CRS F3 User manual

F3 Robot Arm

for C500C Controller

User Guide

UMI-F3-310

ii 99-05-31

F3 Robot Arm for C500C

Revision

Number History Date

001 First issue as F3 for C500C controller (UMI-F3-310). 99-05

Copyright © 1999 CRS Robotics Corporation

RAPL-3 and RAPL are trademarksofCRS RoboticsCorporation and maybe used to describe onlyCRS

Robotics products.

All brand names and product names used in this guide are trademarks, registered trademarks, or trade

names of their respective holders.

The information in this document is subject to change without notice.

CRS Robotics Corporation makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose. CRS Robotics

Corporation assumes no responsibility for any errors that may appear in this document. CRS Robotics

Corporation makes no commitment to update nor to keep current the information contained in this

document.

CRS Robotics Corporation assumes no responsibility for the use of any circuitry other than circuitry

embodied in a CRS product.

CRS Robotics Corporation software products shall remain the property of CRS Robotics Corporation.

99-05-31 iii

iv 99-05-31

99-05-31 v

Preface

About This Guide

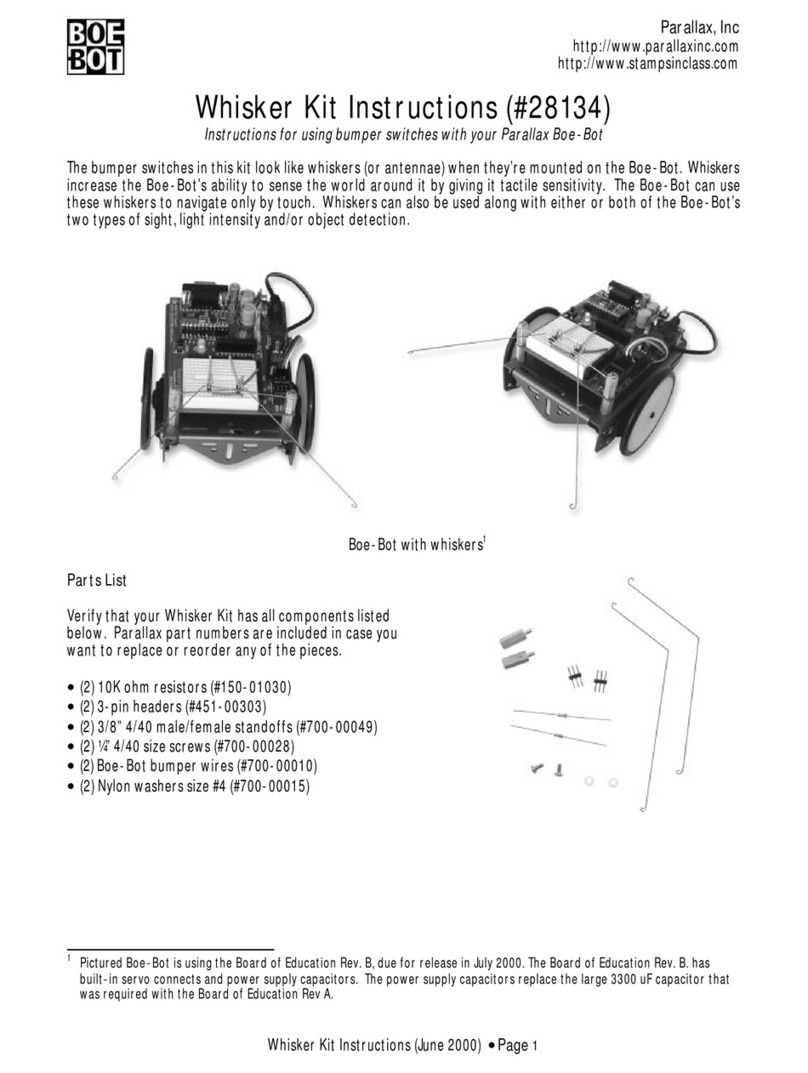

This user guide accompanies the CRS Robotics F3 robot system. It contains

general information, system specifications, safety precautions, installation

instructions, and basic operating instructions for the F3 robot arm and

controller.

