Crommelins Cromtech 7000ie User manual

CROMTECH 7000ie

OPERATION MANUAL

INVERTER GENERATOR

1

WARRANTY TG7000IE

12 months / 300 hours (whichever comes rst)

Cromtech™ and Crommelins™ are a registered trademark of Crommelins

Machinery. Crommelins Machinery warrants their goods against defects

in materials and workmanship under normal use and service. The

warranty does not cover fair wear commensurate with the age of the

product, any damage caused by accident, abuse, misuse, neglect or

failure to observe proper operang instrucons or proper machinery

maintenance as described in the instrucon manual. It is the owner’s

responsibility to regularly maintain a product in accordance with the

owner’s manual and only use the equipment for its designed purpose.

Our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entled to a replacement or refund

for a major failure and for compensaon for any other reasonably

foreseeable loss or damage. You are also entled to have goods repaired

or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

CONSUMER ADVICE

Any claim under these warranes must be made in the warranty

period from the date of purchase of the product. There are over

185 naonal authorised service/repair agents available, visit

www.crommelins.com.au for their details and locaons. To make a

claim under the warranty, you must return the product (with proof of

purchase) to the closest warranty agent or to the place of purchase.

Where a failure does not amount to a major failure, Crommelins

Machinery is entled to choose between providing you with a repair,

replacement or refund. To obtain compensaon, you would need to

provide documentary evidence of the loss or damage suered, and

documentary evidence that such loss or damage was a reasonably

foreseeable consequence of a failure by Crommelins Machinery to

comply with a consumer guarantee under the Australian Consumer Law.

Crommelins Operaons Pty Ltd trading as Crommelins Machinery,

The Crommelin Group and Crommelins Australia.

Ph: 1300 650 659

PO Box 352, BENTLEY WA 6982

Email recepon@crommelins.com.au

www.crommelins.com.au

ABN 11 008 889 656

CONTENTS

INTRODUCTION ................................................................................. 3

SAFETY PRECAUTIONS...................................................................... 3

IMPORTANT ICONS ........................................................................... 3

SAFETY INFORMATION..................................................................... 4

Connecon to a Home Power Supply .........................................6

Safety Regulaons ....................................................................... 6

CONTROL FUNCTION ........................................................................ 8

TG7000ie Diagram ........................................................................ 8

Control Panel Diagram.................................................................. 9

Engine Switch..............................................................................10

Start Buon.................................................................................10

Recoil Starter...............................................................................10

ESC Throle Switch.....................................................................11

Digital Display Meter..................................................................12

Oil Warning Light ........................................................................15

Overload Indicator Light (Red)...................................................16

AC Pilot Light (Green) .................................................................16

Ground (Earth) Terminal.............................................................16

AC Circuit Breaker .......................................................................17

Folding Handle ............................................................................17

Maintenance Door......................................................................17

PRE-OPERATION...............................................................................18

Fuel...............................................................................................18

Add fuel ....................................................................................18

Engine Oil.....................................................................................18

Oil level .....................................................................................18

OPERATION.......................................................................................19

Starng The Engine.....................................................................19

Start BUTTON ...........................................................................19

APP Start – ANDROID...............................................................20

APP Start – APPLE.....................................................................21

Recoil Start................................................................................22

Stopping The Engine...................................................................23

Alternang Current (AC) Connecon ........................................24

32

INTRODUCTION

Thank you for purchasing this Cromtech generator.

We recommend that the operator read this manual

carefully before using this generator, and fully understand all

requirements and operang procedures.

SAFETY PRECAUTIONS

This generator will work in a safe, eecve and reliable way

only when it is kept, operated and maintained properly.

Before operaon or maintenance of the generator, the

operator should:

• Know well and strictly observe local laws and regulaons.

• Read and observe all safety warnings in this manual and

on the device.

• Be familiar with all safety warnings in this manual.

IMPORTANT ICONS

To ensure safe operaon, please read carefully the four vital

safety warnings in this manual and on the generator, preceded

by a Safety Alert Symbol including:

DANGER: You WILL be KILLED or SERIOUSLY HURT if you

don’t follow instrucons.

WARNING: You CAN be KILLED or SERIOUSLY HURT if you

don’t follow instrucons.

CAUTION: You CAN be HURT if you don’t follow

instrucons.

NOTICE: Your generator or other property could be

damaged if you don’t follow instrucons

WARNING: PLEASE READ AND UNDERSTAND THIS

MANUAL BEFORE OPERATING THE GENERATOR.

NOTE: We connually seek advancements in product

design and quality. Therefore, there may be minor

discrepancies in actual machine and printed manual.

MAINTENANCE ................................................................................25

Refueling......................................................................................25

Engine Oil Inspecon..................................................................26

Engine Oil Replacement .............................................................26

Oil Specicaon Table ................................................................27

Air Filter .......................................................................................27

Air Filter Cleaning .....................................................................28

Spark Arrester .............................................................................28

Spark Plug....................................................................................29

Baery .........................................................................................30

Removing The Baery..............................................................30

Installing The Baery ...............................................................30

Protecve Fuses..........................................................................31

WHEEL SET INSTALLATION.............................................................32

TRANSPORTING ...............................................................................33

STORAGE ...........................................................................................34

Fuel...............................................................................................34

Draining The Fuel .....................................................................34

Engine ..........................................................................................34

TROUBLESHOOTING .......................................................................35

SPECIFICATIONS...............................................................................36

WIRING DIAGRAM ..........................................................................37

54

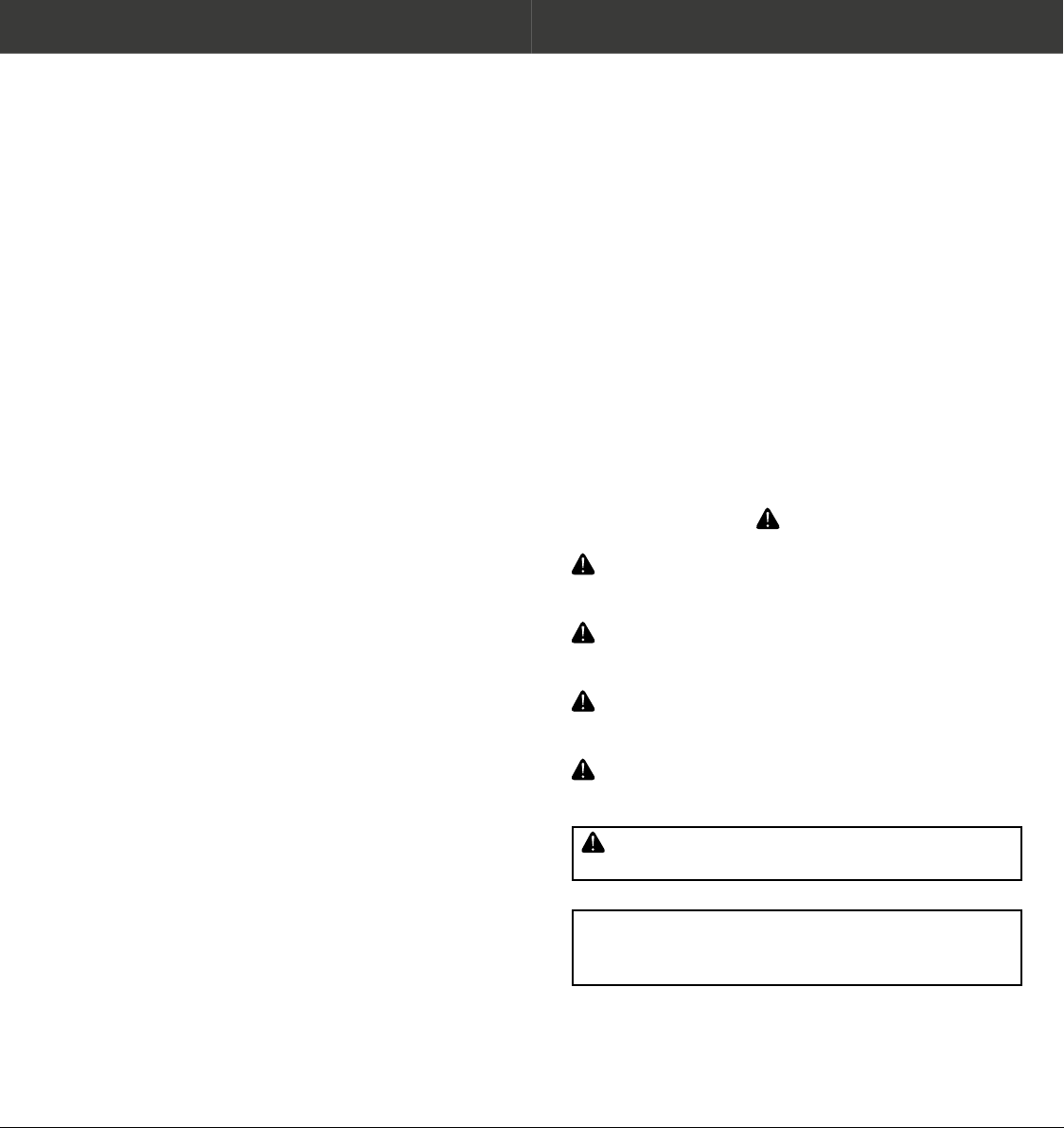

SAFETY INFORMATION

DANGER

Do not use indoors.

DANGER:

Keep the machine clean and

avoid spilt combusbles,

including petrol, on it.

WARNING:

Do not use it in wet condions.

WARNING:

Turn the generator “OFF”

when refueling.

WARNING:

Do not smoke while refueling.

WARNING:

Keep children and

pets away from the

area of operaon.

