Gossen MetraWatt MID U1281 User manual

Other Gossen MetraWatt Measuring Instrument manuals

Gossen MetraWatt

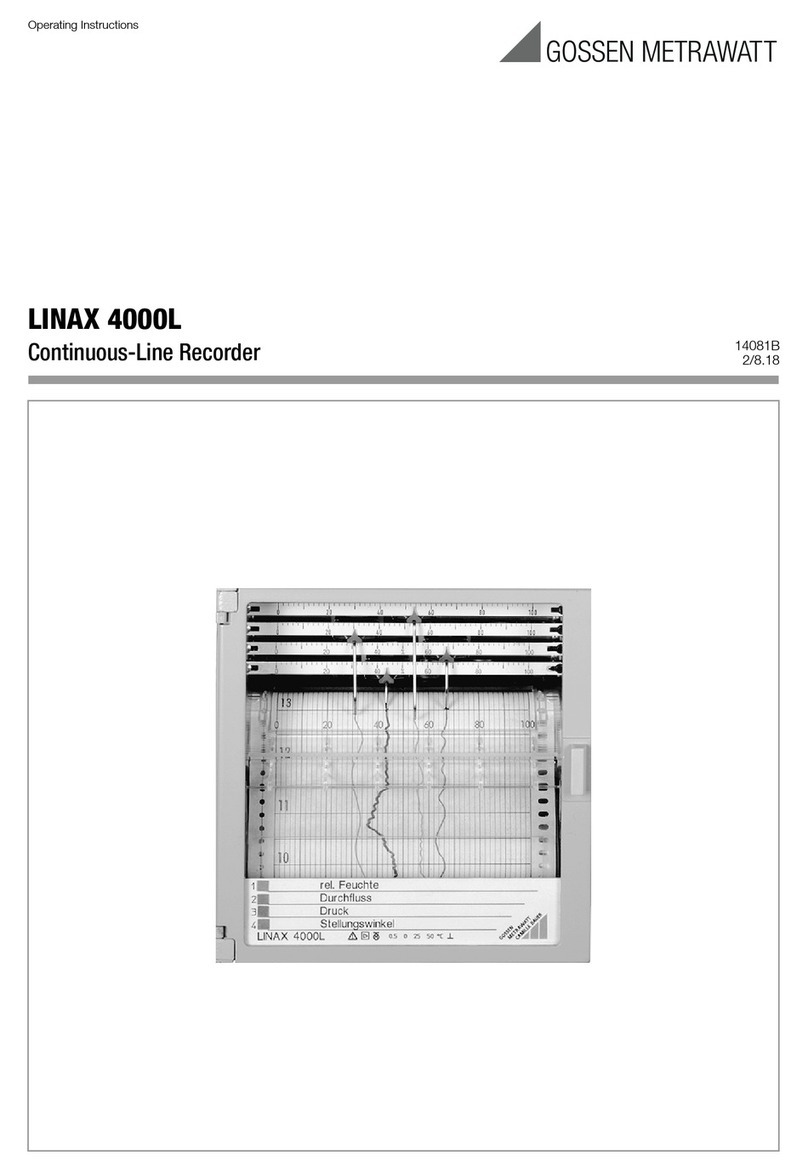

Gossen MetraWatt LINAX 4000L User manual

Gossen MetraWatt

Gossen MetraWatt PROFITEST Master IQ Series User manual

Gossen MetraWatt

Gossen MetraWatt U1281 User manual

Gossen MetraWatt

Gossen MetraWatt MAVOWATT 4 User manual

Gossen MetraWatt

Gossen MetraWatt DIGISKY User manual

Gossen MetraWatt

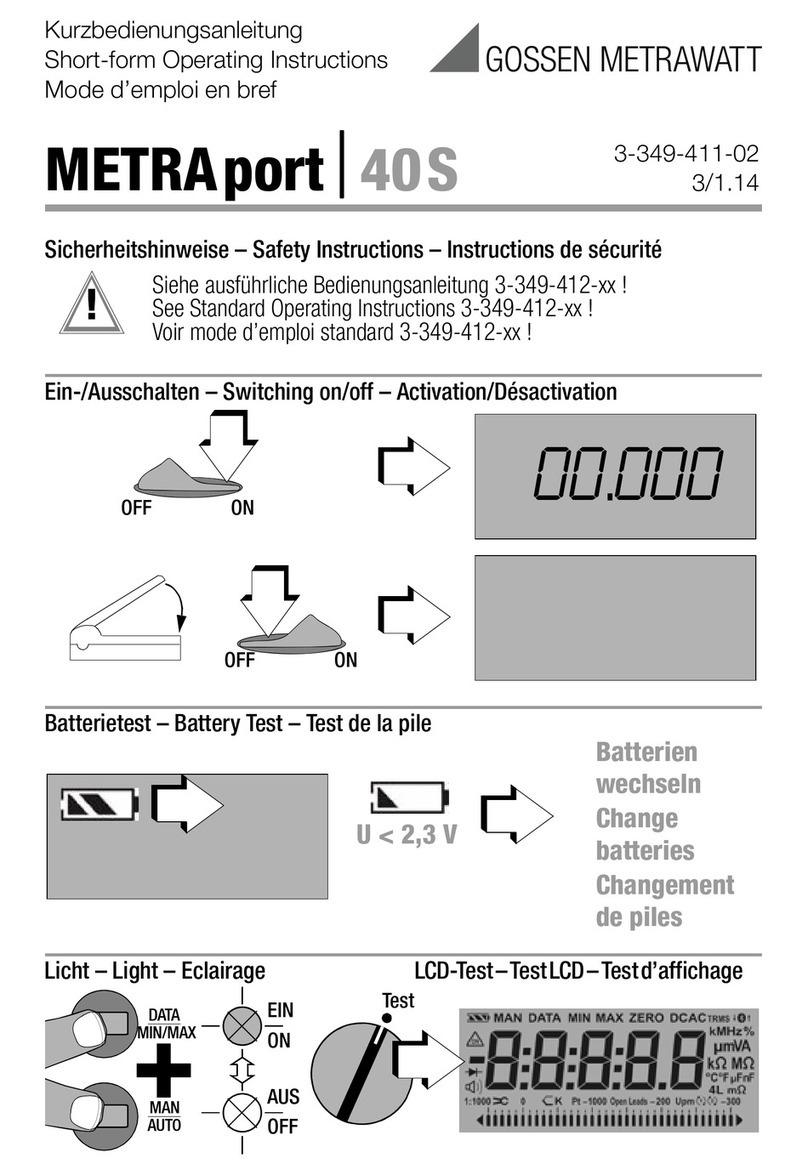

Gossen MetraWatt METRAport 40S User manual

Gossen MetraWatt

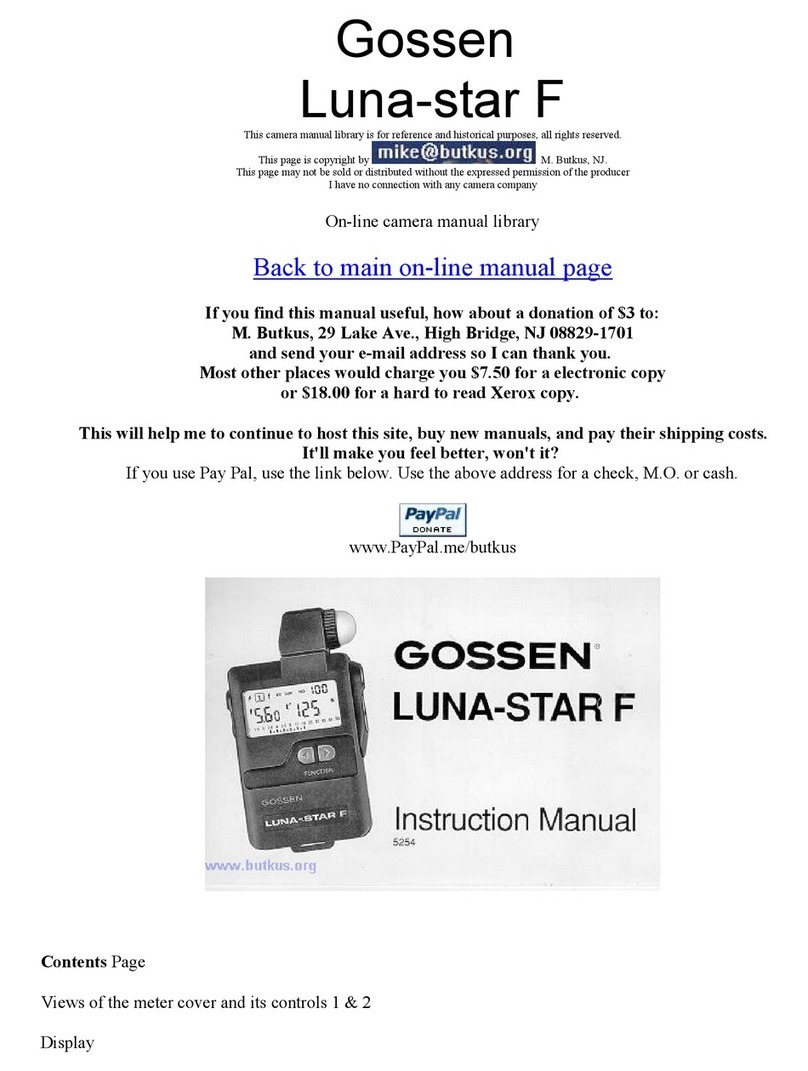

Gossen MetraWatt Luna-star F User manual

Gossen MetraWatt

Gossen MetraWatt SECUTEST PRO User manual

Gossen MetraWatt

Gossen MetraWatt SECUTEST PRO User manual

Gossen MetraWatt

Gossen MetraWatt SECULIFE IA User manual

Gossen MetraWatt

Gossen MetraWatt METRAFLEX 6001XBL User manual

Gossen MetraWatt

Gossen MetraWatt PROFITEST PV 1500 User manual

Gossen MetraWatt

Gossen MetraWatt DIGISKY User manual

Gossen MetraWatt

Gossen MetraWatt METRISO PRO User manual

Gossen MetraWatt

Gossen MetraWatt mavolog pro User manual

Gossen MetraWatt

Gossen MetraWatt lunasix Instruction Manual

Gossen MetraWatt

Gossen MetraWatt METRACLIP 88 User manual

Gossen MetraWatt

Gossen MetraWatt METRAPHASE 1 User manual

Gossen MetraWatt

Gossen MetraWatt METRACLIP EARTH User manual

Gossen MetraWatt

Gossen MetraWatt MAVO-SPOT 2 USB User manual