In this guide, there are references to the layout drawing of the robot on page

iii of this guide. A larger copy of the same drawing is included in the

envelope on the exterior surface of the shipping crate.

To obtain additional copies of this guide, installation guides in other

languages, or other CRS literature, contact the Sales Department or the

Customer Support Department of CRS, or contact an authorized CRS

distributor.

Other Guides

For additional information, refer to the following documentation:

•Application Development Guide

•RAPL-3 Language Reference Guide

•F3t Track User Guide

Training

This user guide is not intended as an independent training tool, but rather

as a guide for those who have received CRS training and have a basic

knowledge of the F3 robot system.

Training is offered at CRS headquarters in Burlington, Ontario, Canada, or

can be conducted at your facility. For additional information, contact the

Training department.

vi 99-05-31

Contact

CRS Robotics Corporation

Mail/Shipping:

5344 John Lucas Drive, Burlington, Ontario L7L 6A6, Canada

Telephone:

1-905-332-2000

Telephone (toll free in Canada and United States):

1-800-365-7587

Facsimile:

1-905-332-1114

E-Mail (General):

info@crsrobotics.com

E-Mail (Customer Support):

support@crsrobotics.com

E-Mail (Sales):

sales@crsrobotics.com

E-Mail (Training):

training@crsrobotics.com

Web:

www.crsrobotics.com

99-05-31 vii

How to Use This Guide

This user guide is organized so that each chapter covers a different topic.

The following guidelines will assist you in reading through the chapters.

•Refer to the layout drawing for reference to physical parts of the robot.

•Read the chapter on Safety Precautions before installing and using the

robot.

•If you are working with an F3 robot for the first time or wish to review

pertinent information about the system, read the chapters on

Specifications and Installation.

•If you are installing the robot yourself, read the chapters on Installation

and Commissioning.

•If CRS or a distributor has installed the robot, read the chapters on

Commissioning and Operating Basics.

Before attempting to follow any procedure or examples provided in this or

any other manual on CRS products, read the entire section first.

Throughout this user guide, warnings are marked by an “!” icon in the left

margin. Failure to comply with these warnings can result in injury to persons, damage

to the robot, tooling, work pieces, loss in robot memory, or system errors.

Failure to unpack, install, use, and maintain the F3 robot system as instructed

in this user guide may lead to problems including failures and injuries for which

CRS Robotics Corp. cannot be held responsible.

This user guide describes the F3 robot system and only operating instructions

specifically pertinent to this system. You should attend a CRS training course and

read the appropriate documentation before programming the robot to execute any

type of command or application beyond the simple examples offered herein.

viii 99-05-31

99-05-31 ix

Contents

Important Tips ..................................................................xiii

chapter 1...........................................1

Getting Started Quickly........................................................1

Brief Installation and Startup Instructions .......................... 2

Minimum Installation Requirements.............................. 2

Turning On the System ................................................. 2

Turning on Arm Power................................................... 3

chapter 2...........................................5

Introduction.........................................................................5

Component Parts................................................................ 6

F3 Arm............................................................................... 7

Axes.............................................................................. 7

Umbilical Cable .................................................................. 8

F3 Options.......................................................................... 9

Off-Robot Hardware....................................................... 9

End-of-Arm Tools.......................................................... 9

End-of-Arm I/O........................................................... 10

chapter 3..........................................11

Safety Precautions..............................................................11

Safety Principles in Operating Robots................................ 12

F3 Safety Features............................................................ 13