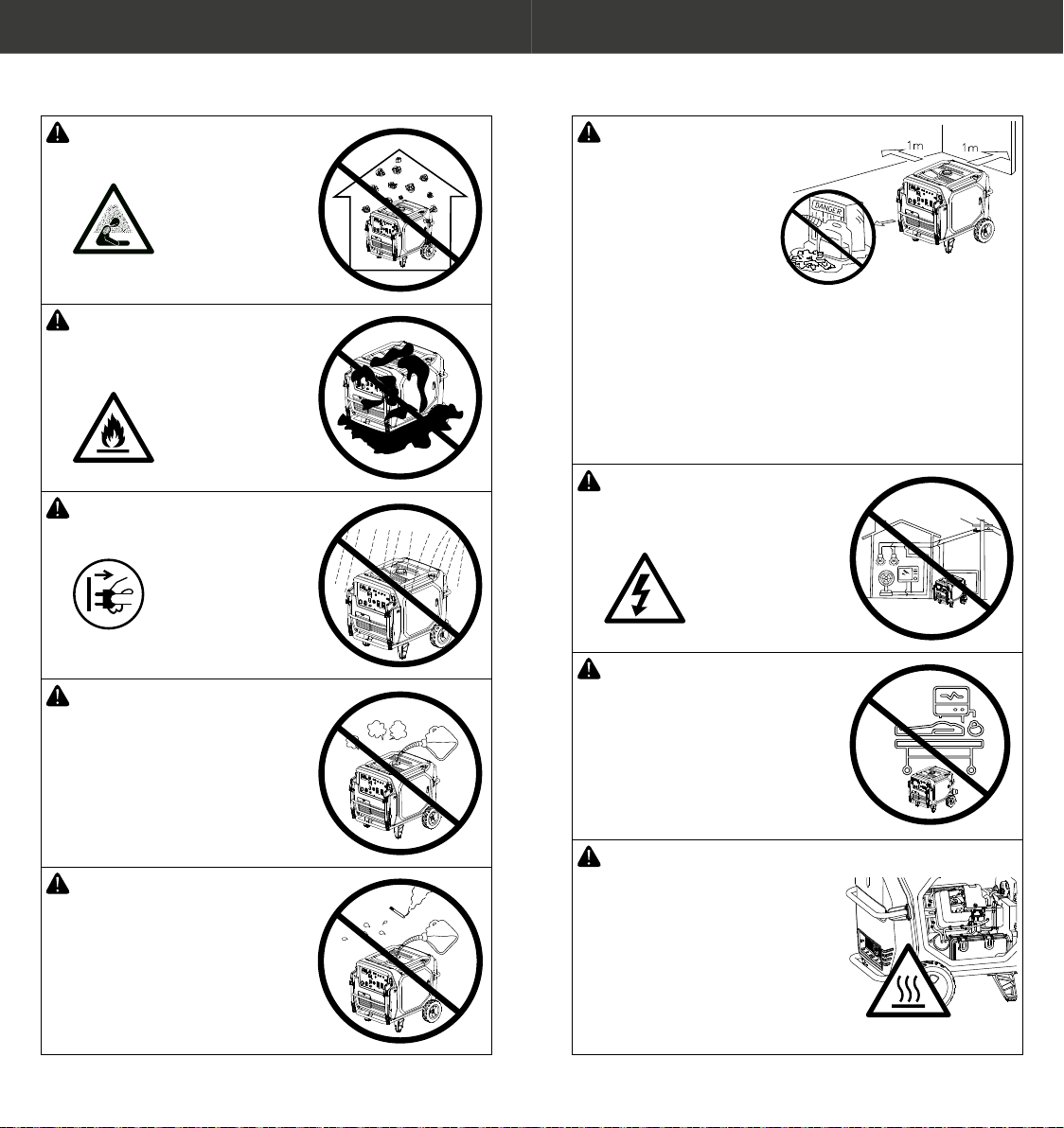

Do not place

ammable objects

close to the exhaust

when generator is

operang. Keep at

least one metre away

from ammable

materials. Do not use

in conned spaces.

WARNING:

Do not connect to a home

power system.

WARNING: This generator

is not designed for medical

applicaons.

WARNING: Hot Surfaces.

When the generator is running

or just aer stopping, it will

have hot surfaces which if

touched can cause burns. Do

not touch areas where this

warning symbol is located.

Also, avoid contact with hot

exhaust gases.

76

Connecon to a Home Power Supply

Connecons for standby power to a building’s electrical system

must be made by a qualied electrician. The connecon must

isolate the generator power from ulity power and must

comply with all applicable laws and electrical codes.

WARNING: Improper connecon to a building’s electrical

system can allow current from the generator to backfeed

into the ulity lines. Such backfeed may electrocute

people who come into contact with the lines during

the power outage, such as ulity company workers.

Furthermore, the generator may explode, burn or cause

res when power is restored. Consult the ulity company

or a qualied electrician prior to making any power

connecons.

RIGHT

RIGHT

WRONG

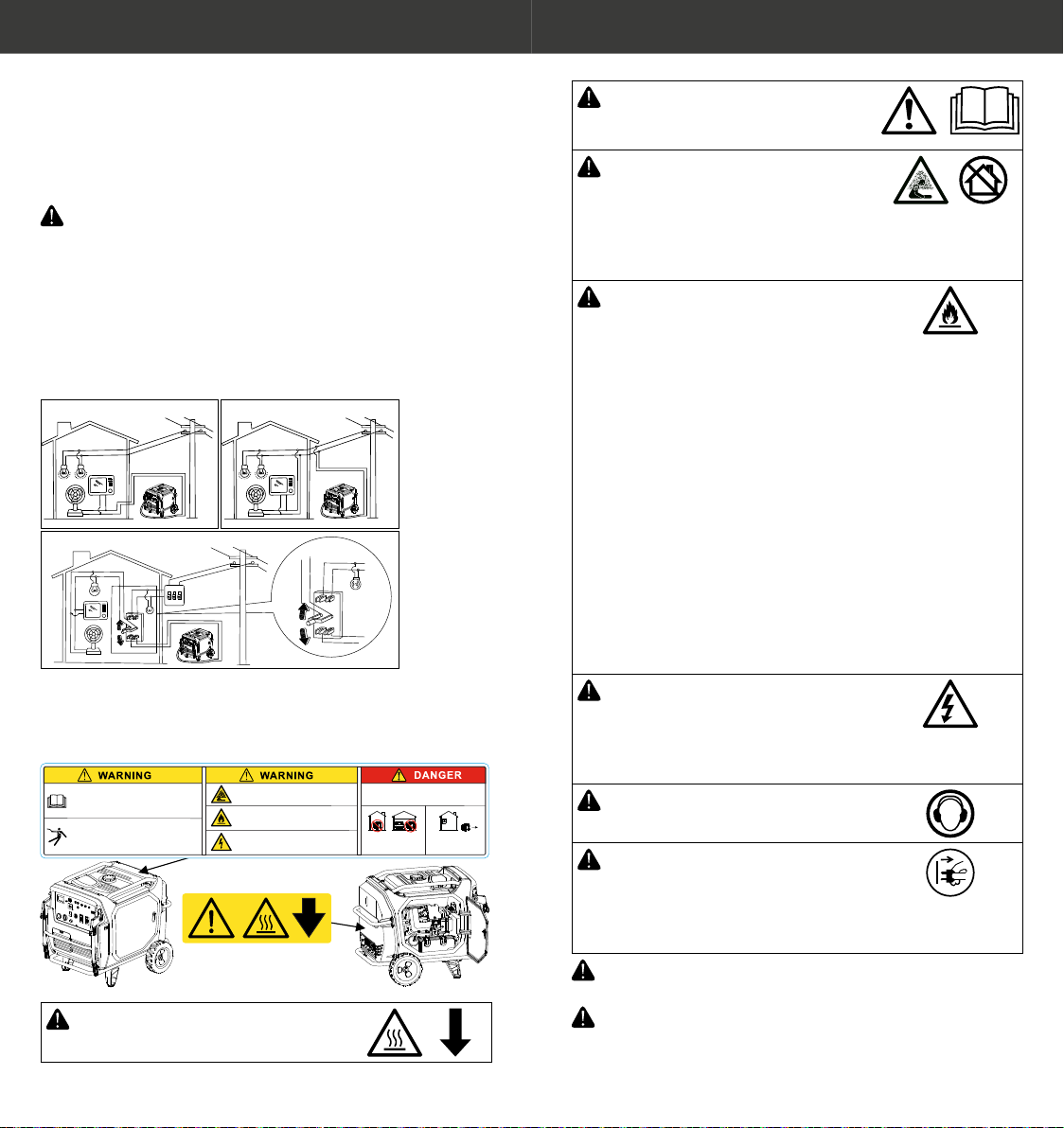

Safety Regulaons

There are warning labels on the machine to remind you of

safety regulaons.

NEVER USE INSIDE a home

or garage. EVEN IF doors

and windows are open.

ONLY USE OUTDOORS

and far away from

windows, doors & vents.

READ THE OPERATION MANUAL BEFORE USE

Pay attention to important safety and health

warnings and instructions.

■Understand and follow warnings and cautions.

■Do not operate unless guards are in place.

HIGH VOLTAGE GENERATOR

■Do not connect to any building electrical system.

■Do not overload generator.

■Non-qualified people (including under-aged

children) are not allowed to operate.

EXHAUST FUMES ARE POISONOUS

■Do not operate in unventilated areas.

■ Carbon monoxide (CO) danger.

Using a generator indoors CAN KILL IN MINUTES.

Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

PETROL AND ITS VAPOUR ARE

FLAMMABLE AND EXPLOSIVE

■Keep away from heat, sparks & flame sources.

■DO NOT refuel when operating.

GENERATORS PRODUCE ELECTRICITY THAT

CAN CAUSE SERIOUS INJURY OR DEATH

■Operate only in dry areas away from

moisture, rain, snow and standing water.

CAUTION: Hot Surfaces.

CAUTION: Read the safety

instrucons before using the

generator.

CAUTION: Gases such as carbon

monoxide (colourless and odourless

gas) are produced during operaon

which may lead to suocaon. Only

use the generator in well-venlated

areas.

