Hypnocube 4Cube Instructions v 6.5, December 2013

- 2 -

Introduction

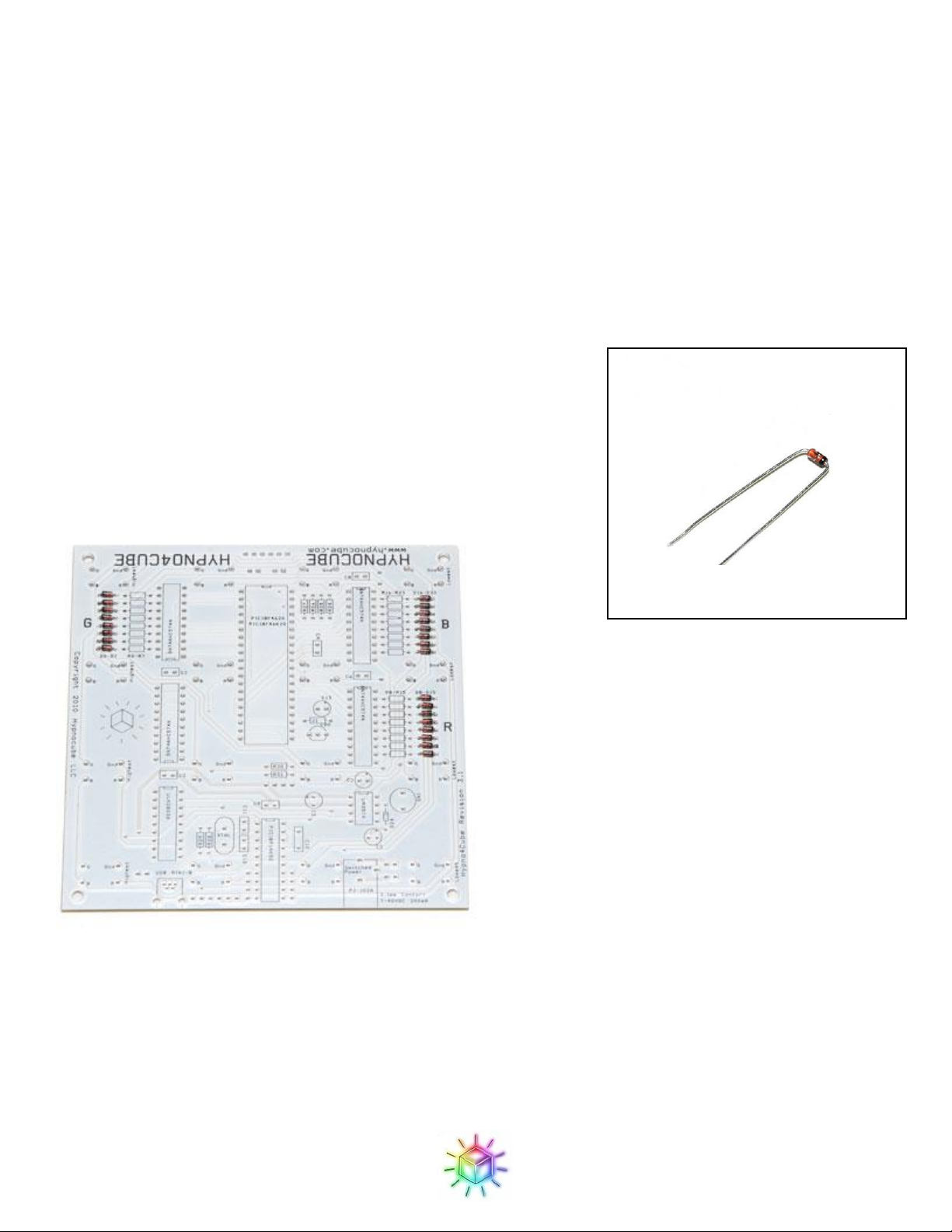

