CRE Technology PM-PROGRESS Guide

MULTIFUNCTION POWER

METER

Technical Documentation

PM-PROGRESS

Part Number:

PMP

CRE Technology

130, Allée Victor Naudin

Zone des Templier

Sophia-Antipolis

06410 Biot

FRANCE

Phone: +33 (0)4 92 38 86 82

Fax: +33 (0)4 92 38 86 83

Website: www.cretechnology.com

Email: info@cretechnology.com

NOTE

Read this entire manual and all other publications pertaining to the work to be performed

before installing, operating, or servicing this equipment. Apply all plant and safety

instructions and precautions. Failure to follow instructions can cause personal injury and/or

property damage.

Motors, turbines and any other type of generator must be equipped with protections

(overspeed, high temperature, low pressure…) depending on the power plant.

Any changes of the normal use of the equipment can cause human and material damage.

For further information, please contact your CRE Technology distributor or the After-Sales Service Team.

All CRE Technology products are delivered with one year warranty, and if necessary we will be happy to come

on site for product commissioning or troubleshooting. The company also provide specific trainings on our

products and softwares.

Technical support: +33 (0)4 92 38 86 86 (office hours: 8.30AM-12AM / 2PM-6PM GMT+1).

Email: support@cretechnology.com

SKYPE: support-cretechnology.com

INFORMATION

You can download the most up-to-date version of this documentation and different

other documentations relating to CRE Technology products on our Web site

http://www.cretechnology.com.

CRE Technology believes that all information provided herein is correct and reliable and reserves the right to

update at any time. CRE Technology does not assume any responsibility for its use.

Technical documentation history

Date

Version

Comments

2011

A

Initial version.

Dec. 2015

B

Added details about internal current connection.

Typos.

Documentations available on CRE Technology Web site:

pmp-sales-documentation.pdf

pmp-technical-documentation.pdf

pmp-documentation-commerciale.pdf

Table content

1INSTALLATION AND OPERATING INSTRUCTION....................................................................................................... 1

1.1 MEASUREMENT ................................................................................................................................................... 1

1.2 SETTING UP......................................................................................................................................................... 1

1.3 SETUP MENU STRUCTURE ....................................................................................................................................... 2

1.4 MENU OPTION SELECTION ...................................................................................................................................... 3

1.5 INSTALLATION...................................................................................................................................................... 4

1.5.1 Single phase, two wire ................................................................................................................................. 4

1.5.2 Three phase, three wire ............................................................................................................................... 5

1.5.3 Three phase, four wire ................................................................................................................................. 5

1.5.4 Cut-out details............................................................................................................................................. 6

1.5.5 Wiring ......................................................................................................................................................... 6

2PM-PROGRESS MODBUS PROTOCOL IMPLEMENTATION......................................................................................... 8

2.1 MODBUS PROTOCOL OVERVIEW ............................................................................................................................... 8

2.2 INPUT REGISTERS .................................................................................................................................................. 9

2.2.1 PM-progress input registers......................................................................................................................... 9

2.3 MODBUS PROTOCOL HOLDING REGISTERS AND DIGITAL METER SET UP ............................................................................ 11

2.3.1 PM-progress MODBUS Protocol Holding Register Parameters .................................................................... 11

3R5485 GENERAL INFORMATION ............................................................................................................................ 14

3.1 HALF DUPLEX .................................................................................................................................................... 14

3.2 CONNECTING THE INSTRUMENTS ............................................................................................................................ 14

3.3 AAND BTERMINALS ........................................................................................................................................... 15

3.4 TROUBLESHOOTING ............................................................................................................................................ 16

4MAINTENANCE AND SAFETY REQUIREMENT ......................................................................................................... 17

4.1 MAINTENANCE .................................................................................................................................................. 17

4.2 SAFETY ............................................................................................................................................................ 17

4.3 EMC INSTALLATION REQUIREMENT......................................................................................................................... 17

5CRE TECHNOLOGY ................................................................................................................................................. 18

Figures

Figure 1 - Single phase, two wire....................................................................................................................................... 4

Figure 2 - Three phase, three wire..................................................................................................................................... 5

Figure 3 - Three phase, four wire....................................................................................................................................... 5

Figure 4 –Case dimensions and Cut-out details................................................................................................................. 6

Figure 5 –Modbus via RS485 network overview.............................................................................................................. 15

Figure 6 –Recommended wiring..................................................................................................................................... 15

Figure 7 –A and B terminal............................................................................................................................................. 15

Figure 9 –Access to CRE Technology............................................................................................................................... 18

Figure 10 - CRE Technology distributors .......................................................................................................................... 19

Tables

Table 1 - Measurement..................................................................................................................................................... 1

Table 2 - PM-Progress input registers.............................................................................................................................. 10

Table 3 –PM-progress modbus protocol holding register parameters ............................................................................. 12

Table 4 –R5485 General Information.............................................................................................................................. 14

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

1

1Installation and operating instruction

PM-Progress is designed for accurate measurement and display of all major electrical and power quality

parameters, in single-phase two wire, and three-phase three and four-wire system configurations.

This manual provides all the necessary instructions to safely install and operate the instrument. For more

information please contact your distributor.

1.1

Measurement

In measurement mode, the buttons control the displayed measurement as follows:

Used to select the Voltage and Frequency

display screens.

In set-up mode this is the “Back” button.

Used to select the Current display screens.