CAUTION: Fuel is highly ammable

and extremely explosive. Fire or

explosion can cause severe burns

or death. Keep ammable items

away while handling fuel. Fill

fuel tank outdoors and in a well-

venlated area with the generator

stopped. Always wipe o spilled

fuel and wait unl the fuel has dried

before starng the generator. Do

not operate the generator with

known leaks in the fuel system. Use

proper fuel storage and handling

procedures. Do not store fuel or

other ammable materials nearby.

Empty the fuel tank before storing

or transporng the generator. Keep

re exnguisher handy and be

prepared if a re starts.

WARNING: Dangerous voltages

are present when the generator is

in operaon. The generator must

always be switched o before

performing maintenance.

CAUTION: Wear ear protecon

when operang the generator.

CAUTION: Disconnect all devices

from the connecons before

performing maintenance works,

before leaving the device and aer

switching it o.

WARNING: Modicaons to any part of the generator is

not allowed and may void your warranty.

WARNING: This generator is intended for residenal

consumer use only. This generator is not designed for

permanent installaon.

98

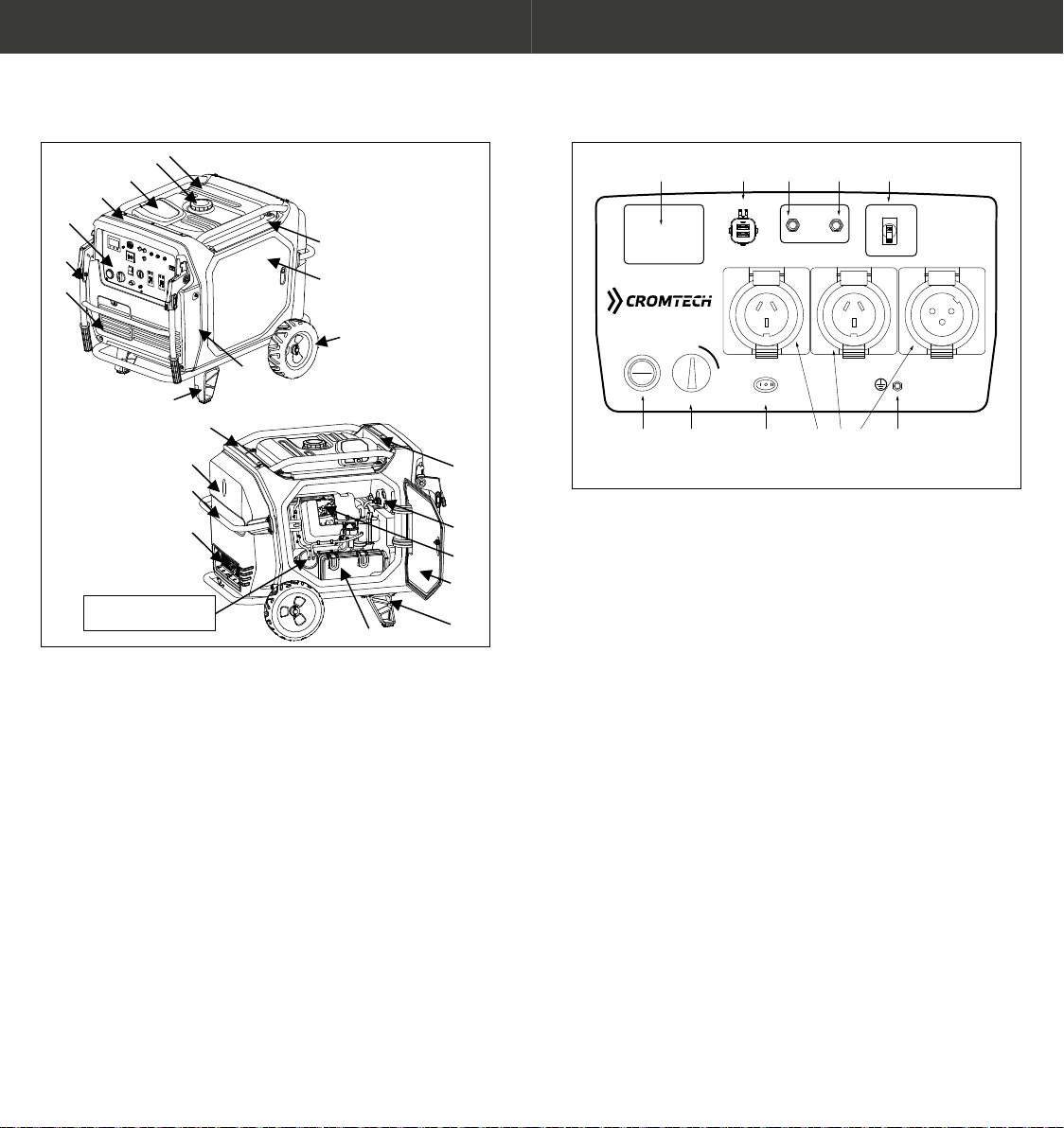

CONTROL FUNCTION

TG7000ie Diagram

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(11)

(10)

(12)

(13)

(14)

(15)

(16)

(17) (18)

(19)

(20)

(21)

(22)

Serial No. T***YYMM********

The YYMM is year and month

of manufacture.

(1) Fuel tank

(2) Fuel tank cap

(3) Cover plate of oil level sensor

(4) Frame components

(5) Control panel

(6) Folding handle

(7) Baery maintenance cover

(8) Frame shock absorber bracket (right)

(9) Panel bed

(10) Wheel

(11) Right maintenance door

(12) Seal ring (fuel tank)

(13) Tank cover (back)

(14) Frame hood

(15) Handle

(16) Silencer spark collector

(17) Air lter

(18) Frame shock absorber bracket (le)

(19) Le maintenance door

(20) Spark plug

(21) Combinaon switch

(22) Tank cover (front)

Control Panel Diagram

1 2 3 4 5

6 9 10 11 127 8

INVERTER

GENERATOR 7000ie

7000ie

ESC THROTTLE

GROUND

DIGI TAL DISPLAY METER

5V 1A/ 2.1A

TOTAL 3 A MAX

USB

AC BREA KER

AC 24 0V 15A

AC BREA KER

ENGINE

STANDARD

TURBO

START

STOP

ECO

ON

ON

OFF

OFF

15A 15 A

25A

AC 24 0V 15A AC 24 0V 25A

(1) Digital display meter

(2) USB charging port

(3) AC breaker 15 amp

(4) AC breaker 15 amp

(5) AC breaker 25 amp for 32 amp outlet

(6) Engine Stop/Start Buon

(7) Engine Switch

(8) ESC Throle Switch

(9) AC socket 15 amp

(10) AC socket 15 amp

(11) AC socket 32 amp

(12) Earth terminal

1110

Engine Switch

OFF

ENGINE SW.

ON

This switch controls ignion system, fuel system, power

system and solenoid valve.

OFF Stop the engine: Ignion system is in the closed state,

fuel switch is o, solenoid valve switch is o, and power

system switch is o; the engine can’t be started normally.

ON Start/run the engine: Ignion system is in the working

state, fuel switch is on, solenoid valve switch is on, and

power system switch is on. The engine can be started by

the Start Buon, the Recoil Starter or the Bluetooth App.

Start Buon

START

____________

STOP

ON

OFF

When the engine switch is placed in the “ON” posion, use

the Start Buon to start the engine.

Recoil Starter

When baery voltage is too low or at, use the manual recoil

starter to start the engine.

ESC Throle Switch

ESC THROTTLE

STANDARD

TURBO

ECO

1 2 3

①“ECO”

When the ESC switch is turned to “ECO”, the economy

control unit controls the engine speed according to the

connected load. The results are beer fuel consumpon

and less noise.

②“STANDARD”

When the energy saving switch is placed in the

“STANDARD” posion, with load less than 4.5kW, the

engine runs at the rated speed (3,100r/min).

③“TURBO”

When the energy saving switch is placed on the posion

of “TURBO” the engine runs at the rated speed (3,600r/

min) regardless of whether the load is connected or not.

NOTE: When high current devices are applied, such as air

conditioners, hotplates or water pumps, ESC Throle must

be placed in the “TURBO” posion.

