CRC Battle Axe 3 User manual

8500734 01901

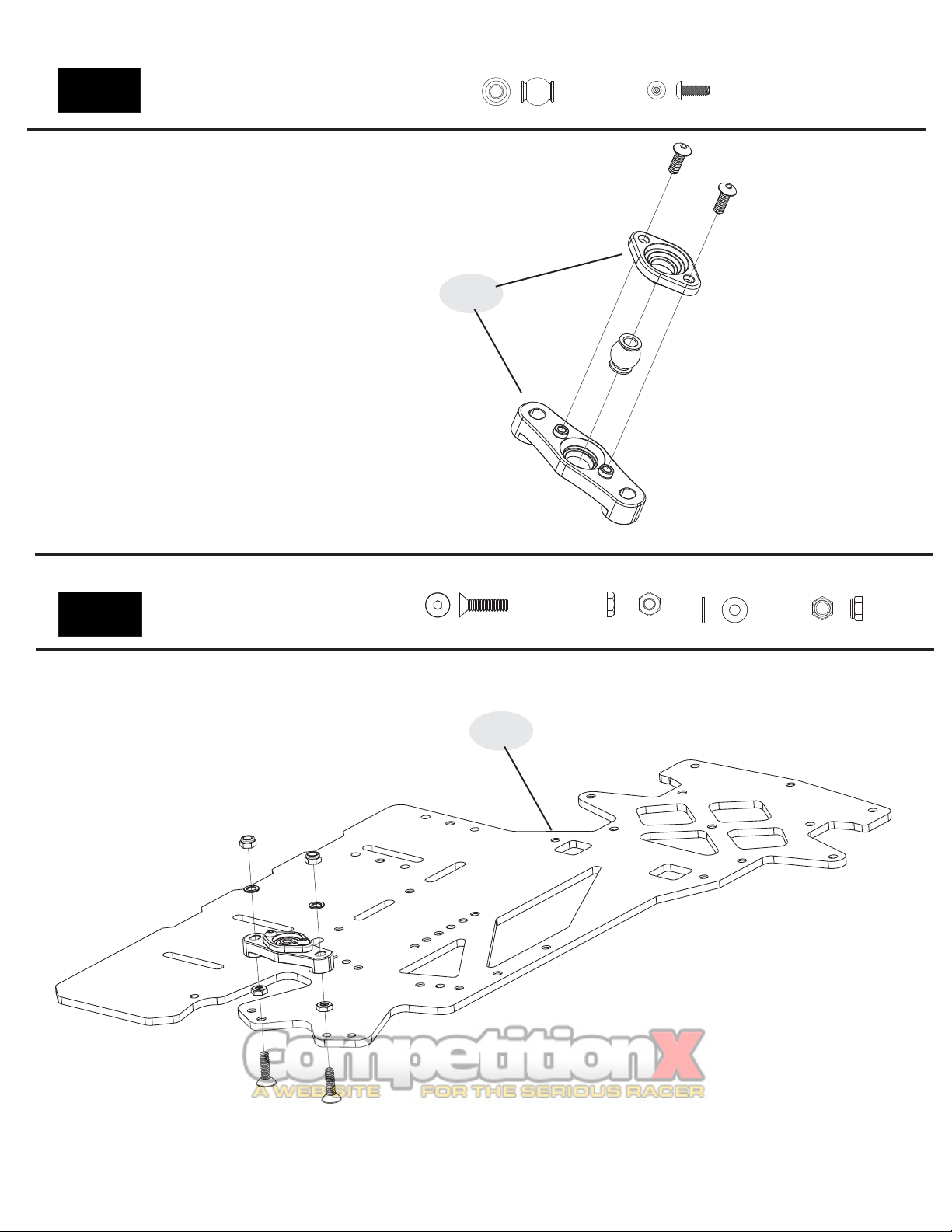

3254 - 2-56 Button Head

4019 - Alum Pivot ball

12772 -

4-40 Thin

Hex Nut

1429 -

4-40 x 7/16”

Flat Head

1209 - Washer

*Note - Sometimes it is helpful to over-tighten the top clamp screws,

then work the ball around by hand, and then loosen the screws so the ball

floats around very free. Do not over-tighten the screws too much or you

could warp the pivot socket.