In set-up mode this is the “Up” button.

Used to select the Power and Power Factor

display screens.

In set-up mode this is the “Down” button.

Used to select the Energy display screens.

In set-up mode this is the “Enter” button.

Table 1 - Measurement

1.2

Setting up

Press and hold the two buttons and simultaneously for five seconds until the password

screen is displayed.

Press four times to enter the default password of “0000”.

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

2

The system setup screen will be displayed on the screen. Press the button to scroll down the

menu until you see the CT primary setting screen.

Press the button to enter the CT primary setting screen. The first digit should start flashing.

Use and buttons to set the digit to the required level then press to confirm. Repeat

this process until all four digits have been set to the desired CT primary value. (e.g. 100A = 0100A,

1000A = 1000A).

The word “SET” should be displayed after the fourth digit has been entered to confirm that the

primary CT value has been set.

Press to return to the first level menu structure, to scroll up and down the structure to adjust

other parameters (if needed). If no other settings are required, press to exit set-up mode and

return to measurement mode.

1.3

Setup menu structure

Change password:

nnnn - 4-digit number –default ‘0000’

Supply systems:

3-phase (3 or 4-wire) or Single phase

CT:

Set maximum current that can be monitored according to CT in use. nnnn –4-digit number 0001 to 9999.

Demand Interval Time:

Selects demand time in minutes from 60/30/20/15/10/8/5/OFF.

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

3

Reset:

Reset cumulative energy and Demand measurements to zero.

Communication parameters:

For RS485 interface (optional), Modbus protocol

Baud rate 2400/4800/9600/19200/38400

Parity none/odd/even

Stop bits 1 (1 or 2 if parity is none)

RS485 network address nnn –3-digit number 1 to 247

Order –Norm/Rev indicates if the Modbus word order is normal or reversed.

Johnson Controls (JC) N2 protocol

RS485 network address nnn –3-digit number 1 to 255.

Relay pulse outputs (optional):

OP1 kWh/kVArh (Active/reactive)

Import from output module 1

OP2 kWh/kVArh (Active/reactive)

Import from output module 2

Rate 0.1/1/10/100/1000 kWh or kVArh per pulse

Pulse width 200/100/60 ms.

Energy:

kilo/Mega

Test:

Phase sequence

Display on –all elements on to check display

Display toggle - Each element is turned on and off

SOFT:

Displays software version number.

1.4

Menu option selection

After entering the correct password, use and buttons to navigate up and down the first

level until the desired parameter is reached. Selection does not roll over from bottom to top of list

or vice versa.

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

4

Press button to select the desired parameter and enter the second level menu structure.

If an item flashes, then it can be adjusted by and keys. If not, there may be a further layer,

e.g. Comms - Baud rate, before adjustment is possible. Press to select the lower layer.

Having selected an option from the current menu layer, press to confirm your selection. The

word SET will come on.

Once all the necessary selections have been made and the required settings entered, press to

return to the first level menu structure. The word SET will turn off and you can then use

and keys for further menu selection.

On completion of all settings, press repeatedly to exit set-up mode and return to measurement

mode.

