFtupnI)%5±(zH06ot05

lortnoC

dohteMlortnoCMWProtceVecapS

noituloseRycneuqerFzH10.0

ycaruccAycneuqerF ycneuqerFmumixaMfo%10.0:gnitteSlatigiD ycneuqerFmumixaMfo%1.0:gnitteSgolanA

oitarF/VelbammargorpresUdnaraeniL

euqroTgnikarB%02yletamixorppA

yticapaCdaolrevOetunim1rof%051

tsooBeuqroTelbammargorp%02-0

gnitarepO

dohteMnoitarepOevitceleSlanimreT/dapyeK

noitceleSycneuqerFAm02~4,CDV01~0:golanA/dapyeK

emit.leceD/.leccA.ces000,6ot1.0

noitceleSdeepSelbammargorp,spets5otpU

elbammargorP tupnI tupnIelbammargorP )MCotgnikniS,CDV42si6P(6P,P,5,4,3,2-stupnixiS

noitcetorP

tluaFretrevnI retrevnI,tluaFdnuorG,nepOesuF,tnerrucrevO,egatlovrednU,egatlovrevO ssoLesahP,rorrEUPCniaM,taehrevOrotoM,taehrevO

noitneverPllatSnoitneverPtnerrucrevO

eruliaFrewoPsuoenatnatsnI noitarepOsuounitnoC:.cesm51woleB )evitceles(tratseRcitamotuA:.cesm51revO

latnemnorivnE snoitidnoC

erutarepmeTtneibmA)F°401ot°41(C°04ot°01-

ytidimuH)gnisnednoCnoN(%09rednU

edutitlA)teef0823(m000,1nahtsseL

metsysgnilooCriAdecroF

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

10

Table 1.1.2: SV200 Drive Specifications for 460 Volts

SpaceVector™ Drive Specifications

(460 V)

epyTretrevnI )XX-584644( 02-12- 22-32- 42-52- 62-72-

elbacilppA rotoM

euqroTtnatsnoC]PH[ 35 5.701 5102 5203

euqroTtnatsnoC]Wk[ 2.27.3 5.55.7 1151 5.8122

sgnitaRtuptuO

euqroTtnatsnoC]AVk[ 2.41.6 1.92.21 3.819.22 7.923.43

euqroTtnatsnoC]ALF[ 68 2161 42 03 9354

ycneuqerF.xaM.zH0.021

egatloVtuptuOegatloVtupnIot0,esahP3

tupnI sgnitaR

egatloVtupnI)%01±(V064-083,esahP3

ycneuqerFtupnI)%5±(.zH06ot05

lortnoC

dohteMlortnoCMWProtceVecapS

noituloseRycneuqerF.zH10.0

ycaruccAycneuqerF ycneuqerFmumixaMfo%10.0:gnitteSlatigiD ycneuqerFmumixaMfo%1.0:gnitteSgolanA

oitarF/VelbammargorpresUdnaraeniL

euqroTgnikarB%02yletamixorppA

yticapaCdaolrevOetunim1rof%051

tsooBeuqroTelbammargorp%02-0

noitarepO

dohteMnoitarepOevitceleSlanimreT/dapyeK

noitceleSycneuqerFAm02~4,CDV01~0:golanA/dapyeK

emit.leceD/.leccA.ces000,6ot1.0

noitceleSdeepSelbammargorp,spets5otpU

elbammargorP tupnI tupnIelbammargorP )MCotgnikniS,CDV42si6P(6P,P,5,4,3,2-stupnixiS

noitcetorP

tluaFretrevnI retrevnI,tluaFdnuorG,nepOesuF,tnerrucrevO,egatlovrednU,egatlovrevO ssoLesahP,rorrEUPCniaM,taehrevOrotoM,taehrevO

noitneverPllatSnoitneverPtnerrucrevO

eruliaFrewoPsuoenatnatsnI noitarepOsuounitnoC:.cesm51woleB )evitceles(tratseRcitamotuA:.cesm51revO