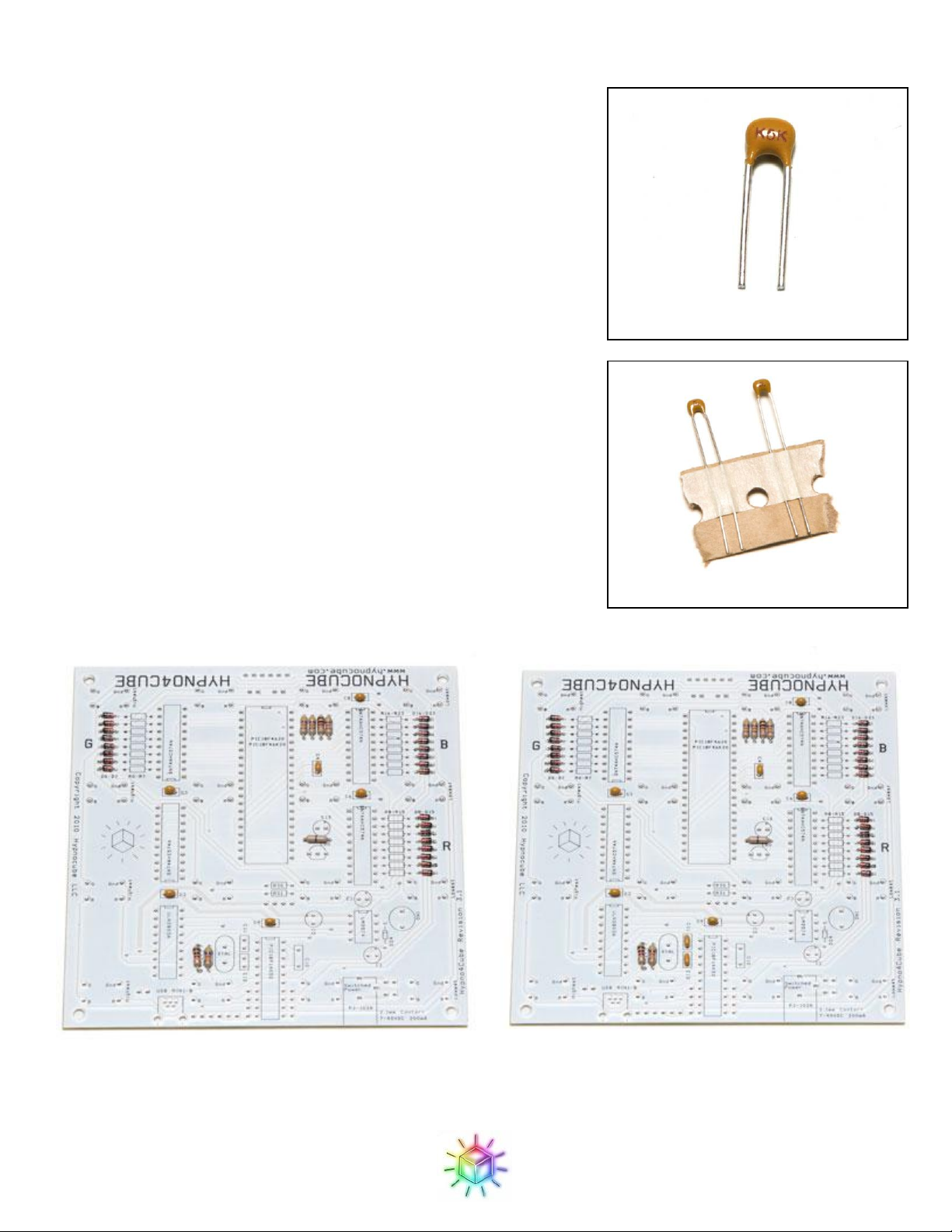

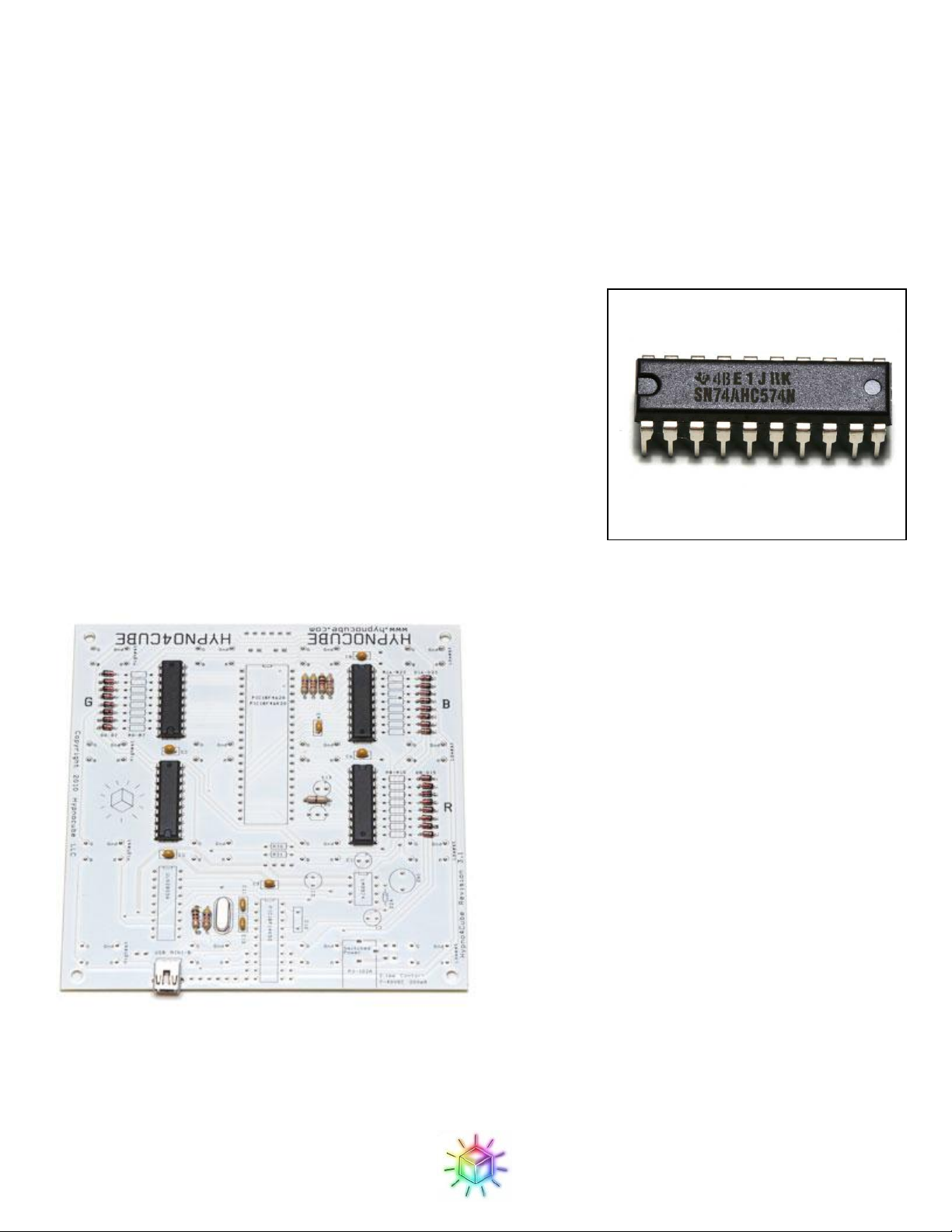

This is the instructions for building the 4×4×4 “4Cube”kit.

The three main parts are titled “The Good”, “The Bad” and “The Ugly”.