1.5

Installation

1.5.1

Single phase, two wire

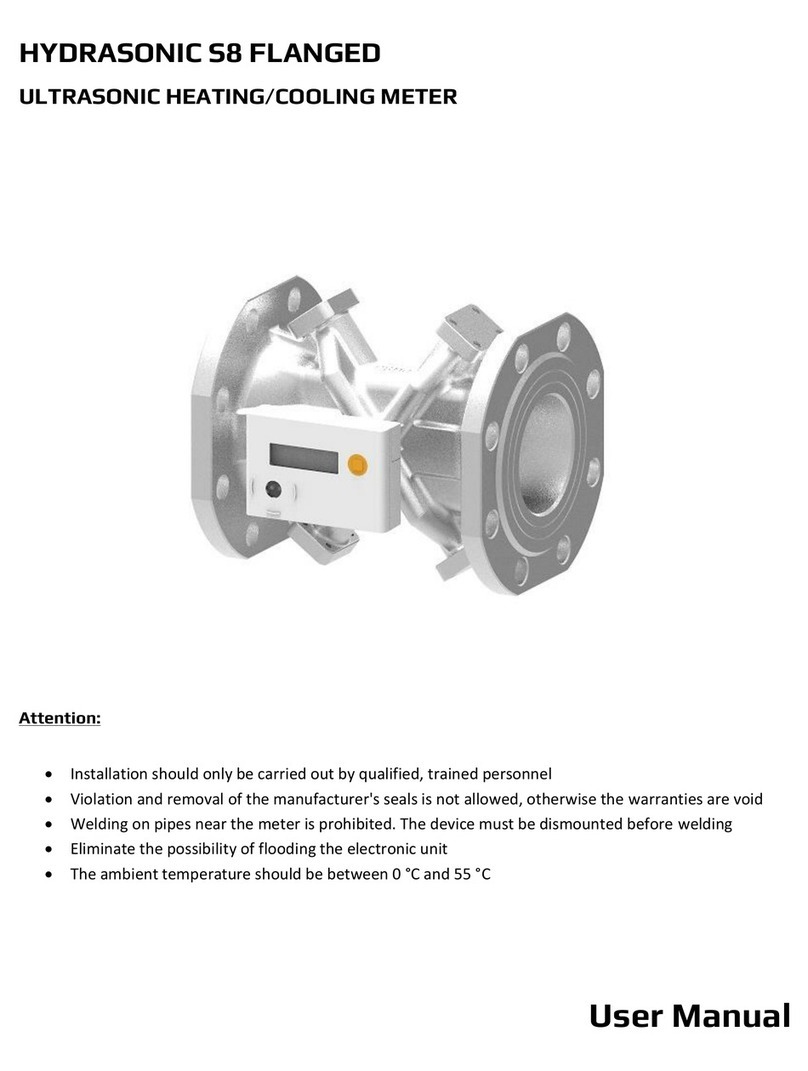

Figure 1 - Single phase, two wire

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

5

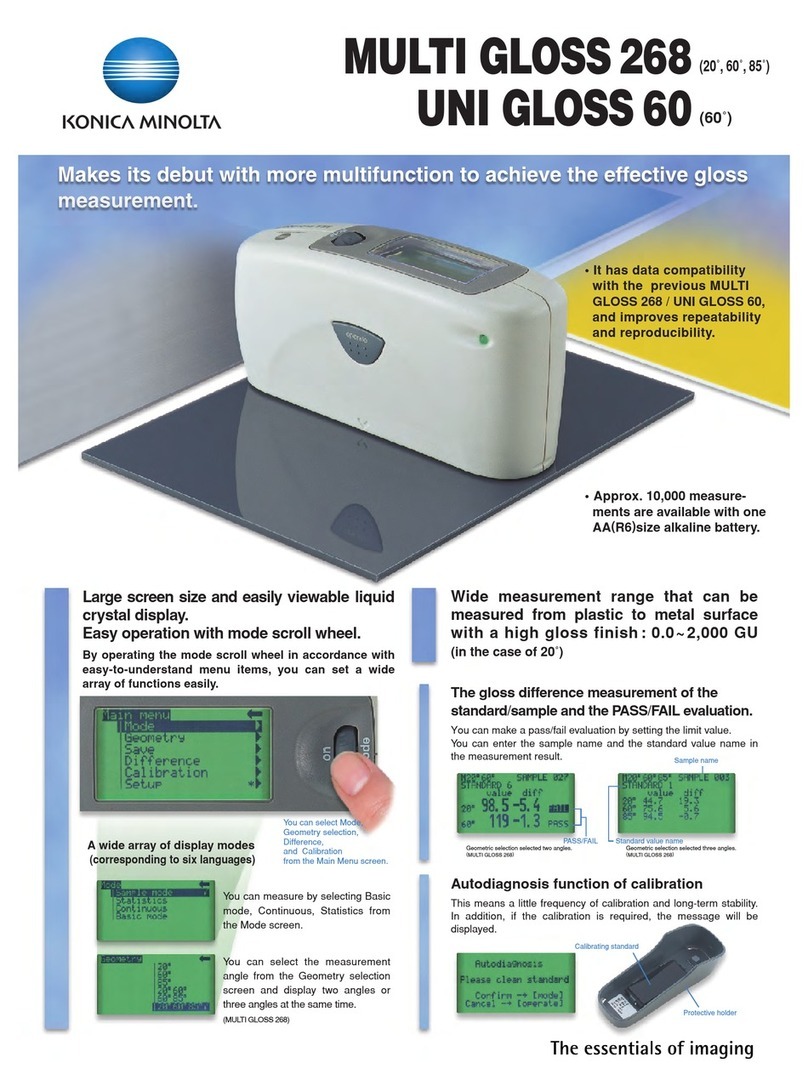

1.5.2

Three phase, three wire

Negative current inputs are

internally connected together.

