Crossbow Technology CXM539 User manual

Crossbow Technology, Inc., 41 E. Daggett Dr., San Jose, CA 95134

Tel: 408-965-3300, Fax: 408-324-4840

CXM539 User’s Manual

High Speed Digital 3-Axis Fluxgate

Magnetometer

Revision 1.2 October 2001

PN 6001-0014

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

©1999-2000 Crossbow Technology, Inc. All rights reserved. Information

in this document is subject to change without notice.

Crossbow and SoftSensor are registered trademarks and DMU is a

trademark of Crossbow Technology, Inc. Other product and trade names

are trademarks or registered trademarks of their respective holders.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

Table of Contents

1Description of the System.....................................................1

2System Specifications ...........................................................2

3Electrical and Mechanical Interface.....................................3

4System Startup and Checkout..............................................5

4.1 Startup Using a Terminal Emulator Program.....................................5

4.2 System Checkout.....................................................................................6

5CXM539 Configuration Options and Data Output Formats 8

6Appendix A. CXM539 command spec................................11

6.1 Main Commands (available in all modes)........................................11

6.2 Calibration Commands (only available in config mode)...............12

6.3 EEROM Map.........................................................................................12

6.4 Software Data Correction Equations.................................................14

7Appendix B. Filter Values and Data Rates.........................15

8Appendix C. Warranty and Support Information..............16

8.1 Customer Service ..................................................................................16

8.2 Contact Directory..................................................................................16

8.3 Return Procedure...................................................................................16

8.4 Warranty.................................................................................................17

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

About this Manual

The following annotations have been used to provide additional

information.

XNOTE

Note provides additional information about the topic.

þEXAMPLE

Examples are given throughout the manual to help the reader understand the

terminology.

PIMPORTANT

This symbol defines items that have significant meaning to the user

MWARNING

The user should payparticular attention to this symbol. It means there is a

chance that physical harm could happen to either the person or the

equipment.

The following paragraph heading formatting is used in this manual:

1 Heading 1

1.1 Heading 2

1.1.1 Heading 3

Normal

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 1

1Description of the System

The model CXM539 High Speed Digital 3 Axis Fluxgate Magnetometer is

the first high-speed digital output 3-axis fluxgate magnetometer to be

commercially available. The system can convert and transmit over its serial

port (at 38400 baud) all three axes outputs at a rate of 250 samples per

second. Slower data rates can also be selected; transmission rate and baud

rates are user programmable. The CXM539 uses 3 separate 16-bit sigma

delta analog to digital (A to D) converters to achieve the high throughput.

The scale factor is set so that a full scale input of 10-4T (1 G) represents

32768 counts on the system A to D converters. The least count represents

about 3 nT. Noise of the system is 1 -2 counts.

The CXM539 system is ideallysuited to situations where high speed

magnetic data must be acquired and analyzed. In the past, such systems

have normally used a combination of an analog output fluxgate and an A to

D board in a PC. The CXM539 simplifies and reduces the cost of the

magnetic data acquisition system by eliminating the cumbersome A to D

board.

The CXM539 can be used in either a command mode or autosend mode. In

the command mode, the CXM539 responds to commands to transmit data

issued by an external computer. In the autosend mode, the CXM539

commences sending data as soon as power is applied to the unit.

The CXM539 can be supplied with an optional connector box, which allows

easy powering and connection to an external computer.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 2

2System Specifications

Accuracy ±0.1 µT (±1 mGauss)

Noise level ±0.003 µT (±0.03 mGauss)

Range ±100 µT (±1 Gauss)

Scale stability ±.05% FS/°C

Initial offset <±200 nT (±2 mG)

Offset vs. temp <5 nT/°C (<0.05 mG)

Orthogonality of axes better than ±0.5°

Alignment of axes with package better than ±0.5°

Linearity ±0.1% full scale

Maximum data transfer speed(38,400 baud) 250 -3 -axis samples/sec

Power 100 ma @ +6 to +15 VDC

A to D 3 -16 bit Sigma Delta

Baud rate (user selectable) 300, 1200, 2400, 4800, 9600,

19200, 38400, 72800

Temperature range -25 to 70°C

Size 1.60”W x 4.08”L x 1.13”H

4 cm x 10.4 cm x 2.9 cm

Connector 9 pin nonmagnetic “D”

(female)

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 3

3Electrical and Mechanical Interface

The CXM539 is powered from a single inputvoltage that can range

between +6 V and +15 V. Current consumption is 100 ma. Two serial

interfaces are present; one that uses RS-232 levels and one that uses TTL

levels. The baud rate is user programmable and can be set at the following

values: 300, 1200, 2400, 4800, 9600, 19200, 38400, and 72800. The data

words employ 8 bits with one stop bit and no parity.

