2

Content / Contenido / Содержание / Зміст / Мазмұны /

English

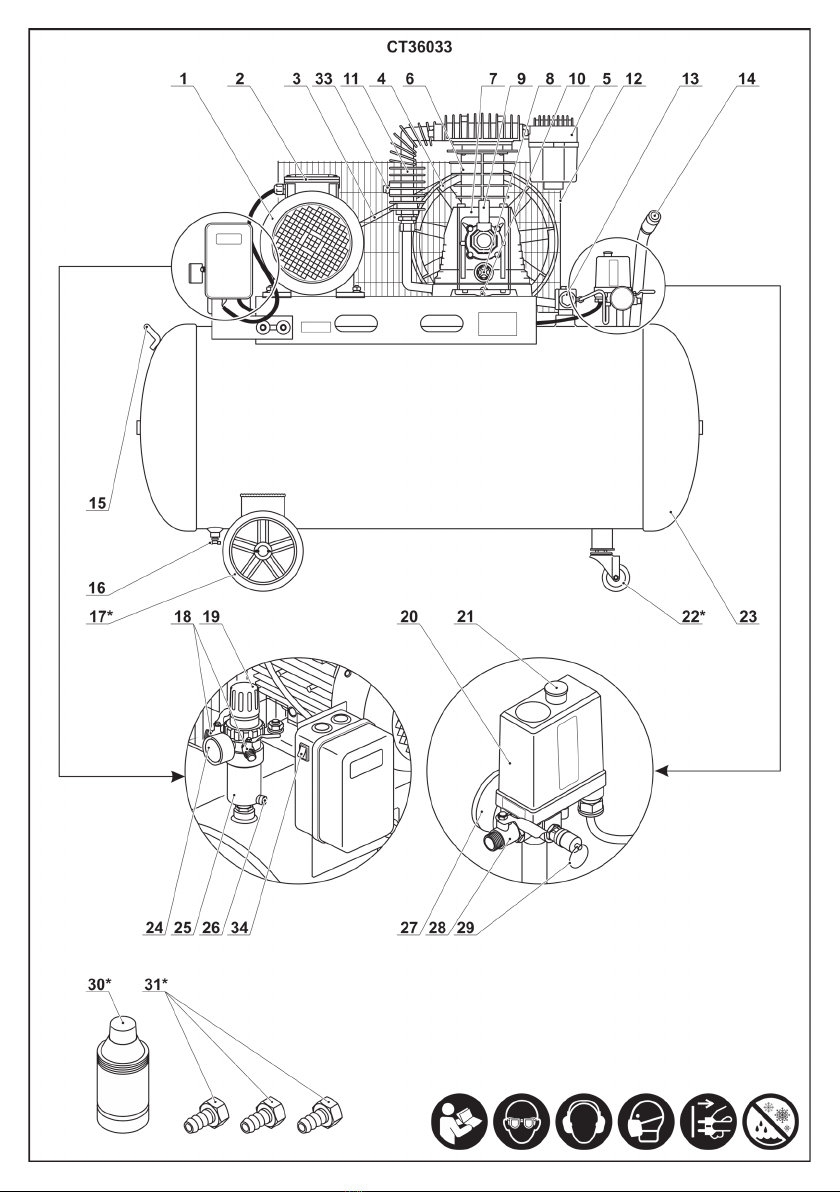

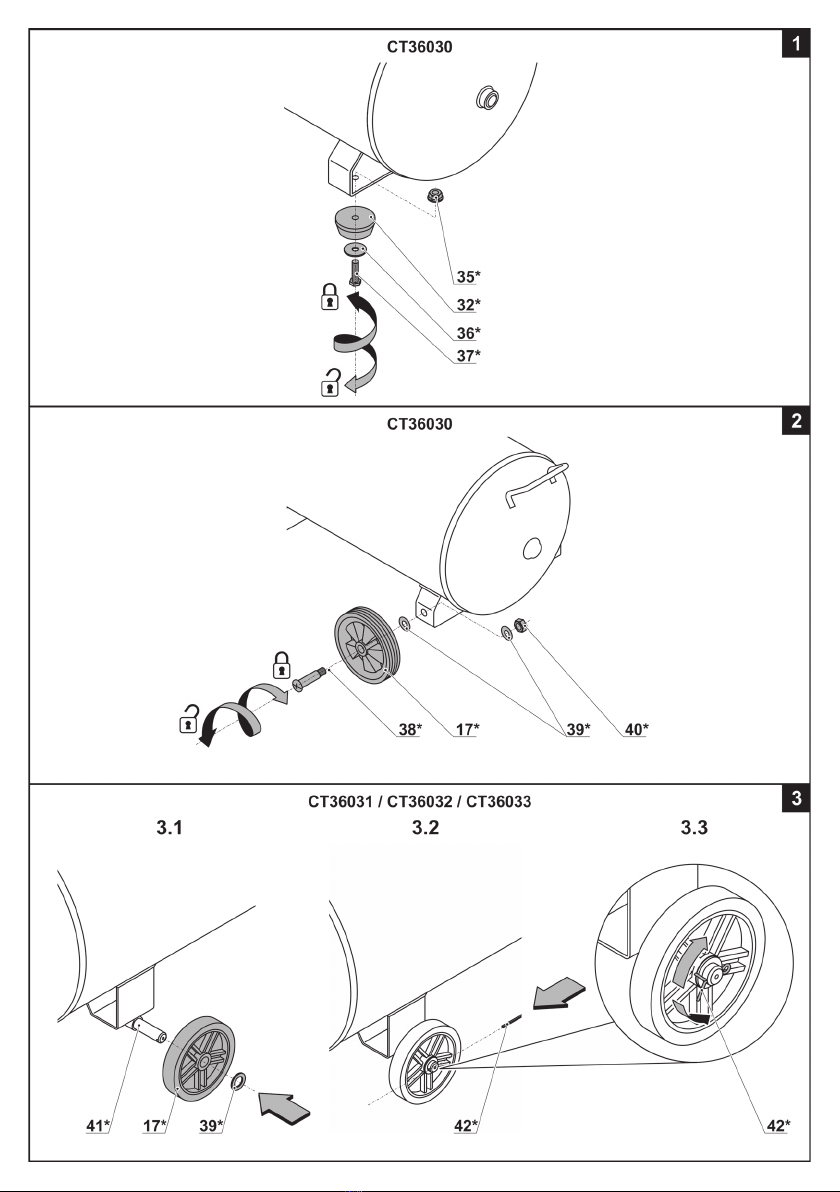

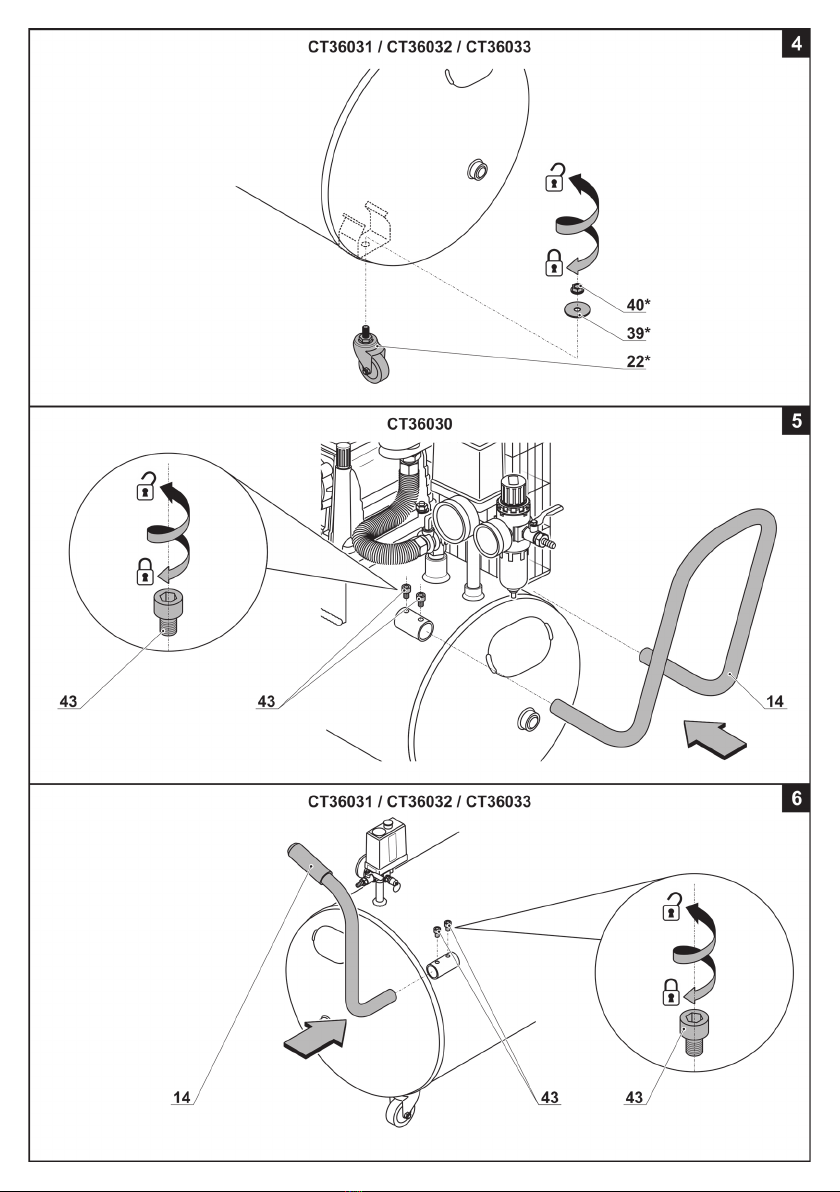

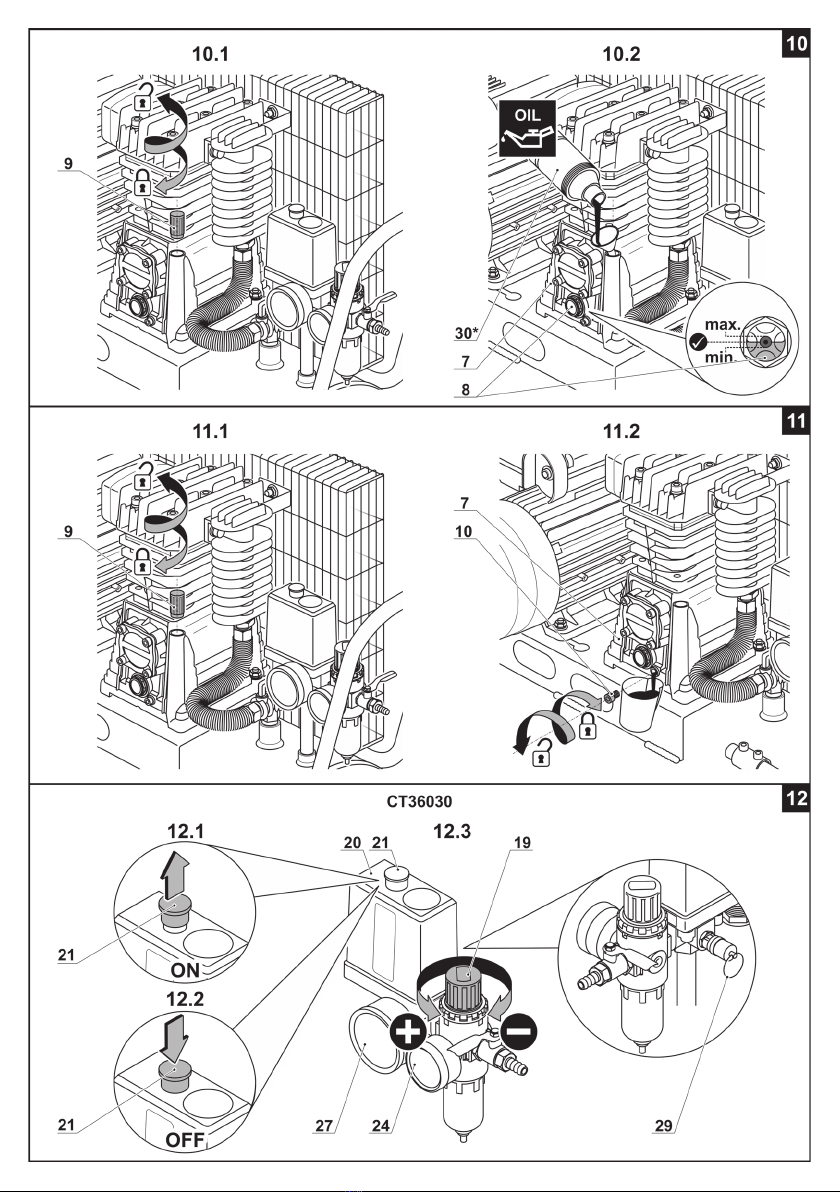

Explanatory drawings ������������������������������������������������������������������������������������������������������������ pages

General safety rules, instructions manual ����������������������������������������������������������������������������� pages

3 - 13

14 - 20

Español

Dibujos explicativos ������������������������������������������������������������������������������������������������������������ páginas

Recomendaciones generales de seguridad, manual de instrucciones ������������������������������ páginas

3 - 13

21 - 28

Русский

Пояснительные рисунки ������������������������������������������������������������������������������������������������ страницы

Общие указания по ТБ, инструкция по эксплуатации ������������������������������������������������� страницы

3 - 13

29 - 36

Украïнська

Пояснювальні малюнки ��������������������������������������������������������������������������������������������������� сторінки

Загальні вказівки по ТБ, iнструкція з експлуатації ��������������������������������������������������������� сторінки

3 - 13

37 - 44

Қазақ тілі

Түсіндіргіш әлеміштер �������������������������������������������������������������������������������������������������������� беттер

Жалпы қауіпсіздік жөніндегі ұсыныстар, пайдалану нұсқаулығы ���������������������������������������� беттер

3 - 13

45 - 52

����������������������������������������������������������������������������������������������������������������������������

����������������������������������������������������������������������������������������������������

3 - 13

53 - 59

�������������������������������������������������������������������������������������������������������������������������

��������������������������������������������������������������������������������������������

3 - 13

60 - 67