Figure 2 - Three phase, three wire

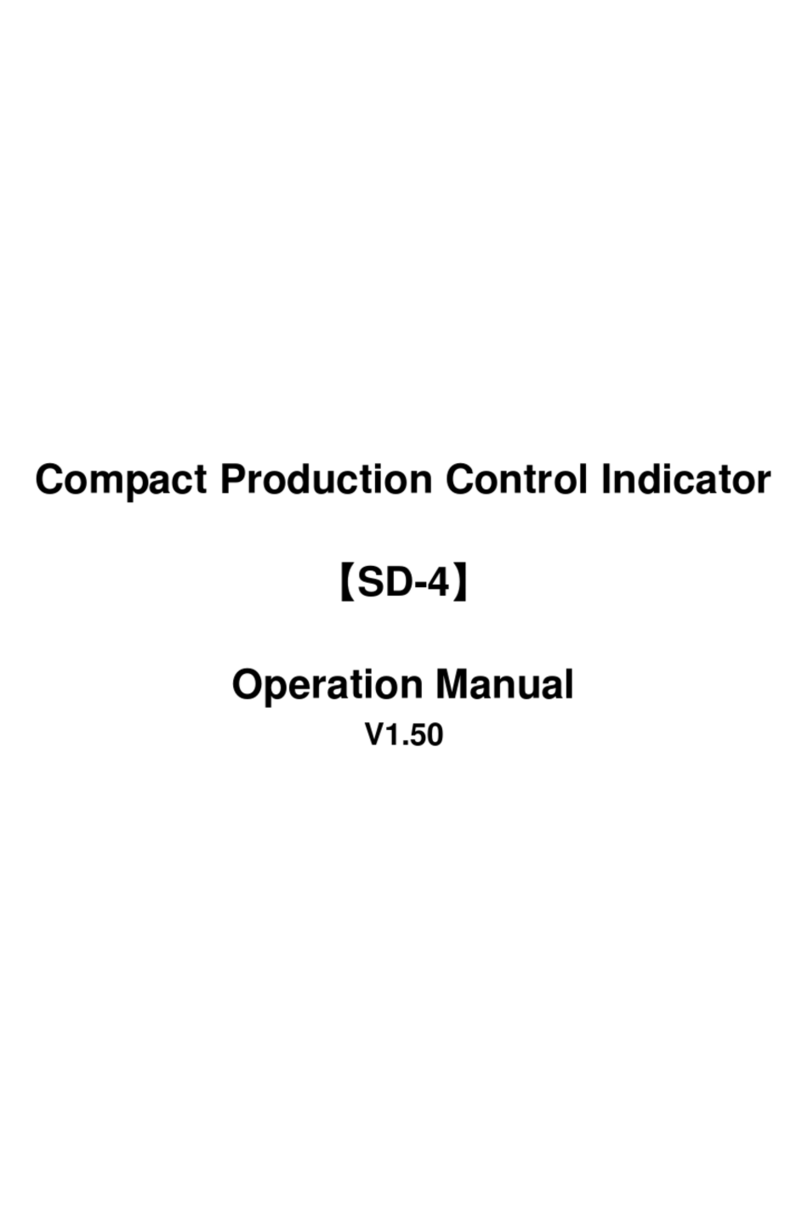

1.5.3

Three phase, four wire

Negative current inputs are

internally connected together.

Figure 3 - Three phase, four wire

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

6

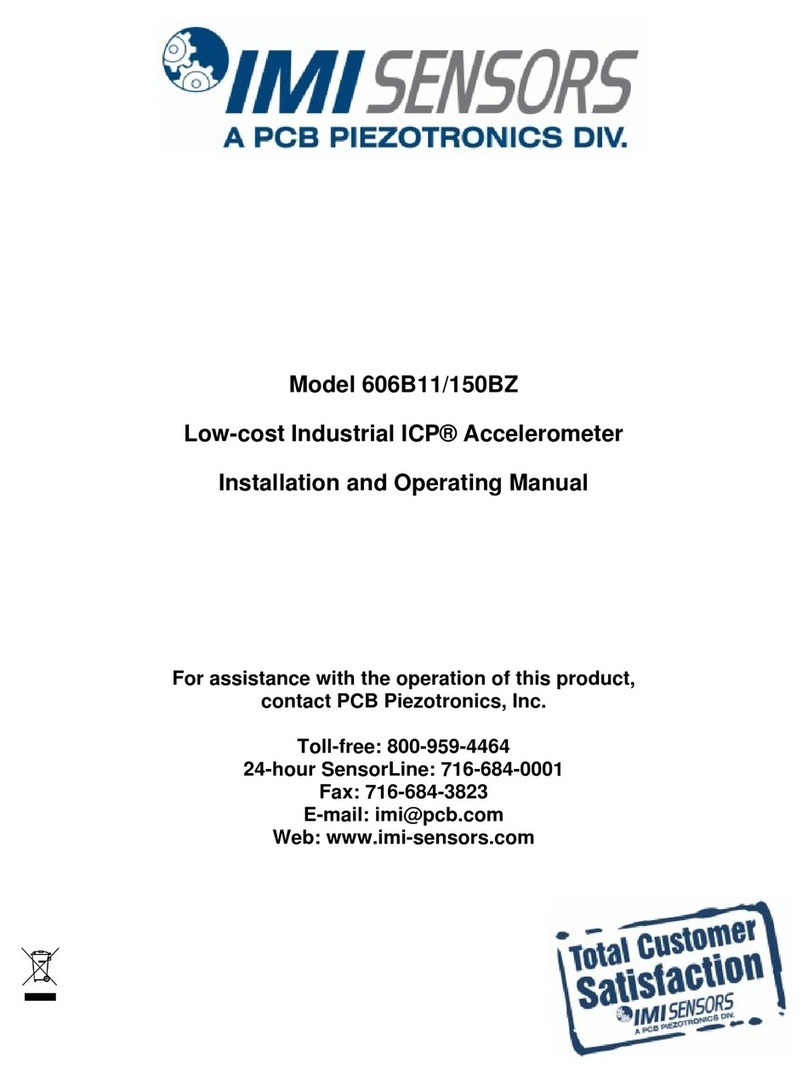

1.5.4

Cut-out details

Figure 4 –Case dimensions and Cut-out details

The unit may be mounted in a panel of any thickness up to a maximum of 6 mm (0·25in). Leave enough

space behind the instrument to allow for bends in the connection cables. As the front of panel enclosure

conforms to IP52, it is protected from dripping water.

The unit is intended for use in a reasonably stable ambient temperature within the range -10 to +55°C. Do

not mount the unit where there is excessive vibration or in excessive direct sunlight.

1.5.5

Wiring

Input connections are made to screw clamp terminals. Connection cable should meet local regulations for

the operating voltage and current. The current inputs of these products are designed for connection into

systems via current transformers only.

All negative current inputs are connected together inside the unit and grounding should be done at one

point only. To minimize measurement errors, the CTs should be grounded as shown in the wiring diagrams

above. CT secondaries must be grounded in accordance with local regulations. It is desirable to make

provision for shorting links to be made across CTs to permit easy replacement of a unit should this ever be

necessary.