1312

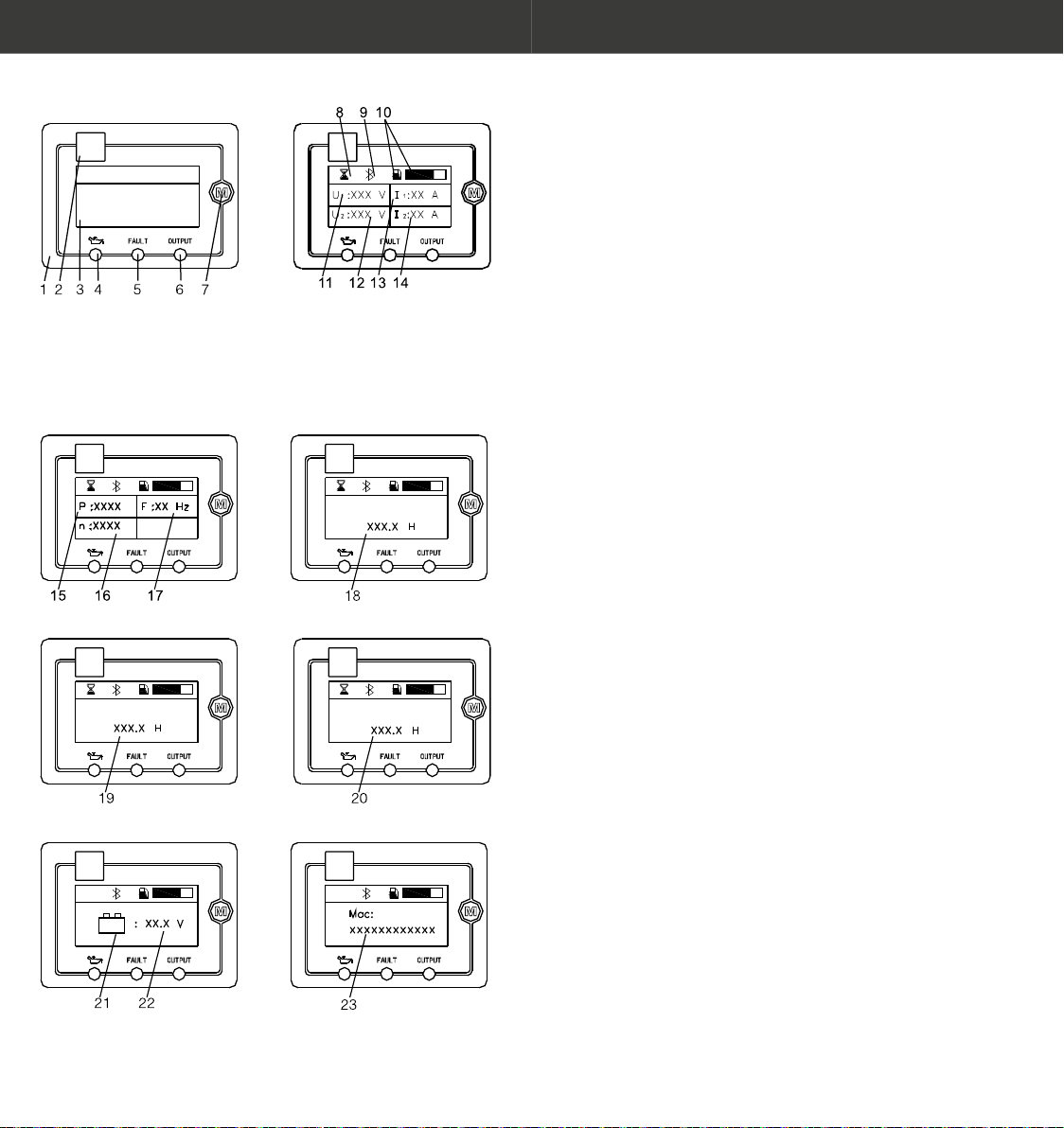

Digital Display Meter

(1) Multimeter

(2) QR Code for Bluetooth Connection

(3) LCD screen

(4) Oil warning light

(5) Overload indicator light

(6) AC pilot light

(7) Operating key

(15) Power (16) Speed (17) Frequency (18) Current run time

(19) Cumulative running time

(21) Battery normal

(22) Battery (Voltage greater than 10V)

(23) MAC address

(20) Remaining run lime

(8) Operation identification

(Normal operation)

(9) Bluetooth logo

(10) Fuel level

(11) AC Voltage

(12) AC Voltage

(13) AC Current

(14) AC Current

1. When the Engine Switch is placed in the “OFF” posion

(when the engine is not started):

Operate key 7, only the content of 19 is displayed on the

screen interface (aer each operaon of key 7, the display

will disappear automacally aer 5 seconds).

2. When the engine is not started, but the switch is in the

“ON” posion:

a. No content is displayed on the screen interface.

NOTE: If the baery has been installed, this interface

indicates that the baery voltage is less than 8V

(the baery needs to be charged), one-key start and

Bluetooth APP start cannot be carried out, but the

engine can be started by recoil starter. If there is no

display aer replacing the baery with new one,

please contact your dealer.

b. The screen interface displays the contents of 21-22

and 23 (2 display interfaces in total).

NOTE: The interface with the display contents of 21-

22 indicates that the baery voltage is more than 10V,

one-key start and Bluetooth APP start can be carried

out.

c. The screen interface displays the contents of 24-26

and 23 (2 display interfaces in total).

NOTE: The interface with the display content of 24-26

indicates that the baery voltage is more than 8V but

less than 10V, one-key start and Bluetooth APP start

cannot be carried out, but the engine can be started

by recoil starter.

NOTE: The interface with the display content of 23 can

be used for connecng the MAC address of Bluetooth

device.

The display interface can be switched by operaon of

key 7, and the contents are displayed in turn.

When the above contents are displayed in each

display interface, the contents of 27, 9 (displayed with

Bluetooth, not displayed without Bluetooth) and 10

are also displayed at the same me.

3. When the Engine Switch is placed in the “ON” posion,

and the engine starts successfully and runs normally: the

screen interface displays the contents of 11-14, 15-17, 18,

19, 20, 21-22 and 23 (7 display interfaces in total).

1514

(24) Operation identification (Not running)

(25) Battery (loss of) capacity

(26) Manual start information

(27) Battery (More than 8V / less than 10V)

(29) Fault identification

(30) Fault code symbol

(31) Maintenance identification

(28) Maintenance

NOTE: The interface content of 23 is used for the MAC

address of connecng Bluetooth device.

The display interface can be switched by operaon of key

7, and the contents are displayed in turn.

When the above contents are displayed in each display

interface, the contents of 8, 9 (displayed with Bluetooth,

not displayed without Bluetooth) and 10 are also displayed

at the same me.

4. When engine runs with failure: the screen interface

displays the contents of 29-30, and the content of 30

represents the fault informaon as follows:

U> a: AC over voltage, indicang the character of AC

(alternave indicaon of AC and digit)

U< a: AC under-voltage, indicang the character of AC

(alternave indicaon of AC and digit)

I> Output over current of generator.

Output short circuit of generator.

Over heat of frequency converter.

NOTE: When the above contents are displayed in each

display interface, the contents of 9 (displayed with

Bluetooth) and 10 are also displayed at the same me.

5. When the engine switch is in the “ON” posion, and the

engine is either running or not, the screen interface will

display content 28 advising a service interval is required.

If the service has already been carried out , operate key 7

to clear this informaon.

NOTE: Operate key 7 to clear the maintenance

informaon, the screen automacally switches to the next

interface.

If key 7 is not operated to clear the maintenance

informaon, the content of 28 will be displayed once every

1 minute in each screen interface for 10 seconds and the

content of 28 will not be displayed again unl 2 hours

later. At the same me, the maintenance mark will not be

displayed on the right side of the Bluetooth mark on the

screen interface, unl the generator set is maintained and

key 7 is operated to clear the maintenance informaon.

Oil Warning Light

When the oil level falls below

the low level, the oil warning

light comes on and then the

engine stops automacally.

Unless you rell with oil, the

engine will not start again.

NOTE: If the engine stalls or does not start, turn the engine

switch to “ON” and then pull the recoil starter. If the oil

warning light ickers for a few seconds, the engine oil is

insucient. Add oil and restart.

1716

Overload Indicator Light (Red)

The overload indicator light

comes on when an overload of

a connected electrical device

is detected, the inverter

control unit overheats, or the

AC output voltage rises. Then,

the AC protector will trip,

stopping power generaon in

order to protect the generator and any connected electric

devices. The AC pilot light (Green) will go o and the overload

indicator light (Red) will stay on, but the engine will not stop

running.

When the overload indicator light comes on and power

generaon stops, proceed as follows:

1. Turn o any connected electric devices and stop the

engine.

2. Reduce the total waage of connected electric devices

within the rated output.

3. Check for blockages in the cooling air Inlet and around the

control unit. If any blockages are found remove.

4. Aer checking, restart the engine.

NOTE: The overload indicator light may come on for a few

seconds at rst when using electric devices that require

a large starng current, such as an air condioner or a

water pump. However, this is not a malfuncon.

AC Pilot Light (Green)

The AC pilot light comes on

when the engine starts and

produces power.

Ground (Earth) Terminal

The ground terminal on this

generator is connected to NON-

current carrying parts of the

generator frame and to each AC

outlet. Before aaching a

ground (earth) lead, consult with

a qualied electrician on the

intended use of this generator.

AC Circuit Breaker

The AC Circuit Breaker will trip

to protect the electric device

when current is too heavy.

Folding Handle

This generator is ed

with a folding handle

set to enable the user

to manoeuvre the

generator with ease. To

engage, li handle up

and lock handle in

place. To fold down, press down on both locking levers at the

same me and the handle will fold down. Do not use

generator with handle set in the xed posion. Do not use the

handle set to raise the generator o the ground.

Maintenance Door

Make sure that the maintenance door is closed while the

engine is running. Open and close maintenance doors for unit

maintenance.

In the case of no electrical start,

open the right maintenance

door and start the engine by

recoil starter.

Right door: Inspecon/

replacement of engine oil;

manual start.

Le door: Inspecon/

replacement of spark plugs;

inspecon/cleaning of air lter;

drain of carburetor.

Open maintenance

door: Rotate lock 90°

counterclockwise.

Close maintenance door:

Rotate lock 90° clockwise.

1918

PRE-OPERATION

NOTICE: Pre-operaon checks should be made each me

operang.

WARNING: The engine and muer will be very hot aer

the engine has been run. Avoid touching the engine and

muer while they are sll hot with any part of your body

or clothing during inspecon or repair.