slightly

1412 - Red Locknut

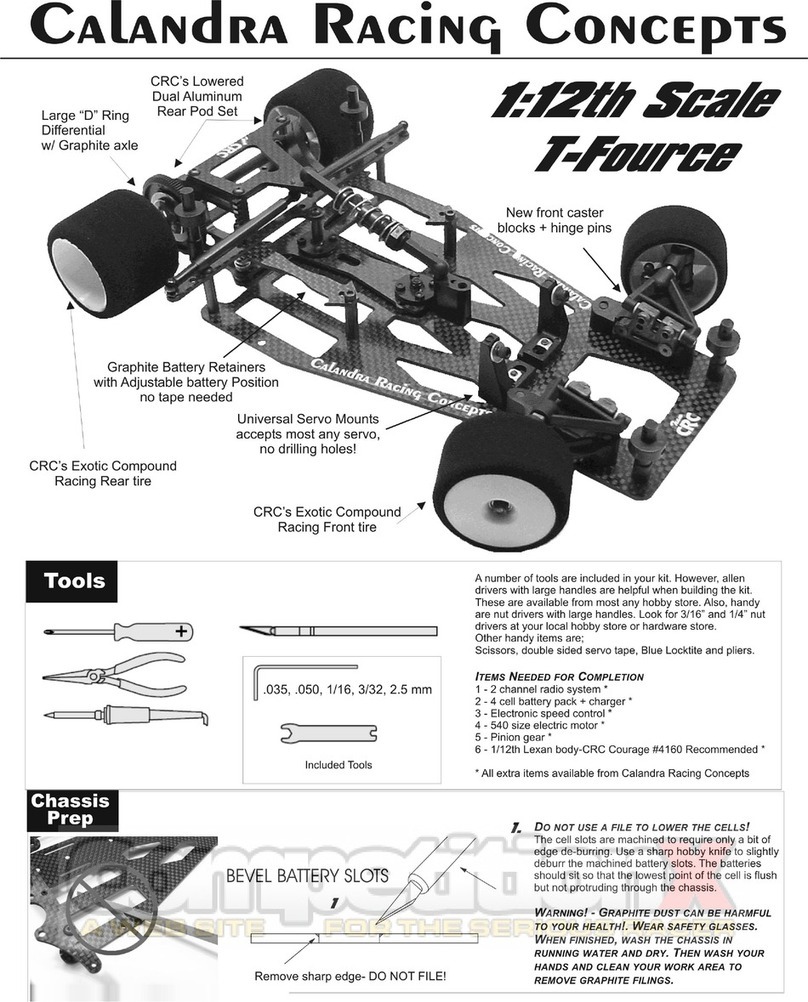

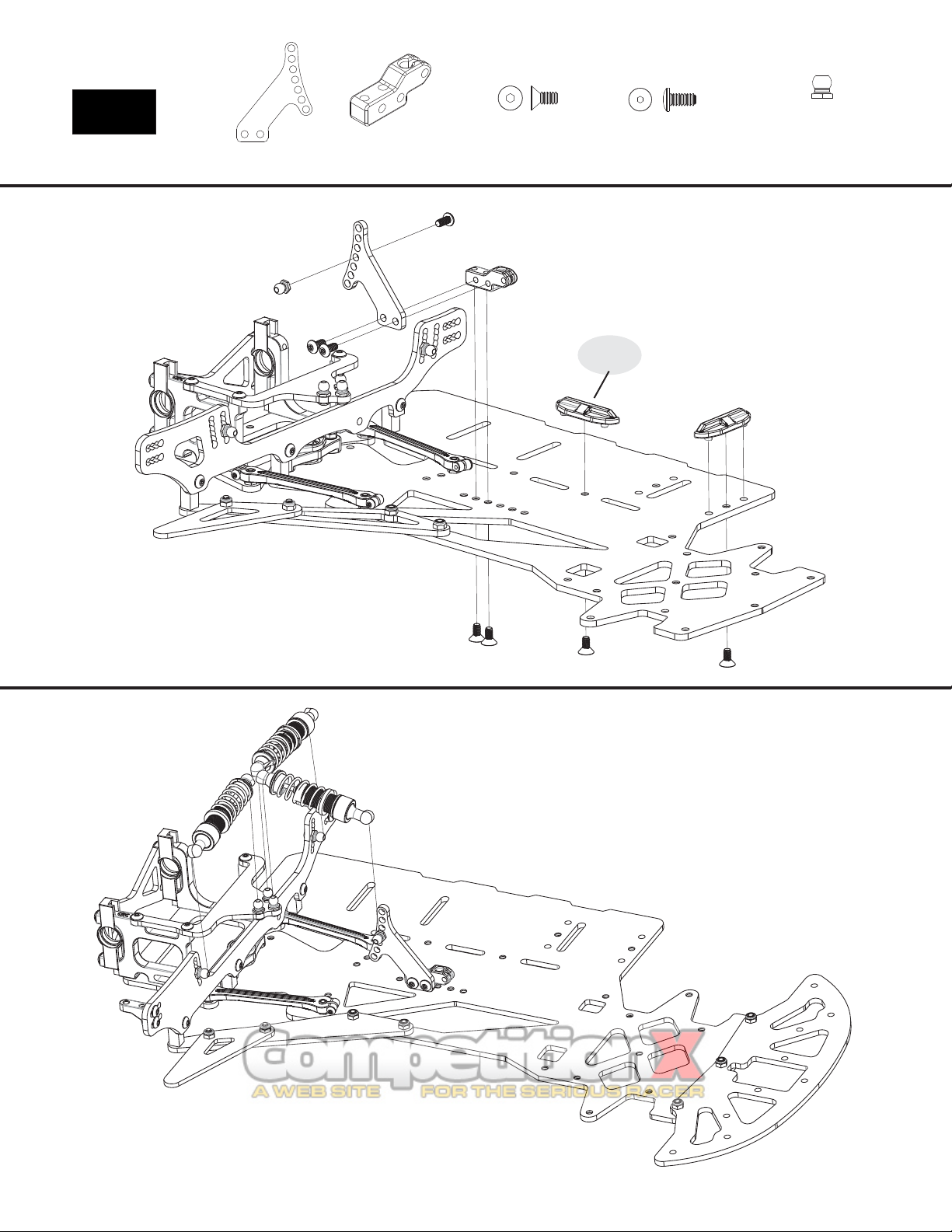

Bag 1

Center Pivot

1

3374 - Center Pivot Socket

Bag 1

Center Pivot

1957 - BA3.0 Chassis Plate

3374

1957

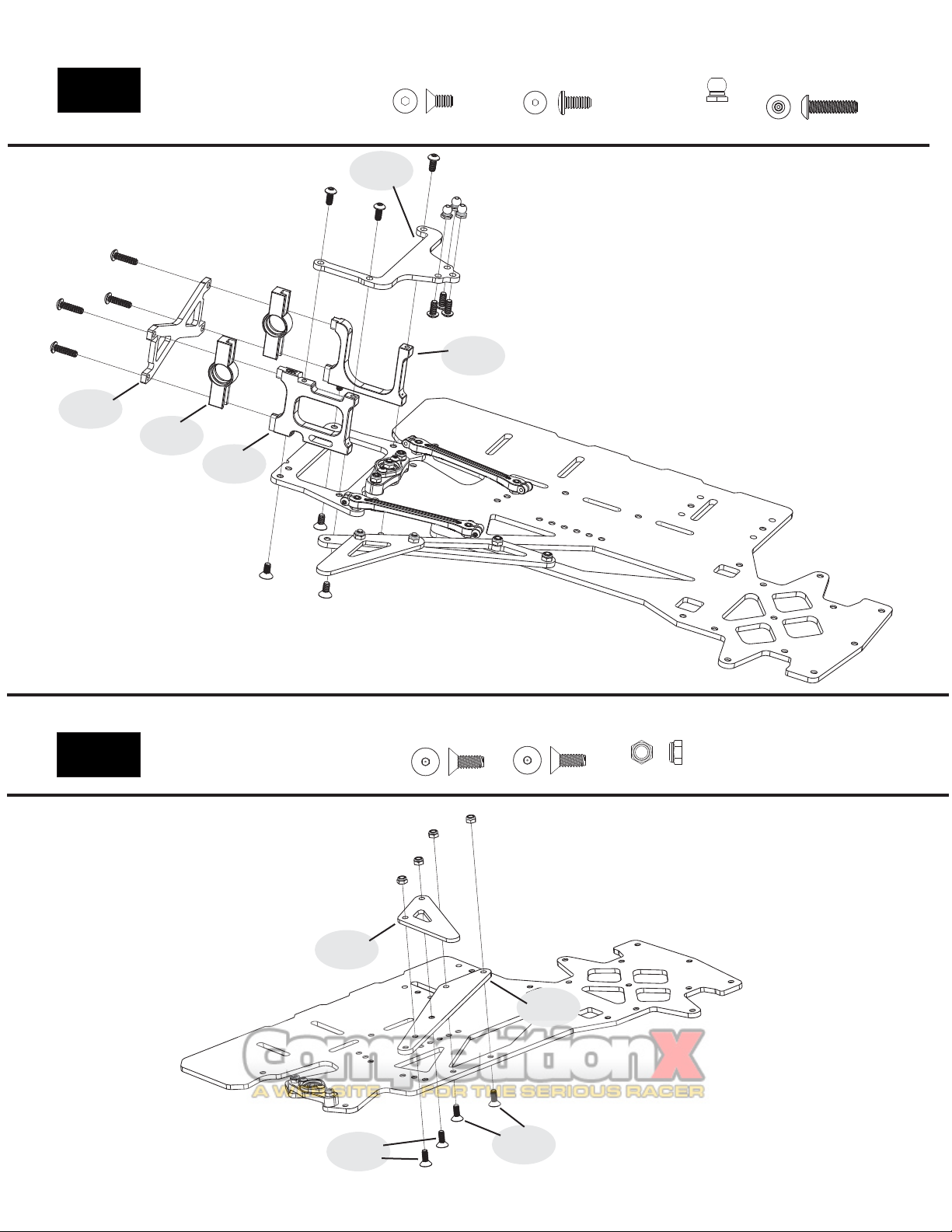

1426 - 4-40 x

5/16” Flat Head 1430 - 4-40 x ½”

Flat Head

One-Piece

Side Links

13615 -

Red Low-

Profile Ball

*NOTE - Before installing, inspect the side links

and you will notice that the screw holes on one

side of the link are larger than the holes on the

other side. Before popping the links on the balls,

be sure that the larger hole faces toward the

outside of the chassis.

Slide the 2-56 button head screws through the

large holes in the outside of the side links, and

then thread them into the small inner holes as

shown in the illustration. Do not tighten these

screws down all the way. Put just enough

tension on them so that there is no play in the

links, but so they pivot freely on the balls. The

car will NOT handle properly if the links are too

tight on the balls!

1 - Be sure the 2 aluminum locknuts on top of the center pivot are slightly loose.

There should be a washer under each alum locknut. Notice that the center pivot

“floats" or moves slightly on the 2 screws. This "floating" allows the links

to "free up". This ensures that the rear pod plate pivots freely on the links