A female 9 pin D connector is used to provide an electrical interface to the

CXM539 system. The Pin out of this connector is as follows:

Pin Function

1not used

2RS 232 out

3RS 232 in

4not used

5ground

6TTL serial out

7TTL serial in

8configure

9+ V in (+7.5 V to +15 V)

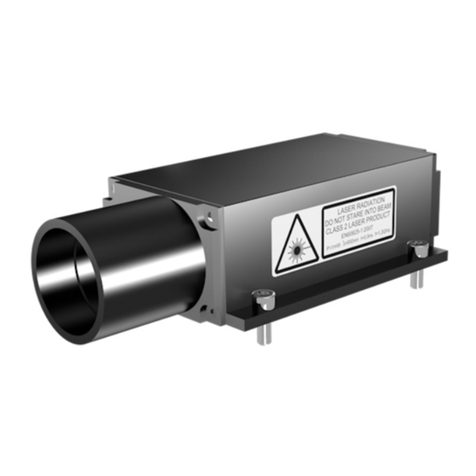

A drawing showing the dimensions and mounting hole design of the

CXM539 is shown belowin Fig. 1.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 4

4X 16

Φ

4.08”

(10.4 cm)

1.60”

(4 cm)

3.70”

(9.4 cm)

1.10”

(2.8cm)

4.08”

(10.4 cm)

3.32” (8.4 cm)

1.125”

(2.9 cm)

1

Fig. 1 CXM539 High Speed Digital 3 Axis Fluxgate Magnetometer

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 5

4System Startup and Checkout

4.1 Startup Using a Terminal Emulator Program

Connect the CXM539 to the connection box using the supplied ribbon cable

(use 9 pin male on connection box). Connect a cable from a serial port on a

PC to the connection box (use 9 pin female on connection box). Select the

AUTO option on the connection box switch. This connects pin 1 (CD) of

the 9 pin serial interface connector to the configure port on the CXM539.

Note that on the 9 pin computer connector, pins 1, 4 and 6 are shorted and

pins 7 and 8 are shorted). Connect a power supply (+7.5 V to +15 V) to the

red (positive) and black banana plug on the connection box.

Alternatively, according to the I/O pin functions described in Chapter 3, use

the RS-232 interface when connecting to a PC com port.

Start up a terminal emulator program on the PC, e.g. Windows

HyperTerminal, PC Plus, etc. Configure the terminal emulator program for

direct connect toan available com port and select the baud rate 9600 with

one stop bit and no parity. On the electrical interface to the system ground

pin 8; this will put the system in configure mode and assure that the baud

rate is 9600 baud. If a connection box is used, select the “config” option on

the connector box switch.

Apply power to the system and check to see that the unit transmits a start up

message:

APS 539 V1.12 Config. Mode

The system can now be configured for operation in various modes as

described in Appendix A by issuing commands over the serial interface.

After configuring the CXM539 system, ungrounded pin 8. If a connector

box is used, select the “Run” option in the connector box switch. In run

mode, the CXM539 sign on message sent at power on is

APS 539 V1.12.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 6

In run mode, most of the CXM539 parameters, e.g. baud rate, sample rate,

etc. can be set by the user. The main differences between the system

operation in run and configure mode are as follows:

1. The CXM539 can only be calibrated in config mode (by issuing

the l command). The unit is always factory calibrated and

recalibration by the user is not normally required.

2. The unit always starts in the (known) baud rate of 9600 baud.

3. The unit always starts in command mode (as opposed to autosend

mode).