Known F3 Hazards............................................................ 14

Safeguards and Safety Measures in Workcell Design.......... 15

Physical Barriers......................................................... 15

Emergency Stops (E-Stops).......................................... 16

Presence Sensing Interlocks......................................... 17

Other Safety Measures ................................................ 20

Local Regulations........................................................ 20

Environmental Requirements............................................ 21

Indoor Use .................................................................. 21

Temperature ............................................................... 21

Humidity..................................................................... 21

Atmospheric Contaminants ......................................... 21

Ingress Protection........................................................ 21

Vibration and Shock.................................................... 21

Electromagnetic Interference ....................................... 21

Power Requirements ......................................................... 22

AC Power Supply......................................................... 22

Other Energy Sources.................................................. 22

Power Distribution ...................................................... 23

Power Failure.............................................................. 23

Electrical Ground........................................................ 23

Cables and Circuitry ................................................... 24

Robot Handling................................................................. 25

Relocating the Robot ................................................... 25

Live AC Power ............................................................. 26

Electrically Conductive and Live Objects...................... 26

Static Electricity.......................................................... 26

Operator Safety................................................................. 27

Awareness of Robot ..................................................... 27

x99-05-31

Operator Training........................................................ 27

Safety and Operation Checks ............................................ 28

Working Within the Robot’s Workspace ............................. 29

chapter 4..........................................31

Specifications.....................................................................31

Physical Characteristics.................................................... 32

F3 Arm........................................................................ 32

Electrical Power........................................................... 32

Dimensions ...................................................................... 33

Arm ............................................................................ 33

System Control............................................................ 34

Robot Performance Summary............................................ 35

Workspace........................................................................ 36

Reach............................................................................... 37

Torque Ratings ................................................................. 39

Arm Torque................................................................. 39

Wrist Thrust and Torque ............................................. 39

Motion Specifications........................................................ 40

Speed at End-Effector.................................................. 40

Joint Speeds ............................................................... 40

Joint Accelerations...................................................... 40

Slew Time ................................................................... 41

Resolution ........................................................................ 43

Positioning Resolution................................................. 43

Load................................................................................. 44

System Features............................................................... 45

Absolute Encoders....................................................... 45

Arm Power Light.......................................................... 46

Brakes........................................................................ 46

Brake Release ............................................................. 46

Chain Tensioners ........................................................ 46

Embedded Control and Power Electronics.................... 47

chapter 5..........................................49

Installation.........................................................................49

Unpacking the F3 System ................................................. 50

Unpacking the Arm ..................................................... 50

Lifting the Arm............................................................ 51

Collecting the Shipping Materials................................. 52

Mounting the Arm............................................................. 53

Positioning the Arm..................................................... 53

Mounting Platform ...................................................... 54

Preparing a mounting platform.................................... 55

Mounting the arm on the platform............................... 55

Connecting the Umbilical Cable......................................... 57

Disconnecting the Umbilical Cable............................... 57

Grounding the System ...................................................... 58

chapter 6..........................................59

Customizing Installations...................................................59

Installing a Tool on the Robot............................................ 60

Settings of the F3 Robot’s Dual Air Valve Port .............. 61

Connecting a Hose to the Pneumatic Port.......................... 62

Enabling the Gripper................................................... 62

99-05-31 xi

chapter 7..........................................63

Commissioning the Robot ..................................................63

Verifying Installation......................................................... 64

Checking Arm and Controller Installation .................... 64

Powering Up the Controller ............................................... 65

Starting the Application Shell on the C500C Controller...... 66

Checking All E-Stops ........................................................ 67

Scheduling Regular Checking of E-Stops...................... 67

Moving Out of the Shipping Position.................................. 68

Checking the Live-man Switch .......................................... 69

chapter 8..........................................71

Operating Basics.................................................................71

Units................................................................................ 72

Coordinate Systems and Reference Frames........................ 73

Motion Modes................................................................... 74

F3 Joint Command...................................................... 74

F3 Motor Control......................................................... 74

Cartesian Motion Commands in the Tool Frame........... 74

System Operation ............................................................. 76

Brake Release ............................................................. 76

Point of Control........................................................... 76

Delay after Turning on Arm Power ............................... 77

Abnormal Process Termination .................................... 77

Chapter 9..........................................79

Troubleshooting .................................................................79

Arm Power Failure ............................................................ 80

