Mangelmann Elektrotechnische

Holtumsweg 13, D-47652 Weeze, Tel. +49 2837/9134-0, Fax. +49 2837/1444

www.uni-geraete.de info@uni-geraete.de

Seite 6

/ 14 TM 4021

220.100.038-18

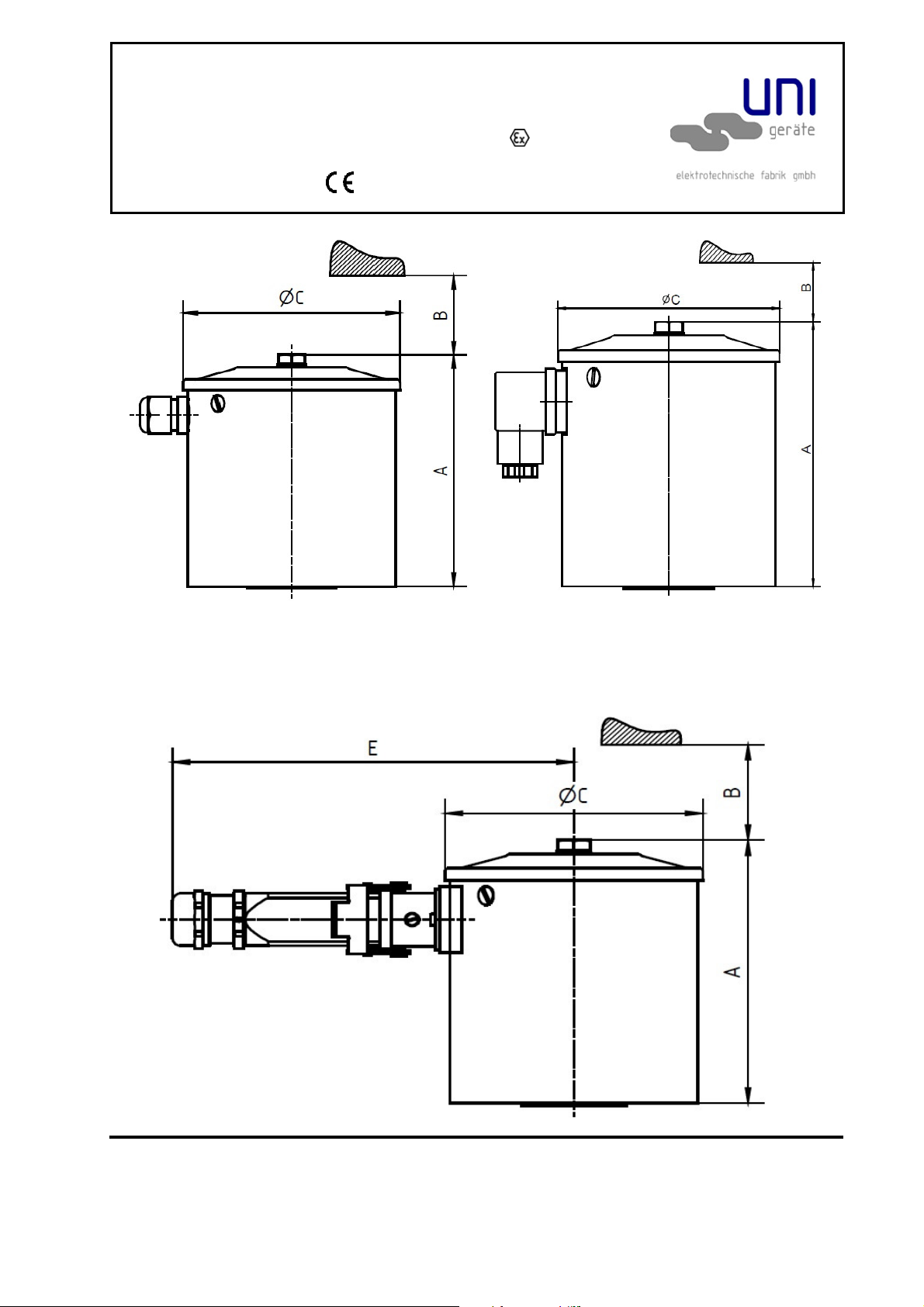

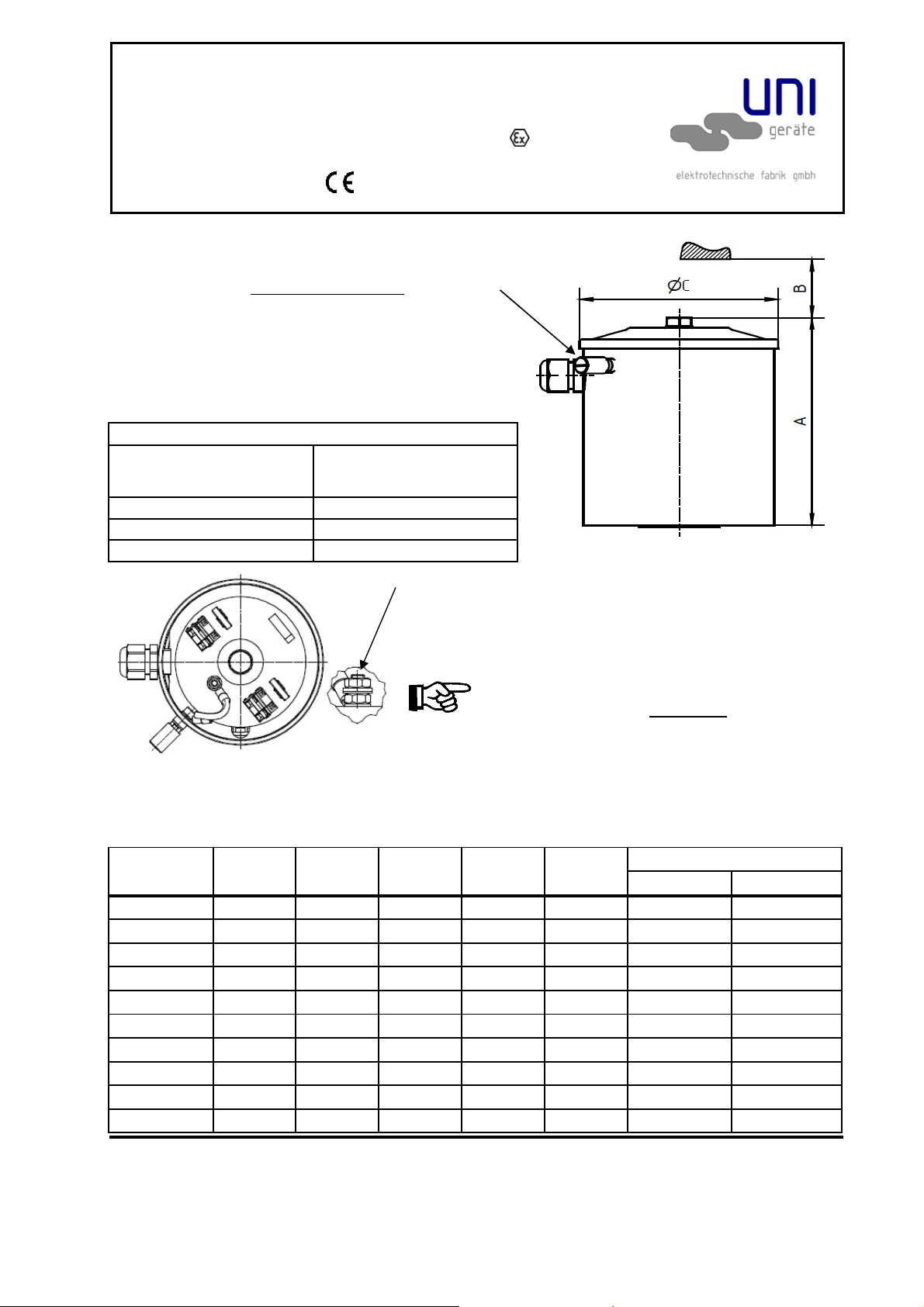

Solenoid drive

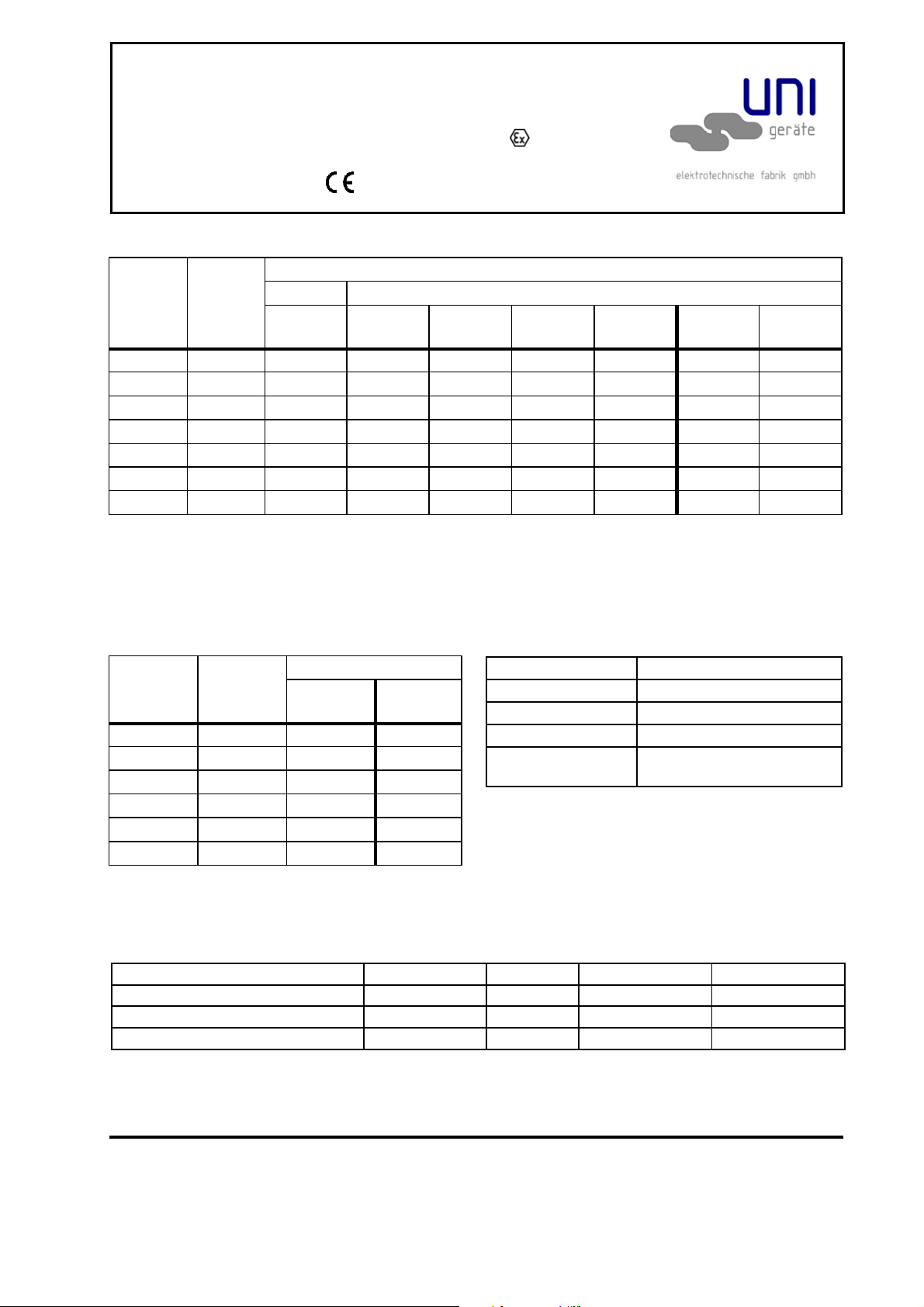

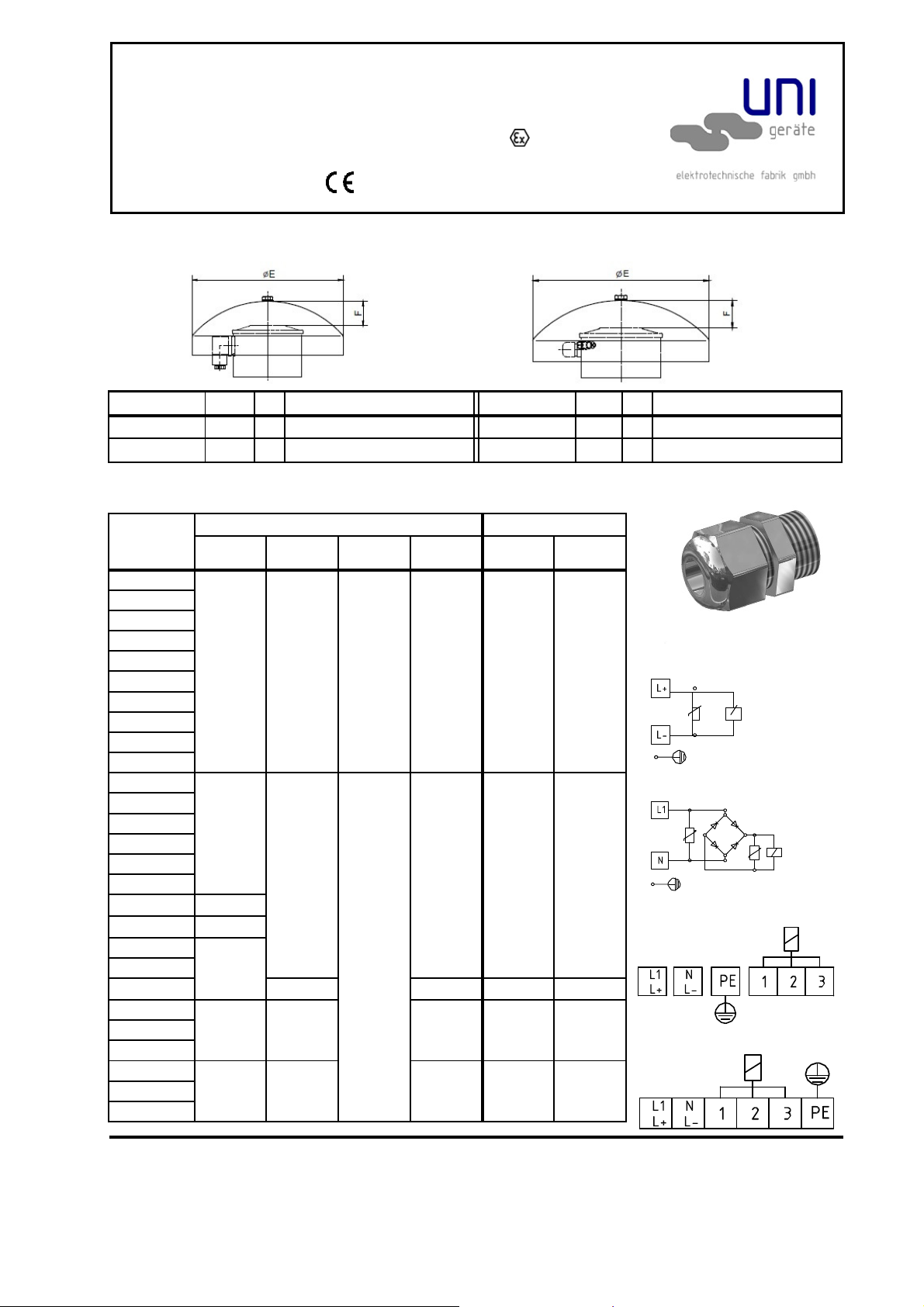

Series MG.., MG..A, MG..A..C (no explosion protection)

Series MG..Xn, MG..A..Xn, MG..A..C..Xn (with - protection

for the intended use in zone 2) in accordance with

