CATALOGUE

1. SYMBOLS ON THE LABEL ..................................................................................4

2. SAFETY AND WARNINGS ..................................................................................5

3. UNPACKING.........................................................................................................6

3.1 Scope of Delivery..............................................................................................................6

3.2 Product Overview .............................................................................................................6

4. INSTALLING .........................................................................................................8

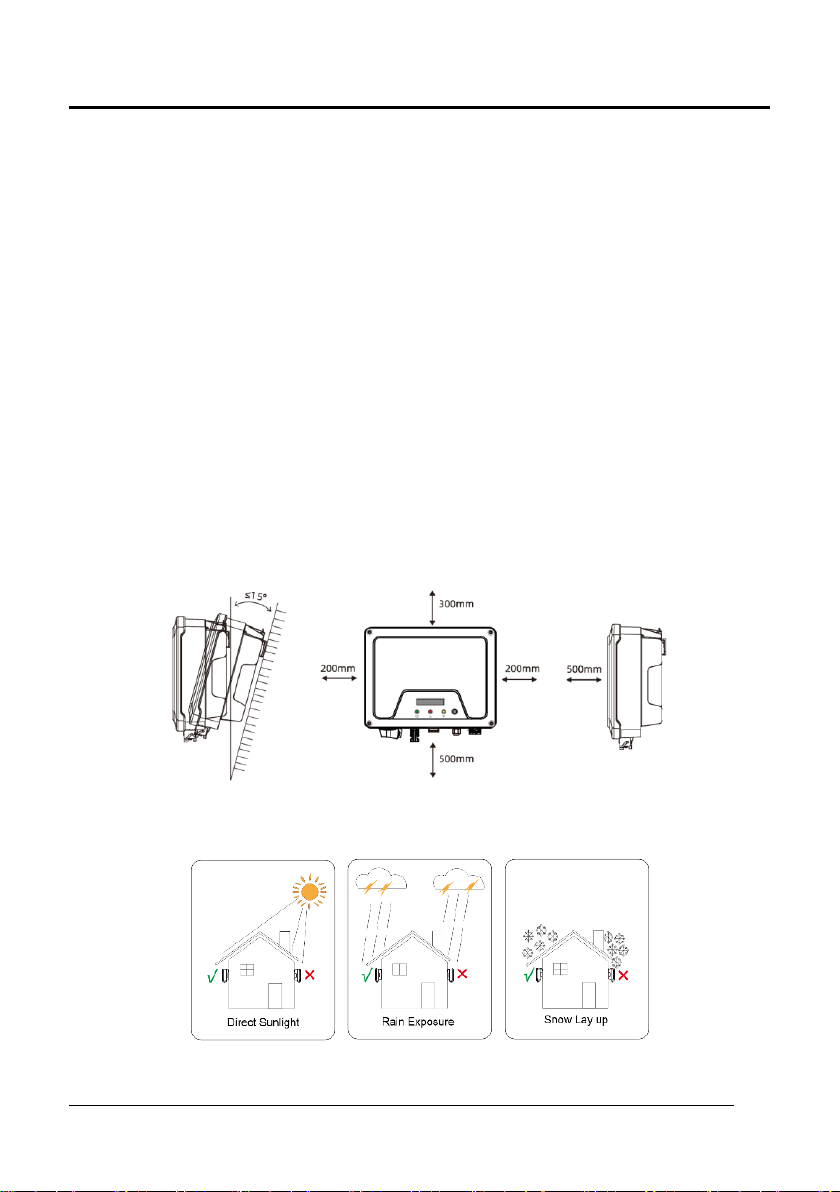

4.1 Installation Requirement ..................................................................................................8

4.2 Mounting Location ...........................................................................................................9