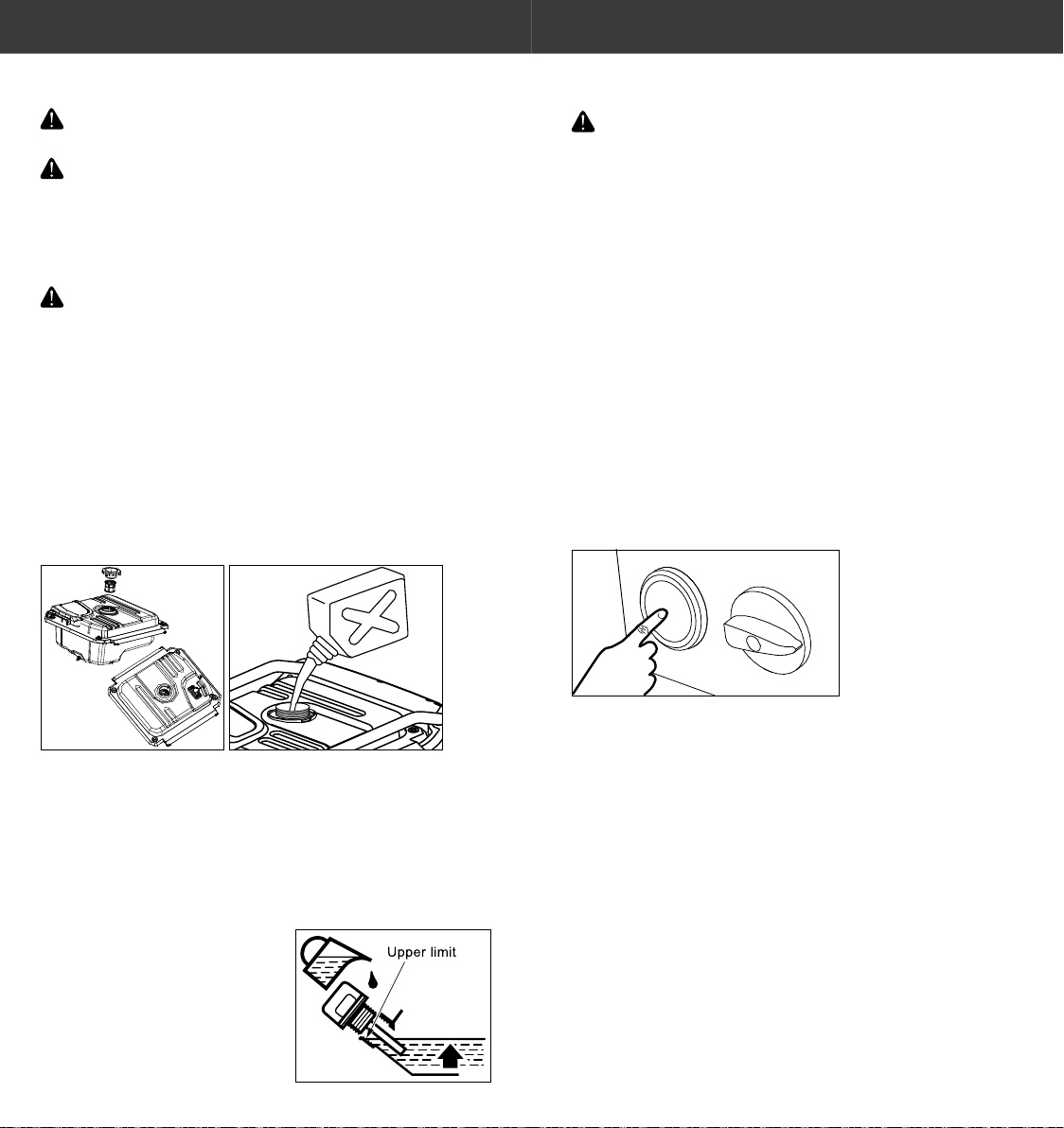

Fuel

WARNING

• Fuel is highly ammable and poisonous. Check “SAFETY

INFORMATION” (See page 7) carefully before lling.

• Do not overll the fuel tank, otherwise it may overow

when the fuel warms up and expands. Aer lling make

sure the fuel tank cap is ghtened securely.

• Immediately wipe o spilled fuel with a clean cloth.

• Use only unleaded petrol.

Only ll tank to red full level indicator in the fuel strainer.

Recommended fuel: Unleaded gasoline

Fuel tank capacity (total): 25.0 litres

ADD FUEL

Engine Oil

The generator has been shipped without engine oil. Do not

start the engine unl lled to the correct level.

Do not lt the generator when adding oil to the engine. This

could result in overlling and damage to the engine.

OIL LEVEL

Recommended engine oil:

SAE 10W – 30

Engine oil quanty: 1.45 litres

OPERATION

NOTICE: Never operate the engine in a closed area or

it may cause unconsciousness and death within a short

me. Operate the engine in a well venlated area. The

generator has been shipped without engine oil. Do not

start the engine unl lled to the correct level.

NOTE:The generator can be used with the rated output load

at standard atmospheric condions.

“Standard atmospheric condions” = Ambient

temperature 25°C. Barometric pressure 100kPa;

Relave humidity 30%

The output of the generator varies due to change

temperature, altude (lower air pressure at higher

altude) and humidity.

The output of the generator is reduced when the

temperature, the humidity and the altude are higher

than standard atmospheric condions.

Starng The Engine

START BUTTON

START

____________

STOP

ON

OFF

1. Do not connect any electrical equipment before starng

the generator. Turn the ESC Switch to standard.

2. Turn the Engine Switch to “ON” posion.

3. Start Buon – press and release the start switch buon

on the control panel. The start switch will start the motor

for 5 seconds. When the engine starts successfully, the

starter will stop automacally. If the engine does not start

successfully, wait at least 10 seconds before starng again.

NOTE: Do not leave the Engine Switch in the “ON” posion

when the generator is not in use or in storage. This will

aen the baery.

2120

APP START – ANDROID

1. Download and install the app by scanning the above QR

code via the phone’s camera or QR Reader and follow the

download link. Follow prompts to install.

2. Once downloaded, open the app. Enter the

“Management” tab, press the + icon and then use one of

the following three methods to connect your device.

a. Scan the QR code of the Bluetooth module on the

digital display meter.

b. Click to enter the device scanning page and let the app

automacally nd the generator. The generator must

be switched on.

c. Enter the MAC address of the Bluetooth device you

want to connect to. The MAC address can be found on

the digital display meter.

3. Aer nding the Bluetooth device, go back to the device

management page.

4. Click “Connect” to connect to the Bluetooth device. Aer

successful connecon, the model icon will become bright.

5. Enter the home tab of the mobile app and click the start

buon to start the engine.

NOTE: We recommend connecng to your generator via

opon B as a preferred method of connecng.

NOTE: You can have mulple devices paired to the device,

however only one connected at a me.

APP START – APPLE

1. On your Apple device, visit the App Store.

2. In the App Store search for “ILONCIN”.

3. When you nd ILONCIN press

“GET” to download the

generator app. Once the app is

downloaded, open. Enter the

“Management” tab, press the

+ icon and then use one of the

following three methods to

connect your device.

a. Scan the QR code of the

Bluetooth module on the

digital display meter.

b. Click to enter the device

scanning page and let the

app automacally nd the

generator. The generator

must be switched on.

c. Enter the MAC address of the Bluetooth device you

want to connect to. The MAC address can be found on

the digital display meter.

4. Aer nding the Bluetooth device, go back to the device

management page.

5. Click “Connect Now” to connect the found Bluetooth

device. Aer successful connecon, the model icon will

become bright.

6. Enter the homepage of mobile APP and click the start

buon to start the engine.

NOTE: We recommend connecng to your generator via

opon B as a preferred method of connecng.

NOTE: You can have mulple devices paired to the device,

however only one connected at a me.

2322

RECOIL START

Turn the lock 90° counter-

clockwise, and open right

maintenance door. First,

pull the recoil starter

gently, unl resistance is

felt, then pull hard. Turn

the lock 90° clockwise and

close right maintenance

door.

If you want to use the energy saving funcon, turn the ESC

Throle to the “ECO” posion aer the engine has been

running for 2-3 minutes.

Stopping The Engine

ESC

THROTTLE

STANDARD

TURBO

ECO

ENGINE

ON

OFF

To shut down the engine:

1. Turn o all electrical

equipment.

2. Turn the ESC Throle

to the “Standard”

posion.

3. Disconnect all electrical

equipment from the AC

socket.

4. Manual stopping: press

and release the start

switch buon on the

control panel. Enter the

homepage of Bluetooth

APP of the mobile

phone, click the start

buon to turn o the

engine (to skip this step

proceed to the next

step).

5. Turn the Engine Switch

to the “OFF” posion.

When the generator is not

running or not in use, put

the Engine Switch in the

“OFF” posion, otherwise the baery will aen and aect

the next one-key start.

NOTE: If the engine is to be turned o in an emergency, rotate

the Engine Switch quickly to the “OFF” posion.

2524

Alternang Current (AC) Connecon

WARNING: Be sure any electric devices are turned o

before plugging them in.

NOTICE

• Be sure all electric devices including the cable and plug

connecons are in good condion before connecon to

the generator.

• Be sure the total load is within generator rated output.

• Be sure the receptacle load current is within receptacle

rated current.

1. Start engine and make sure that AC indicator light is green.

2. Insert the plug into AC socket/

3. Make sure that AC indicator light is on.

4. Turn on the electrical equipment.

Many electric load devices require starng power above their

rated power to start.

The ESC throle must be turned to “Standard” or “Turbo”

before applying high start up loads.

• Some motorised appliances require more than their

electrical rang for startup. When an electrical motor is

started, the overload indicator (red) may come on. This

is normal if the overload indicator (red) goes o within 4

seconds. If the overload indicator (red) stays on, consult

your generator dealer.

• If the generator is connected to mulple loads or

electricity consumers, please remember to rst connect

the one with the highest starng current. And last connect

the one with the lowest starng current.

• If the generator is overload, or if there is a short circuit in

a connected appliance, the overload indicator (red) will

go ON. The overload indicator (red) will stay ON, and aer

about 4 seconds, current to the connected appliance (s)

will shut o, and the output indicator (green) will go OFF.

Stop engine and invesgate the problem. Determine if

the cause is a short circuit in a connected appliance or an

overload, correct the problem and restart the generator.

MAINTENANCE

It is the owners requirement to periodically inspect, adjust,

lubricate and maintain the generator to keep it in good

working condion.

WARNING: Turn ENGINE SWITCH to “OFF” to avoid any

accidental start up during all maintenance procedures.

Stop the engine and allow the engine to cool before

starng maintenance work.

NOTE: Use only genuine replacement parts, contact your local

authorised service agent.

NOTE: Consult your local authorised service agent for all

major maintenance work.

