Createc Prusa i3 User manual

www.createc3d.com Portada

CREATEC4 S.C.A

C./ Ángel Barrios, 1 - Bajo

18004 - Granada

+34 958 373 434 / info@createc3d.com

www.created3d.com

http://shop.createc3d.com

Instruction manual for mounting the

Prusa i3 Mount

3D Printer Kit from Createc3D

Rev. 07 –Ver. English

10/01/2015

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 2 de 66

1.-INTRODUCTION

2.-MATERIALS

3.-MOUNTING PROCESS

3.1 Structure

3.1.1 Main Structure

3.1.2 Crossbar

3.1.3 Structure Axis Z

3.1.4 Axis Y

3.1.5 Axis X

3.1.6 Axis Z

3.1.7 Final Structure

3.1.8 Extruder and Hotend

3.1.9 Heatbed and limit switches

3.1.10 Electronic Spacers

3.2 Electronics

3.2.1 Engines

3.2.2 End stops

3.2.3 Heatbed

3.2.4 Power Supply

3.2.5 Hotend

aBudas

bE3D Full Metal

3.2.6 Wiring

aKit electronics

bEnd stops

cLCD

dEngines

eThermistors

fHotend y heatbed

gRelay 12V40A with diode

hElectronic Power Supply

iWiring Diagram

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 3 de 66

PREFACE

If you are reading this instruction manual it’s because you purchased recently a kit for

assembling a Prusa 3D Printer i3 Createc3D.

We appreciate your trust in our products, that have been carefully selected and respects

the highest quality standards for the effective mounting of your Reprap Prusa 3D Printer i3.

In Createc 3D, we work hard every day to make easier for entrepreneurs, makers,

innovators, etc. the contact with an interdisciplinary group of professionals that can make

your ideas and projects come true.

It would be our pleasure to answer any questions that arises during the assembly

We wish you enjoy all the assembly process and, above all, you enjoy your 3D printed

objects.

Kindest regards,

The technical team of Createc 3D

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 4 de 66

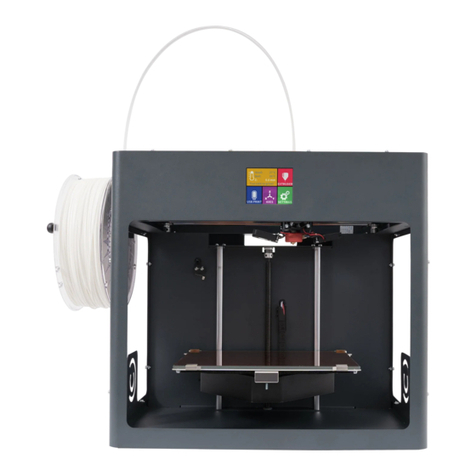

1.-INTRODUCTION

In this tutorial we explain step by step the assembling process of the Prusa 3D printer

Createc i3. These models of 3D printers are numerical control machines (NCN), that

operate depositing layers of plastic.

The three Cartesian axes are assigned as shown in the picture below:

Looking at the front the axes describe the following movements:

• X-axis: left / right.

• Y axis: Forward / backward.

• Z axis: Up / Down.

Combining those three movements and the amount of plastic deposited, we obtain our

3D parts.

The material is heated and deposited in thin layers by a hot tip, Hotend, that provides

the temperature necessary to melt the material and deposit the plastic, and, depending on

the selected material, the diameter of the outlet, the quality of the model, etc..

You must process the 3D model first using a software laminate, that is responsible for

generating the necessary code, gcode, then the printer develops the model.

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 5 de 66

2.-MATERIALS

The first things we need to build our printer are printed plastic parts (made by another 3D

printer, of course).

In addition to these parts we have other materials, also known as vitamins:

2.1 Electronics

•Board AT Arduino Mega 2560 compatible

• 5 A4988 Driver

• RAMPS 1.4v

• Wires Kit

• Heatbed

• Hotend

• Stepper motors (the most common are Nema 17)

• Power supply (at least 12V 20A) and wiring

• Thermistors

• Mechanical limits

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 6 de 66

2.2 Mechanical parts:

•Frame (plexiglass, aluminum, steel, wood, etc..)