and center pivot ball. This is a crucial step when setting up the Battle Axe.

2 - Snap the 2 links on the balls (done in previous step). They should rock freely on

the pivot balls.

3 - Place the chassis / rear bottom plate assembly on a flat surface. No tires and

no diff on the car! A smooth table or desk should do. Be

sure that the rear bottom plate and chassis are in a

straight line, flat against the table, again, no tires on the

car. Lightly “tap” the chassis and rear pod releasing any

tension in the links. Keep the chassis flat on the table for step 4.

4 - Hold the chassis at the hold point “H” by pressing

the chassis down to the table. Slowly tighten the 2 locknuts that

secure the center pivot assembly. For now, just lightly

snug one side then the other.

5 - Pick up the car and check the pivoting action of

rear lower plate. Rotate the rear plate from side-to-

side. It should move free without binding or "clicking".

If it does not, loosen the pivot locknuts and repeat steps 3+4.

If it rotates smoothly, tighten the locknuts on the center pivot more

securely. Do this by again holding the chassis down to the table at the

hold point “H”. Slowly and carefully, fully tighten the locknuts that hold the center pivot

assembly to the chassis. The handling of the Battle Axe hinges (pun intended!) on the

free movement of this rear plate. Be sure that the rear links and rear plate are free and not binding.

(not the rear pod)

