3

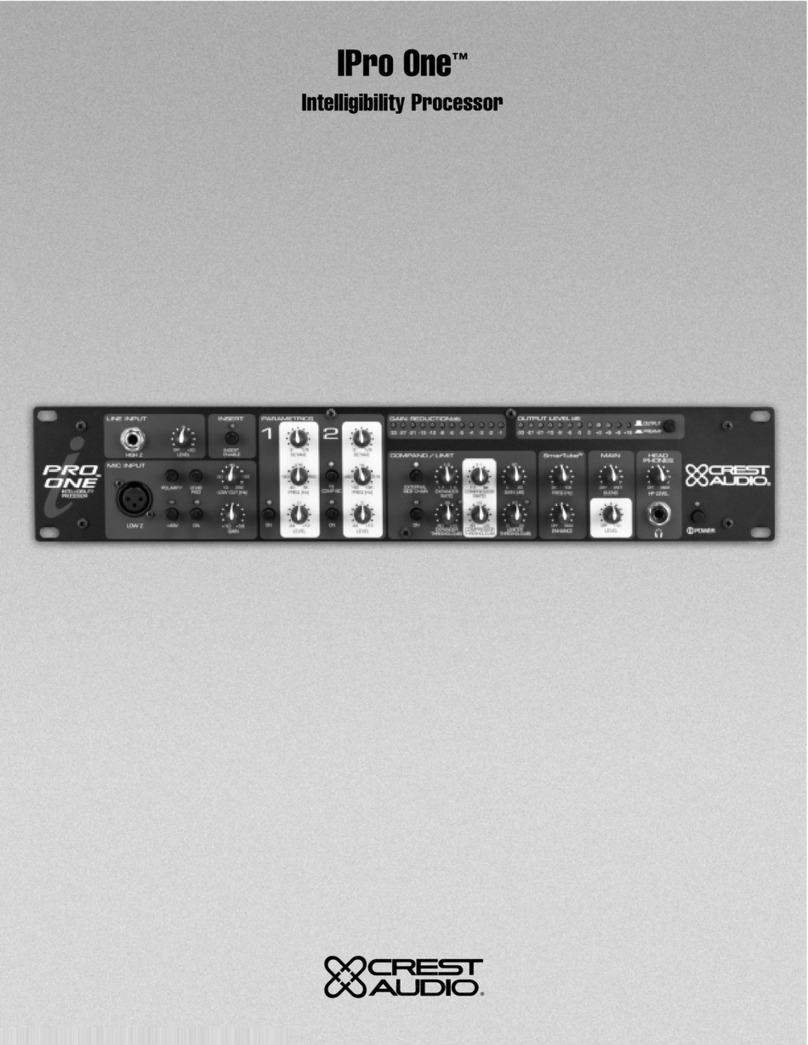

IPro Two™

DESCRIPTION:

The IPro Two is a two microphone, two stereo line input, all analog processor that is especially designed to optimize

audio signals (low or high impedance) for recording or live applications. It is loaded with features that distinguish it from

other units.

The dual full featured mic inputs can be set up as a stereo pair, or independently panned/mi ed in the stereo field.

Phantom power, pad, polarity, low cut, gain, and enable are separately provided for each mic. Added to these inputs are

a high impedance stereo line input, which can be mi ed with the mic signals, or used by itself. The output of the mic/line

mi is routed through stereo insert jacks which have an enable switch. This provides an additional unprocessed output

(the tip signal is always present), if one is required, as well as a place to insert alternate effects.

The equalization is comprised of two wide range, fully parametric filters. A cut and boost of 15 dB, a bandwidth of 2

to 1/6 octave and a frequency adjustment range of 40 Hz to 15 kHz will shape the sound as needed. Each parametric

equalizer has its own on/off switch to route the signal around it if it is unused.

The second parametric equalizer has an additional feature. It can be moved out from the main signal path into the

dynamic section’s side-chain path, where it is in series with (after) the side-chain insert jacks of the RMS detectors. By

setting it up in this mode, it can be used to define the frequencies that control the dynamics’ circuitry (e pander,

compressor, and limiter). This is used for de-essing, for removing rumble modulation, or for specifying a problematic

frequency band to compress. When configured in this manner, any e ternal signals brought in through the side-chain

insert jacks pass through this equalizer before being sent to the detector to allow frequency shaping to be applied to that

source as needed. The on/off switch still bypasses this filter even in this mode, just as you would e pect.

A key part of the IPro Two is its true RMS summed, stereo-linked dynamics section. Using state-of-the-art integrated

circuits for the voltage controlled amplifiers and true RMS detectors, it has very low distortion and noise. Incorporated in

the processing is a downward e pander, a compressor, and a limiter. Each has an independently adjustable threshold

control. The e pander and compressor sections also have ratio controls. There are side-chain inserts in the detector

path that can be enabled from the front panel (see previous paragraph). The e pander is of soft knee topology, and has

a ratio control to allow it to be used as a gentle-slope noise reduction circuit (low ratio), or a gate (high ratio). A threshold

LED illuminates when the e pander is active. The compressor is also soft knee, but has a more gradual knee action for

even smoother transitions. It can be adjusted from no compression (1:1) to limit (infinite:1). The limiter is a compressor

with a fi ed infinite:1 ratio, a faster knee transition, and an LED to show when it is functioning. All have preset (program

dependent) attack and release times. A twelve segment gain reduction meter displays all VCA activity (e pander,

compressor, and limit) so that control action is easily seen, making adjustments a snap.

Heavy compression will give the perception of darkening the signal, since the low frequency components (which

have the most energy) dominate the compressor action. As the signal is compressed, the treble material is reduced at

the same ratio as the bass, causing it to lose definition. To compensate for this apparent loss and to add a new sheen to

signals which do not have much high frequency content, the SmarTube™Enhance process was developed. This is a

high frequency harmonic generator based on our SmarTube tube simulation circuitry. A unique feature of the circuitry is

that it behaves as a tube does in its distortion characteristics and is level dependant. This means that more harmonics

are created at higher levels, which decrease as the source fades out, just as a natural sound would. It is tunable and will

add pleasing high frequency detail not found in the source. It can bring a mic to the front of a mi , or add atmosphere to

an instrument.

There may be an occasion when certain frequencies must be compressed then added back to the original “dry”

signal, similar to using the IPro Two as one of the bands of a multi-band compressor. A blend control was added so that

this could be done without having to sacrifice an e ternal mi er channel (if one is available) to accomplish this feat.

Simply turn it to “wet” and set up the frequency band and dynamic action that you want processed, then blend this with

the “dry” signal to taste. By compressing the bass and adding it back to the original, a “fatter” sound can be created.

A headphone monitoring function with an independent level adjustment is included. This is especially needed when

the unit is used as a stereo channel recording preamp. Its signal is picked up before the main level control, and drives a