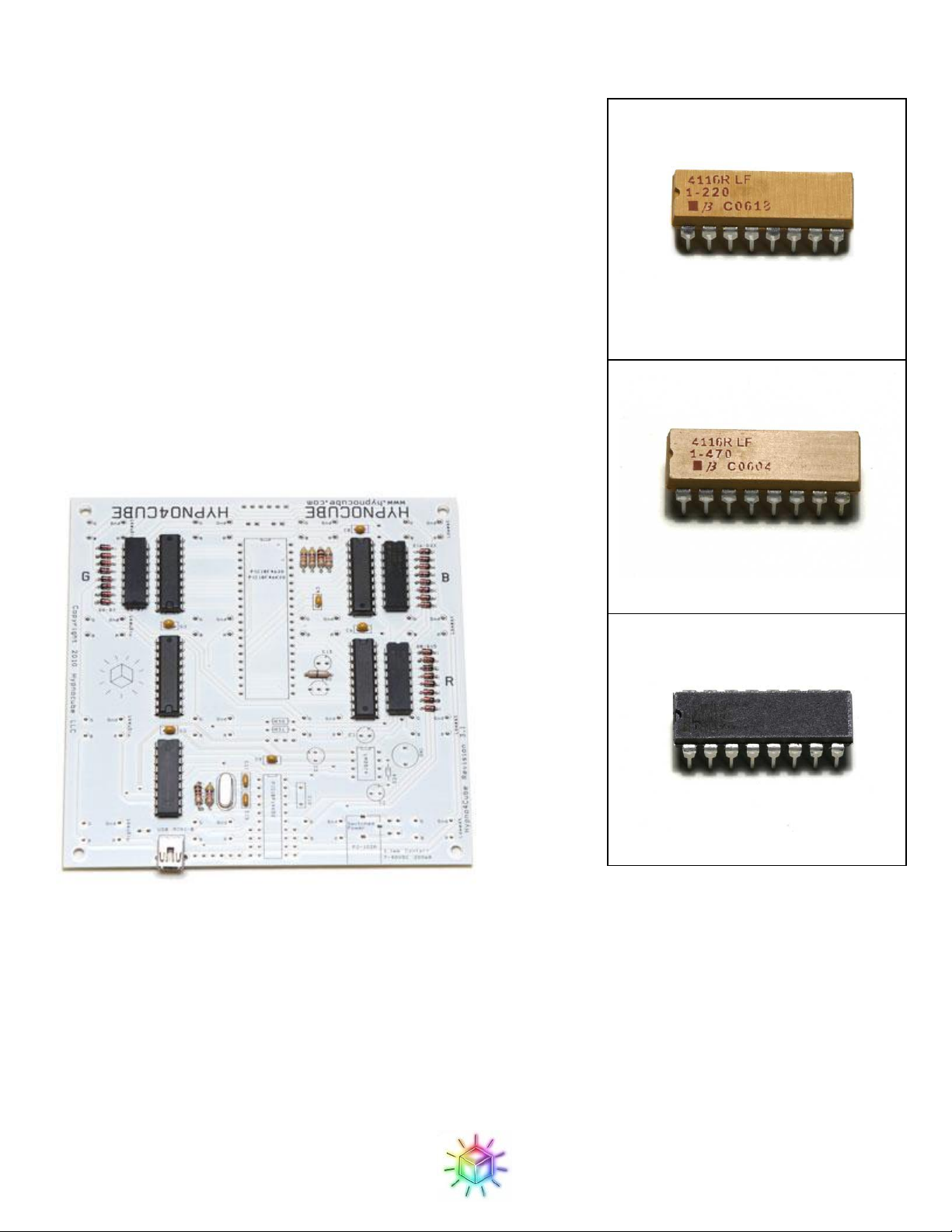

In “The Good” we construct the circuit board. This should be similar to any other electronics kit.

In “The Bad” we will construct four planes of LEDs, each being a 4×4 grid. This is the hardest part of the kit.

In “The Ugly” we will attach the LEDs to the PCB, testing as you go, and finally put it all together in the case.

Tools

You will need the following minimum set of tools:

1. Soldering iron. Any iron can work, but a nicer one will make the job a lot easier.

2. Solder - we recommend 63/37 Sn/Pb rosin core. All normal electronics solders should work fine for the

PCB, but the wire lattice can be quite particular (see page 17 for more details.)

3. Hardened wire cutter. Take care not to damage a delicate pair on the steel lattice wire.

4. Wire strippers (for 24 AWG wire).

5. Needle nose pliers.

6. Small Phillips screwdriver.

To make the jig you'll also need one of the following:

1. Cardboard for making a poor jig.

2. Wood and wood tools for making a good jig.

Disclaimers!

Before you begin, some items to note:

1. READ EVERYTHING IN THE INSTRUCTIONS BEFORE YOU START! You will make a much

nicer cube by knowing where steps are leading before constructing items. The instructions attempt to

make the kit foolproof, but we all know that is impossible :) Don’t become a FAQ entry.

2. One good idea is to print out the instructions and cross off each paragraph as you finish it, to ensure you

don’t miss a sentence or instruction step. This can save you trouble later.

3. This kit assumes you have built electronic kits before, and are proficient at soldering items to a circuit

board. Chips and LEDs can be damaged from ESD and too much heat, so make sure you are properly

grounded and don’t hold the iron on the leads too long. Make sure all solder joints connect well.

4. Many of the parts in this kit require correct orientation (rotation). When mentioned there is a right way

and a wrong way to connect something, both of which look similar. Be sure to have them correctly

positioned before soldering.

5. The LEDs are difficult to bend correctly. Make sure you are EXTREMELY diligent in bending them

correctly.

6. Plan on spending some time constructing the kit. Chris’s first (and only) kit build took him about 10

hours, over three nights. Gene, with much experience (having constructed all others) can build one in

about four hours. We have heard from a number of first-time builders who report from 6 –12 hours.

Plan on setting aside at least that much time.

For a look at the finished cube see Figure 77.

Good luck :)