Classification

Type of protection against electric shock……………………………………………….…………...……...Class 1

Allowable leakage current…………………………………………………………..……..does not exceed 200µa

Reliability of earth protection………………………………………….………………does not exceed 0.1 ohm

Mode of operation………………………………………………………………………………..................continuous

Protection against explosion hazards.…..not to be used in presence of flammable anesthetics

Protection against hazardous parts and ingress of liquids………………………………………………..IP20

Safety tests…………………….…UL 60601-1, 3rd Edition; IEC 60601-1-2, CSA/CAN C22.2 No. 601.1

Electrical

Input……………………………………………………………………………...100V-240VAC, 50/60HZ 9W or 18 W

LED……………………………………………………………………………………………………………..2 x 3 LED Modules

Power cord…………………………………………………………..8ft (2.4m), NEMA 5-15, hospital grade plug

Fuses (2)…………………………………….…..T 0.5A L (250V) each, located inside transformer housing

Environmental Conditions

Transport and Storage

Ambient temperature…………………………………………………………………………………...0° C to 70° C

Relative humidity………………………………………………………………….……….10% to 75% (keep dry)

Atmospheric pressure………………………………………………………………………..500hPa to 1060hPa

Shipping Container Markings……………………………………………………………………….Fragile, Keep Dry

Operation

Ambient temperature…………………………………………………………………………………..10° C to 40° C

Relative humidity………………………………………………………………….……………………..….30% to 75%

Atmospheric pressure……………………………………………………………….………..700hPa to 1060hPa

Weights and Dimensions

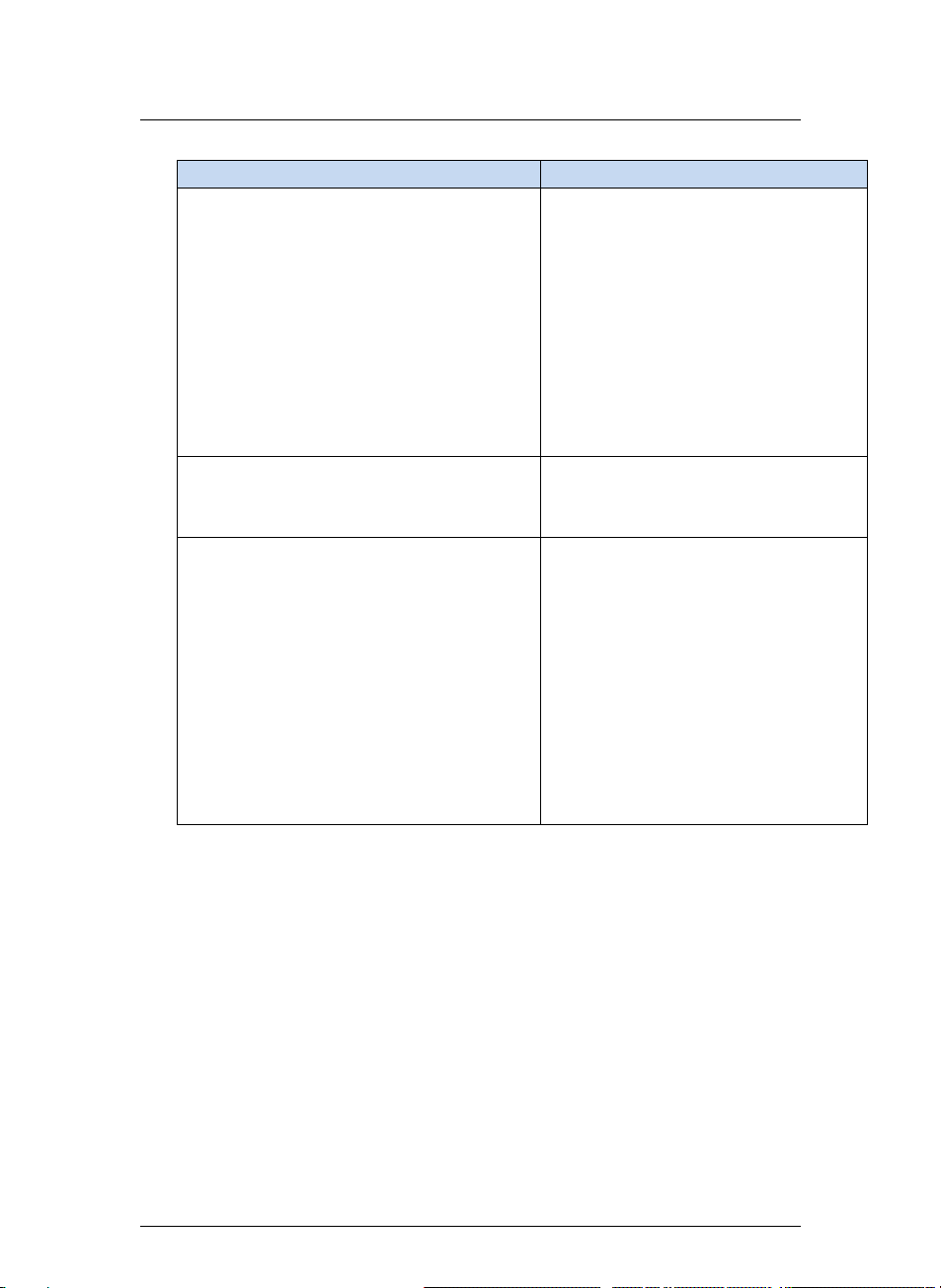

Net weight (Light head, flexible arm, transformer housing, cord)……………………………7lbs (3kg)

Light head width, including handles………………………………………………………………………9 in (23cm)

Light head length, including neck……………………………………………………………………… 10 in (28 cm)

Arm length………………………………………………………………………………………………………..41 in (104 cm)

Effective swing radius from Pivot to front of Light head/…………………………………..51 in (130 cm)

Colors………………………………………………………………………………………………………………………….…White

Optical Performance

Central Illuminance, One LED Module, Ec at 18 in. (46 cm)……………………………….……25,000 Lux

Central Illuminance, Two LED Module, Ec at 18 in. (46 cm)………………………………..…..50,000 Lux

Central Illuminance, Ec at 1 meter……………………………………………………………….9,000 Lux (840 fc)

Total Irradiance at 1 meter…………………………………………………………………………………………30W/m2

Total Irradiance at 18 in. (46 cm)………………………………………………………………………….…..131W/m2

Ultraviolet radiation……………………………………………………………………………………………… 0.02W/cm2

Color temperature……………………………………………………………………………………………………..4600° K

CRI (Color Rendering Index) ……………………………………………………………………………………………….93

LED Operating Life………………………………………………………………………………………………….40,000 hrs

4