Setting the One-piece links

2

Rotate

Center Pivot

H

3254 - 2-56 Button Head

3280 -

1412 - Red Locknut

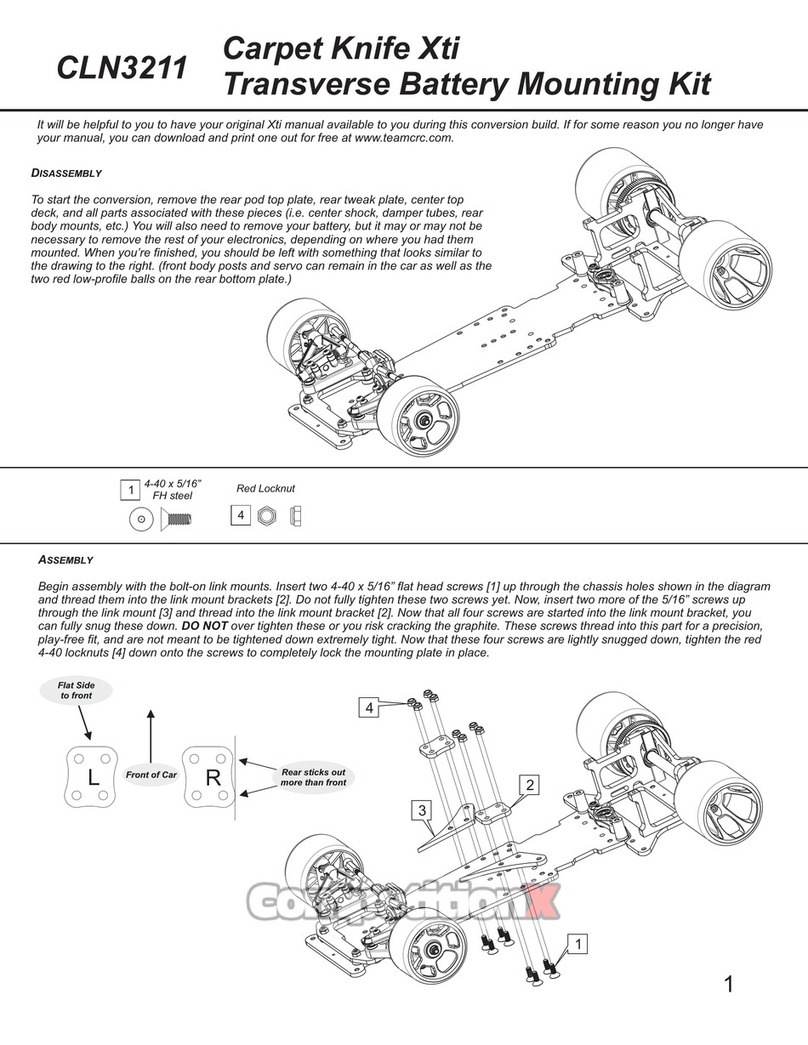

Bag 2

1967 - BA3.0 Rear Bottom Plate

1967

33401 - Motor Plate

3375 - Graphite X-brace

3

1424 - 4-40 x 1/4”

Flat Head

33421 - Left Side Pod Plate

Bag 3

Slider Pod

33411 - Slider Bearing Carrier

33411

33401

33421

3375

1434 - 4-40 x 1/4”

Button Head 13615 -

Red Low-

Profile Ball

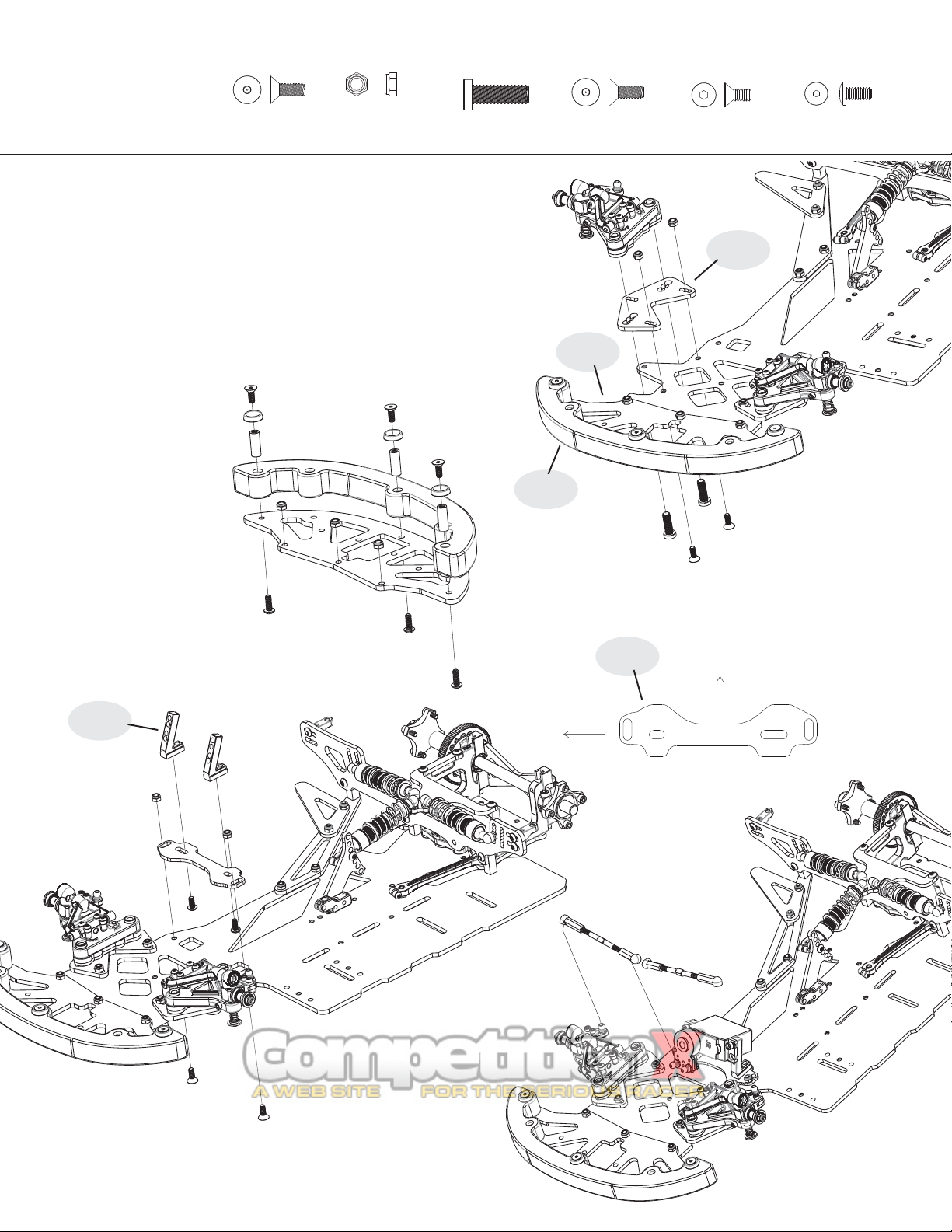

1963 - Rear Top Plate

Bag 4

Shock Tower 1426 - 4-40 x

5/16” FH

1451 - 4-40 x

5/16” FH Red 1412 - Red Locknut

1959 - Nerf Wing

1958 -Shock Tower Mount Wing

1426

1451

1959

1958

1435 - 4-40 x 7/16”