• Hardware Kit, Kit of smooth and threaded rods

• Bearings, flexible couplings, pulleys and belts

• Glass or mirror

In addiction to these components (all included in the kit offered by Createc

3D), we need tools and supplies for the installation such as:

• Allen wrench set, welder and tin

• Hex wrenches 13 and 17

• Plan and Star Screwdriver

• Tape measure, gauge

• Scissors, Pliers, file, Blade

• Drill and drill bits metric 3, 5 and 8

• Acetone, Glue (cyanoacrylate recommended)

3.-INSTALLATION PROCESS

Before mounting the printer, the preparation of the plastic parts is essential: remove

the support structures of the parts that presents it, shape and / or drill the holes, weld the

nuts etc.. the most common preparations are shown below:

Extruder:

It is a very important part because it sustain the hot tip, the engine and where the

plastic filament pass through:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 7 de 66

The extruder can be purchased without a support structure,

Or with supporting structure,

To remove it, simply apply an upward force on the section indicated in the picture

above, continue until the plastic is completely removed.

To allow the plastic filament to pass into the hole smoothly, we need to pass a 4mm drill

into it, see the arrows on the following page images:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 8 de 66

We place the piece upside down and we drill it with 4mm drill until it reaches the other

end.

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 9 de 66

For the nuts placement:

in each hole shown in the picture weld a metric nut 5. To achieve this we press against

the plastic nut, minding the correct position (matching the sides of the opening with the

sides of the nut), with a soldering iron until the nut is completely embedded in the hole.

See next image:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 10 de 66

Pulleys extruder:

The small pulley hole must be drilled or filed until it fits into the motor shaft. The motor

shaft must be modified with a file or grinder until a portion of it with is flat, this is to allow

the stud to fit well.

Note: Section of how the shaft of the motor must be after the flatting process:

On the other hand, in the space indicated in the screenshot below, you must weld a

metric nut 3:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 11 de 66

With the help of a welder, enter the nut inside the piece paying attention that it

coincides with the hole intended for clamping the screw on the shaft.

Hobbed bolt (type with Allen head wrench):

To place the hobbed bolt (screw that pushes the filament inside the hotend) in the large

pulley proceed as follows:

Insert the screw with the head in the position shown in the image.

Put a lock nut metric 8 at the end of the bolt and introduce the Hobbed lock nut in the

hole of the pulley. Look at the picture on next page:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 12 de 66

Place the pulley on a flat surface, place the Hobbed bolt upside down with the lock nut

resting on the flat surface. Pressed on both sides of the pulley until the self-locking nut fits

into the hole:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 13 de 66

Hobbed bolt (threaded rod type):

Put a lock nut metric 8 in one end of the Hobbed bolt and press it against the pulley:

Place the pulley on a flat surface with the lock nut against the flat surface and press

firmly on both sides of the pulley until the lock nut fits into the hole.

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 14 de 66

X Axis Driving Part:

The piece we proceed to modify is the motor holding of the "X" axis and is guided by the

smooth rods. The holes we have to file are specified in the following images:

Place a brass nut in the space indicated in the image:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 15 de 66

We need the help of a soldering iron: heat the nut until it is fully inserted into the hole

and remains attached.

X-Idler:

We prepare the holes Like in the previous piece with an 8mm drill bit or with a round

file:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 16 de 66

Place a brass nut in the hole indicated with the help of a welding iron, until the nut fits

snugly. It is very important that the nut is flush and perpendicular to the vertical axis.

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 17 de 66

Z-top and Z-bottom:

To allow a smooth movement of the rods into the holes we pass with a drill metric 8 in

the hole and remove the tiny plastic part that closes the circle:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 18 de 66

X-carriage:

In this piece we weld two nuts Metric 3 in the holes shown in the picture below:

We proceed like we did with the previous pieces. Apply heat with a soldering iron on the

nut and place it in the bottom of the hole:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 19 de 66

Y-belt holder:

Place a nut metric 3 in the hole shown in the picture below. Use the soldering iron to

apply heat on the nut until it fits into the hole and it is flush with the surface of the part:

Instruction Manual for Pi3 Createc3D

Rev.06 - Ver. English –10/09/2104

www.createc3d.com Page 20 de 66

3.1 Structure

The materials necessary for the assembling are:

- 10mm Methacrylate frame

- Threaded Rods and Kit Flat bright bars

- Kit hardware

- Transmission kit

- Set of Printed Parts ABS

We begin to make the assembly of the main structure and guides the Y axis. We need:

-2x Flat Rods Ø8mm x 340mm

-3x Linear Bearings LM8UU

-4x Y-Corners

-12x M10 Washers

-4x Self-locking nuts M10

-8x M10 Nuts

Table of contents