2

IFX-F100

Operating Instructions

Index

Page

1Safety instructions................................................................................4

1.1 Symbols used in these operating instructions..................................4

1.2 Safety instructions ...........................................................................5

2Introduction ..........................................................................................6

2.1 How to order....................................................................................7

3Installation ............................................................................................8

3.1 Unpacking and storage ....................................................................8

3.1.1 Unpacking ................................................................................8

3.1.2 Storage......................................................................................8

3.1.3 Identification of components....................................................8

3.2 Clamp-on sensor installation ...........................................................9

3.3 Installation location .......................................................................10

3.4 Pipe preparation.............................................................................12

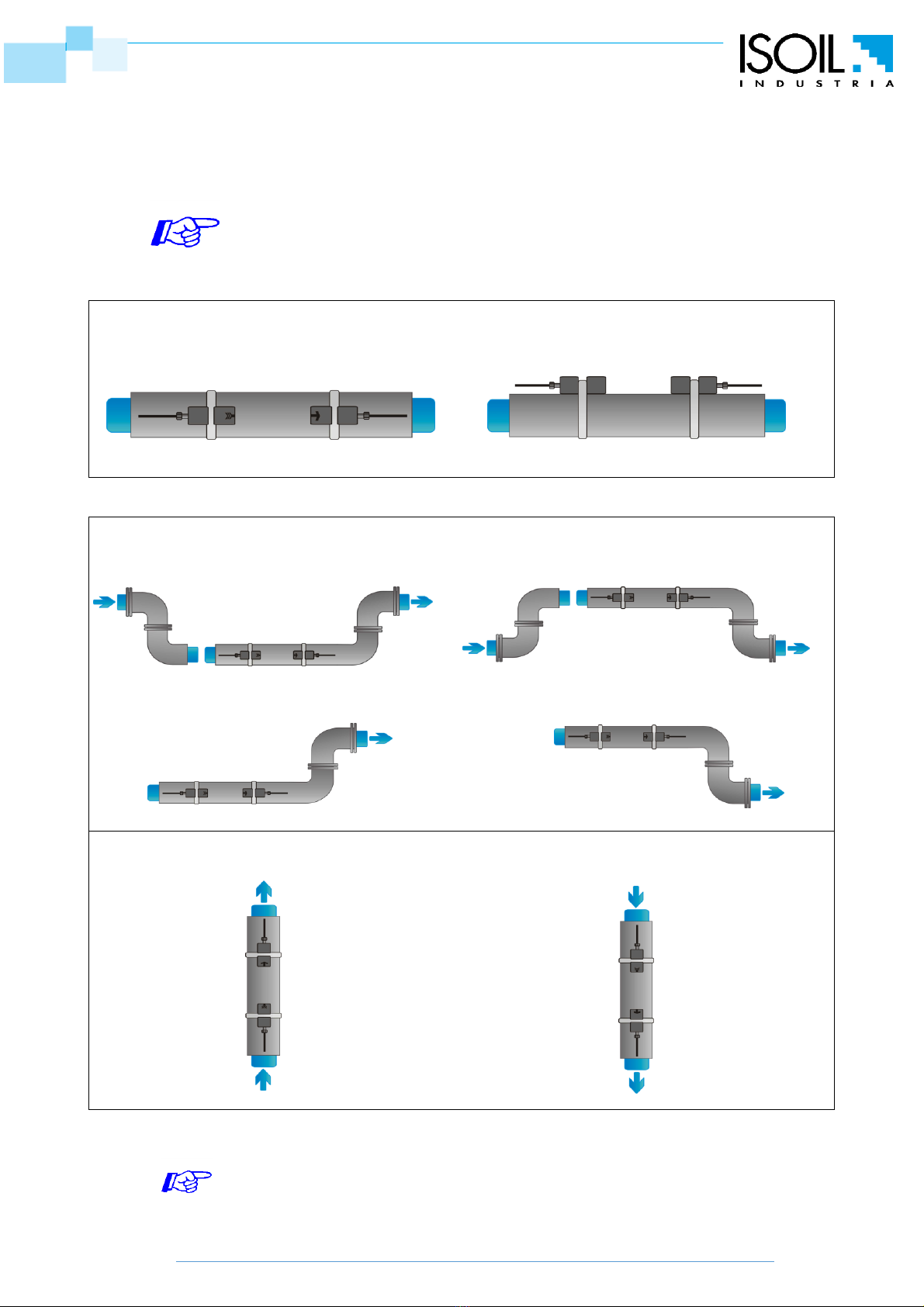

3.5 Clamp-on sensor mounting configurations and distance...............12

3.6 Flowmeter installation ...................................................................14

3.6.1 Outline dimensions.................................................................14

3.6.2 Electrical connections ............................................................15

3.7 Clamp-on sensor mounting............................................................16

3.7.1 Sensor pipe mounting configurations.....................................17

3.7.2 Acoustic coupling gel.............................................................17

3.7.3 Correct positioning of the sensors..........................................17

3.7.4 Sensor mounting with tension straps......................................18

4Operation ............................................................................................19

4.1 Switching On/Off ..........................................................................19

4.2 Keypad and display .......................................................................19

4.2.1 Keypad key functions (internal keypad) ................................19

4.2.2 Display functions ...................................................................20

4.3 Quick setup wizard ........................................................................21

4.4 Measurements................................................................................24

4.4.1 Main process value (PV) display ...........................................24

4.4.2 Diagnostic displays ................................................................25

4.4.3 Totalisers ................................................................................25