Button Head

1963

4

Bag 4

Shock Tower 1434 - 4-40 x 1/4”

Button Head

1971 - Shock Tower

3355 - Shock Tower Mounts

1424 - 4-40 x 1/4”

Flat Head

1971

3355

13615 -

Red Low-

Profile Ball

5

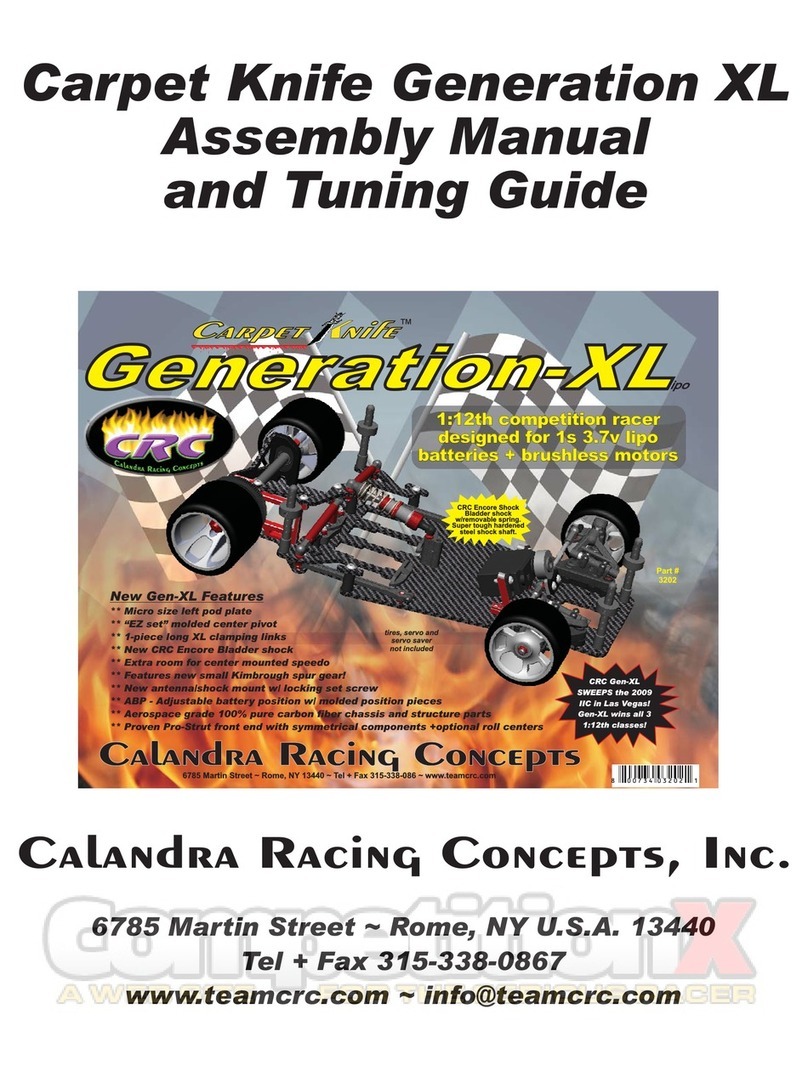

1 - Thread the spring adjuster nut onto the shock body as shown. *This needs to be installed first or you will not be able to get it on later after the lower endof

the shock is assembled!*

2 - Insert only 1 of the small o-rings into the lower end of the shock body. Next, install the bottom shock plug and tighten the bottom shock cap.

3 - Insert 1 of the small e-clips into the lower groove of the shock shaft. Slide the piston over the shaft until it stops against the e-clip and then secure it in place

with the other e-clip in the end groove.

4 - Put a small dab of the included shock oil on the threads of the shock shaft to lube it and then slide the shock shaft through the bottom end of the shock

carefully so you do not damage the o-ring with the threads on the shock shaft. Pull the shaft all the way through until the piston bottoms out in the shock body.

5 - Wipe off any excess oil from the threads of the shock shaft and then thread on the longer of the 2 included ballcups. *If you need to hold the shaft with pliers,

be sure to wrap a rag around the shaft first so the pliers do not damage the shaft. If there is any damage to the shaft, the sharp edges will damage the o-ring and

cause the shock to leak.

6 - Now with the shaft still fully extended, hold the shock body upright and fill with the included shock oil. Press the shaft in about half way and then return it to

full extension. Look inside the shock and you will notice small air bubbles in the oil. This is the rest of the air that was trapped below the piston. Allow enough

time for the air bubbles to work their way to the surface and pop.

7 - Once satisfied that all of the air is out of the shock, top off with oil and then insert the shock bladder by laying one side into the oil and then rolling your finger

across the top of the bladder to expel any excess air and/or oil.

8 - Insert the flanged ballcup into the upper shock cap and then tighten this down over the shock bladder, being careful to not knock the bladder off its seat and

allowing air to enter the shock. *Double check that the shock is working smoothly through its range of motion and that you can fully compress the shock. Ifit

binds up before being fully compressed, then it has too much oil and you will need to crack the top cap loose and expel a very small amount of oil and re-tighten.

9 - Slide the shock spring over the shock body and keep in place by clicking the spring retainer over the shock shaft and sliding it down over the short ballcup to

keep it in place.