latnemnorivnE snoitidnoC

erutarepmeTtneibmA)F°401ot°41(C°04ot°01-

ytidimuH)gnisnednoCnoN(%09rednU

edutitlA)teef0823(m000,1nahtsseL

metsysgnilooCriAdecroF

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

11

Table 1.1.3: 230 V Class Dynamic Braking Resistors

Table 1.1.4: 460 V Class Dynamic Braking Resistors

.P.H ecivreSDroC,B,AssalCecivreSEssalC

*BLMhtiwtsioH*BLMtuohtiwtsioHesrevarT*BLMtuohtiwtsioH

1

0A-584644 002 W

0A-584644 002 W

0A-584644 002 W

0A-584644 002 W

25A-584644 002 W5A-584644 002 W

30B-584644 002 W0B-584644 002 W

51A-584644 001 W2B-584644 021 W3A-584644 031 W2B-584644 021 W

5.7

2A-584644 05 W

8B-584644 08 W7A-584644 58 W8B-584644 08 W

01 9B-584644 06 W8A-584644 06 W9B-584644 06 W

51 1C-584644 04 W1B-584644 04 W1C-584644 04 W

02 4A-584644 33 W2C-584644 03 W3B-584644 03 W2C-584644 03 W

52 6A-584644 021 W6C-584644 02 W6B-584644 02 W6C-584644 02 W

03

*MLB = Mechanical Load Brake

.P.H ecivreSDroC,B,AssalCecivreSEssalC

*BLMhtiwtsioH*BLMtuohtiwtsioHesrevarT*BLMtuohtiwtsioH

11A-584644 001 W1A-584644 001 W1A-584644 001 W1A-584644 001 W

22A-584644 05 W8A-584644 06 W2A-584644 05 W8A-584644 06 W

3

53A-584644 031 W3B-584644 03 W4A-584644 33 W3B-584644 03 W

5.7 6A-584644 02 W6B-584644 02 W9A-584644 51 W

6B-584644 02 W

01 9A-584644 51 W0C-584644 61 W0C-584644 61 W

51 4B-584644 01 W3C-584644 01 W

4B-584644 01 W3C-584644 01 W

02 5B-584644 8W5B-584644 8W

52 7B-584644 5W4C-584644 7W7B-584644 5W4C-584644 7W

03

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

12

Section 1.2: Mounting the Drive

1.2.1Environmental Conditions

1. Verify the ambient condition of the drive mounting location. The ambient temperature

rangeshould be 14°to 104°F (-10°to40°C) for NEMA1 and orNEMA4/12 enclosures.

2. The relative humidity should be less than 90% (non-condensing), below the altitude of

3280 ft. or1000m.

3. Do not mountthedrivein directsunlight. Thedriveshouldalsobeisolated fromexcessive

vibration.

4. The drive should be protected from moisture, dust, metallic particles, corrosive gases

and liquids.

5. Consult Factory for severe environments.

1.2.2 Electrical Conditions

1. Verify that Input voltage is within drive nameplate +/- 10%. If input line voltage varies

due to sags and or surges input line reactors are recommended.

2. Analog input requires individually shielded twisted pair cable for installations where the

cable leaves the control cabinet.

3. If length of motor leads between drive and motor exceed 100 ft. (30 m) a load reactor

between drive and motor is recommended.

Mounting

The SV200 must be mounted vertically with sufficient space (horizontally and vertically)

between adjacent equipment to permit proper heat dissipation. See Figure 1.2.1. See

Figures 1.2.2 - 1.2.5 for actual drive dimensions.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

13

Fig. 1.2.1: Recommended Clearances for Drive Mounting

A: over 6.0'' (15cm)

B: over 2.0'' (5cm)

A

A

B

B

Note: Allow more room between drive and other heat producing components (such as

transformers and drive ballast resistors) than shown in Fig. 1.2.1. These

components radiate enough heat to damage the drive and its internal

components.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

14

Drive Dimensions and Weights

Fig. 1.2.2: SV200 Part No. - 446485-10 / 446485-11 418.74lbs (8.5kg)

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

15

Fig. 1.2.3: SV200 Part Nos. 446485-12 / 446485-13 22.1lbs / 23.2lbs

446485-20 / 446485-21 / 446485-22 (10 / 10.5kg)

446485-23

7.48’’ (190mm)

8.07’’ (205mm)

.87’’ (22mm)

.87’’ (22mm) 3-dia 1.1’’ (28mm)

.28’’(7mm)

.28’’(7mm)

13.39 (340mm)

13.78 (350mm)

13.98 (355mm)

8.23 (209mm)

5.20 (132mm)

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

16

Fig. 1.2.4: SV200 Part Nos. 446485-14 / 446485-15 46.3 lbs. / 48.5 lbs.

446485-24 / 446485-25 (21kg / 22kg)

2 - .39’’ (10mm)dia.

9.00’’ (228.7mm)

10.19’’ (258.7mm)

11.02’’ (280mm)

18.90’’ (4 8 0 m m )

18.23’’ (4 6 3 m m )

17.19’’ (4 3 6 .5 m m )

.39’’ (1 0 m m )

.47’’ (12mm)

10.24’’ (2 6 0 .2 m m )

7.48’’ (1 9 0 m m )

5.17’’ (1 3 1 .4 m m )

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

17

Fig. 1.2.5: SV200 Part Nos. 446485-16 / 446485-17 63.9 lbs. / 68.4 lbs.