4. The data output format is selected to be A to D count mode.

The main functions of the config mode are to assure that the CXM539

communicates using a known baud rate (9600) and to enable calibration of

the system.

MWARNING

Always operate the CXM539 in run mode (when using a terminal program)

unless the baud rate setting of the unit is unknown or calibration of the unit

is required. The output of the CXM539 in the calibrated mode (M=C) is

only valid in the run and auto modes.

4.2 System Checkout

After the CXM539 is operational and communicating with a computer, its

proper operation can be qualitatively checked out by using it to measure the

earth’s magnetic field. Around the globe, the magnitude of the earth’s

magnetic field varies from about 0.4 Gauss to 0.6 Gauss. In the northern

hemisphere, the field points north and dips into the ground (dip angle) at

about 60°.

Point the X axis generally north and down at an angle of 60° from

horizontal. Verify that the X axis reads about 0.5G and the Y and Z axis is

read near zero. Repeat the measurement with the Y and Z axes in turn

pointed into the field and verify that these two axes correctly read the

earth’s magnetic field magnitude.

If a terminal program is used before checking the system operation, ensure

that the following commands are given:

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 7

M = T <CR> <LF>

M = C <CR><LF>

A <CR> <LF>

These commands set the transmission mode to be autosend calibrated text.

After issuing the A command, the terminal output will display the

continuous output from the CXM539. Orient the system in the earth’s

magnetic field to verify proper operation as discussed above.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 8

5CXM539 Configuration Options and Data

Output Formats

The user can configure the CXM539 system in the following ways:

1. Mode

2. Autosend or command

3. Baud rate

4. Pacing

The mode settings are used to change the format of the data output. The

user can select the data output to be raw A/D counts (M=R) or calibrated

(in Gauss) (M =C) data. The serial output format can be selected to be text

(M=T) or binary (M=B). The user can also choose whether to append a

checksum to the transmission (M=E) or omit this (M=N).

Some examples of different data output formats and the commands used to

create them are as follows:

Commands Data Formats

to set up

M=T Raw data in a text hex format without a checksum:

M=R X Y Z

M=N 1234 5678 9ABC <CR><LF>

The X,Y,& Z values are encoded as four digit hex values

separated from each other with a single space. The last

digit of the Z data is followed by a carriage and a line

feed.

M=T Raw data in a text hex format with a checksum (cs):

M=R X Y Z cs

M=E 1234 5678 9ABC 4E <CR><LF>

This just like the last example except for an addition of a

space and a two digit checksum in Hex between the last

digit of Z and the carriage return. The checksum is

composed of the sum of all of the digits in the X,Y,& Z

data values.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 9

M=T Corrected data in a text decimal format without a

checksum:

M=C X Y Z

M=N 0.23456 0.78900 0.23997 <CR><LF>

The X,Y,& Z values are encoded as decimal values in

Gauss. Each is separated from the next with a single

space. The last digit of the Z data is followed by a

carriage return and a line feed.

M=T Corrected data in a text decimal format with a checksum:

M=C X Y Z cs

M=E 0.23456 0.78900 0.23997 4C <CR><LF>

This is just like the last example except for an addition of

a space and the two-digit checksum in Hex between the

last digit of Z and the carriage return. The checksum is

composed of the sum of all of the digits in the X,Y,& Z

data values.

M=B Raw Data in a binary format without a checksum:

M=R X Y Z SB

M=N 12 34 56 78 9A BC 5A <CR> <LF>

The X,Y,& Z values are each encoded as a two byte

value. The X, Y, Z data is followed by a constant

synchronization byte (SB) of 5A.

M=B Raw data in a binary format with a checksum:

M=R X Y Z cs SB

M=E 12 34 56 78 9A BC AE 5A <CR><LF>

PIMPORTANT

When in Binary mode, the X, Y & Z values for magnetometer data are

encoded as a signed integer, 2's complement, with a conversion factor of

(

)

15

2

256*LSBMSB

MorMorMzyx +

=in Gauss

This is followed by a checksum consisting of the lower eight bits of the sum

of the bytes comprising the X, Y & Z Data and calculated as

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 10

256 5Aandchecksumexceptbytesallofsum

Checksum=

This is followed by a synchronization byte of 5 A, which represents the end

of the data packet.