All connections are made to screw clamp terminals. Terminals are suitable for copper wires only and will

accept one stranded 0.05 - 2.5mm² (30 - 12AWG) stranded or solid core cables.

Terminal screws are fully tightened for shipment and must be undone before wire insertion. Terminal

screws should be tightened to 0.5 Nm (4.4 lbf in) only.

Additional considerations for three wire systems

The neutral terminal (terminal N) is indirectly connected to the voltage input terminals (terminals L1, L2,

L3). When connected to a three wire system the neutral terminal will adopt a potential somewhere

between the remaining lines. If external wiring is connected to the neutral terminal it must be connected to

either the neutral line or earth (ground) to avoid the possibility of electric shock from the neutral terminal.

PMP 9 0020 B EN –Technical documentation

Chapter : Installation and operating instruction

7

Fusing

This unit must be fitted with external fuses in voltage and auxiliary supply lines. Voltage input lines must be

fused with a quick blow fuse 1 A maximum. Auxiliary supply lines must be fused with a slow blow fuse rated

1 A maximum. Choose fuses of a type and with a breaking capacity appropriate to the supply and in

accordance with local regulations

A switch or circuit breaker allowing isolation of supplies to the unit must be provided.

Earth/Ground Connections

For safety reasons, current transformer secondary connections should be grounded in accordance with

local regulations. The unit relies on this ground connection as a Protective Earth.

Under no circumstances should the product be operated without a Protective Earth connection.

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

8

2PM-Progress modbus protocol

implementation

2.1

Modbus protocol overview

This section provides basic information for interfacing the PM-Progress to a Modbus Protocol network. If

background information or more details of the PM-Progress implementation is required please refer to

section 2 and 3 of this document.

PM-Progress offers the option of an RS485 communication facility for direct connection to SCADA or other

communications systems using the Modbus Protocol RTU slave protocol. The Modbus Protocol establishes

the format for the master's query by placing into it the device address, a function code defining the

requested action, any data to be sent, and an error checking field. The slave's response message is also

constructed using Modbus Protocol. It contains fields confirming the action taken, any data to be returned,

and an error-checking field. If an error occurs in receipt of the message, PM-Progress will make no

response. If PM-Progress is unable to perform the requested action, it will construct an error message and

send it as the response.

The electrical interface is 2-wire RS485, via 3 screw terminals. Connection should be made using twisted

pair screened cable (typically 22 gauge Belden 8761 or equivalent). All "A" and "B" connections are daisy

chained together. The screens should also be connected to the “GND” terminal. To avoid the possibility of

loop currents, an earth connection should be made at only one point on the network.

Line topology may or may not require terminating loads depending on the type and length of cable used.

Loop (ring) topology does not require any termination load.

The impedance of the termination load should match the impedance of the cable and be at both ends of

the line. The cable should be terminated at each end with a 120 ohm (0.25 Watt min.) resistor.

A total maximum length of 3900 feet (1200 meters) is allowed for the RS485 network. A maximum of 32

electrical nodes can be connected, including the controller.

The address of each PM-Progress can be set to any value between 1 and 247. Broadcast mode (address 0) is

not supported.

The maximum latency time of PM-Progress is 60ms i.e. this is the amount of time that can pass before the

first response character is output. The supervisory program must allow this period of time to elapse before

assuming that the PM-Progress is not going to respond.

The format for each byte in RTU mode is:

Coding System: 8 bits per byte

Data Format: 4 bytes (2 registers) per parameter.

Floating point format ( to IEEE 754)

Most significant register first (Default). The default may be changed if required - See Holding

Register "Register Order" parameter.

Error Check Field: 2 bytes Cyclical Redundancy Check (CRC)

Framing: 1 start bit

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

9

8 data bits, least significant bit sent first

1 bit for even/odd parity (or no parity)

1 stop bit if parity is used; 1 or 2 bits if no parity

Data Coding

All data values in the PM-Progress are transferred as 32 bits IEEE 754 floating point numbers, (input and

output) therefore each PM-Progress value is transferred using two MODBUS Protocol registers. All register

read requests and data write requests must specify an even number of registers. Attempts to read/write an

odd number of register will prompt the PM-Progress to return a MODBUS Protocol exception message.

However, for compatibility with some SCADA systems, PM-Progress will respond to any single input or

holding register read with an instrument type specific value.

The PM-Progress can transfer a maximum of 40 values in a single transaction; therefore the maximum

number of registers is 80. Exceeding this limit prompts the PM-Progress to generate an exception response.

Data Transmission speed is selectable between 2400, 4800, 9600, 19200 and 38400 bauds.

2.2

Input registers

Input registers are used to read actual values of all measured and calculated electrical quantities.

Each internal parameter is held in two consecutive 16 bits registers. Table below details the Modbus 3X

register addresses, and the values of the address bytes within the Modbus request. Each parameter is held

in the 3X registers. Modbus Protocol Function Code 04 is used to access all parameters.

The three columns on the right indicate if the parameter is available in a specific wiring system (single

phase or three phase system with 3 or 4 wires). Reading a parameter that is not available in the current

system will return a value set to zero.

Example of a Modbus request to read parameter 5 (Phase 2 current):

Modbus function = 04

Start address = 0008

No of registers = 0002 (as said above: each parameter is held in 2 consecutive 16 bits registers)

2.2.1

PM-progress input registers

Modbus

register

Parameter

Number

Description

Unit

Start address

(Hex., MSB first)

3 Ph.

4 W.

3 Ph.

3 W.

1 Ph.

2 W.

30001

1

Phase 1 line to neutral volts.