Roune maintenance

cycle (1) Each

check

First

months

or 20 Hr

3 months

or 50 Hr 6 months

or 100 Hr 12 months

or 300 Hr

Item Roune

Oil Inspect ●

Replace ● ●

Air lter

Inspect ●

Clean ●(2)

Replace ●*

Spark plug Clean

Replace ●

Spark arrester Clean ●

Valve

clearance

Inspect-

Adjustment ●(3)

Combuson

chamber Clean Every 1000 hours (3)

Fuel tank Clean Every 2 years or 1000 hours (3)

Fuel lter Replace Every 2 years or 1000 hours (3)

Fuel hose Clean Every 2 years (Replacement if necessary) (3)

Tip: *Replace the paper lter element.

Refueling

WARNING: Petrol is ammable and explosive.

When refueling you can get burns or serious injuries.

Before refuelling, stop engine

and allow to cool.

• Only refuel outdoors

• Clean up any spilled fuel

and allow to dry

• Do not over ll the fuel

tank. Only ll tank to red

full level indicator in the

fuel strainer.

NOTICE: Petrol can damage paint and plascs.

When refueling, take care not to spill petrol.

2726

Engine Oil Inspecon

Check engine oil when engine is stopped and placed on a level

surface.

1. Rotate the lock 90° counter clockwise, and open right

maintenance door.

2. Remove the oil gauge.

3. Check the oil. If the oil level is below the highest mark, add

the specied oil to the highest mark.

4. Reinstall the oil gauge.

5. Rotate the lock 90° clockwise and close right maintenance

door.

Low oil shut down. If the engine oil is too low, the engine

will automacally shut down to protect the engine. To avoid

unnecessary engine shutdowns, check oil levels regularly.

Engine Oil Replacement

1. Rotate the lock 90° counterclockwise and open right

maintenance door.

2. Remove the black rubber seal ring under the oil drain bolt.

3. A suitable container for oil is placed at the boom of the

engine.

4. Remove the oil gauge.

5. Remove oil drain bolt and washers to drain oil thoroughly.

6. Reinstall the oil drain bolts and washers and ghten the oil

drain bolt.

7. Reinstall the black rubber seal ring.

8. Place the generator on a horizontal surface and add the

specied oil to the maximum scale.

9. Reinstall the oil gauge.

10. Rotate the lock 90° clockwise and close right maintenance

door.

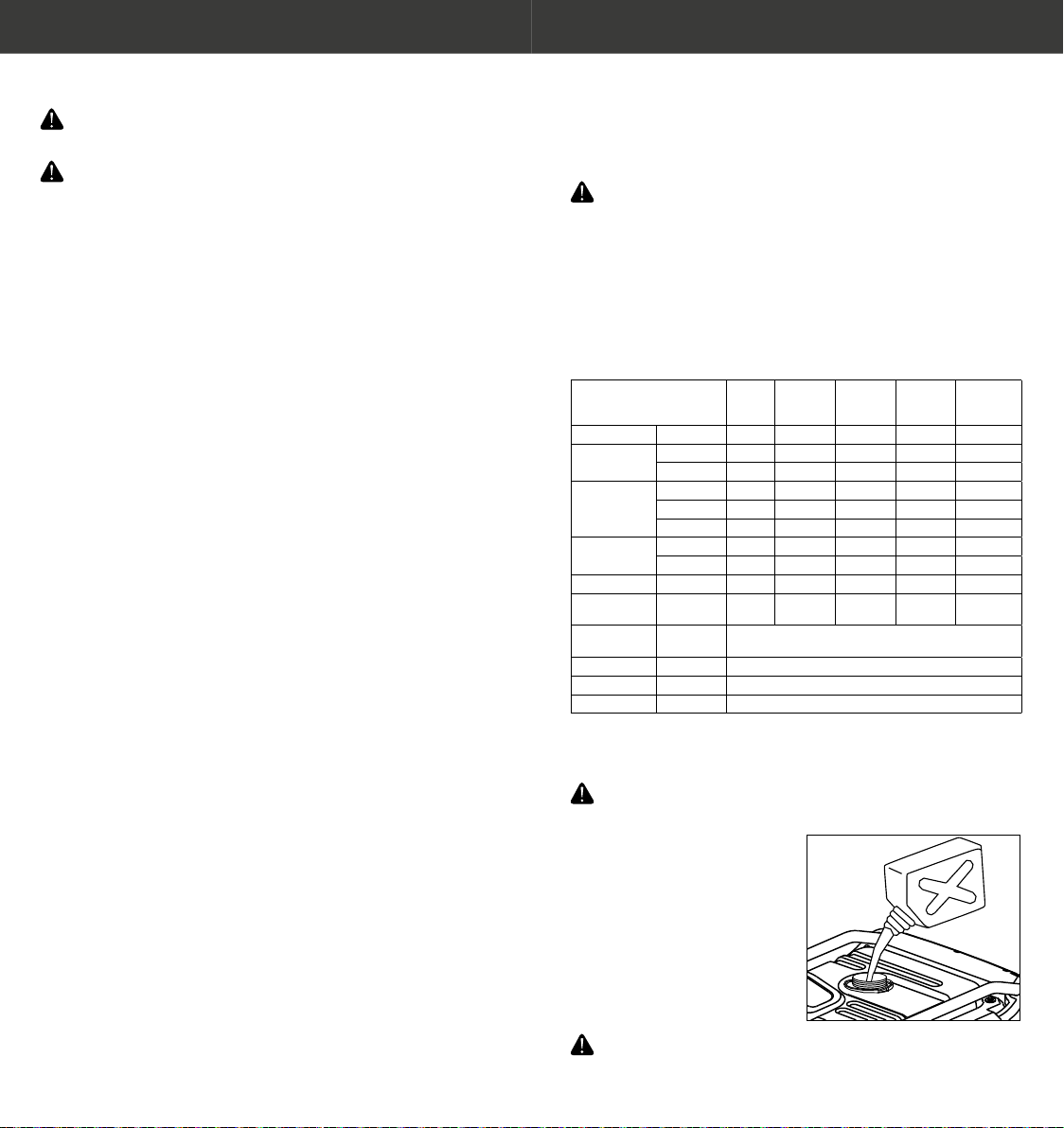

Oil Specicaon Table

Use four-stroke oil.

SAE 10W30 is

recommended for regular

use. However, when the

average temperature in

your area is within the

recommended range, you

can use other viscosity

types of oil shown in the

chart.

Air Filter

1. Rotate the lock 90° counter clockwise, and open le

maintenance door.

2. Loosen the air lter cover clamp and remove the air lter

cover, foam lter core, lter core bracket and paper lter

core together.

3. Paper lter element:

a. Remove the paper lter element from the lter holder.

b. If the paper lter element is dirty, replace it with a new

one. Do not wash the paper lter element.

c. Insert the paper lter element into the lter holder.

4. Foam lter:

a. Remove the foam lter element from the empty lter

cover.

b. Check the foam air lter to make sure that it is clean

and in good condion. If the foam lter element is

dirty, refer to the following page for cleaning. If the

foam lter element is damaged, replace it with a new

one.

5. Put the foam lter element, the lter holder and the paper

lter element together into the empty lter cover.

6. Install the air lter cover and lock the cover clamp.

7. Close the le maintenance door, and rotate the lock 90°

clockwise.

2928

AIR FILTER CLEANING

NOTICE: Do not operate the engine without an air cleaner

element as this will cause damage to the inner parts of

the engine. In unusually dusty condions regular cleaning

or replacing is required.

The foam lter element of the dirty air lter will restrict the air

ow to the fuel system and reduce the engine performance.

If the generator is used in a dusty area, the maintenance

frequency of the air lter’s foam lter element is higher than

that in the maintenance requirements.

1. Wash the lter element in warm soapy water and let it dry

naturally, or clean and dry it in a non – ammable solvent.

2. Dip the lter element into clean oil and squeeze out excess

oil. If there is too much oil le in the lter element, start

the engine and the engine will smoke.

3. Use a damp cloth to remove dirt from the inside of the air

lter’s cover. Take care to prevent dust from entering the

air ducts which leads to the fuel system.