2014/34/EU (ATEX 95))

T

yp

M

G...

P

W

Nominal current A

24

V

DC

230

VA

C

010-A5 200/20 8,3/0,8 1,2/0,9

012-A5 200/20 8,3/0,8 1,2/0,9

014-A5 200/20 8,3/0,8 1,2/0,9

016-A5 200/20 8,3/0,8 1,2/0,9

018-A5 200/20 8,3/0,8 1,2/0,9

019-A5 200/20 8,3/0,8 1,2/0,9

Solenoid drive MG...A / MG...A...Xn with integrated control TS900, TS1500

T

yp

M

G..A..

P

W

Nominal current

A*

TS 900 TS 1500

24

V

DC

110

V

DC

220

VDC

230

V

DC

240

VDC

110

VA

C

230

VA

C

016-A 720/70 30/2,9 6,5/0,6 3,3/0,3 3,1/0,3 3,0/0,3 6,5/0,6 3,1/0,3

018-A1 900/70 38/2,9 8,2/0,6 4,1/0,3 3,9/0,3 3,8/0,3 8,2/0,6 3,9/0,3

018-A2 1200/70 - 11/0,6 5,5/0,3 5,2/0,3 5,0/0,3 11/0,6 5,2/0,3

019-A1 1200/120

- 11/1,1 5,5/0,6 5,2/0,5 5,0/0,5 11/1,1 5,2/0,5

019-A2 1500/90 - 14/0,8 6,8/0,4 6,5/0,4 6,3/0,4 14/0,8 6,5/0,4

019-A5.3

400/20 17/0,9 3,6/0,2 1,8/0,09 1,7/0,09 1,7/0,08 3,6/0,2 1,7/0,09

019-A5.4

400/50 17/2,1 3,6/0,5 1,8/0,23 1,7/0,2 1,7/0,2 3,6/0,5 1,7/0,22

*Amb.-temp. 20°C at 100% duty cycle stationary warmed up (Amb.-temp. 20°C at 0% duty cycle – switch

on moment / values x factor 1,25)

Solenoid drive MG...A5 / MG...A5...Xn

With integrated control TS200

Switching Frequenzy:

*

Amb.-temp. 20°C at 0% duty cycle – switch on moment

Soelnoid valve control

Solenoid valvce control TS 200 TS 800 TS 900 / 1500 RKS 5-1500 / 5-4000

max. switching capacity Watt 200 800 900/1500 1500/4000

Switch over time Sec. 1,5 40(*) 3 3

For opening delay Sec. - - 10 10

(*) Charging time

switchings / hour Solenoid drive MG

1000 004 - 020

20 016A - 020A

600 010A5 - 019A5

20 016A5C6, 019A5C6 ;

016A5.2C6, 019A5.2C9