Amplifier Communications Failure .................................... 81

F3 Calibration & Re-Homing ............................................. 82

F3 Calibration............................................................. 82

Restoration of Calibration File ..................................... 82

F3 Re-Homing............................................................. 82

chapter 10.........................................85

Preventive Maintenance .....................................................85

Regular Inspection............................................................ 86

Weekly Inspection ....................................................... 86

Monthly Inspection...................................................... 86

After Collision ............................................................. 87

Lubricating the Chain....................................................... 88

Re-lubricating Joint 2.................................................. 88

Re-lubricating Joint 3.................................................. 89

Re-Lubricating Joint 5................................................. 89

Replace and Update..................................................... 90

Battery Maintenance......................................................... 91

Background ................................................................ 91

Shutting Down the System for Less Than 6 Weeks....... 91

Extended Shutdown.................................................... 92

Six Month Battery Check............................................. 92

Battery Replacement ................................................... 92

Log Update.................................................................. 93

Chain Replacement........................................................... 94

Harmonic Drive Lubrication.............................................. 95

xii 99-05-31

Wire Harness Replacement................................................ 96

Cleaning the Robot System ............................................... 97

APPENDIX A.........................................99

Umbilical Cable Connector .................................................99

APPENDIX B........................................101

System Fuses ...................................................................101

Glossary ...........................................................................103

Index................................................................................113

99-05-31 xiii

Important Tips

Work Safely

Follow all safety information.

Work Safely in the Workspace

Always stay within reach of an e-stop button when you are in the arm’s

workspace. There is an e-stop on the teach pendant.

Back-up Calibration

Keep the calibration file that was delivered on the calibration diskette. Do

not lose it.

If you re-calibrate the robot, update the backup file.

Maintain the Robot

Keep to the recommended inspection and maintenance schedule. Keep a log

of all maintenance and service activities as well as the number of working

hours.

For maintenance, use the same chain lubricant that was applied at CRS

during initial assembly.

Replace the encoder backup batteries 12 months after receiving your robot.

Use only nickel-metal-hydride batteries. Contact CRS Customer Support for

more detailed specifications or purchase of replacement units.

Lift the Robot Carefully

Do not lift the robot without assistance of a crane or other persons.

Design the Workcell

Always design your workcell to be serviceable.

1. Teach at least one robot location where it is easy to access the arm and

the drawer at the base of the arm. Teach at least one robot location that

gives ample room for mounting and dismounting the robot.

2. Install the controller so that it can be easily relocated to an open area for

service.

3. Provide adequate clearance at the base of the robot and at the rear of the

controller for the umbilical cable.

Get Trained

Attend an F3 training course.

Use Correct Tool Frame of Reference

The tool frame of reference on the F3 is defined according to the ISO

convention. This is different from earlier models of CRS robots.

xiv 99-05-31

Use Correct Power with GPIO and SYSIO

Do not use the internal 24V power supply for any functions when interfacing

to the GPIO or SYSIO. Use an external power supply.

Shut Down Properly

To shut down the system:

1. Turn off arm power by hitting an e-stop.

2. Properly shut down the operating system with the command

shutdown now.

3. Turn off the controller at the controller’s main power switch.

1

99-05-31

CHAPTER 1

Getting Started Quickly

This chapter gives a quick overview on how to install and begin using the F3

robot system. It is intended for those who are experienced with robots in

general and have received training with the F3 system.

For full instructions on installing and starting up the robot, and for users

inexperienced with the F3 system or robots in general, read the entire user

guide before proceeding with any action.

After completing quick installation and startup, reading through the entire

user guide is still necessary for users with any level of experience.

2 F3 Robot Arm User Guide

99-05-31

Brief Installation and Startup Instructions

Detailed installation and startup instructions are found in Chapter 5. If you

do not possess real experience with robots, preferably specific F3 experience,

patiently read through the detailed instructions.