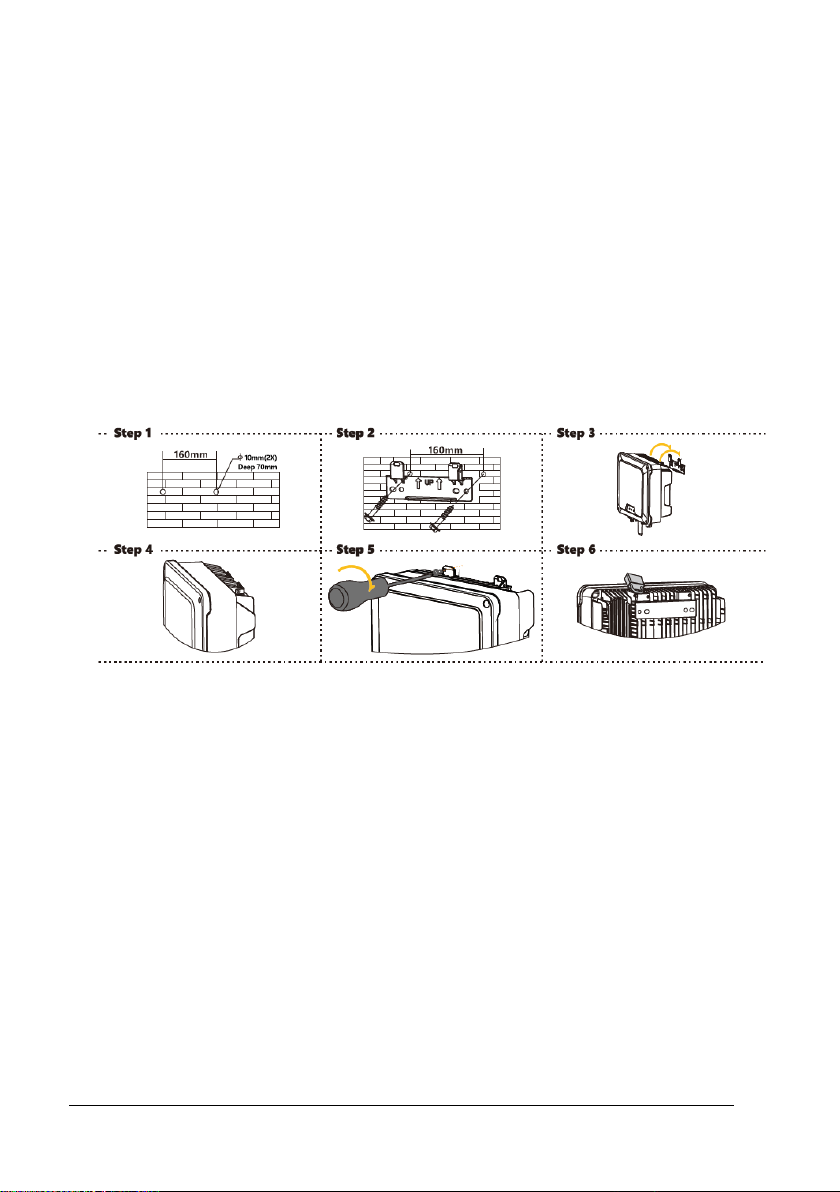

4.3 Mounting.........................................................................................................................10

4.4 Installing the PE cable ....................................................................................................10

4.5 Cable Specification .......................................................................................................11

5. COMMISSIONING.............................................................................................12

5.1 Safety Instructions ..........................................................................................................12

5.2 AC Wire Assembly and Connection ..............................................................................12

5.3 DC Wire Assembly and Connection ..............................................................................13

5.4 Residual Current Protection...........................................................................................14

6. COMMUNICATION ...........................................................................................15

6.1 System monitoring via Datalogger - RS485/Wi-Fi /GPRS (Optional) ........................15

6.2 Output Power Control via Smart Meter........................................................................16

6.3 Demand Responsive Modes(DRMs)........................................................................16

6.4 Auto Test (ONLY for Italian Market)..............................................................................17

7. START UP AND OPERATION...........................................................................19

7.1 Safety Check Before Start Up.........................................................................................19

7.2 Inverter LED Indicators ...................................................................................................20

7.3 Display and Control Logics ............................................................................................21

8. DISCONNECTING FROM VOLTAGE SOURCES .............................................22

9. TECHNICAL PARAMETERS...............................................................................23

10. TROUBLE SHOOTING ...................................................................................26

11. SYSTEM MAINTENANCE..............................................................................31

12. RESTARTS .......................................................................................................32