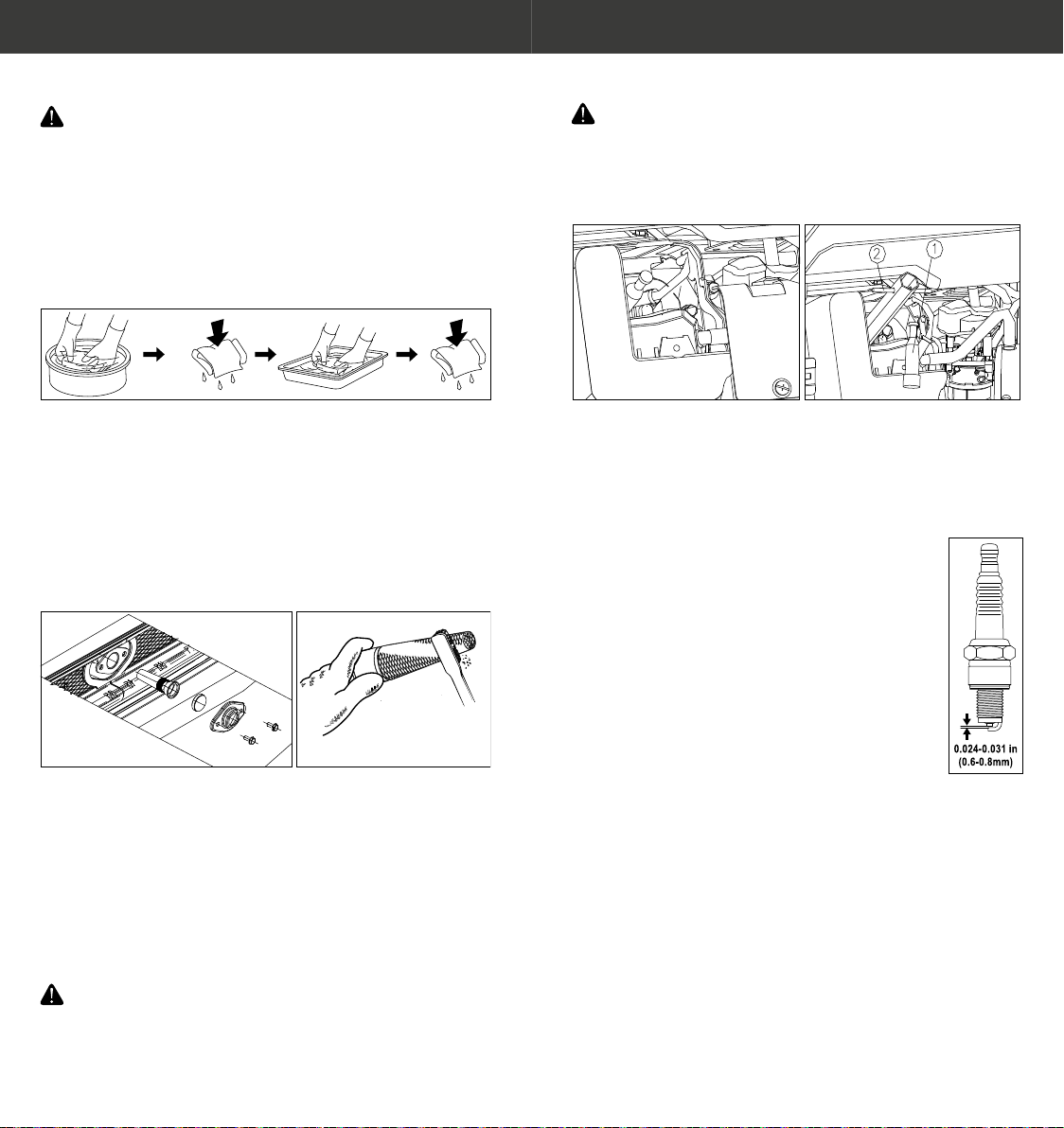

Spark Arrester

The spark arrester must be cleaned every 100 hours to

maintain engine performance. Ensure exhaust outlet and

engine is cold before cleaning and maintenance.

To remove and clean the spark arrester.

1. Loosen two M5x12 pan head bolts and remove mounng

cover, muer mesh cover and spark collector.

2. Clean the muer’s mesh cover and the cumulave carbon

on the spark collector with a steel wire brush.

3. Ret and ghten the spark arrester.

NOTICE: Clean with steel wire brush gently to avoid

damage or scratch to muer mesh and spark arrester.

The spark arrester must not be broken or cracked. If it is

damaged, it must be replaced.

Spark Plug

NOTICE: Incorrect spark plug can cause damage to the

engine.

To replace or clean the spark plug use the spark plug spanner

kit supplied. Allow engine to cool before aempng to

remove the spark plug.

1. Rotate the lock 90° counterclockwise, and open le

maintenance door.

2. Loosen bolt of spark plug’s maintenance cover and remove.

3. Remove the spark plug cap, remove dirt and dust from

around the spark plug.

4. Use the spark plug spanner and rotate counter-clockwise

and remove the spark plug.

5. Check the spark plugs. Replace the spark plug,

if the electrode is worn or burnt, or if the

insulator is cracked or broken. Standard spark

plug: NGK BPR7ES, clearance of spark plug:

0.6-0.8mm.

6. Aer ensuring that the spark plug is in good

condion, x the spark plug gently to the

head of the cylinder by hand to prevent

thread damage caused by force.

7. Aer the spark plug is xed, ghten it with the

spark plug spanner. If the used spark plug is to

be reinstalled, ghten 1/8-1/4 circle manually

aer xing the spark plug and before

ghtening it to the specied posion. If the newly installed

spark plug is to be reinstalled, ghten 1/2 circle manually

aer xing the spark plug and before ghtening it to the

specied posion. Torque: 13.3 LBS. Ft (18 N.M, 1.8kg.m)

8. Install the spark plug cap.

9. Install spark plug maintenance cover and ghten

maintenance cover’s bolts.

10. Close the le maintenance door, and rotate the lock 90°

clockwise.

NOTE: Spark Plug Type: NGK BPR7ES

NOTE: If the spark plug is installed without torque wrench, a

beer esmaon method is to ghten 1/4-1/2 circle

manually, but the spark plug should be ghtened to the

specied torque.

3130

NOTICE: Loose spark plugs may overheat and damage the

engine. Excessive ghtening of spark plugs can damage

the thread on the head of cylinder.

Baery

When the engine is running, the generator’s charging

system will automacally charge the baery. However, if the

generator is not used regularly, it must be charged monthly to

maintain the service life of the baery.

REMOVING THE BATTERY

1. Li handle up, lock handle and x it in place.

2. Loosen the bolts of maintenance cover and remove the

baery maintenance cover CD.

3. Remove the negave (-) cable from the negave (-)

terminal of the baery, and then remove the posive (+)

cable from the posive (+) terminal of the baery.

4. Remove the baery band from the hook at the boom of

generator.

5. Remove the baery from the mounng box.

INSTALLING THE BATTERY

1. Put the baery

in the mounng box.

2. Connect the posive

(+) cable with the

posive (+) terminal

of the baery, ghten

the bolt and cover

the rubber cap.

3. Connect the negave (-) cable with the negave (-)

terminal of the baery, and ghten the installaon bolt.

4. Install the baery band.

5. Reinstall baery maintenance cover and ghten the bolts.

NOTICE: The generator must not run without the baery

maintenance cover ed as this will aect the internal

cooling air ow of the generator and will void the warranty.

CAUTION: Baery Terminals and leads may have a build

up of dirt and corrosion. Wash hands immedialtey aer

handling the baery.

Protecve Fuses

If the fuse blows, the generator will stop.

In the case of a fuse failure, nd out the cause of the failure

and x it before connuing to use. If the fuse connues to fail,

stop using the generator and contact the dealer.

1. Turn the Engine Switch to the “OFF” posion, before

checking and replacing the fuse.

2. Loosen the bolts of baery maintenance cover, remove

the baery maintenance cover CD.

3. Open the cover of the fuse mounng box® (90°

counterclockwise)

4. Replace the fuse with the one of the same type and grade.

Specicaons of fuse: SA, 20A.

5. Cover the fuse mounng box and install the baery

maintenance cover.

NOTICE: Only use the specied, rated and type of fuse as

ed as this may cause damage to the electrical system

and will void the warranty.

3332

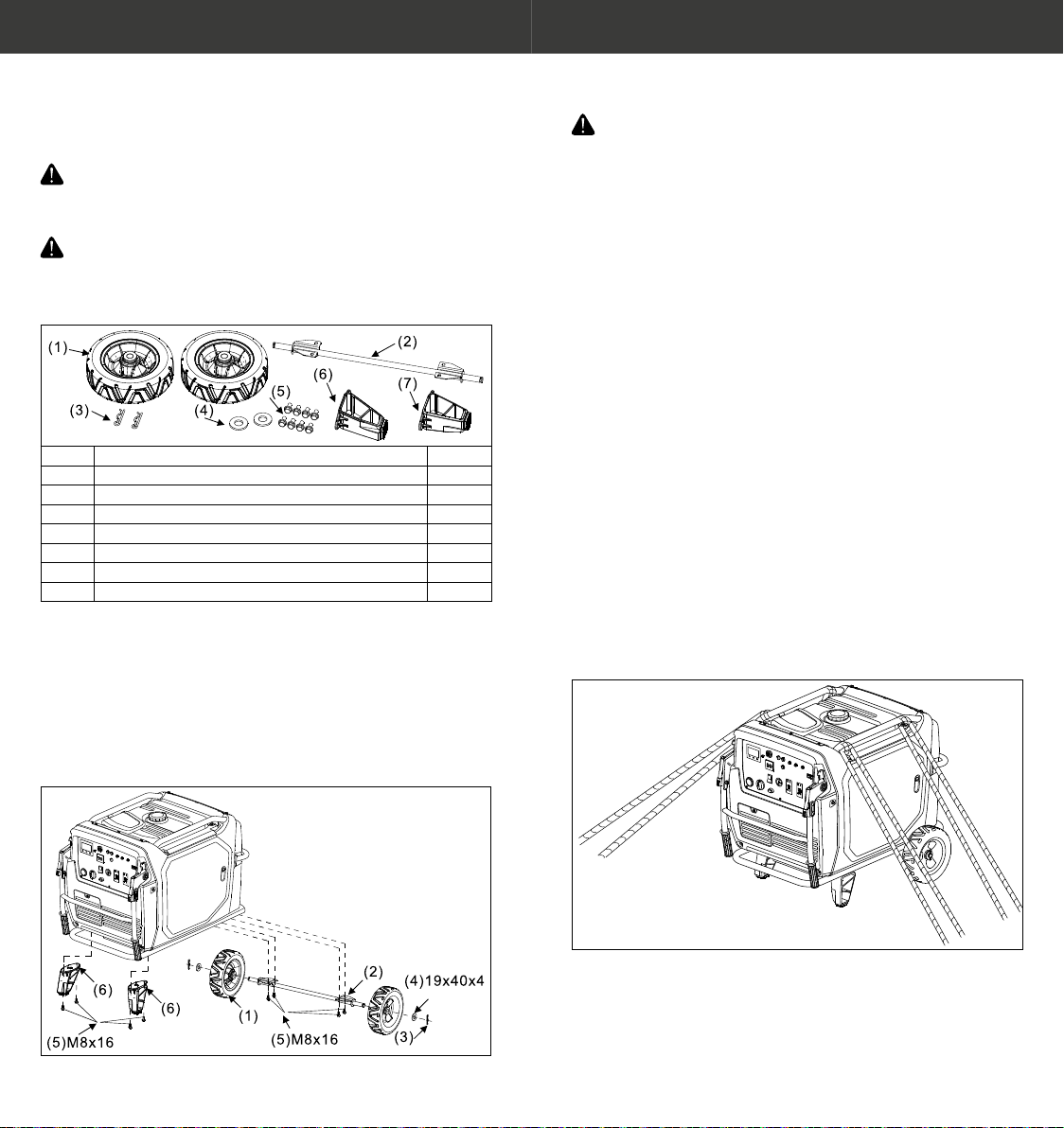

WHEEL SET INSTALLATION

Tool requirements: 12mm wrench, 10mm wrench, crosshead

screwdriver used for baery wiring, and clamp.