Minimum Installation Requirements

•As a minimum, the F3 robot should be mechanically secured by four

M12 x 1.75 fasteners to a rigid platform. Each fastener should have at

least 2 cm (or 0.8”) of thread engagement. For precise location, two M6

dowel pins should be used. A drawing of the base with the relevant

dimensions is found in Chapter 5.

Warning: The F3 robot’s compact size is not indicative of its significant

power. Failure to use four fasteners as recommended may result in unstable

installation.

•Remove the eyebolt.

•Do not turn on the controller until the umbilical cable has been

connected to both the robot and the controller.

•The umbilical cable connects to the back of the robot base. There should

be at least 45 cm or 18 inches of clearance in this area to provide

adequate strain relief for the cable.

•There should also be 45 cm or 18 inches of clearance at the back of the

controller to provide adequate strain relief for the cable at that end.

•The umbilical cable has a minimum bend radius of 23 cm (9 in).

•Verify that the controller is properly configured for the local AC power

supply.

Turning On the System

Do not forget to observe guidelines listed here prior to powering on the robot.

Warning: Do not turn the controller on until the umbilical cable has been connected at

both ends.

If you are starting up the robot system for the first time, it is recommended

that you connect a host computer to the controller via a RS232 serial cable.

If you are using only a teach pendant, refer to the Teach Pendant section of

the Application Development Guide.

The host computer should be a PC operating Windows 95 or higher, or

Windows NT 4.0, with Robcomm 3 or a compatible terminal emulator

installed.

•Start up Robcomm 3 or the terminal emulator.

•Turn on the controller by striking the black power switch on the left side

of the front panel of the controller.

The controller will display a number of messages on the terminal window at

startup.

When startup is successful, you see the following message as one of the last

messages displayed:

Chapter 1: Getting Started Quickly 3

99-05-31

Amplifier status

1……OK 2……OK 3……OK

4……OK 5……OK 6……OK

This message reports the results of a diagnostic test performed by the

controller on the in-robot electronics. In its absence, or if an error message is

displayed, refer to Chapter 9 for instructions on troubleshooting.

After successful startup of the controller and before turning on arm power,

you should note whether the HOME indicator light on the front panel is lit.

This light indicates whether a proper calibration file was found in the

controller memory. If not, go to Chapter 9 for instructions on

troubleshooting.

Turning on Arm Power

Warning: Ensure that no one is in the workspace of the robot before turning on

arm power.

Warning: Ensure the e-stop button on either the front panel or the teach pendant

is easily accessible before turning on arm power.

•Press the Arm Power button at the top right hand corner of the front

panel of the controller.

•Verify that the light on the Arm Power button is lit.

•Verify that the amber beacon on the robot arm is flashing.

If either of these indicators fails to turn on, turn to Chapter 9 for

instructions on troubleshooting.

You are almost ready to start moving and programming using the robot. The

following guidelines will be helpful:

•Verify that you have removed the eyebolt before commanding robot

motion.

•Read the sections of application development in the documentation set

supplied with your system:

•The Application Development Guide, particularly the sections on ASH

and CROS, as well as the RAPL-3 Language Reference Guide.

•Always move the robot slowly at first when starting up the system for the

first time.

•Keep the e-stop button accessible at all times.

•Ensure there is no one in the workspace of the robot while arm power is

on.

•If you have not read the rest of this user guide or received training on the

F3 system, limit your use of the robot to simple commands from ash at a

speed below 20%.

4 F3 Robot Arm User Guide

99-05-31

5

99-05-31

CHAPTER 2

Introduction

The F3 robot system has been designed to automate tasks such as machine

loading, specimens handling, product testing, dispensing, polishing and

deburing.

The system consists of a six-axis robot arm, teach pendant, gripper or other

tool, a controller running ash, as well as an umbilical cable. The cable

conducts communications between the robot and controller as well as power

for the electronics embedded in the robot.