1

5

2.1

2.3

2.2

4

3.1

3.2

7

(Lower groove)

(End groove)

CRC Encore Shock

Bag 5

Side Shocks

3290 -

8.1

8.2

9.2

9.1

Bag 7

Center Shock

&

1946 - Graphite Shock

Mount Plates

1745 - Alum Shock /

Antenna Mount

6

Bag 6

Center Shock

Mount

1424 - 4-40 x 1/4”

Flat Head 1434 - 4-40 x 1/4”

Button Head 13615 -

Red Low-

Profile Ball

3373

3373 - Plastic Battery Position Pieces

3242 - 2-56 x ½” SH

3233 - Plastic Ride Height

Spacers 3, 4, 5mm

3246 - Delrin

Pivot Ball

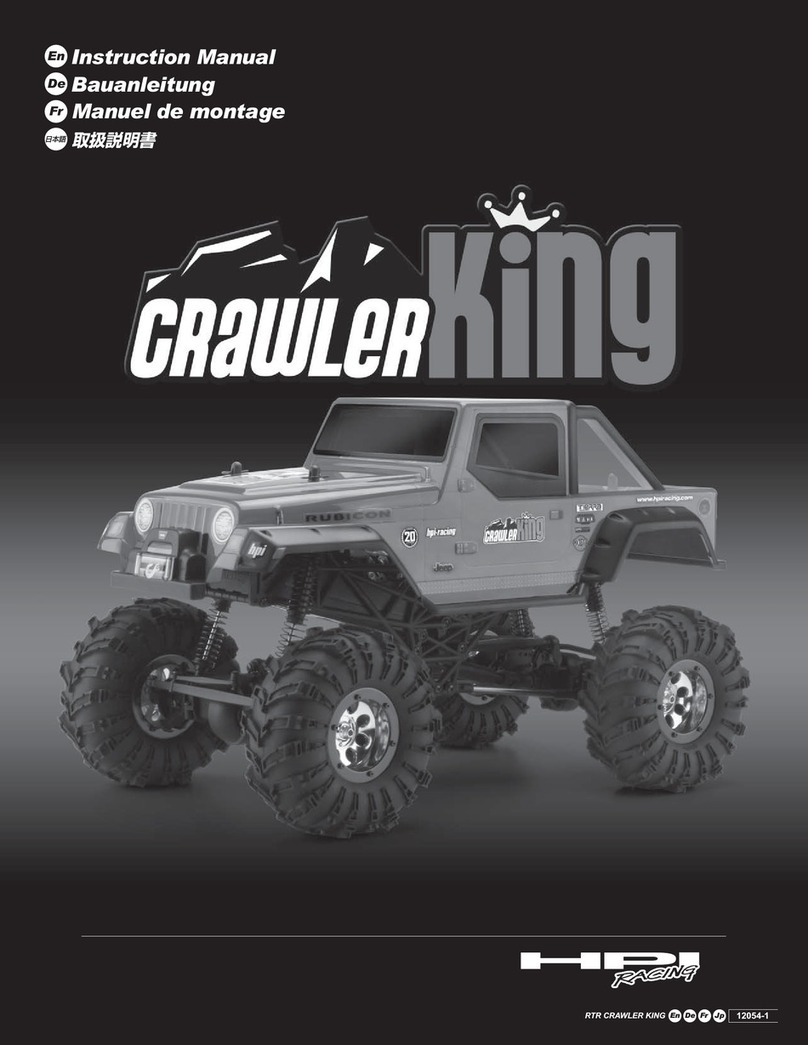

CRC Pro-Strut

Front End

3242 & 1472 -

2-56 Red Locknut

1429 - 4-40 x 7/16” FH

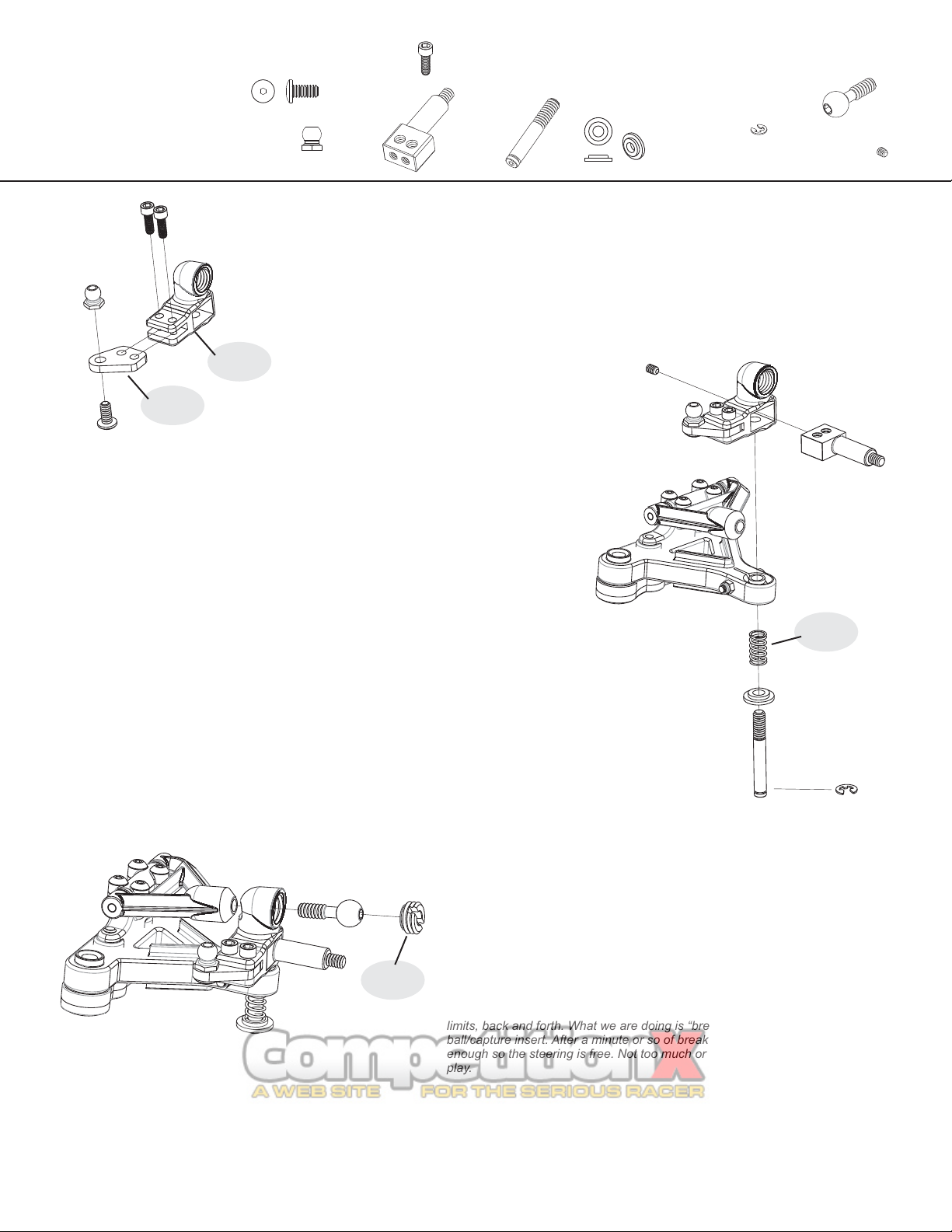

1 - Pop the delrin pivot ball into the lower arm. Place the arm on a strong table and push the ball in

with the back of screwdriver handle. Or preferably, you can use CRC’s 4279 Ball popper pivot ball

tool. Notice the “lip” of the delrin pivot ball is pointing upward. The diagram to the left represents a

right side lower arm. For the left side, flip the second arm over and be sure the pivot ball is installed

with the lip again facing up.

2 - Once the ball is popped in, insert the black 2-56 clamp screw through the horizontal hole in the

lower arm. Thread the 2-56 red locknut onto the black screw. Tighten the screw slowly continuously

checking the pivot ball. When it begins to bind a bit, back the 2-56 screw off a bit. The ball should

be free to pivot with just a bit of drag. There is no need to have this ball super loose and free, a

slight drag will be just the right amount of clamping force.

Check this fit after a few runs as the ball will wear and require additional clamping force.

Lip

1 - Install the upper A-arm mount with the amount of Dynamic Caster desired. The options are 0, 5 and 10

degrees. The part shown to the right in the diagram is the 5 degree version, however it is most common to use

0 degree blocks for oval racing. The 10 will angle down more toward the front of the car, and the 0 will be

parallel to the chassis. The general thought is the more Dynamic Caster, the more steering the car will have at

corner entry.

2 - Use the 5 mm thick ride height block for 1/10th scale tires. For fine front ride height adjustments, use the

CRC #4262 optional front shim set. This set contains .010, .020 and .030” plastic ride height shims. After

selecting the proper spacer, push the 4-40 x 7/16” screw through the plastic ride height spacer, then through

the lower arm, and then thread the screw into the upper A-arm mount. Be sure NOT to over tighten. Just snug,

you are threading a metal screw into the plastic upper A-arm mount.

Bag F

3247

7

1 - Break the mold tree from the upper A-arm. You can clean up the mold

gates with a hobby knife or rotary tool.

2 - Locate the upper arm hinge pin and slide it into one half of the upper

arm. Locate 3 small caster shims. Push the hinge pin through the 3 shims.