NOTICE: The generator must not be run without the

wheel kit ed as the wheel kit provides airow between

the ground and the airow inlet of the generator.

WARNING: If the wheel kit is not installed dust and debris

may be drawn into the air intake of the generator. This

will cause major damage to the generator and will void

the warranty.

No. Name Quanty

1Wheel 2

2Axle 1

3B pin 2

4Washer 2

5Bolt 8

6Frame shock absorber bracket (le) 1

7Frame shock absorber bracket (right) 1

1. Install the wheels to the generator with two washers and

pin clamps.

2. Install the axle onto the generator with four M8x 16 bolts.

3. Install the frame shock absorber bracket (le) onto the

generator with two M8x16 bolts.

4. Install the frame shock absorber bracket (right) onto the

generator with two M8x16 bolts.

Torque: 11-16 LBS. Ft (15-22 N.M, 1.5-2.2kg.m).

TRANSPORTING

TRANSPORTATION

Before transportaon allow the generator set to cool

completely.

To prevent fuel spillage, when transporng or during

temporary storage, the generator should be secured upright

in its normal operang posion, with the all switches in the

“OFF” posion

Do not overll the tank. Do not operate the generator while it

is on a vehicle. Take the generator o the vehicle and use it in

a well-venlated place.

Avoid a place exposed to direct sunlight when pung the

generator on a vehicle.

If the generator is le in an enclosed vehicle for many hours,

high temperature inside the vehicle could cause fuel to

vaporize, resulng in a possible explosion.

Do not drive on a rough road for an extended period with the

generator on board. If you must transport the generator on a

rough road, drain the fuel from the generator beforehand.

Note: Take care not to drop or strike the generator during

transport. Do not place heavy objects on the generator. When

using e-downs to secure the generator for transportaon,

use only the two upper frame protecon bars to aach to. Do

not aach e-downs to the main body of the generator or to

any part of the folding handle.

3534

STORAGE

In order to keep your generator trouble-free and in good

condion, proper storage preparaon is essenal. The

following steps will help to make it easier to start the engine

when you use the generator again.

Fuel

NOTICE: Fuel will deteriorate and oxidise over me. It is

important to remove fuel for longer term storage. Engine

failure due to stale fuel is not covered by warranty.

DRAINING THE FUEL

1. Remove fuel tank cap and fuel lter screen and extract

fuel into an appropriate container. Note: Fuel is extremely

volale and dangerous. Handle with cauon.

2. Turn the Engine Switch to the “ON” posion.

3. Start the engine and let it run unl the fuel runs out. The

engine will automacally stop.

4. Allow engine and generator to cool completely before

proceeding with next steps.

5. Unlock and open the le maintenance door.

6. Loosen the drain bolt on the carbureor and drain the fuel

into an appropriate container.

7. Turn the Engine Switch to the “OFF” posion.

8. Tighten the drain bolt on the carbureor.

9. Close and lock maintenance door.

Engine

• Remove the spark plug and pour about 15 ml of oil into

the cylinder.

• Turn the Engine Switch to the “OFF” posion.

• Crank the engine by pulling the manual recoil starter a few

mes to lubricate the cylinder.

• Ret the spark plug and maintenance cover.

• Clean and store the unit in a dry, dust free area out of

direct sunlight.

TROUBLESHOOTING

No. Fault Soluon

ENGINE WON’T START

1The Engine Switch is placed on the

"O" posion.

Turn the Engine Switch to the "On"

posion.

2Not enough fuel in the tank. Add fuel.

3Old or stale fuel. Drain the fuel from the tank, and

rell with new gasoline.

4Too low oil level causes the oil

alarm system to operate.

Add engine oil.

5No spark. Remove and clean or replace worn

or damaged spark plug.

6Ignion system fault, wiring harness

fault, valve clearance, etc.

Contact dealer

DECREASE OF OUTPUT POWER

1Air lter element failure Clean or replace lter element.

2Ignion system fault, wiring harness

fault, valve clearance, etc.

Contact dealers for handling.

NO OUTPUT OF CONTROL PANEL

1AC indicator light is o, and

overload indicator light is on.

Check AC load. Stop and restart the

engine.

Check the inlet of cooling vent.

Stop and restart the engine.

2AC Over-load buon trips out. Remove load and reset AC buon.

Check appliance before replugging

in.

3Other engine faults. Contact dealers for handling.

3736

SPECIFICATIONS

Model No. TG7000ie

Generator Type Inverter

Rated frequency 50Hz

Rated voltage 240V

Maximum power MAX 7000 WATTS

Rated power COP 6000 WATTS

Power factor 1.0

THD ≤1. 5%

Noise Level dB/LpA/LwA/K 4m

(3/4 load)

70 / 90

Overload Protecon Control by inverter overload

protect program

Engine Engine LC190FD-2

Engine type Single cylinder, 4-Stroke, forced

air cooling, OHV

Displacement 420cc

Fuel type Unleaded Petrol

Fuel capacity 25 litres

Connuous Running Time (at

rated power)

6.5 hours

Oil Capacity 1.45 litres

Spark Model No. NGK BPR7ES

Starng mode Recoil start/ Electric start/

APP start

Generator Length x Width x Height 950x765x773 mm

Wheel - Solid 2 x 250mm

Net weight 130kg

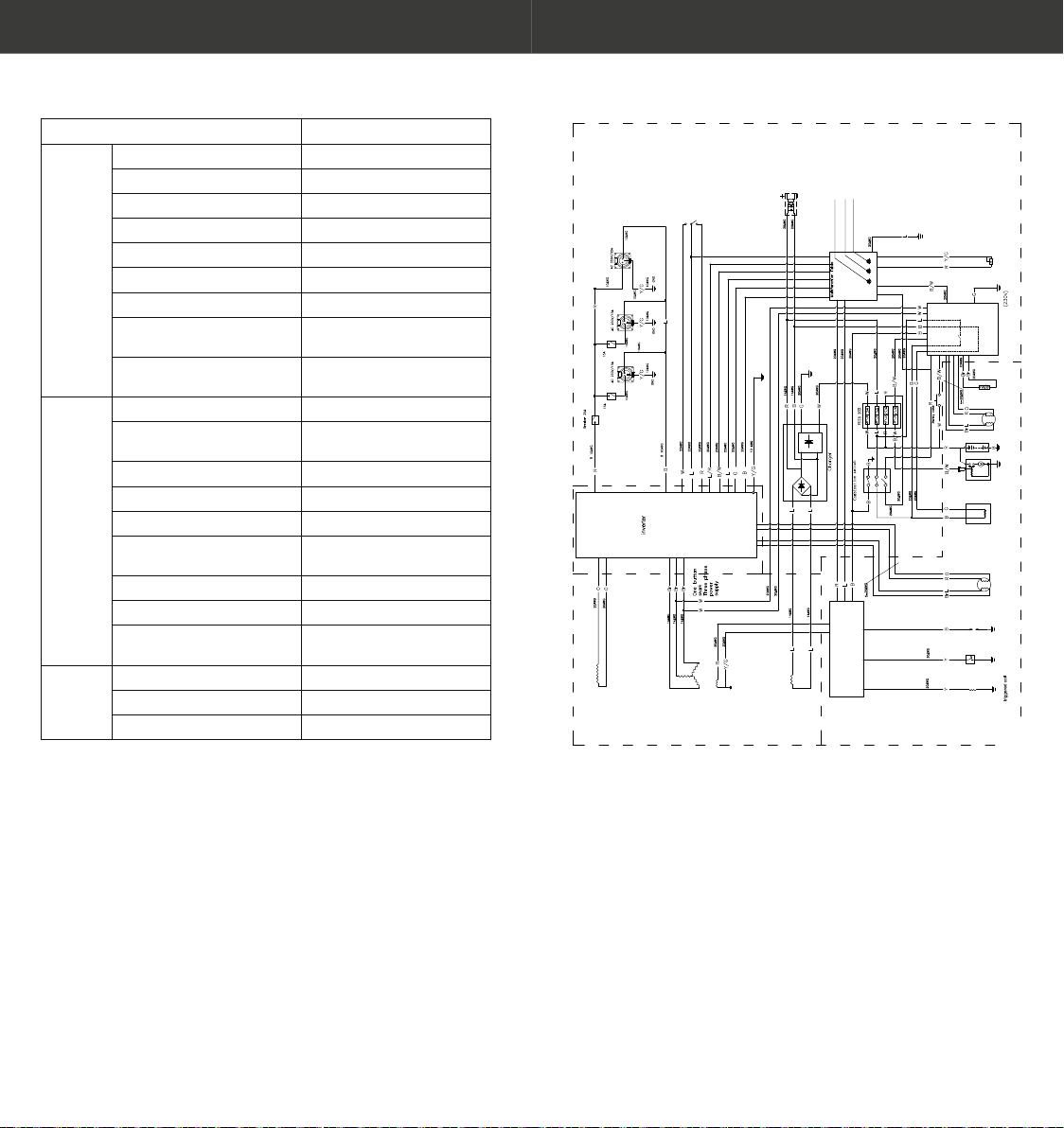

WIRING DIAGRAM

Subspoel

lgnition coil

Hoofdspoel

ESC switch

Choke

stepper motor

oil warning indicator light

overload indicator light

AC pilot light

Black

Brown

Green

Blue

Orange

Red

White

Yellow

Black/White

Yellow/Green

Red/White

B

Br

G

L

O

R

W

Y

B/W

Y/G

R/W

CONTROL PANEL BLOCK

GENERATOR BLOCK

ENGINE BLOCK

oil sensor

Ignition

spark plug stepper motor speed

Cylinder

temperture sensor

USB receptacle

Carburetor

solenoid valve Starter motor Battery start-stop controller Gasoline level sensor

DC coil

DC5V

3A

Table of contents