V

00

00

Avail.

N/A

Avail.

30003

2

Phase 2 line to neutral volts.

V

00

02

Avail.

N/A

N/A

30005

3

Phase 3 line to neutral volts.

V

00

04

Avail.

N/A

N/A

30007

4

Phase 1 current.

A

00

06

Avail.

Avail.

Avail.

30009

5

Phase 2 current.

A

00

08

Avail.

Avail.

N/A

30011

6

Phase 3 current.

A

00

0A

Avail.

Avail.

N/A

30013

7

Phase 1 power.

W

00

0C

Avail.

N/A

Avail.

30015

8

Phase 2 power.

W

00

0E

Avail.

N/A

N/A

30017

9

Phase 3 power.

W

00

10

Avail.

N/A

N/A

30019

10

Phase 1 volt amps.

VA

00

12

Avail.

N/A

Avail.

30021

11

Phase 2 volt amps.

VA

00

14

Avail.

N/A

N/A

30023

12

Phase 3 volt amps.

VA

00

16

Avail.

N/A

N/A

30025

13

Phase 2 volt amps reactive.

VAR

00

18

Avail.

N/A

Avail.

30027

14

Phase 1 volt amps reactive.

VAR

00

1A

Avail.

N/A

N/A

30029

15

Phase 3 volt amps reactive.

VAR

00

1C

Avail.

N/A

N/A

30031

16

Phase 1 power factor(1).

None

00

1E

Avail.

N/A

Avail.

30033

17

Phase 2 power factor(1).

None

00

20

Avail.

N/A

N/A

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

10

Modbus

register

Parameter

Number

Description

Unit

Start address

(Hex., MSB first)

3 Ph.

4 W.

3 Ph.

3 W.

1 Ph.

2 W.

30035

18

Phase 3 power factor(1).

None

00

22

Avail.

N/A

N/A

30037

19

Phase 1 phase angle.

Degrees

00

24

Avail.

N/A

Avail.

30039

20

Phase 2 phase angle.

Degrees

00

26

Avail.

N/A

N/A

30041

21

Phase 3 phase angle.

Degrees

00

28

Avail.

N/A

N/A

30043

22

Average line to neutral volts.

V

00

2A

Avail.

N/A

N/A

30047

24

Average line current.

A

00

2E

Avail.

Avail.

Avail.

30049

25

Sum of line currents.

A

00

30

Avail.

Avail.

Avail.

30053

27

Total system power.

W

00

34

Avail.

Avail.

Avail.

30057

29

Total system volt amps.

VA

00

38

Avail.

Avail.

Avail.

30061

31

Total system VAR.

VAR

00

3C

Avail.

Avail.

Avail.

30063

32

Total system power factor(1).

None

00

3E

Avail.

Avail.

Avail.

30067

34

Total system phase angle.

Degrees

00

42

Avail.

Avail.

Avail.

30071

36

Frequency of supply voltages.

Hz

00

46

Avail.

Avail.

Avail.

30073

37

Import Wh since last reset(2).

kWh/MWh

00

48

Avail.

Avail.

Avail.

30075

38

Export Wh since last reset(2).

kWh/MWh

00

4A

Avail.

Avail.

Avail.

30077

39

Import VARh since last reset(2).

kVARh/MVARh

00

4C

Avail.

Avail.

Avail.

30079

40

Export VARh since last reset(2).

kVARh/MVARh

00

4E

Avail.

Avail.

Avail.

30081

41

VAh since last reset(2).

kVAh/MVAh

00

50

Avail.

Avail.

Avail.

30083

42

Ah since last reset(3).

Ah/kAh

00

52

Avail.

Avail.

Avail.

30085

43

Total system power demand(4).

W

00

54

Avail.

Avail.

Avail.

30087

44

Max. total system power demand(4).

W

00

56

Avail.

Avail.

Avail.

30101

51

Total system VA demand.

VA

00

64

Avail.

Avail.

Avail.

30103

52

Maximum total system VA demand.

VA

00

66

Avail.

Avail.

Avail.

30105

53

Neutral current demand.

A

00

68

Avail.

N/A

N/A

30107

54

Maximum neutral current demand.

A

00

6A

Avail.

N/A

N/A

30201

101

Line 1 to Line 2 volts.

V

00

C8

Avail.

Avail.

N/A

30203

102

Line 2 to Line 3 volts.

V

00

CA

Avail.

Avail.

N/A

30205

103

Line 3 to Line 1 volts.

V

00

CC

Avail.

Avail.

N/A

30207

104

Average line to line volts.

V

00

CE

Avail.

Avail.

N/A

30225

113

Neutral current.

A

00

E0

Avail.

N/A

N/A

30235

118

Phase 1 L/N volts THD

%

00

EA

Avail.

N/A

Avail.

30237

119

Phase 2 L/N volts THD

%

00

EC

Avail.

N/A

N/A

30239

120

Phase 3 L/N volts THD

%

00

EE

Avail.

N/A

N/A

30241

121

Phase 1 Current THD

%

00

F0

Avail.

Avail.

Avail.

30243

122

Phase 2 Current THD

%

00

F2

Avail.

Avail.

N/A

30245

123

Phase 3 Current THD

%

00

F4

Avail.

Avail.

N/A

30249

125

Average line to neutral volts THD.