Then continue to push the hinge pin all the way into the upper arm.

3 - Now, install the arm/pin/washer assembly onto the upper arm mount. Put

the hinge pin in the channel. At this point you can set your starting caster

setting by moving these washers forward and back. The position shown to

the left will result in a competitive handling. Moving them to the rear will

increase steering from the center and exit of the corner.

If the fit of the upper arm is tight, trim the upper arm mount SLIGHTLY with a

hobby knife.

4 - Install the upper cap with 4 black 2-56 button head screws. The topper is

the “clamp” for the hinge pin. Be sure to tighten so that any gap is gone,

however, do not tighten beyond that point as damage can occur to the upper

a-arm mount holes.

3245 - Hinge Pin

1253 - Caster Shim 3243 & 3230 -

Upper Cap

3247

3243

3254 - 2-56 Button Head

3247 - CRC Front Arm set

3243 - Upper Arm mnt set-0,5,10

3233

3235 -

Dual Axle 3228 -

King Pin

3234 - Brass

Set Screw

1382 -

E-Clip

3253 -

2-56 SH

1 - Build up the left and right steering blocks as shown to the left. Start by threading the button head screw through

the steering arm and into the red low profile ball.

2 - Then, slide the steering arm assembly into the steering block, lining up the 2 mounting holes. Using the black 2-56

socket head screws, fasten the arm to the steering block. DO NOT OVER tighten. You will drive the screw through

the steering block, deforming the part.

1 - Push the Dual aluminum axle into the plastic steering block. Push it all the way in firmly.

Notice you can install the axle inline or trailing. Typically, this is installed inline for oval

racing. (as shown to the right) This will increase the steering response as compared to

trailing.

2 - Insert the e-clip into the groove on the end of the King pin. Next, slide the nylon spring

cup all the way down until it rests against the e-clip. Make sure the larger diameter of the

spring cup is against the e-clip and the smaller diameter side faces up. Now slide the spring

down against the spring cup.

3 - Now put your king pin / spring assembly on the end of the Allen key and slide it through

the lower arm pivot ball, & then thread it into the steering block (with the steering block all

the way down against the pivot ball). Thread the king pin in until the spring just touches the

lower arm pivot ball. The preload on the spring can be adjusted with the king pin length.

4 - Once happy with the preload position, lock the king pin with the 4-40 brass set screw

through the back of the steering block.

CRC Pro-Strut

Front End - cont.

3235 - Upper

Pivot Ball

1751 - Steering Arm

8

3287 - Nylon

Spring Cup

1 - Take the upper pivot ball and push it through the steering block and thread

into the upper arm. Thread it in so there are no threads showing.

