3

Thedisplayboardis shownintheabovefigure, therearethree areas fromup todown:I, II and III.

Part I contains4LEDstatusindicatorlamps andconductivityvaluedisplayarea.The4LEDstatus

indicatorlamps respectivelyindicate:

POWER----indicatorlampforpowersupply

HIGH----indication forconductivityoverlimit alarm

μS/cm----conductivityvalue,representingthatthedisplayedvalueistheconductivityvalueofthe

producedwater

℃----temperaturevalueofthefluid,representingthatthedisplayedvalueisthetemperaturevalueof

thecurrentfluid

SLP(displayedinthenixietube)----ECS is notswitchedon and systemis inthestandbystatus.

FULL(displayedinthenixietube)----watertank is full and the FULL”lampwill belightened

ALA(displayedinthenixietube)---- ALARM”lampwill belightenedwhenalarmappears。

Part II istheindicationofROsystemoperationstatus,whichcontains9LEDindicatorlamps, andthe

lamps respectivelyindicate:

LOWFEEDPRESS----indicatorlampforlowfeedalarm,indicatingthatthereisnowaterintheraw

watertank orthewateris notsufficient.

LOWPRESS----indicationforinletwateroperation ofhighpressurepump, indicatingthattheinlet

wateroperation pressureofhigh pressurepumpis too low.

HIGH PRESS----indicationforoverpressureoperationofhighpressurepump, indicatingthatthe

outletpressureofhigh pressurepumpis too high.

INLETVALVE----indication forinletmagneticvalveturningon,indicatingthattheinletmagnetic

valveis turnedon.

M1----indicationforlowpressurepumpoperation,indicatingthatthelowpressurepumpisswitched

on.

M2---- indicationforhighpressure pumpoperation,indicatingthatthehighpressurepumpis

switchedon.

RO----indicationforwaterproducingstatus,indicatingthattheROsystemisinwaterproducing

operation.

FLUSHVALVE----indicationforflushmagneticvalveturningon,indicatingthattheflushmagnetic

valveis turnedon.

FULL----indicationforfull purewatertank,indicatingthatthewaterlevelinthepurewatertankhas

reachedthehigh limit.

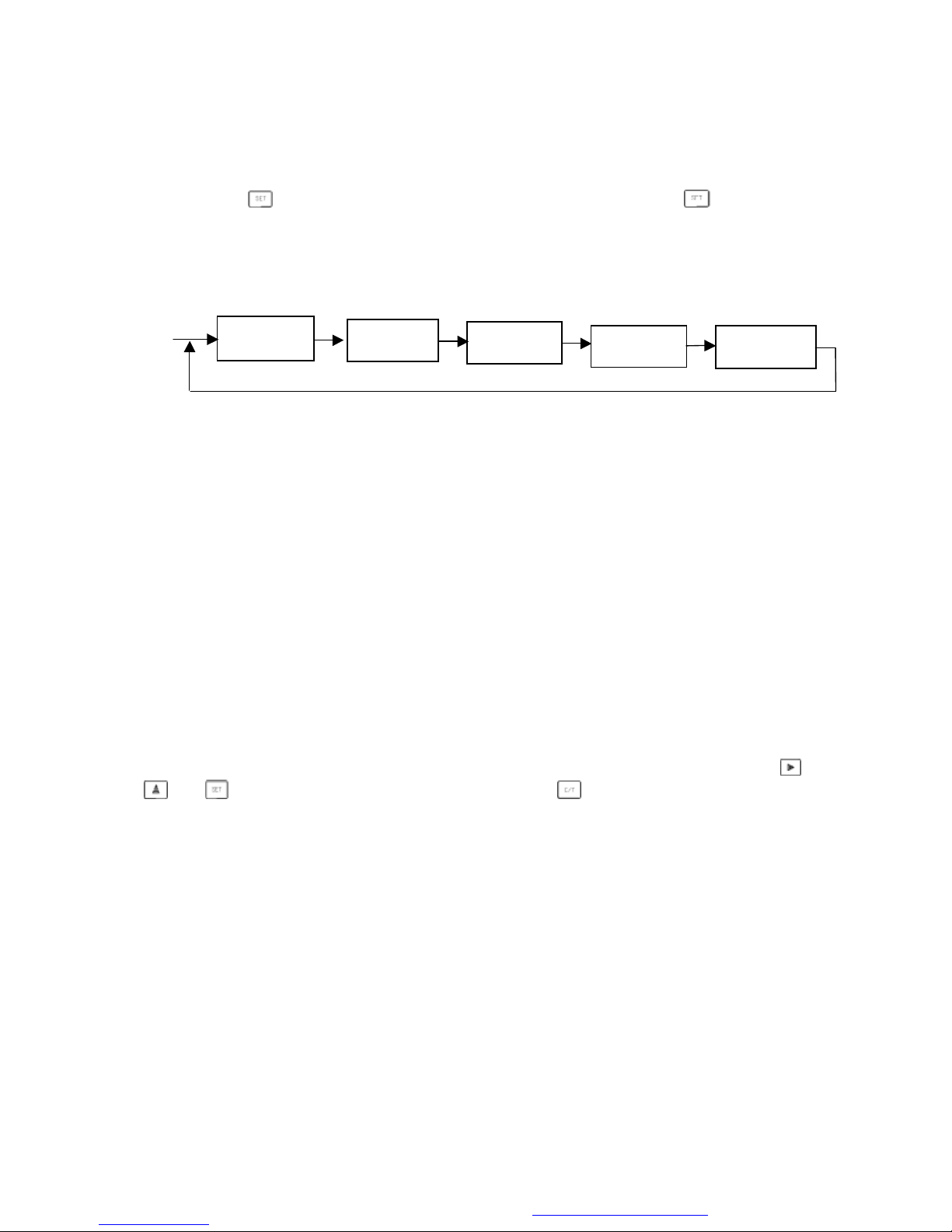

Part III contains setting and operation keys, theirmeanings are:

----parametersetting key, selecttheparameteritems tobemodifiedorinquired.

----circularlyselectthousand, hundred, tenand unit digit, theselecteddigit flashes.

----adjustthenumberoftheselecteddigit (circlefrom0 to9)

----C/Tkey,confirmtosavethemodifiedparameterinparametermodification orswitch between

theindication valueofconductivityand temperatureinmeasuring status.

PDF 件使用 "FinePrint pdfFactory Pro" 试用版本创建 www.fineprint.com.cn