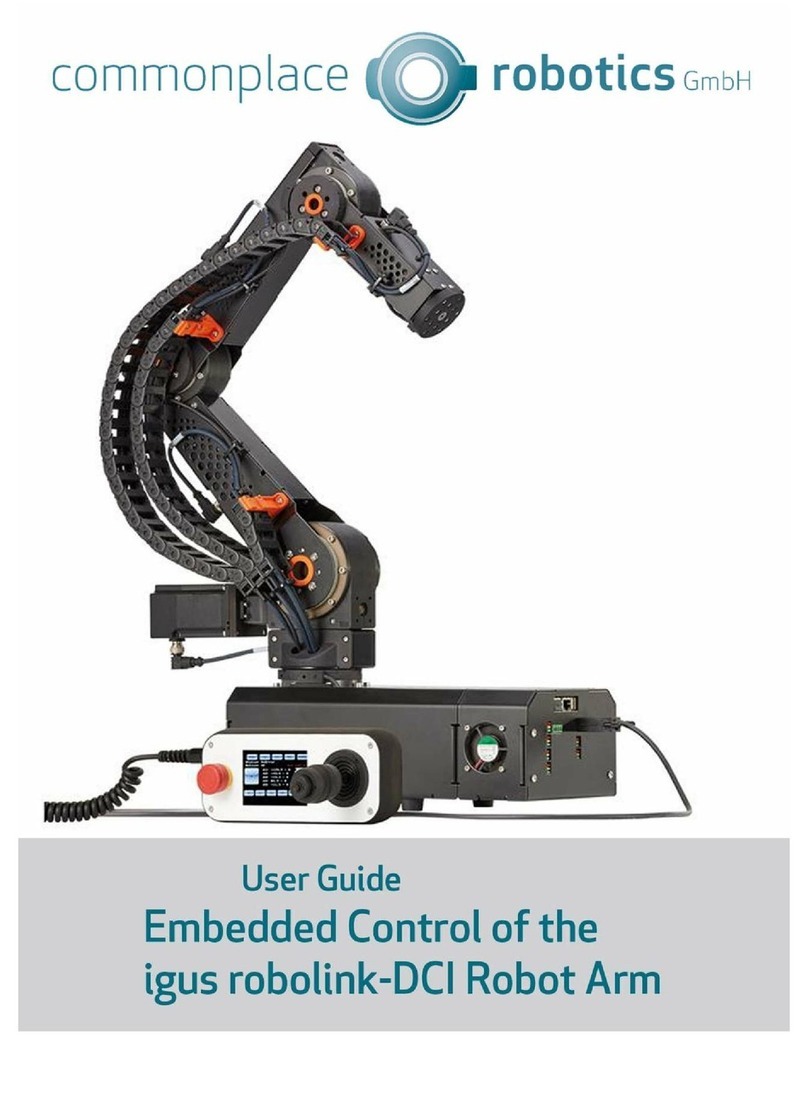

An F3 system: computer, teach pendant, controller, and arm.

The F3 robot is run by a program that can be developed either on the

controller with a terminal or teach pendant, or off-line on a computer using

Robcomm 3 or equivalent tools. From the teach pendant or a terminal you

can move the arm and teach locations. The robot can also be operated with

limitations using the front panel of the controller.

6 F3 Robot Arm User Guide

99-05-31

Component Parts

Before installing the robot system, locate and check that you have received

all the components.

•If you did not order options, the robot system is packaged in two

containers.

•Options may be shipped in separate containers and may include: gripper,

teach pendant, user guides, diskette(s), cable extensions, spares, etc.

•Use the following table to check off the components, which have been

ordered and received.

Component Check if

ordered Delivery

date Serial

number

•F3 arm

•hex key

•C500C controller

•umbilical cable

•fuse kit with AC power cable

•teach pendant override plug

•SYSIO override plug

•CROS diskettes (2)

•calibration diskette

•F3 User Guide

•Application Development Guide

•RAPL-3 Language Reference

Guide

Option Check if

ordered Delivery

date Serial

number

•Robcomm 3 diskettes

•teach pendant

•servo gripper

•end-of-arm i/o kit

Table of contents

Other CRS Robotics manuals