To determine the mode of a CXM539, issue the command M?

The autosend command (A) enables data to be sent continuously upon

power on. The output rate of the sent data is set by the pacing variable,

which can vary from 0000 (full speed) to FFFF (very slow). Pacing values

are set by commands of the form:

P = XXXX <CR><LF>

The filter value for A/D can be set and the data rate can be accordingly

changed by,

F = XXXX <CR><LF>

Different filter values and corresponding data rates, resolution and

frequency are provided in Appendix B.

The user can set the baud rate of the CXM539 to the standardvalues from

300 to 76800 baud. The baud rate command is of the form:

B = XXXX <CR><LF>

A complete list of the CXM539 commands can be found in Appendix A.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 11

6Appendix A. CXM539 command spec

6.1 Main Commands (available in all modes)

All Commands Must be followed by a return.

All changes to the mode value are saved as the power-up mode.

M? Send the current mode value.

M=R All Data is Sent as raw A/D Counts in ASCII four digit

Hex values or Binary Values depending on the current

mode.

M=C All Data is Sent as Gammas, Formatted as base Ten fixed

point Text or Binary Values depending on the current

mode.

M=B Set Data is Formatted as Binary Numbers.

M=T Set Data is Formatted as Text Numbers.

M=E Send a checksum with all Data.

M=N Don't Send a checksum.

AStart Auto Send Data.

SStop Auto Send.

DSend the current Data Value.

B? Send the run mode Baud Rate.

B=##### Set Run Mode Baud Rate 300 -76800 Baud is accepted.

In Config Mode the baud rate is always 9600.

P? Display the current pacing value.

P=#### Set a Pacing value to slow the data rate.

E? Send All EEROM Data.

E#### Send EEROM Data followed by 4 hex digits address and

optional 2 digits representing the number of bytes to send.

W####XX Write EEROM Data followed by a 4 hex digit address

and 2 hex digits of Data.

CReset and Calibrate A/D(s).

ISend ID and many internal values.

*Reset and Restart Sensor.

?Display Help.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 12

6.2 Calibration Commands (only available in config mode)

LUnlock Calibration Mode (This command is only available in config.

mode)

O Zero All the Sensors for cal. (available only after executing L)

X+1/2 Gauss X Field Applied for cal. (available only after executing L)

Y+1/2 Gauss Y Field Applied for cal. (available only after executing L)

Z+1/2 Gauss Z Field Applied for cal. (available only after executing L)

Q-1/2 Gauss Applied Field Delta for cal. (available only after executing

L)

6.3 EEROM Map

For all EEROM constants the least significant byte is stored in the lowest

address and the mostthe most significant byte is stored in the highest

address.

00 Not Used

01 CPU Clock Speed Divisor

1-7 Clock Divisor

8-0=Run at Full clock speed 1=Enable clock division

CPU Speed = 4.9152 MHz/(129-ClockDivisor)

This used to allow the use of lower UART baud rates and

Lower power consumption.

For example 300 baud could be used with the Clock

Divisor set to 125 to divide the clock rate by 4 and the

baud rate control register set to 255.

02 Operating Mode

1-Send Corrected Data.

2-Autosend Data until Stop autosend command received.

3-Send Data Only Once (On power up or single data by

command)

4-Send Data in a Text Format

5-Send Data in a decimal format (Only checked if in Text

format)

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 13

6-Calibration Mode 000 -Run Mode 001 -Unlocked

010 -Zero Mode

7-Calibration Mode 011 -XField 100 -YField 101 -

ZField

8-Calibration Mode 110 -Field Delta

03 More Operating Mode

1-Send Check Sum with Data

2-Not Used

3-Not Used

4-Not Used

5-Not Used

6-Not Used

7-Not Used

8-Not Used

04 Baud Rate Control

BaudRate = 4.9152Mhz / 16*(BaudRateControl+1)

Values for Common Baud Rates with no clock dividing:

1200: 255(FFH) 19200: 31(1FH)

2400: 127(7FH) 38400: 7(7H)

9600: 63(3FH) 76800: 3(3H)