%

00

F8

Avail.

N/A

Avail.

30251

126

Average line current THD.

%

00

FA

Avail.

Avail.

Avail.

30255

128

Total system power factor(5).

Cos Ø

00

FE

Avail.

Avail.

Avail.

30259

130

Phase 1 current demand.

A

01

02

Avail.

Avail.

Avail.

30261

131

Phase 2 current demand.

A

01

04

Avail.

Avail.

N/A

30263

132

Phase 3 current demand.

A

01

06

Avail.

Avail.

N/A

30265

133

Maximum phase 1 current demand.

A

01

08

Avail.

Avail.

Avail.

30267

134

Maximum phase 1 current demand.

A

01

0A

Avail.

Avail.

N/A

30269

135

Maximum phase 1 current demand.

A

01

0C

Avail.

Avail.

N/A

30335

168

Line 1 to line 2 volts THD.

%

01

4E

Avail.

Avail.

N/A

30337

169

Line 2 to line 3 volts THD.

%

01

50

Avail.

Avail.

N/A

30339

170

Line 3 to line 1 volts THD.

%

01

52

Avail.

Avail.

N/A

30341

171

Average line to line volts THD.

%

01

54

Avail.

Avail.

N/A

Table 2 - PM-Progress input registers

Notes:

1. The power factor has its sign adjusted to indicate the nature of the load: a positive value for a capacitive load, a

negative value for an inductive load.

2. There is a user option to select either “k”or “M”for the energy prefix.

3. The same user option applies a prefix of “none”or “k”for Ampere hours.

4. The power sum demand calculation is for import power only.

5. The negative total system power factor is a sign inverted version of parameter 32, the magnitude is the same as

parameter 32.

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

11

2.3

Modbus Protocol Holding Registers and

Digital meter set up

Holding registers are used to store and display instrument configuration settings. All holding registers not

listed in the table below should be considered as reserved for manufacturer use and no attempt should be

made to modify their values.

The holding register parameters may be viewed or changed using Modbus Protocol. Each parameter is held

in two consecutive 4X registers. Modbus Protocol Function Code 03 is used to read the parameter and

Function Code 16 is used for write access. Write to only one parameter per message.

2.3.1

PM-progress MODBUS Protocol Holding Register

Parameters

Address

(Register)

Parameter

Number

Parameter

Start address

(Hex, MSB 1st)

Valid range

Mode

40001

1

Demand Time

00

00

Read minutes into first demand calculation.

When the Demand Time reaches the Demand

Period then the demand values are valid.

ro

40003

2

Demand Period

00

02

Write demand period: 0, 5, 8, 10, 15, 20, 30 or

60 minutes, default 60. Setting the period to 0

will cause the demand to show the current

parameter value, and demand max to show the

maximum parameter value since last demand

reset.

r/w

40007

4

System Volts

00

06

Read system voltage, VLL for 3P3W, VLN for

others.

ro

40009

5

System Current

00

08

Write system current, limited to 1 to 9999A.

Requires password, see parameter 13

r/wp

40011

6

System Type

00

0A

Write system type: 3p4w = 3, 3p3w = 2 & 1p2w

= 1

Requires password, see parameter 13

r/wp

40013

7

Relay Pulse

Width

00

0C

Write relay on period in milliseconds: 60, 100 or

200, default 200.

r/w

40015

8

Password Lock

00

0E

Write any value to password lock protected

registers.

Read password lock status:

0 = locked. 1 = unlocked.

Reading will also reset the password timeout

back to one minute.

r/w

40019

10

Network Parity

Stop

00

12

Write the network port parity/stop bits for

MODBUS Protocol, where:

0 = One stop bit and no parity, default.

1 = One stop bit and even parity.

2 = One stop bit and odd parity.

3 = Two stop bits and no parity.

Requires a restart to become effective.

r/w

40021

11

Network Node

00

14

Write the network port node address: 1 to 247

for MODBUS Protocol, default 1. Requires a

restart to become effective. Note, both the

MODBUS Protocol and Johnson Controls node

addresses can be changed via the display setup

menus.

r/w

40023

12

Pulse Divisor

00

16

Write pulse divisor index: n = 2 to 6 in Wh/l0^n,

default 3.

r/w

40025

13

Password

00

18

Write password for access to protected

registers. Read zero. Reading will also reset the

password timeout back to one minute. Default

password is 0000.

r/w

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

12

Address

(Register)

Parameter

Number

Parameter

Start address

(Hex, MSB 1st)

Valid range

Mode

40029

15

Network Baud

Rate

00

1C

Write the network port baud rate for MODBUS

Protocol, where:

0 = 2400 baud.

1 = 4800 baud.

2 = 9600 baud, default.

3 = 19200 baud.

4 = 38400 baud.

Requires a restart to become effective

r/w

40031

16

Energy Units

Prefix

00

1E

Write the units prefix for energy output values.

0 = k, e.g. kWh, default. But Ah for ampere

hours.

