Instruction Manual

Digital Gauge

DF830SVR

General precautions

• Before and during operations, be sure to check that our products

function properly.

• Provide adequate safety measures to prevent damages in case our

products should develop malfunctions.

• Use outside indicated specications or purposes and modication

of our products will void any warranty of the functions and

performance as specied of our products.

• When using our products in combination with other equipment,

the functions and performances as noted in this manual may

not be attained, depending on operating and environmental

conditions.

Read all the instructions in the manual carefully before use and

strictly follow them.

Keep the manual for future references.

Safety Precautions

Magnescale Co., Ltd. products are designed in full consideration of

safety. However, improper handling during operation or installation

is dangerous and may lead to re, electric shock or other accidents

resulting in serious injury or death. In addition, these actions may

also worsen machine performance.

erefore, be sure to observe the following safety precautions in

order to prevent these types of accidents, and to read these “Safety

Precautions” before operating, installing, maintaining, inspecting,

repairing or otherwise working on this unit.

Warning Indication Meanings

e following indications are used throughout this manual, and

their contents should be understood before reading the text.

Symbols requiring attention Symbols prohibiting actions

CAUTION ELECTRICAL

SHOCK DO NOT

DISASSEMBLE

Warning Failing to follow the precaution items given

below may lead to severe injury or death.

• Do not damage, modify, excessively bend, pull on, place

heavy objects on or heat the cable, as this may damage the

cable and result in re or electric shock.

• Do not disassemble or modify the unit, as this may result

in injury or electric shock. ese actions may also damage

the internal circuitry.

Caution Failing to follow the precaution items given

below may lead to injury or damage to

surrounding objects.

• e unit does not have an explosion-proof structure.

erefore, do not use the unit in an atmosphere charged

with inammable gases as this may result in re.

2020.6

Printed in Japan

©2015 Magnescale Co., Ltd.

DF830SVR

2-A01-974-1B

[For U.S.A. and Canada]

THIS CLASS A DIGITAL DEVICE COMPLIES WITH PART15 OF

THE FCC RULES AND THE CANADIAN ICES-003. OPERATION

IS SUBJECT TO THE FOLLOWING TWO CONDITIONS.

(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE,

AND

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

UNDERSIGNED OPERATION.

CET APPAREIL NUMÉRIQUE DE LA CLASSE A

EST CONFORME À LA NORME NMB-003 DU CANADA.

45 Suzukawa, Isehara-shi, Kanagawa 259-1146, Japan

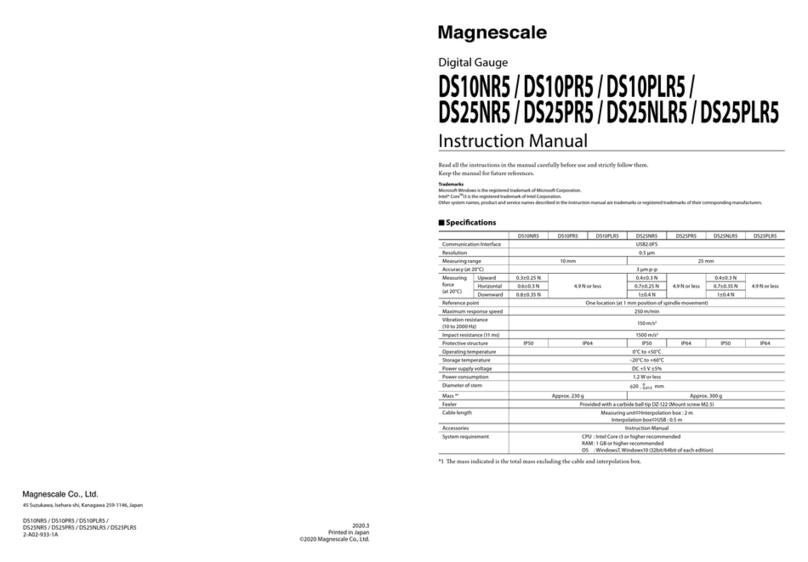

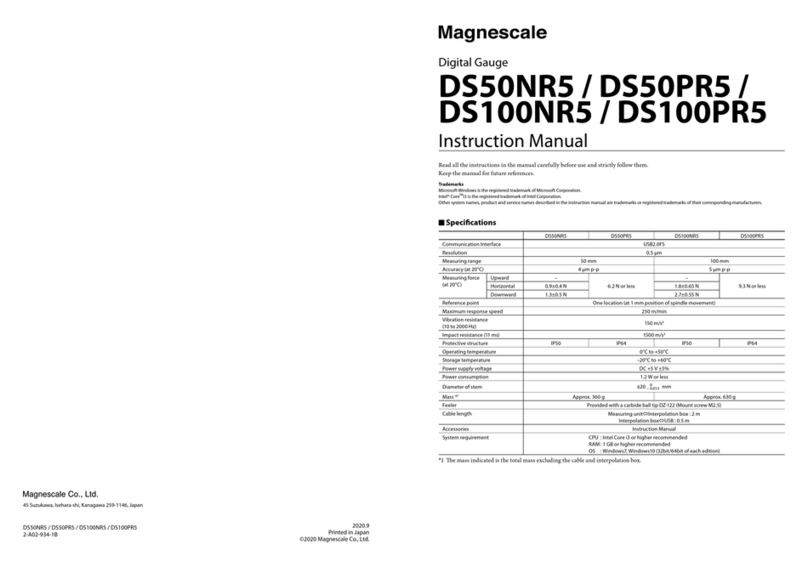

Specications

Model name DF830SVR

Measuring range 30 mm

Resolution 0.1 μm

Accuracy (at 20°C) 1.7 μm

Measuring force (at 20°C) Air pressure of 0.07 Mpa: 1.9 N or less in all directions

Air pressure of 0.09 Mpa: 2.6 N or less in all directions

Maximum response speed 80 m/min

Reference point Position at spindle movement of 1±0.5 mm

Reference point response speed 80 m/min

Output Serial communication protocol

Spindle drive system Air pressure ejection

Number of cycles tested 60 million

(Depends on the evaluation test dened by Magnescale Co., Ltd.)

Protection grade

(Not including interpolation box

and connector)

IP53

When using the DZ830BV: IP67

Vibration resistance 100 m/s2(20 to 2000 Hz)

Impact resistance 1000 m/s2(11 ms)

Operating temperature 0 to 50°C

Storage temperature –20 to 60°C

Power supply DC +10 to +30 V

Power consumption 1.2 W or less

Mass Approx. 80 g (Not including cable and interpolation box)

Cable length 2 m

Feeler Carbide ball tip, Mounting screw M2.5

Accessories Instruction Manual, Spanner

*Use the CE34 that is sold separately for the output cable. (Cable length Max.20 m)