05 Not Used

06-07 Soft Offset X

08-09 Soft Offset Y

0A-0B Soft Offset Z

0C-0D Soft Scale X

0E-0F Soft Scale Y

10-11 Soft Scale Z

12-13 Soft Ortho XY

14-15 Soft Ortho XZ

16-17 Soft Ortho YX

18-19 Soft Ortho YZ

1A-1B Soft Ortho ZX

1C-1D Soft Ortho ZY

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 14

1E-1F Pacing Value

30-32 A/D Offset Calibration 0 Set When the A/D is Calibrated

33-35 A/D Gain Calibration 0 Set When the A/D is Calibrated

36-38 A/D Offset Calibration 1 Set When the A/D is Calibrated

39-3B A/D Gain Calibration 1 Set When the A/D is Calibrated

3C-3E A/D Offset Calibration 2 Set When the A/D is Calibrated

3F-41 A/D Gain Calibration 2 Set When the A/D is Calibrated

42-43 Filter Settings (Set for Data Rate Vs Data Noise)

01-FAST Mode Enabled

02-Skip Mode Enabled

03-Chop Mode Enabled

04-Must Be 0

05-16-12 bit Sync Filter

6.4 Software Data Correction Equations

Xout = ((((Xin + XOffset) * XScale)/32768)+

((((Yin + YOffset) * YScale)/32768) * YOrtho)+

((((Zin + ZOffset) * ZScale)/32768) * ZOrtho))/65536

Yout = ((((Yin + YOffset) * YScale)/32768)+

((((Xin + XOffset) * XScale)/32768) * XOrtho)+

((((Zin + ZOffset) * ZScale)/32768) * ZOrtho))/65536

Zout = ((((Zin + ZOffset) * ZScale)/32768)+

((((Xin + XOffset) * XScale)/32768) * XOrtho)+

((((Yin + YOffset) * YScale)/32768) * YOrtho))/65536

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 15

7Appendix B. Filter Values and Data Rates

A table containing some filter values and corresponding data rates,

resolution and frequency tested on CXM539 at 38.4K baud is provided

below.

Filter

Value Text

Data

rate

(/sec)

Binary

Data

rate

(/sec)

Raw

Binary

data

rate

(/sec)

A/D

Sample

rate

(/sec)

A/D

Resolution

in bits

-3db

Frequency

(Hz)

8000 150 150 150 150 17.5 39.3

6000 200 200 200 200 17 52.4

4000 240 300 300 300 17 78.6

3000 240 370 400 400 16.5 104.8

2000 240 370 548 600 16.5 157

1800 240 370 548 800 16 209

1000240 370 548 1200 15.5 314

900 240 370 548 1600 15 419.2

800 240 370 548 2400 14 629

600 240 370 548 3200 13 838.4

400 240 370 548 4800 12 1260

300 240 370 548 6400 11 1676

XNOTE

For the text data (hex data was sent), the data sample length was 16 bytes

and hence the baud rate will limit the data rate to 240 samples/sec.

For binary data, the data sample length was 7 bytes and hence the baud rate

will limit the data rate to 548 samples/sec.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

CXM539 User’s Manual

Doc.# 6001-0014 Rev1.2Page 16

8Appendix C. Warranty and Support

Information

8.1 Customer Service

As a Crossbow Technology customer you have access to product support

services, which include:

•Single-point return service

•Web-based support service

•Same day troubleshooting assistance

•Worldwide Crossbow representation

•Onsite and factory training available

•Preventative maintenance and repair programs

•Installation assistance available

8.2 Contact Directory

United States: Phone: 1-408-965-3300 (7 AM to 7 PM PST)

Fax: 1-408-324-4840 (24 hours)

Non-U.S.: refer to website www.xbow.com

8.3 Return Procedure

8.3.1 Authorization

Before returning any equipment, please contact Crossbow to obtain a

Returned Material Authorization number (RMA).

Be ready to provide the following information when requesting a RMA:

•Name

•Address

•Telephone, Fax, Email

•Equipment Model Number

•Equipment Serial Number

•Installation Date

•Failure Date

•Fault Description

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:[email protected]m

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:[email protected]

Table of contents

Other Crossbow Technology Measuring Instrument manuals