1 = M, e.g. MWh. But kAh for ampere hours.

r/w

40037

19

System Power

00

24

Read the total system power, e.g. for 3p4w

returns System Volts x System Amps x 3.

ro

40041

21

Register Order

00

28

Write the value 2141 in the required register

order.

r/w

40043

22

Serial Number Hi

00

2A

Read the first product serial number.

ro

40045

23

Serial Number Lo

00

2C

Read the second product serial number.

ro

40087

44

Relay1 Energy

Type

00

56

Write MODBUS Protocol input parameter for

pulse relay 1:

0 = relay off

37 = Import Wh

39 = Import VArh

Default 37.

r/w

40089

45

Relay2 Energy

Type

00

58

MODBUS Protocol input parameter for pulse

relay 2:

0 = relay off

37 = Import Wh

39 = Import VARh

Default 37.

r/w

40217

109

Reset Logged

Data

00

D8

Write code to reset datagroup.

Code 1 for Energy.

Code 2 for Demand Maximums.

Code 3 for Demand Maximums and Demand

Time.

r/w

Table 3 –PM-progress modbus protocol holding register parameters

Register Order controls the order in which the PM-Progress receives or sends floating-point numbers:

normal or reversed register order. In normal mode, the two registers that make up a floating point number

are sent most significant register first. In reversed register mode, the two registers that make up a floating

point number are sent least significant register first.

To set the mode, write the value '2141.0' into this register - the instrument will detect the order used to

send this value and set that order for all Modbus Protocol transactions involving floating point numbers.

It is perfectly feasible to change PM-Progress set-up using a general purpose Modbus Protocol master, but

often easier to use the PM-Progress display or PM-Progress configuration software, especially for gaining

password protected access. The PM-Progress configuration software has facilities to store configurations to

disk for later retrieval and rapid set up of similarly configured products.

Password

Some of the parameters described above are password protected and thus require the password to be

entered at the Password register before they can be changed. The default password is 0000. When the

password has been entered it will timeout in one minute unless the Password or Password Lock register is

read to reset the timeout timer.

PMP 9 0020 B EN –Technical documentation

Chapter : PM-Progress modbus protocol implementation

13

Once the required changes have been made to the protected parameters the password lock should be

reapplied by following one of these actions:

Allowing the password to timeout

Writing any value to the Password Lock register

Power cycling the instrument.

PMP 9 0020 B EN –Technical documentation

Chapter : R5485 general information

14

3R5485 general information

RS485 or EIA (Electronic Industries Association) RS485 is a balanced line, half-duplex transmission system

allowing transmission distances up to 1.2 km. The following table summarizes the RS-485 Standard:

Parameters

Description

Mode of Operation

Differential

Number of Drivers and Receivers

32 Drivers

32 Receivers

Maximum Cable Length

1200 m

Maximum Data Rate

10 M baud

Maximum Common Mode Voltage

12 V to –7 V

Minimum Driver Output Levels (Loaded)

+/–1.5 V

Minimum Driver Output Levels (Unloaded)

+/–6 V

Drive Load

Minimum 60Ω

Driver Output Short Circuit Current Limit

150 mA to GND

250 mA to 12 V

250 mA to –7 V

Minimum Receiver Input Resistance

12 kΩ

Receiver Sensitivity

+/–200 mV

Table 4 –R5485 General Information

Further information relating to RS485 may be obtained from either the EIA or the various RS485 device

manufacturers, for example Texas Instruments or Maxim Semiconductors. This list is not exhaustive.

3.1

Half duplex

Half duplex is a system in which one or more transmitters (talkers) can communicate with one or more

receivers (listeners) with only one transmitter being active at a time. For example, a “conversation” is

started by asking a question, the person who has asked the question will then listen until he gets an answer

or until he decides that the individual who was asked the question is not going to reply.

In a RS485 network the “master” will start the “conversation” with a “query” addressed to a specific

“slave”, the “master” will then listen for the “slave’s” response. If the “slave” does not respond within a

pre-defined period, (set by control software in the “master”), the “master” will abandon the

“conversation”.

3.2

Connecting the instruments

When connecting an RS485 network to a PC, be careful if using an RS232 to RS485 converter together with

a USB to RS485 adapter. Consider either an RS232 to RS485 converter connected directly to a suitable

RS232 port on the PC or use a USB to RS485 converter (or any other suitable RS485 plug in card): many

cheap RS232 to RS485 converters draw power from the RS232 socket and when connected to a USB to

RS232 adapter, this USB adapter may not be able to supply enough power to the RS485 converter.

Screened twisted pair cable should be used. For longer cable runs or noisier environments, use of a cable

specifically designed for RS485 may be necessary to achieve optimum performance. All “A” terminals

PMP 9 0020 B EN –Technical documentation

Chapter : R5485 general information

15

should be connected together using one conductor of the twisted pair cable and all “B” terminals should be

connected together using the other conductor in the pair. The cable screen should be connected to the

“GND” terminals.

A Belden 9841 (Single pair) or 9842 (Two pair) or similar cable with a characteristic impedance of 120 ohms

is recommended. The cable should be terminated at each end with a 120Ω, quarter Watt (or greater)

resistor. Note: diagram below shows the only acceptable wiring topology. Always follow terminal

identification on PM-Progress product label.

Figure 5 –Modbus via RS485 network overview

There must be no more than two wires connected to each terminal, this ensures that a “Daisy Chain” or

“straight line” configuration is used. A “Star” or a network with “Stubs (Tees)” is not recommended as

reflections within the cable may result in data corruption.

Figure 6 –Recommended wiring

3.3

A and B terminals

The A and B connections to the PM-Progress can be identified by the signals present on them while there is

activity on the RS485 bus:

Figure 7 –A and B terminal

This manual suits for next models

1

Table of contents

Other CRE Technology Measuring Instrument manuals