2 - Take the slotted capture insert and thread it into the steering block. THIS

IS A BIT TRICKY .... as the insert must be fitted at a down angle as shown to

the left. DO NOT try to insert it horizontally into the steering block. It is

actually threaded in at a down angle toward the center of the car.

3 - Tighten this capture insert so that the steering movement is bound and

slow. Yes, we are actually slightly over tightening this piece FOR NOW. With

the steering movement bound from over tightening, move the steering to it’s

limits, back and forth. What we are doing is “breaking in” the upper

ball/capture insert. After a minute or so of break in, loosen the insert just

enough so the steering is free. Not too much or you will induce excessive free

play.

1434 - 4-40 x 1/4”

Button Head

13615 -

Red Low-

Profile Ball

3251

3393

3251

1751

3251 - Steering Block Set

3393 - .50mm

Front Spring

1757

1740

1760

9

Installing the Lower arm to the Chassis

1 - Insert three 4-40 x 5/16” FH screws through the chassis, then through the Front End

Mounting Plate. Secure this with three red locknuts. We recommend starting in the

middle hole of the plates as shown in the pic. This will give you the option to go either

wider or narrower if need be.

2 - Now, secure the front end assembly to the plate using the 8-32 x 5/8” low head front

end screws. Again, we recommend starting in the middle hole, giving you the option to

go longer or shorter.

3 - Repeat these steps for the other side.

4 - For fine ride height adjustments, you can use CRC’s 4262 plastic shim kit (optional).

CRC Pro-Strut

Front End - cont.

17394 - 8-32 x 5/8”

Low Head Screw

1412 - Red Locknut

1426 - 4-40 x

5/16” FH 1451 - 4-40 x

5/16” FH Red

1434 - 4-40 x 1/4”

Button Head

1424 - 4-40 x 1/4”

Flat Head

1715

Front of Car

Left

1753

1740 - Fr. End Mnt Plates 1757 - Graphite Bumper 1760 - Foam Bumper 1753 - Adj Servo Mnt Plate 1715 - Servo Mounts

4201 - Diff Ring 1387 - 1/4” x 3/8”

Plain Bearing Lip

4121 - Diff Spacer 4123 -

Spring Washer 4126 -

Nylon Diff Nut

4732 - 1/4” Shim

1-INSTALL AND GREASE THE DIFF BALLS

Place the spur gear flat on the table in front of you with the side that says “CRC”

facing down. The diff balls will fall into each of the outer ring of holes in the diff

gear, but won’t fall out the other side. Place a small dab of silicone diff grease on

each ball to lube the ball and prevent the balls from falling back out of the holes

during assembly. Use very little!

*(Holding the car on it’s side, with the rear axle pointing upright will ease assembly

of the diff.) Place 1 diff ring, and then a 1/4” x 3/8” plain bearing over the end of

the axle. Align the diff ring so that it notches into the axle flange. Place the

assembled gear with the greased diff balls over the axle and push it down over the

plain bearing. Next, insert the other plain bearing into the back of the diff hub.

Then, align the second diff ring with the notch on the back of the diff hub. *(place a

small dab of the diff grease on the hub first to hold the ring in place.)* Now, slide

the hub, bearing, & diff ring down over the axle. Next, slide a flanged bearing over

the axle and into the front of the diff hub.

2-DIFF ASSEMBLY

Small lip

toward bearing

1

** Balls in outer ring of holes in gear **

1386 - 1/4” x 3/8”

Flanged Bearing

DIFF ASSEMBLY -CONTINUED...

The diff spacer has a small machined lip on one

side, point that lip toward the bearing. Now,

place the spring washer so that the cone points

away from the gear. The outside of the washer

should be against the diff spacer, and the inside

of the washer should be against the diff nut,

which now goes on last. *Be sure the 2 “D” rings

have settled into their notches. Just snug the nut

so the parts stay together on the diff axle.

DON’T over-tighten so the outer diff hub bearing

gets crushed! Correct diff tension needs to be

set with tires on the car.

1376 - 4-40 x 3/8”

Steel Socket Cap

10

3 - Setting the Diff

Once the tires are on: Adjust the diff nut so that the tires spin back and forth freely when holding the

spur gear, but it is very difficult to slip the spur gear with your thumb when holding both tires. Again -

DON’T over-tighten so the outer diff hub bearing gets crushed! Re-check diff tension after the first run.

Bag 8

Differential Axle

Bag 9

Differential

1728

1933

*NOTE -THE 1/4” SHIMS ARE FOR FINE TUNING THE WIDTH OF

THE REAR END.THEY ARE NOT NECESSARY LIKE THE TWO RED

SPACERS SHOWN IN THE DIAGRAM BELOW.

4720 - Axle Spacer-

Xti-2 + 5mm

64072

64080

64088

64096

1228

1925

Dot of

grease

1728 - 1/10 Graphite Axle

1933 - Narrow Left Clamp Hub

1925 - Long Diff Hub

1228 - 3/32 Diff Balls (100)

13783 - 4-40 x 1/8”

Set Screw

11

1462 - 4-40 x 3/8”

Red Socket Cap

4745 -

3/16” Shim

3248 - 3/16” x 5/16”

Flanged Bearing

1 - Use the 4-40 x 3/8” red cap head screws to bolt the rear

wheels to the hubs.

2 - Insert the flanged bearings into the front wheels. Place a

3/16” shim over the axle, then the front wheel, & then a red

locknut last. The front wheels should spin very free. Do not

over-tighten the front wheel nuts so that the bearings are

pinched.

(Tires not included)

1436 - 4-40 x 3/8”

Button Head

1264

Bag 10

Bag 11

1412 - Red Locknut

1264 - Long Body Posts

w/ collars (3 in.)

This manual suits for next models

1

Table of contents

Other CRC Motorized Toy Car manuals