446485-26 / 446485-27 (29kg / 31kg)

10.63’’ (270m m )

4.72’’ (1 2 0 m m )

8.17’’ (2 1 0 m m )

11.02’’ (2 8 0 m m )

.39’’ (1 0 m m )

9.06’’ (230m m )

11.81’’ (300m m )

21.89’’ (5 5 6 m m )

21.06’’ (5 3 5 m m )

22.83’’ (5 8 0 m m )

.47’’ (1 2 m m )

2- .39’’ (1 0 m m )dia.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

18

Section 1.3: Wiring the Drive

1.3.1 Remove Cover From Drive

The cover is held on with four screws and must be removed in order to connect the

power, motor, and control wires.

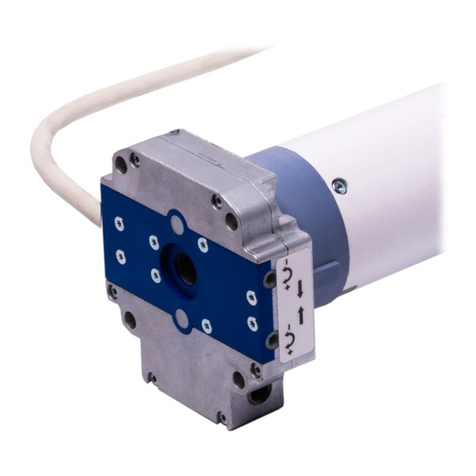

Figure 1.3.1 is a reference for the basic Input / Output Terminals of an SV200 drive.

Fig. 1.3.1: SV200 Layout For Basic Wiring

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

19

SV200

Drive Class Drive Rated

Amp. Input

AWG Output

AWG Ground

AWG DB Resistor

AWG Control

AWG

230V

Class

11.0 12 12 12 12

16

16.0 1024.0 10 10 10

32.0

46.0 6666

59.0

74.0 4444

87.0

460V

Class

6.0

12 12 12 12

8.0

12.0

16.0

24.0

10 10 10 10

30.0

39.0

45.0

1.3.2 Check For CorrectWire Gauges

Insure the correct wire gauges for the input and output power leads are being used before

wiring the drive. Use Table 1.3.1 for reference.

Table 1.3.1: Wire Gauge Reference Table

1.3.3 Fuse and Circuit Breaker Selection

Reference Table 1.3.2 to properly apply fuses and circuit breakers to the drive.

Table 1.3.2: Fuse and Circuit Breaker Selection

SV200

Drive Voltage Ref. HP SV200

Part Number Fuse Rating

Class (J) Molded Case

Circuit Breaker

230V

3446485-10 20A 25A

5446485-11 25A 30A

7.5 446485-12 35A 50A

10 446485-13 40A 60A

15 446485-14 50A 75A

20 446485-15 80A 100A

25 446485-16 80A 125A

30 446485-17 100A 150A

460V

3446485-20 10A 15A

5446485-21 15A

7.5 446485-22 20A 30A

10 446485-23 25A

15 446485-24 35A 40A

20 446485-25 40A 50A

25 446485-26 50A 60A

30 446485-27 65A 75A

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

20

R S T E U V W E B1 B2

1.3.4 Wire The Power Leads

Use Figure 1.3.2 as shown below to assist in wiring the power leads to the drive.

Fig. 1.3.2: Input / Output Power and Dynamic Braking Resistor Wiring Diagram.

Arrangement of Power Terminal Strip

L1 L2 L3 Earth T1 T2 T3 DBR DBR

3 Phase Input Power

230 VAC or 460 VAC 3 Phase Output to

Motor Dynamic Braking

Resistor Unit

Earth

Ground

Note: Slotted tongue terminals are recommended for connections shown in Figure

1.3.2.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com

Table of contents

Popular DC Drive manuals by other brands

GFA

GFA ELEKTROMAT SIK 25.10 WS-30,00 installation instructions

GFA

GFA ELEKTROMAT ST 16.24 installation instructions

Hydro-Gear

Hydro-Gear 310-1500 Service and repair manual

ABB

ABB ACH580-31 Hardware manual

Danfoss

Danfoss VLT Micro Drive FC 51 Series quick guide

Invertek Drives

Invertek Drives OPTIDRIVE P2 Series Easy Start Up Guide